Professional Documents

Culture Documents

Application & Design of Energy Recovery Wheels - Airxchange, Inc

Uploaded by

miniongsky0 ratings0% found this document useful (0 votes)

63 views8 pagesenergy

Original Title

Application & Design of Energy Recovery Wheels – Airxchange, Inc

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentenergy

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

63 views8 pagesApplication & Design of Energy Recovery Wheels - Airxchange, Inc

Uploaded by

miniongskyenergy

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

Log-in | Contact Us | Home

Resource Center : Application & Design

Project Profiles

Case Studies

White Papers and Technical

Reports

Technical Notes

Application & Design

Software

Catalog

Savings Calculators

Application Considerations

Ventilation and its role in IAQ

Why Energy Recovery Ventilation

The Airxchange Matrix Media

Frost Control

Silica Gel Desiccant

Purge

Performance Impact of Unequal Air Flows

Fan Location Options

Venti l ati on and i ts rol e i n IAQ:

The HVAC community plays a vital role in providing healthful indoor environments in which to live, learn, work, and play. With half of

all illnesses attributable to indoor airborne contaminants, the EPA has declared indoor air quality a public health priority. Ventilation

with outdoor air is the only strategy that can simultaneously reduce the levels of all indoor pollutants. This strategy, in general

accordance with the Dilution Principle, is shown in the illustration below.

Dilution Principle

Each doubling of the ventilation rate results in a 50% reduction in the concentration of all constant source air pollutants evenly mixed

within the space. At 1.0 ACH, pollutant concentrations are reduced by a factor of 5. National, state and local codes mandate

minimumoutdoor air ventilation rates based on ASHRAE Standard 62, Ventilation for Acceptable Indoor Air Quality. The challenge is

to intro-duce the outdoor air at the levels required by the codes while maintaining indoor comfort and conserving energy.

Why Energy Recovery Venti l ati on:

Building Code requirements for increased outdoor air ventilation rates have placed new demands on HVAC equipment and on

building operating budgets. Energy recovery ventilation reduces the load on the systemdue to outdoor air by taking advantage of the

work that has already been done to heat, cool, humidify or dehumidify the space. Instead of exhausting building energy to the

outside, it is temporarily captured on the surfaces of the enthalpy wheel heat exchanger and then released to pre-heat, pre-cool,

humidify or dehumidify the incoming air. Enthalpy wheels do this with exceptional efficiency and are the leading technology for

achieving energy conservation while ventilating for health and comfort.

The next Two figures illustrate the power of enthalpy exchange. The first chart shows the result of just adding the required load from

increased ventilation to the normal air conditioning process line.

Application & Design of Energy Recovery Wheels Airxchange, Inc http://www.airxchange.com/resource-center-application-design.htm

1 of 8 7/25/2014 1:02 PM

The chart below shows the new process line when using enthalpy recovery. As one can see, the cooling load (work) saved is a

direct result of the difference in the two enthalpies

The Ai rxchange Matri x Medi a

All Airxchange Energy Recovery Ventilation (ERV) components utilize a unique parallel plate energy transfer matrix design that

optimizes the energy recovery surface area for a given diameter and depth of a rotary heat exchanger. In addition, a polymer film

matrix offers ideal properties that limit counterproductive axial conduction of heat. This combination achieves the required

performance in a thin, light weight configuration.

All Airxchange desiccant-coated enthalpy wheels are corrosion resistant. They are washable due to patented and proprietary

processes that secure the desiccant to the matrix substrate with a permanent mechanical bond without the use of adhesives.

Recognizing the different needs of the unitary packaged and air handling segments of commercial space conditioning equipment,

Airxchange components are available in Standard Matrix and Channel Matrix configurations.

Standard Matrix

The standard construction employs a series of small conical internal dimples (standoffs) to separate the filmlayers and define the

geometry of the matrix.

The standard construction is always suitable for ventilation in comfort applications and is generally specified for:

Stand-alone ERVs

Accessories, or integration into packaged unitary HVAC Equipment

Channel Matrix

Airxchange 3-inch depth components are available in the Channel Matrix configuration with an optional adjustable mechanical purge

sector. Channel matrix wheels employ the same ideal parallel plate geometry as the standard configuration, however, the internal

standoffs are axial ridges that separate intake and exhaust air streams while determining the matrix geometry.

Application & Design of Energy Recovery Wheels Airxchange, Inc http://www.airxchange.com/resource-center-application-design.htm

2 of 8 7/25/2014 1:02 PM

With the channel matrix configuration, a mechanical purge sector may be required to control the amount of exhaust air that transfers

to the supply air streamby the carryover mechanism. Using an adjustable purge sector, carryover can be reduced to less than 1%

while limiting excess fan energy to less than 10%. This configuration is ideal for air handlers and other high pressure applications

where the Standard Matrix might allow higher carryover or excessive fan energy losses. It is also responsive to applications and

engineering specifications in which it is necessary to limit the recirculation of exhaust air.

Frost Control

Frost control is required in extremely cold climates to preserve performance and assure the continuous supply of outdoor air.

Enthalpy wheel frost control strategies take advantage of inherently low frosting thresholds, which result in minimized energy use

and maximized design load reductions.

Frost Threshold

Frost formation causes reduction of airflow through the heat exchanger. Without frost control, energy recovery and airflow may be

significantly reduced. The frost threshold temperature is the point at which frost begins to accumulate on heat exchanger surfaces. It

is a function of both outside temperature and indoor relative humidity. The following figure compares the frost threshold of a

plate-type sensible heat exchanger with that of an enthalpy wheel.

Note that while frost forms at between 22 F and 30 F in a plate-type exchanger, frost thresholds for enthalpy wheels are generally

20 to 30 degrees lower. This is because the enthalpy wheel removes water fromthe exhaust air stream, effectively lowering the

dewpoint of the exhaust. The water removed is subsequently picked up through desorption, re-evaporation or sublimation by the

entering outdoor air.

For Frost Control strategies please rerefer to our technical note: Click here

Si l i ca Gel Desi ccant

What is it?

Silica gel is a highly porous solid adsorbent material that structurally resembles a rigid sponge. It has a very large internal surface

composed of myriad microscopic cavities and a vast systemof capillary channels that provide pathways connecting the internal

microscopic cavities to the outside surface of the sponge. Silica gel enthalpy wheels transfer water by rotating between two air

streams of different vapor pressures. The vapor pressure differential drives water molecules into/fromthese cavities to transfer

moisture fromthe more humid air streamto the drier air stream.

Adsorption: Silica Gel vs. Molecular Sieve

The following figure shows the characteristic curve for adsorption of water on silica gel. It shows the percent weight adsorbed versus

relative humidity of the air streamin contact with the silica gel. The amount of water adsorbed rises linearly with increasing relative

humidity until R.H. reaches near 60%. It then plateaus at above 40% adsorbed as relative humidity approaches 100%. For contrast,

the curve for molecular sieves rises rapidly to plateau at about 20% adsorbed at 20% R.H.

Application & Design of Energy Recovery Wheels Airxchange, Inc http://www.airxchange.com/resource-center-application-design.htm

3 of 8 7/25/2014 1:02 PM

The graph explains the following application considerations:

Molecular sieves are preferred for regenerated applications such as desiccant cooling and dehumidification systems that must

reduce processed air streams to very low relative humidities.

Silica gel has superior characteristics for recovering space conditioning energy fromexhaust air and handling high relative

humidity outside conditions. Another key point is that the transfer of water by sorption/desorption is not dependent on

temperature. Thus, the silica gel enthalpy wheel works to reduce latent load at difficult part-load conditions.

Purge

Purge removes exhaust air that would be otherwise carried to the supply air streamby the rotating wheel matrix. Outdoor air is used

to clean or purge the wheel matrix before it rotates from

the exhaust air streamto the supply air stream. The driving force for the purge streamis the pressure differential between the

outdoor air and return air compartments adjacent to the wheel. Purge is accomplished by utilizing the wheel matrix or by mechanical

means.

Two Choices of Purge Technology

Airxchange offers two distinct technologies to support the purge process.

Through-Matrix Purge using Standard Matrix components

Channel Matrix with optional Mechanical Purge

Design Considerations

If purge is desired, the design considerations include:

Use of outdoor air to flush carryover through the open matrix

Adjusting fans and pressures so that any seal leakage is fromsupply to exhaust

Ensuring that pressures are not excessive resulting in wasted fan energy

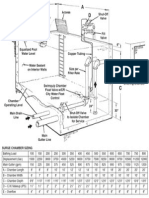

The following diagramdefines the terminology of airflow for consideration of purge.

Application & Design of Energy Recovery Wheels Airxchange, Inc http://www.airxchange.com/resource-center-application-design.htm

4 of 8 7/25/2014 1:02 PM

EATR (%) is composed of carryover leakage resulting fromthe rotation of the wheel fromReturn air to Supply air and any seal

leakage in that direction, minus the impact of purge. Purge airflow removes return air fromthe wheel volume before it enters

the supply side of the component.

Outdoor Air Correction Factor (OACF) is the difference in airflow measured between OA and SA, presented as a ratio. The

OACF includes air lost through purge and leakage fromthe outdoor air streamto the exhaust stream. Accordingly, OACF is

used to size the fans

Through-Matrix Purge

This technology employs the Airxchange standard energy transfer matrix. It is well suited for comfort applications where EATR values

of 4% to 6% are acceptable. The performance of through-matrix purge is competitive with mechanical purge sectors supplied with

fluted wheels, however, through-matrix purge is less expensive and simpler for most field applications. Effective purge yielding an

EATR of 1% or less can be achieved with through-matrix technology whenever static pressure differences are positive fromsupply to

exhaust on both sides of the wheel. By making best use of systemcharacteristics and fan placement, EATR (cross-leakage) can be

held to 1% or less. For example, in the draw-thru, draw-thru configuration shown below, where all static pressures are negative,

nominal wheel delta P is 1" on both sides.

Typical data for standard wheels with through-matrix purge is given in the following table which indicates that in order to obtain less

than 1% EATR, as much as 14% of the flow entering

the outdoor air hood will be used to purge the matrix and seals into the exhaust compartment. To achieve this, the exhaust fan must

be sized to result in 114% of normal flow.

Application & Design of Energy Recovery Wheels Airxchange, Inc http://www.airxchange.com/resource-center-application-design.htm

5 of 8 7/25/2014 1:02 PM

Channel Matrix with Mechanical Purge

Airxchange channel matrix technology is the option of choice to limit excessive leakage of air in critical higher pressure applications.

Channel technology results in greater energy savings

throughout the system. These designs require a mechanical purge if it is necessary to minimize the impact of carryover of exhaust

air. This is a wedge-shaped sector that captures and redirects the supply air to the exhaust side.

In summary, channel matrix designs:

Limit excessive leakage of air and limit resulting additional fan energy requirements in high differential pressure applications

With adjustable purge, limit EATR (exhaust air transfer, or cross-leakage) to less than 1% in sensitive applications over a wide range

of pressure differentials

The following diagramdefines airflows and delta P:

The driving forces for OACF and purge are provided by the plenumpressures in the wheel compartment and adjusted by systemand

component pressure loss and fan placement.

EATR of 1% or lower can be provided whenever pressures are positive fromsupply to exhaust on both sides of the wheel.

Application specific leakage ratings can be obtained by utilizing the Airxchange AIRX 3.0 selection software. Click here to learn more

Application & Design of Energy Recovery Wheels Airxchange, Inc http://www.airxchange.com/resource-center-application-design.htm

6 of 8 7/25/2014 1:02 PM

ARI Certified leakage ratings can be obtained via the ARI Directory

Performance Impact of Unequal Ai r Fl ows:

When outdoor air and exhaust airflows are equal at the ARI rated condition, the systemis balanced and energy recovery

effectiveness is equal for both flows. This results in maximumrecovery effectiveness of the entire ventilation system. As shown in the

adjacent graph, when the airflows are unequal, the effectiveness of the higher airflow decreases while that of the lower airflow

increases. This building systemimbalance is made up by infiltration or ex-filtration having an energy recovery effectiveness of 0%.

Thus, unbalanced flow reduces the benefit of energy recovery for the building system. The effect of unequal airflow on efficiency is

potentially significant and can be calculated, as follows:

Determine the Flow Ratio.

Flow Ratio = CFMmin / CFM max

1.

Use the adjacent graph to find the effect on effectiveness

by locating the flow ratio value on the X-axis and drawing

a vertical line fromthat point. emax will be the lower line

and emin will be the upper line.

2.

Example:

Outdoor air =5000 CFM; Exhaust Air =4000 CFM

For a flow ratio of 4000 CFM / 5000 CFM =0.8,

the adjacent figure results in:

emax =12% lower and emin =6% higher.

Thus, if base effectiveness for the systemis 80%, these unequal flows result in emax =68% and emin =86%.

The Airxchange AIRX 3.0 performance modeling software automatically calculates performance for unbalanced flow conditions. For

more information please click here

Fan Locati on Opti ons:

Application & Design of Energy Recovery Wheels Airxchange, Inc http://www.airxchange.com/resource-center-application-design.htm

7 of 8 7/25/2014 1:02 PM

2014 Airxchange Inc. All Rights Reserved. | Contact Us | Sitemap | Privacy Policy | 781.871.4816

Application & Design of Energy Recovery Wheels Airxchange, Inc http://www.airxchange.com/resource-center-application-design.htm

8 of 8 7/25/2014 1:02 PM

You might also like

- Bolger Group Logistics Consultants To Management - Pdfwarehouse Fire ComplianceDocument6 pagesBolger Group Logistics Consultants To Management - Pdfwarehouse Fire ComplianceminiongskyNo ratings yet

- Application & Design of Energy Recovery Wheels - Airxchange, Inc PDFDocument8 pagesApplication & Design of Energy Recovery Wheels - Airxchange, Inc PDFminiongskyNo ratings yet

- Combining DOAS and VRF, Part 2 of 2Document9 pagesCombining DOAS and VRF, Part 2 of 2miniongskyNo ratings yet

- CIH Taco7aExpansionTankAirSepDocument16 pagesCIH Taco7aExpansionTankAirSepminiongskyNo ratings yet

- Glossary - Education - CAGI - Compressed Air and Gas InstituteDocument6 pagesGlossary - Education - CAGI - Compressed Air and Gas InstituteminiongskyNo ratings yet

- Selecting Chillers, Chilled Water Systems - Consulting-Specifying EngineerDocument5 pagesSelecting Chillers, Chilled Water Systems - Consulting-Specifying EngineerminiongskyNo ratings yet

- Combining DOAS and VRF, Part 1 of 2Document8 pagesCombining DOAS and VRF, Part 1 of 2miniongskyNo ratings yet

- 16 Ways To Reduce HVAC Energy in Supermarkets and RetailDocument4 pages16 Ways To Reduce HVAC Energy in Supermarkets and RetailminiongskyNo ratings yet

- Types and efficiencies of fuel-fired boilersDocument4 pagesTypes and efficiencies of fuel-fired boilersminiongskyNo ratings yet

- Expert Cooling Tower Repair, LLC - 303.790Document4 pagesExpert Cooling Tower Repair, LLC - 303.790eimrehNo ratings yet

- Sugar - Fluid Flow VelocitiesDocument4 pagesSugar - Fluid Flow VelocitiesminiongskyNo ratings yet

- Improving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringDocument7 pagesImproving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringminiongskyNo ratings yet

- Table - First Hour RatingDocument1 pageTable - First Hour RatingminiongskyNo ratings yet

- "Solutions For The Plastics Industry": Co. IncDocument4 pages"Solutions For The Plastics Industry": Co. IncminiongskyNo ratings yet

- FMDS 1-35 Green Roof SystemsDocument27 pagesFMDS 1-35 Green Roof SystemsminiongskyNo ratings yet

- Air King Ventilation Ashrae 62Document5 pagesAir King Ventilation Ashrae 62miniongskyNo ratings yet

- Cooling-Tower Design Tips - Air Conditioning Content From HPAC EngineeringDocument3 pagesCooling-Tower Design Tips - Air Conditioning Content From HPAC EngineeringminiongskyNo ratings yet

- APEC Building Codes, Regulations and StandardsDocument227 pagesAPEC Building Codes, Regulations and StandardsminiongskyNo ratings yet

- FM Global Property Loss Prevention Data Sheets: List of FiguresDocument13 pagesFM Global Property Loss Prevention Data Sheets: List of FiguresminiongskyNo ratings yet

- ACH Recommended air changes per hourDocument2 pagesACH Recommended air changes per hourminiongskyNo ratings yet

- Table 6 - Demographic2Document1 pageTable 6 - Demographic2miniongskyNo ratings yet

- Table - Hot Water Temperatures NHSDocument1 pageTable - Hot Water Temperatures NHSminiongskyNo ratings yet

- Characteristics, Behavior, and Properties of LPG - Petronas Energy Philippines, IncDocument2 pagesCharacteristics, Behavior, and Properties of LPG - Petronas Energy Philippines, IncminiongskyNo ratings yet

- Surge ChamberDocument1 pageSurge ChamberminiongskyNo ratings yet

- Table - Hot Water Temperatures22Document2 pagesTable - Hot Water Temperatures22miniongskyNo ratings yet

- Back To Basics - Water Pipe SizingDocument5 pagesBack To Basics - Water Pipe Sizingminiongsky100% (1)

- Back To Basics - Water HeatersDocument5 pagesBack To Basics - Water HeatersminiongskyNo ratings yet

- Table 1MDocument2 pagesTable 1MminiongskyNo ratings yet

- Evaporative Pool DehumidificationDocument9 pagesEvaporative Pool DehumidificationminiongskyNo ratings yet

- Design Considerations of Water FeaturesDocument102 pagesDesign Considerations of Water Featuresminiongsky100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)