Professional Documents

Culture Documents

High Strength Pipelines

Uploaded by

jptl6477Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High Strength Pipelines

Uploaded by

jptl6477Copyright:

Available Formats

EUROPIPE. The world trusts us.

Materials and design of high strength pipelines

Yong Bai

Stavanger University College, Stavanger, Norway

Gerhard Knauf

Mannesmann Forschungsinstitut, Duisburg, Germany

Hans-Georg Hillenbrand

Europipe, Ratingen, Germany

1

Materials and Design of High Strength Pipelines

Yong Bai

Stavanger University College, Stavanger, Norway

Gerhard Knauf

MFI (Mannesmann Forschungsinstitut), Duisburg, Germany

Hans-Georg Hillenbrand

Europipe, Ratingen, Germany

ABSTRACT

The demand for high-strength linepipe for

offshore applications has increased considerably

because of the challenges that the offshore

pipelines should be contracted in ever-deeper

waters and that for reasons of reducing

operational costs pipelines should be operated at

increased pressures. The development of new

steels and improved pipe manufacturing

capabilities enable high strength linepipe with

appropriate toughness to be supplied.

In this paper, the following subjects related to the

use of high strength linepipe are discussed:

Materials properties

Evaluation of the use of high strength steel

from design viewpoints;

Assessment of loading conditions for

installation and in-service conditions;

Development of additional design criteria

for the subjects not covered by codes, e.g.

strength design of linepipes with yield

anisotropy.

The paper describes practical considerations on

material properties, design loads, code

requirements and concludes with the

developments in design criteria for strength

design of high strength pipes with yield

anisotropy.

KEYWORDS: Linepipe, Materials, Design, High

Strength,

Pipeline

INTRODUCTION

The demand for high-strength linepipe for

offshore applications has increased considerably

because of the challenges that the offshore

pipelines should be constructed in ever-deeper

waters and that for reasons of reducing

operational costs pipelines should be operated at

increased pressures. The development of new

steels and improved pipe manufacturing

capabilities enable high strength linepipe with

appropriate toughness to be supplied.

These developments cover linepipe for both sour

and non-sour service. The materials under

consideration are grades X70 and X80 for non-

sour service and grades X65 and X70 with a wall

thickness of up to 40 mm for sour service.

Apart from structural strength, key considerations

are:

Toughness of parent linepipe material and all

welded joints;

Corrosion performance of lines that operate

wet;

Weldability, including repairs and hyperbaric

requirements;

Compatibility with external environment;

Availability of bends and fittings required to

complete a piping system;

Suitability for operational modifications

repairs and hot taps;

Cost.

In this paper, materials properties and practical

design considerations will be given. The

anisotropy with respect to tensile properties of

linepipe and longitudinal and hoop design loads

will be discussed for S- and J-laid pipelines.

Existing codes have been evaluated and areas of

improvement have been identified. Finally, an

analytical capacity equation is outlined to design

pipe with yield anisotropy.

MATERIAL PROPERTIES OF HIGH

STRENGTH LINEPIPE

2

The desire to increase the through-put by

increasing the operating pressure or by

increasing the usage factor has led to ever

increasing demands for large-diameter steel pipe.

These requirements refer in particular to strength

properties and tolerances on dimensions. At the

same time, it is endeavored not to compromise

on operational safety and even to improve it,

where possible.

Thanks to the intensive research and

development work carried out and the quality

assurance measures consistently implemented in

pipe production, it has been possible so far to

meet the requirements placed by the market.

However, the limits of physical and technical

feasibility have almost been reached when

producing high strength pipe that can meet the

ever-increasing requirements. As the strength

increases, it becomes extremely difficult, if not

impossible to achieve the specified limits for the

yield-to-tensile ratio or to fulfill increased

toughness requirements.

In addition to the tensile properties in the

transverse direction, the tensile properties in the

longitudinal direction of the pipe play a crucial role

in the context of offshore pipelines. This fact has

been taken into account in the usual offshore

pipeline codes in that the values specified for

yield and tensile strength for the longitudinal

direction are the same as those specified for the

transverse direction. So far, the anisotropy with

respect to the strength properties of the pipe

produced by the UOE method has not been taken

into account adequately in the codes.

Figure 1 shows schematically the yield and tensile

strength frequency distribution curves for the

transverse and longitudinal directions for plate

and pipe. Because of the elongation of the

microstructure in the rolling direction, the yield

and tensile strength values for the longitudinal

direction are lower than those for the transverse

direction.

Figure 1. Comparison of strength distributions for plate

and pipe specimens in transverse and longitudinal

direction.

As a result of the pipe forming and subsequent

cold expanding, there is a marginal increase in

the tensile strength for both directions and in yield

strength for the longitudinal direction. In contrast,

the yield strength of the transverse, flattened strip

specimen is reduced. Comparison of these data

with those for the round bar specimen indicates

that the reduction of the yield strength in the case

of the strip specimen can be attributed to the

Bauschinger effect resulting from the flattening

operation of the specimen prior to the tensile test.

The anisotropy described and its development in

the course of pipe forming is typical of standard

pipe and depends on the material grade, chemical

composition and pipe geometry. This dependency

is readily seen in the case of low carbon sour

service grades.

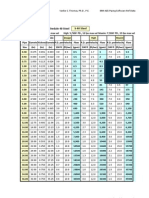

Figure 2 shows, by way of example, the

distribution curves determined on a production lot

of grade X65 pipe intended for sour service. As

can be seen, the distributions for the transverse

specimens are shifted to the right relative to

those for the longitudinal specimens. It had been

necessary to optimize the rolling process to raise

the strength values for the transverse specimens

so that the tensile requirements specified for the

transverse specimens are also met by the

longitudinal specimens.

Figure 2. Results on 610 mm OD x 14.3 mm W.T. X65

production line pipe for sour service (PH3).

Such measures adopted to compensate for the

anisotropy result in pipe with transverse strength

properties corresponding to those of a next

higher material grade. Of course, these

measures are cost intensive and may have an

unfavorable effect on other material properties

(toughness, Y/T, corrosion resistance).

It is therefore prudent to check whether the

pipeline design can tolerate the anisotropy in that

0

0,05

0,1

0,15

0,2

0,25

0,3

0,35

0,4

0,45

0,5

6,5 8,5 10,5 12,5 14,5 16,5

Yield strength, transverse

0

0,05

0,1

0,15

0,2

0,25

0,3

0,35

0,4

0,45

0,5

7 9 11 13 15 17

Tensile strength, transverse

0

0,05

0,1

0,15

0,2

0,25

0,3

0,35

0,4

0,45

0,5

5 7 9 11 13 15

Yield strength, longitudinal

0

0,05

0,1

0,15

0,2

0,25

0,3

0,35

0,4

0,45

0,5

4 6 8 10 12 14

Tensile strength,longitudinal

Pipe : strip specimen

Plate : strip specimen

Pipe : round bar spec.

0

30

60

90

120

150

180

460 490 520 550 580

Yield strenght, transverse

0

30

60

90

120

150

180

520 550 580 610 640

Tensile strength, transverse

0

30

60

90

120

150

180

460 490 520 550 580

Yield strength, longitudinal

0

30

60

90

120

150

180

520 550 580 610 640

Tensile strength, longitudinal

3

it can accept reduced yield and tensile strength

values for the longitudinal direction.

DESIGN EVALUATION

OF HIGH STRENGTH STEEL

Review of the Usage of High Strength Steel

Linepipes in Offshore Pipelines

For offshore pipelines, the current trend is

towards linepipe in grade X70 with a wall

thickness up to 40 mm. Fulfillment of the

requirements for DWTT transition temperature

will be progressively difficult as the wall thickness

increases. For wall thickness in excess of 30

mm, low transition temperatures can only be

achieved by means of highly expensive rolling

processes.

Until now, there has been only limited offshore

use of X70 material. The main installation

contractors have completed three projects with

X70 and have two planned until 1997. Again,

these references are only indicative and not

comprehensive.

One example use of X70 linepipe in offshore

applications is the Britannia pipeline for which

Europipe supplied the linepipe. The Britannia field

is a gas condense reservoir in the Central North

Sea approximately 200 km northeast of

Aberdeen and 45 km north of Forties.

The Gas Export Pipeline, 682.4 mm OD 15.9

mm WT, is 186 km long. The pipeline design

pressure is 179.3 barg and the design life of the

pipeline is 30 years. The pipe grade is X70. The

mechanical properties of the pipe used are given

in Figure 3. The pipeline was subject to reliability-

based limit state design techniques in order to

justify a wall-thickness thinner than that permitted

by BS8010. The Britannia pipelines were

completed in 1997.

Figure 3. Production results on 682.4 mm OD x

15.9 mm W.T., API grade X70 linepipe.

Another large offshore project in grade X70 is the

pipeline in the North Sea operated by Statoil,

connecting Karst, Norway, together with

Dornum, Germany. This pipeline has a length of

600 km and is built of pipe 42 x 25 to 30 mm WT.

Europipe completed in the 1990's the

development of grade X80 pipe 48" in OD and

18.3 to 19.4 mm in wall thickness for onshore

pipelines. It has been demonstrated that it is

feasible to manufacture commercially large

diameter X80 pipe consistently for long

transmission pipelines, see Grf and Hillenbrand

(1995).

As regards offshore applications, a series of

pipes have been supplied for qualification testing

with respect to pipelaying. Use of X80 linepipe for

offshore field development is being qualified by a

joint industry project EXPIPE.

For low-alloy steel pipelines operating in sour

service, X65 is currently the established material.

Special treatment in the steelmaking shop and

fulfillment of special requirements for chemical

composition help prevent the formation of

nucleation sites for HIC. Production trials show

big potential for the development of higher grades

up to X80 for slightly sour conditions, see Grf

and Hillenbrand (2000).

Potential Benefits of Using High Strength

Steel

It is clear that the obvious advantage for using

higher strength steels is cost saving. However,

new approaches to design, manufacture and

construction and the use of high-grade materials

will expose potential pipeline projects to

increased levels of technical and commercial

risks. This section of the paper identifies the

benefits and disadvantages associated with the

use of high strength steels.

Potential Cost Reduction

Increasing the grade of linepipe used for

construction of a pipeline provides the opportunity

to reduce overall material costs. The cost

reduction is based on the premise that increasing

material yield strength reduces the wall thickness

required for internal pressure containment and

hence the overall quantity of steel required. The

4

implications of using high-grade material are

considered in relation to linepipe manufacturing

and pipeline construction.

A published study (Price (1993)), which

considered both direct and indirect

consequences of using a high strength steel,

suggested a 7.5% overall project saving for a 42-

inch offshore line laid with X80 instead of X65.

Although the X80 pipe cost 10% more per ton, it

was 6% less per meter. Further savings were

identified for transportation, welding

consumables, welding equipment rental and

overall lay time.

On the recently completed Britannia gas pipeline,

cost studies during detailed engineering showed

that by increasing the linepipe material grade

from X65 to X70, an approximate cost reduction

of US$ 3.5 million could be achieved. The project

CAPEX is approximately US$ 225 million.

Although not directly related to the use of high

strength material, other potential cost savings

identified in the same study include:

Tighter than normal (API 5L) definition of

dimensions. Consideration should be given

to reducing linepipe tolerances on ovality

and wall thickness from API 5L

requirements. The actual tolerances

required will be determined by evaluating

potential cost reductions anticipated during

pipeline construction and mechanical

design, compared to the expected increase

in linepipe manufacturing.

Use of fracture mechanics acceptance

criteria for determination of maximum

allowable defect sizes in pipeline girth

welds. Traditionally, the acceptance criteria

for weld defects are based on workmanship

standards. More recently, alternative

criteria such as Engineering Criticality

Assessment (ECA) have been used to

determine the acceptability of defects, see

Knauf and Hopkins (1996).

Non-standard pipeline diameters should be

considered. Optimization of the pipe ID

based on modeling of the pipelines in

detailed design may demonstrate that the

linepipe cost can be reduced by procuring

pipe of the exact ID required as opposed to

selecting the larger standard size, for

examples on the Britannia gas pipeline.

Conversely, it may be of benefit to modify

the design flowrates to enable selection of a

more economical size of pipe.

A quick and reliable inspection of girth welds is

required in the context of pipelaying, especially of

high strength pipe. There have been considerable

advancements in recent years in this field.

Starting from conventional radiography, the NDT

equipment used for pipeline inspection has been

improved. Radiography systems are available

which produce a real-time image of the weld

being inspected. Such systems can also be used

for the quality control of production welds in pipe

manufacture, followed by automated evaluation of

the data. As an alternative to radiography, high-

speed ultrasonic inspection is available. The

radiographic images and also the ultrasonic

indications are stored electronically and offer

instant retrieval. The time to inspect each weld is

reduced compared to traditional methods, and

thereby significantly reducing construction costs.

Wall Thickness and Construction

Given two similar design conditions, increasing

the grade of linepipe in simplistic terms will

correspondingly decrease the wall thickness and

therefore provide cost benefits. In addition to this,

a thinner wall thickness will also have various

impacts on construction activities. A thinner wall

thickness will require less field welding and

therefore, in theory, has the potential to reduce

construction/lay time.

Increasing the material grade and strength of

linepipe is beneficial to laying pipe in deeper

waters. Furthermore, certain projects can only be

implemented with pipe having reduced weight and

optimized strength and toughness.

The maximum water depth by conventional S-lay

method is being stretched to the extent that

ALLSEAS have installed a 12-inch pipeline using

X70 steel in 1600 m water depth in the Gulf of

Mexico. However, it is questionable that the same

lay method can be used for a larger pipe diameter

in the same water depth. It is widely

acknowledged that the J-lay method is the most

suitable for laying pipe in waters beyond 1000 m.

A thinner wall thickness has a direct impact on

this installation method since the requirements for

lay barge tensioners is related to the water depth

and weight of pipe.

Pigging Requirements

The thicker walled sections of the pipeline in

deeper waters may restrict the full capabilities of

intelligent pigging. There is a limitation on the wall

5

thickness depending on the type of pigging tool

used, which can be overcome by the use of high-

strength steels

Potential Disadvantages of Using

High Strength Steels

Limited Suppliers

The worldwide availability of proven suppliers for

material grades above X70 is relatively limited.

Welding Restrictions

With regards to the weldability of X80 steel, there

is a medium risk of schedule extension and cost

increase since it has only been used on a small

number of onshore projects and there is no

experience offshore. Welding to the required

quality may be slowed by more process

restrictions and more complex controls. Due to

the limited worldwide experience of welding X80

linepipe, certain key welding issues will have to be

addressed in further studies, particularly that of

welding consumables.

Limited Offshore Installation Capabilities

The number of offshore pipelay contractors with

proven experience of welding X70 steel linepipe

is limited. Additionally, the experience of laying

deepwater pipelines by the J-lay method is limited

to relatively small diameter pipelines.

Fatigue and Fracture of High Strength Steel

While an onshore pipeline is essential subjected

to fatigue essentially due to internal pressure

fluctuations, an offshore pipeline experiences

fatigue stresses in the form of longitudinal tension

and bending. Fatigue life under offshore

conditions is used as the basis for many of the

limits placed on pipeline strength design. These

limits have often been established based on

empirical data from tests on low strength steels,

with a safety margin applied. In general, the ability

of steels to resist fatigue failure increases with

increasing strength. But, the notch severity

increases with increasing strength, a finding that

is of significance to the configuration of the girth

weld in the context of the fatigue life of offshore

pipelines.

Pipe materials, as a rule, should possess

adequate toughness to prevent the initiation and

the propagation of long-running fractures in the

pipeline, see Re et al (1995), ISO 3138 and DNV

OS F101 (2000). For pipes with increasing

strength also an increasing toughness level is

required. This relationship is also valid for girth

welds, i.e. with increasing strength of linepipe,

weld metals of increased strength and sufficient

toughness are required to ensure overmatching

behavior of girth welds.

LONGITUDINAL LOADS DURING

INSTALLATION AND IN-SERVICE

General

The objectives of this chapter are to describe the

longitudinal loads acting on pipelines as below:

S-lay installation loads;

J-lay installation loads;

Reeling installation loads;

In-service loads for cold pipelines;

In-service loads for HP/HT (high pressure

high temperature) pipelines.

For large diameter pipelines, the preferred

installation method is S-lay when water depth is

shallower than e.g. 500 m. For deepwater

installation, J-lay is considered more suitable

because it demands less laying tension. The lay

rate for S-lay is 2-3 times faster than J-lay.

Typically a lay rate for S-lay is 3 km per day and a

day rate is approximately 3 millions NOK (0.4

millions USD) for both S-lay and J-lay.

Unless specifically defined, strain is meant to

be total strain.

Installation Loads for S-laid Pipelines

For deep water pipe lay with S-lay method, the

pipes departure angle on the stinger has to be

increased to minimize tension requirements and

provide seabed maneuverability. The requirement

of stinger departure angle is linked to the

minimum curvature radius, or laying strain

criterion. Less conservative laying strain

criterion, is being developed by Deepipe JIP,

Expipe JIP and design projects by operators and

engineering companies.

Recent research projects document that

allowable static strain may be 0.28%. Due to a

reduction of strain hardening for high strength

steel, the allowable laying strain for high strength

pipe is lower than that for X65 pipes. Further

research is therefore required to study the

feasibility of relaxing strain criterion for high

strength pipe in deep water.

High strength steels are beneficial both with

respect to wall-thickness sizing and less tension

6

requirements resulting from smaller weight during

installation. The limiting failure modes with

respect to pipeline installation are considered to

be

Girth weld fracture from weld defects;

Concrete tensile failure due to overstressing;

Low cycle fatigue due to installation and

in-service load cycling;

Buckling as a result of external-over pressure in

sagbend;

Collapse due to bending moment and internal

pressure during operation.

The girth welds are the potential week section if

one of the following situations is presented during

installation:

Strain concentration due to heavy concrete

coating or use of thick buckle arrestors;

Fracture due to less strict requirements of weld

defect inspection and repair;

Fatigue due to long holding period in a rough

wave condition during installation.

The assessment of acceptable defect depth and

length represents a key element evaluating the

strain level that can be accepted on the stinger

and during in-service condition. The acceptable

defect sizes depend heavily on the material

strength and fracture toughness. These material

properties are associated with significant

statistical scatter and systematic variations

around the girth weld. Two kinds of laboratory

tests can be useful to justify an increase of

allowable tensile strain:

Ductile fracture tests for improved fracture

resistance assessment;

Low-cycle fatigue tests.

Installation Loads for J-laid Pipelines

The J-lay method involves installing pipeline in a

vertical mode from a dynamically positioned

vessel and therefore allows installation in water

depth beyond the limits of the S-lay and Reeling

methods.

The feasibility of vertical J-pipelay, in particular

from smaller vessels, was examined by DeepStar

JIP (Ekvall et al, 1994) for deepwater installation.

The pipe diameter for such deepwater pipelines

is typically 10 to 20 while that in the case of the

current Blue stream project in the Black Sea is

24. The major technical difficulties are e.g.

strength against collapse under combined loads,

vessel positioning, stinger integrity, and pipe

handling. For vertical J-lay, the vessel can be

oriented arbitrarily with respect to the pipeline

route to minimize the wind and wave forces acting

on the vessel, allowing J-lay installation to

continue under a wider range of weather

conditions. For offshore pipeline installation,

regardless of the pipelay method, a stinger is

normally used to control the deflection of the

suspended pipe span and to keep the bending

strains within an acceptable limit. A shorter and

less curved stinger is required for J-laying

(compared to S-laying) pipelines in deep waters,

since the pipe span lifts off at a less steep angle.

The maximum bending stress along the

suspended span occurs in the sagbend or around

the stinger.

A major design concern is that pipe strength in

the sagbend is very sensitive to collapse during a

vertical J-lay installation, since the pipe in this

region is subjected to very high stresses due to

combined bending and external pressure.

At the touchdown point, the stress due to change

of the configuration as well as contact force from

the seabed, can be very high. This may induce

some cross-sectional ovalisation that may further

reduce pipe collapse strength. At the touchdown

point, the bending collapse is a displacement-

controlled situation. The laying strain-limit may be

determined using external pressure curvature

interaction equations. Typical strain is 0.2%

during J-installation of pipelines.

Fatigue loads should also be included to design

for an abnormal weather situation, where cyclic

loads may be repeated if the pipe is on-hold for a

long period, due to e.g. repair needs. The

calculation of fatigue loads may be conducted

using dynamic installation analysis.

The methods of strength design for S-laying

installation, as discussed earlier, are generally

applicable to J-laying situations.

Installation Loads for Reeled Flowlines

Strain Level During Reeling

The different stages of the reeling process are:

Reeling on;

Reeling off;

Pipe passing the entry guide and ;

7

Bending at pipe straightener.

Strain as Pipe is Lowered to the Seabed

As in traditional S-lay, the reeled pipe may be

bent as it passes over a stinger leaving the

vessel, and bent in the opposite direction as it

meets the seabed. These bending scenarios are

often referred to as overbend and sagbend,

respectively.

Strain During Pressure Testing

Prior to putting a pipeline into operation the pipe

will be hydrotested to a test pressure higher than

normal operating pressure. The procedure and

the test pressure depend on the pipeline code

used for design. The longitudinal strain at a hydro

test is about 0.2% and the equivalent stress is

close to SMYS (Specified Minimum Yield Stress)

at critical locations (e.g. spans) in a hydro test.

In-service Loads for Cold Pipelines

For cold pipelines, the in-service loads are:

Fatigue due to extensive repair period or rough

wave conditions during installations;

Functional loads (e.g. pressure, temperature,

weight and support reaction);

Environmental loads (e.g. wave and current

loads);

Accidental loads (e.g. impacts, dropped objects,

explosion, fire and anchoring);

Trawling loads (fishing gear loads during impact,

pull-over and hooking process).

The internal pressure may be reversibly

estimated from wall-thickness and material grade

using (pressure containment) hoop stress

criterion. Typically internal pressure is 200 barg

for gas export lines and 350 barg for infield

flowlines, although the exact value is to be given

case by case. The intention to list the above

values is to show that high pressure in offshore

pipelines is far higher than that experienced in

onshore pipelines.

The weight is to be estimated considering the

volume of steel, pipe contents density, coating

thickness and density. The contact force between

a cold pipeline and the seabed may be simply

calculated based on force equilibrium.

The wave and current loads on pipeline are

estimated using Morissons equations given by

design codes. The wave and current velocities

are calculated based on water depth and the gap

distance between the pipe and the seabed.

Again, equations are available from the codes to

calculate wave and current velocities. Statistical

values are used to estimate leads:

For ultimate strength analysis, the extreme

values corresponding to n years return period

are used;

For fatigue strength analysis, characteristic

values are used;

For design against accidental loads, normal

operating loads are to be used;

For design against fishing gear pull-over loads,

loads corresponding to the specific span

heights are to be used.

The characteristic fatigue loads for cold pipelines

are:

Cyclic loads during installation phase, e.g.

induced by wave loads or reeling loads;

Cyclic loads due to free-spans, e.g. due to

vortex-induced vibrations or caused by cyclic

wave force in a shallow water.

For cold pipelines, the temperature induced axial

displacement is negligible. It is perhaps correct to

assume that the typical normal operating loads

are internal pressure. However, global buckling

(e.g. upheaval buckling & lateral buckling) should

not be excluded from design if operating pressure

is high and soil friction is low.

Unless fishing gear loads are large, longitudinal

loads are not a demanding requirement. Normally

very little seabed intervention is required for the

safety of a pipeline in operating conditions.

Unfortunately for design of pipelines in the North

Sea, pull-over loads are governing design

parameter where fishing activities are frequent

and water depth is less than 350 m. The pull-over

loads consist of vertical (downward) component

and horizontal component. Both are functions of

span height, and trawling velocity. The time-

history of the pull-over loads are available from

design guidelines made by the pipeline industry.

As daily practice in design offices, finite element

in-place analysis is conducted to estimate the

structural response due to fishing gear pull-over

loads, and comparisons with limit-state design

criteria are carried out to ensure the structural

response is acceptable.

8

In-service Loads for HP/HT Pipelines

General

HP/HT (High Pressure High Temperature)

pipelines are defined as

Design internal-over pressure is

typically

t D

t

2

8 . 0 SMYS

Operating temperature is 130C and above.

The HP/HT pipelines are typically infield flowlines

where oil and gas are transported without

expensive cooling process.

Seawater is a good cooling system. At a distance

of a couple of kilometers from a platform or a

template, the temperature of the pipe containment

becomes lower than 10 C.

As for cold pipelines, the in-service loads for

HP/HT pipelines are:

Functional loads (e.g. pressure, temperature,

weight and support reaction);

Environmental loads (e.g. wave and current

loads);

Accidental loads (e.g. impacts, dropped

objects, explosion, fire and anchoring);

Trawling loads (fishing gear loads during

impact, pull-over and hooking process).

Differences between Cold Lines

and HP/HT lines

In the following, the difference between HP/HT

pipelines and cold pipelines are described:

The major difference is temperature-

induced strain and thermal buckling. As

known by pipeline industry for many years, a

HP/HT pipeline may experience upheaval

buckling if the pipeline is rock-covered.

Lateral buckling (snaking) may occur if the

line is free on the seabed.

Design of HP/HT pipeline against fishing

gear loads becomes a crucial issue since

large stress and moment may be observed

under pull-over loading and the pipeline

industry does not allow strain-based design

for pull-over loads yet. The moment criteria

for load-controlled situations from design

codes are rather conservative.

Seabed intervention cost for protection of

in-service pipeline is governed by pull-over

loads.

Strain level in operating flowlines

The main source of cyclic loading during

operation is repeated heating-up and cooling-

down due to shut-downs/start-ups. For a pipe

laying on the seabed with no rock cover, the

thermal expansion may cause the pipe to deform

laterally or feed pipe into free-spans, resulting in

bending strain. Similarly, for a fully constrained

buried pipeline there will be radial and hoop strain

variations resulting from the start-up/shut-down

cycles.

Summary of Loads and Load Combinations

Actual

longitudinal

loads

Hoop

loads

Code

Require

ments

Remarks

Reeling Maximum

2% longitu-

dinal strain

No

hoop

loads

Fracture

& local

buckling

checks

For small

diameter

flowlines

S-Lay Maximum

0.3 %

strain

External

pressure

for

sag-bend

Fracture,

Rotation,

Collapse

in sag-

bend

For

shallow

water,

large

diameter

J-lay Maximum

0.3 %

strain

External

pressure

for sagbend

Fracture,

Collapse

in sagbend

For deep

water,

large &

small pipe

Cold

opera-

tion

pull-over

induced

0.3% strain

or stress

of 0.9

SMYS

Hoop

stress of

0.8SMYS

Limit

state

based

design

criteria

Crucial

for sea-

bed inter-

vention

design

HP/HT

opera-

tion

pull-over

induced

0.3% strain

or stress

of 0.9

SMYS

Hoop

stress of

0.8SMYS

Limit

state

based

design

criteria

Crucial

for sea-

bed inter-

vention

design

Table 1. Summary of Installation and Operation

Loads.

DESIGN EXPERIENCE

ON LOADS AND STRENGTH

Limit-state Design of Offshore Pipelines

9

Limit state based strength criteria may be

developed for pipelines covering the potential

failure modes:

Out of roundness for serviceability;

Bursting due to internal pressure, longitudinal

force and bending;

Buckling/collapse due to pressure,

longitudinal force and bending;

Fracture of welds due to bending/tension;

Low-cycle fatigue due to shut-downs;

Ratcheting due to reeling and shut-downs;

Accumulated plastic strain.

The limit-states are to be defined for the following

load situations:

Installation condition;

Empty condition;

Water filled condition;

Pressure test condition;

Operational conditions;

Shut-down conditions.

The strength criteria are to be defined for the

following design situations:

Static and dynamic installation criteria;

In-place behavior;

Trawl pull-over response;

Static free-spans;

Dynamic free-spans.

It should be documented that adequate structural

safety is maintained against the potential failure

modes for the given design situations when the

strength criteria developed are satisfied.

Pipe dimensions, operating conditions and

material dictate the allowable moments, stresses

and strains.

The experience from design of North Sea

pipelines is summarized in the following sections.

Experience from Design of Large Diameter

Export Pipelines

The following is a summary of design experience

on loads and strength:

When water depth is less than 350 m, the

wall-thickness design is normally governed

by internal pressure containment

requirement, e.g. hoop stress criterion. In

order to achieve cost saving, it is

necessary to use high strength steel pipe.

When water depth is greater than 350 m, a

study is required to investigate the nonlinear

relation between the costs and steel grade

for different water depths. Higher yield

strength also helps increase the pipe

buckling/collapse capacity for external-over

pressure situations, however, this

relationship is no longer linear.

As long as strain-based design can be

applied for operating conditions, the

longitudinal loads are far below the capacity.

Therefore, the required longitudinal yield

strength is not so high leading to a

potential use of pipes whose hoop yield

strength is far higher than longitudinal yield

strength.

When a pipe is under a load-controlled

situation, the buckling/collapse capacity of

the pipe may be assessed using moment

criteria.

Experience from Design of Infield Flowlines

The following is a summary of design experience

on loads and strength:

Flowlines are typically installed using reeling

methods. A detailed welding qualification

program is required to ensure that no

fracture or local buckling occurs during the

reeling process and there is no threat to the

fatigue strength after line installations.

For small diameter flowlines in the North

Sea, the governing design loads are the

trawling loads. In this instance,

buckling/collapse criteria (moment criteria)

are governing design parameter.

MATERIAL PROPERTY REQUIREMENTS

General

The purpose of this chapter is to describe the

material requirements, and compare the

requirements for longitudinal direction and

circumferential direction. Typically, the material

properties requirement in hoop direction are

related to pressure containment hoop stress

criterion and buckling/collapse under external

pressure, while longitudinal properties are directly

specified for buckling/collapse under bending and

tension, and weldability.

10

It is beneficial from the viewpoint of

manufacturing to allow hoop yield strength higher

than longitudinal yield strength. In the following,

requirements will be described regarding CTOD,

yield stress, ratio of SMYS and SMTS, fatigue

properties and wall-thickness tolerances.

Material Property Requirement in Hoop

Direction

Necessary CTOD value requirements for HAZ

and weld metal are to be established that are

relevant for the specific design conditions with

regard to type and extent of longitudinal weld

defects likely to exist. Typically, the required

CTOD value is established through ECA

(Engineering Criticality Assessment) using British

Standard PD 6493.

The extent of longitudinal weld defects that likely

to exist, is defined in the operators welding

qualification specifications. Typical values are:

depth 3 mm and width minimum of 25 mm and

pipe wall-thickness.

The required CTOD value, as calculated based

on codes, is rather stringent, due to large

scatters in the CTOD values from tests. Practical

experience from field use of the line pipes have,

demonstrated that there has been very little

structural failure due to lack of CTOD value in

hoop direction for line pipes. It is therefore

suggested to closely evaluate the following:

CTOD testing methods, scatters and statistical

evaluation of scatters;

Possibility to reduce the number of CTOD tests;

Safety factors used in ECA determination of

CTOD requirements;

ECA design equations and analysis methods.

Similar observations may be made on the CTOD

requirements for the longitudinal direction.

It is likely that fracture occurs in the weldment.

Then the CTOD requirements made to pipe base

material are not relevant. However, the CTOD

value for HAZ (Heat Affect Zone) may be

relevant for fracture in HAZ. Weldability of the

pipe is a more important parameter than CTOD

value.

Material Property Requirement in

Longitudinal Direction

The CTOD value for line pipes in longitudinal

direction is influential for fracture limit-state when

ECA such as PD6493 is applied to calculate the

limiting loading condition to avoid fracture.

The CTOD value needed to avoid fracture

depends on the extent of girth weld defects likely

to exist and the applied load. For a defect depth

of 3 mm, a wall thickness of 25.4 mm and loading

up to 0.5% total strain a defect length of 177 mm

(7 x wall thickness) was shown to be safe when

CTOD is minimum 0.10 mm, see Knauf and

Hopkins (1996).

The discussions on unstable fracture and CTOD

for hoop direction are also valid for longitudinal

direction.

The fact is that the yield stress in longitudinal

direction does not significantly affect pipe

strength as long as strain-based design is

applicable to the design situation. The reasoning

for this statement is that strain acting on pipelines

in operating condition is typically as low as 0.2%

unless the pipeline is under a high pull-over load.

With exception of some special material

problems, the Y/T (SMYS/SMTS) ratio

requirements can be replaced by introducing

strain-hardening parameters such as

R

and n

used in a Ramberg-Osgood equation. In Bai et al

(1994), a set of equations are given to relate

SMYS and SMTS with strain-hardening

parameters

R

and n.

The material strain-hardening effect may be

accounted for in fracture mechanics assessment

and local buckling/collapse checks through use of

the stress-strain curves. In fact, a set of design

equations was given by Bai et al (1997) and Bai

et al (1999) for local buckling/collapse. In the

papers by Bai et al. (1997, 1999), the effect of

material strain hardening parameter on

buckling/collapse have been discussed in detail.

The level-2 and level-3 failure assessment

diagrams in PD6493 do also account for strain-

hardening effects.

Comparisons of Material Property

Requirements

11

Which material properties are dominant in local

buckling/collapse? The answer is dependent on

loads as the following:

For internal pressure containment, hoop SMTS;

For external-pressure induced buckling, hoop

SMYS;

For bending collapse, longitudinal SMYS;

For combined internal pressure and bending,

hoop SMTS;

Longitudinal SMYS & SMTS;

For combined external pressure and bending,

hoop SMYS;

Longitudinal SMYS & SMTS.

Pipe strength under combined internal pressure

and bending is an important design case, if

fishing activities are frequent.

It is difficult to compare the requirements of the

material property in hoop and longitudinal

directions. Rather the following is a discussion

on cost-effectiveness of raising materials

performance in hoop and longitudinal directions.

Raising hoop SMYS will directly result in a

proportional reduction of the required wall-

thickness of the line pipe for water depth

shallower than 350 mm. However, if the design

codes, on buckling/collapse for external-over

pressure case, are further upgraded, this water

depth may be extended from 350 m to 450 m. It is

the authors' opinion that the existing design

equations for external-over pressure situations

are rather conservative. To achieve yield and

tensile strength values that conform to the

requirements, as specified for the transverse

direction, a corresponding increase in the

strength in the longitudinal direction is needed.

This in turn leads to increased production costs

and may lead to difficulties in meeting the

requirements for yield-to-tensile ratio, toughness

and sour service suitability, etc..

As a conclusive remark on materials property

requirements, it is believed that:

The minimum CTOD values in both hoop and

longitudinal directions typically should be

0.1mm; the applicability of lower CTOD

values can be validated by ECA methods.

It is economically beneficial and technically

justifiable that for pipe grades X60 to X80

yield and tensile strength in longitudinal

direction can be lower by up to 10% than

those in the transverse direction for water

depths shallower than 450 m.

For fracture and local/buckling failure modes,

the Y/T value requirement can be removed

if the strength analysis explicitly account for

the difference of strain-hardening whose

parameters (

R

and n) are a function of

SMYS and SMTS as the equations given in

Bai et al(1997).

As a further study, it is proposed to compare the

Y/T ratio requirements from alternative codes

(e.g. 0.93 from API for onshore pipelines, 0.85

from EPRG and 0.87 from DNV96 guideline). It

is perhaps possible to find some other rational

criteria that can replace the Y/T ratio requirement

in strength design. In order to develop alternative

criteria, it is necessary to understand the

reasoning of using Y/T ratio as a design

parameter.

STRENGTH DESIGN OF LINE PIPES

WITH YIELD ANISOTROPY

Anisotropy has been taken into account for the

first time in the recently established DNV

offshore standard F101 in that the minimum

tensile strength required in the longitudinal

direction has been reduced by 5%, compared to

that in the transverse direction. It should be

endeavoured to pursue other codes to adopt this

approach and to apply this approach also to yield

strength. Reduction of the strength levels in the

order of 10% for the longitudinal direction is

technically justified.

An analytical solution may be derived for the

calculation of the moment capacity of a pipe with

a corrosion defect subjected to internal pressure,

axial force and bending moment. The maximum

capacity is defined in the solution as the moment

at which the entire cross section yields. The

corrosion defect is conservatively assumed to be

symmetrical to the bending plan.

Criteria for buckling/collapse calculations of

corroded pipes with yield anisotropy were derived

by Bai et al (1999).

The moment criteria were re-visited and extended

for design of high strength steel pipes with yield

anisotropy.

CONCLUSIONS

The paper provides technical information from

linepipe manufacturing and design viewpoints to

promote use of high strength linepipes. The

following is conclusive remarks:

12

1. Material properties are given for high strength

linepipe.

2. Practical considerations on use of high

strength steel have been given, focusing on

cost impact, welding, material and corrosion

aspects.

3. Pipeline design loads have been summarized

for S-laid large diameter export lines and

small diameter infield flowlines.

4. The requirements of material properties have

been discussed to justify use of yield

anisotropy line pipe.

5. Strength design equations have been

developed for high strength linepipes that

have yield anisotropy.

6. Regulatory bodies, specifications and design

codes should pay more attention to the

technical feasibility of pipe properties. Close

co-operation among designers, pipelaying

contractors, pipeline operators and pipe

manufacturers should be intensified.

REFERENCES

1. API 5L (1995): Specification for Line Pipe, 41st

Edition.

2. Bai, Y. Igland, R. and Moan, T. (1994): Ultimate Limit

States for Pipes under Combined Tension and

Bending, International Journal of Offshore and Polar

Engineering, pp.312-319.

3. Bai, Y. Igland, R. and Moan, T. (1997): Tube Collapse

under Combined External Pressure, Tension and

Bending, Journal of Marine Structures, Vol. 10, No.5,

pp.389-410.

4. Bai, Y., Jensen, J.C. and Hauch, S. (1999): Capacity

of Pipes with Yield Anisotropy, Proc. of ISOPE99.

5. DNV (2000): DNV OS-F101, Submarine Pipeline

Systems, Det Norske Veritas.

6. Ekvall, A.G.C., Ju, G.T., Langner, C.G., McClure, S.C.,

Salzer, J.R., and Welsman, B.D. (1994): Evaluation of

Deepwater J-pipelay, DeepStar Phase II, CTR 610,

March 1994.

7. Graf, M.K. and Hillenbrand, H.G. (1997): Grade X80

Linepipe and Pipeline Construction.

8. Graf, M.K., Hillenbrand, H.G. and Niederhoff K.A.

(1993): Production of Large-diameter Line Pipe and

Bends for the Worlds First Long Range pipeline in

Grade X80 (GRS 550) PRC/EPRG Ninth Biennial

Joint Technical Meeting on Line Pipe Research,

Houston, Texas, May 11-14

th

.

9. Graf, M. K. and Hillenbrand, H. G. (1995): Production

of Large Diameter Line Pipe - State of The Art and

Future Development Trends Europipe GmbH.

10. Grf, M.K. and Hillenbrand, H.G. (2000):

Development of larger-diameter linepipe for offshore

applications, 3

rd

International Pipeline Technology

Conference, 22-24 May 2000, Brugge, Belgium.

11. Hillenbrand, H.G., Niederhoff, K.A., Amoris, E.,

Perdrix, C., Streisselberger, A. and Zeislmair, U.

(1997): Development of Line Pipe in Grades up to X

100, PRCI-EPRG 11

th

Biennial Technical Meeting,

Arlington Virginia, April.

12. Hillenbrand et al. (1995): Manufacturability of Line

Pipe in Grades up to X100, TM Processed Plate HG

Pipeline Technology, Volume II.

13. ISO 3138-2 (1996): Petroleum and natural gas

industries - Steel pipe for pipelines - Technical

delivery conditions - Part 2: Pipes of requirement class

B.

14. Knauf, G. and Hopkins, P. (1996): The EPRG

Guidelines on the Assessment of Defects in

Transmission Pipeline Girth Welds, 3R international

(35), heft 10-11/1996, pp. 620-624.

15. Pistone, G. R., Vogt, G., Demofonti, G. and Jones

D.G. (1995): EPRG Recommendations for Crack

Arrest Toughness for High Strength Line Pipe Steels,

3R International, Vol. 34 November 10, pp 606 - 611.

16. Re, G., Pistone, V., Vogt, G., Demofonti, G. and

Jones, D.G. (1995): EPRG Recommendation for

crack arrest toughness for high strength line pipe

steels, 3R International (34), Heft 10-11, pp607-611.

You might also like

- Annexure-1 Technical Specification For PipelinesDocument316 pagesAnnexure-1 Technical Specification For PipelinesUtkarsh ModhiaNo ratings yet

- Evaluating Natural Frequency of Multi-Spanning Offshore Pipelines.Document11 pagesEvaluating Natural Frequency of Multi-Spanning Offshore Pipelines.Hasan MohdNo ratings yet

- CEE 330L Manual (Modified 13-01-2020) - Converted-Compressed PDFDocument55 pagesCEE 330L Manual (Modified 13-01-2020) - Converted-Compressed PDFT Srinivas ReddyNo ratings yet

- Compute stress of rigid pipe with Excel VBADocument7 pagesCompute stress of rigid pipe with Excel VBAHernâni CruzNo ratings yet

- CAESAR II PIPELINE STRESS ANALYSISDocument16 pagesCAESAR II PIPELINE STRESS ANALYSISSikandar_30No ratings yet

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityFrom EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo ratings yet

- Stress Analysis of Buried Pipeline Using Finite Element MethodDocument16 pagesStress Analysis of Buried Pipeline Using Finite Element MethodMaria TnsNo ratings yet

- Iors 2013Document35 pagesIors 2013jeedanNo ratings yet

- Stress Linearization: 1 © 2015 ANSYS, Inc. January 23, 2017Document13 pagesStress Linearization: 1 © 2015 ANSYS, Inc. January 23, 2017Osama AshourNo ratings yet

- Fatigue Life For ASME VII-DIV2Document23 pagesFatigue Life For ASME VII-DIV2Muhammad Abd El KawyNo ratings yet

- Nanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationFrom EverandNanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationNo ratings yet

- Hydrodynamic Forces On Subsea Pipelines - KarremanDocument6 pagesHydrodynamic Forces On Subsea Pipelines - KarremanAlberto darianNo ratings yet

- How To Add or Move Joints in SACS Using Relative To A Line With An AngleDocument3 pagesHow To Add or Move Joints in SACS Using Relative To A Line With An AngleBolarinwaNo ratings yet

- PIPE STRESS ANALYSIS GUIDEDocument39 pagesPIPE STRESS ANALYSIS GUIDEsharmila patil100% (1)

- Determination of Allowable StressesDocument7 pagesDetermination of Allowable Stressesvikas2510No ratings yet

- Axial Stress Calculation For Restrained Pipeline - Intergraph CADWorx - AnalysisDocument5 pagesAxial Stress Calculation For Restrained Pipeline - Intergraph CADWorx - AnalysisSharun SureshNo ratings yet

- The Analysis of Piping Under PressureDocument21 pagesThe Analysis of Piping Under PressureTrungSon NguyenNo ratings yet

- Linearizing StressDocument6 pagesLinearizing Stressbo cambellNo ratings yet

- 2-Trench Effect On The Fatigue Life of A SCR - Y.T.KimDocument15 pages2-Trench Effect On The Fatigue Life of A SCR - Y.T.KimYoungtae KimNo ratings yet

- 10.0000@Www - Onepetro.org@conference Paper@ISOPE I 14 112Document5 pages10.0000@Www - Onepetro.org@conference Paper@ISOPE I 14 112FelipeNo ratings yet

- Signal FFS & FEACrack Analysis With AbaqusDocument20 pagesSignal FFS & FEACrack Analysis With AbaqusbomikaNo ratings yet

- Strain-Based Design Criteria of PipelinesDocument138 pagesStrain-Based Design Criteria of Pipelinesjosemiguel2204100% (1)

- Civ-su-1.28-A Helidecks On Offshore InstallationsDocument12 pagesCiv-su-1.28-A Helidecks On Offshore InstallationsBolarinwaNo ratings yet

- Offshore Pipelaying DynamicsDocument150 pagesOffshore Pipelaying DynamicsfredisterikNo ratings yet

- LNG Supply - Gas Power Plants in Indonesia: LNG Pipe-In-Pipe System Description Gorontalo & Kendari Project CasesDocument13 pagesLNG Supply - Gas Power Plants in Indonesia: LNG Pipe-In-Pipe System Description Gorontalo & Kendari Project CasesLiauw CooperationNo ratings yet

- Fatigue Analysis of Welding Seams and Spot Joints in Automotive StructuresDocument9 pagesFatigue Analysis of Welding Seams and Spot Joints in Automotive StructuresAndreyNo ratings yet

- IPC 2022 - Finite Element Analysis of Cold Field BendsDocument10 pagesIPC 2022 - Finite Element Analysis of Cold Field BendsOswaldo MontenegroNo ratings yet

- Analysis of Components in VIII-2Document16 pagesAnalysis of Components in VIII-2Ricardo Paz SoldanNo ratings yet

- Jet Tour of Release 12.1 and Immersed Boundary Solver in ANSYS FLUENTDocument12 pagesJet Tour of Release 12.1 and Immersed Boundary Solver in ANSYS FLUENTTebong BrowserNo ratings yet

- Pipe in Pipe Swaged Welding New Design by Subsea 7Document19 pagesPipe in Pipe Swaged Welding New Design by Subsea 7Sridharan ChandranNo ratings yet

- New Generation Pipeline Analysis Software PDFDocument17 pagesNew Generation Pipeline Analysis Software PDFmirnori6048No ratings yet

- Annex B2-Recommendations For Linearization of Stress Results ForDocument20 pagesAnnex B2-Recommendations For Linearization of Stress Results ForMarlon VillarrealNo ratings yet

- Gujarat Transformers PVT - Ltd. E-Mail Copy: As Per IS 1180 - Level-2Document5 pagesGujarat Transformers PVT - Ltd. E-Mail Copy: As Per IS 1180 - Level-2THANGAVEL PNo ratings yet

- 25 1Document8 pages25 1pajadhavNo ratings yet

- Strength of Materials - Stresses in Thin Walled Cylinder - Hani Aziz AmeenDocument13 pagesStrength of Materials - Stresses in Thin Walled Cylinder - Hani Aziz AmeenHani Aziz Ameen100% (1)

- ANSYS WorkBench 14.5 Submodeling GuideDocument26 pagesANSYS WorkBench 14.5 Submodeling GuideAshish VajirNo ratings yet

- Pipeline Bottom Roughness AnalysisDocument6 pagesPipeline Bottom Roughness AnalysisLK AnhDungNo ratings yet

- Buried Pipe ModelingDocument22 pagesBuried Pipe ModelingPeter Rodriguez100% (1)

- NT Developments in Eca Methods For PipelinesDocument16 pagesNT Developments in Eca Methods For Pipelineskatfy1No ratings yet

- Redistribution of MomentsDocument29 pagesRedistribution of MomentsShita AlemieNo ratings yet

- Vedeld 2 - VIV Fatigue CalculationDocument36 pagesVedeld 2 - VIV Fatigue Calculationmobin_turkNo ratings yet

- Thermal Buckling Comparative Analysis Using Different FE Tools 01Document4 pagesThermal Buckling Comparative Analysis Using Different FE Tools 01Waldek BanasiakNo ratings yet

- Model Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandModel Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- 16 Qiang Bai and Yong Bai: Pipeline InstallationDocument1 page16 Qiang Bai and Yong Bai: Pipeline InstallationAlireza KhodabandehNo ratings yet

- Resolving Piping and Instrumentation Diagram CommentsDocument16 pagesResolving Piping and Instrumentation Diagram CommentsBurhan Ayub100% (1)

- Flexmen: Register User Forum List Calendar Active Topics FaqDocument19 pagesFlexmen: Register User Forum List Calendar Active Topics FaqParilla13No ratings yet

- PAT 322 - Buckling and Post-Buckling AnalysisDocument26 pagesPAT 322 - Buckling and Post-Buckling Analysishakan demirNo ratings yet

- Guided ANSYS-Mode Hands-On Tutorial: H. Dieter Wilhelm December 11, 2012Document26 pagesGuided ANSYS-Mode Hands-On Tutorial: H. Dieter Wilhelm December 11, 2012marcorreo_peNo ratings yet

- Equalizing Line Mbe 6 WTRDocument2 pagesEqualizing Line Mbe 6 WTRMuhamad Hifni SyahbanaNo ratings yet

- Buckling of Conical Shells Under ExternalDocument81 pagesBuckling of Conical Shells Under Externalabdulsalam yousifNo ratings yet

- Stress CategorisationDocument6 pagesStress CategorisationSachinNo ratings yet

- Pipeline Virtual Anchor Length Calculation (With PDF) - What Is PipingDocument19 pagesPipeline Virtual Anchor Length Calculation (With PDF) - What Is PipingMAHESH CHAND100% (1)

- Pressurized Thermal Shock in Nuclear Power Plants: Good Practices For AssessmentDocument229 pagesPressurized Thermal Shock in Nuclear Power Plants: Good Practices For AssessmentDennis Padec BwochengoNo ratings yet

- Wind-Excited VibrationsDocument12 pagesWind-Excited VibrationsGuilherme SalesNo ratings yet

- IndianOil Pipeline Types, Laying, Maintenance & InspectionDocument34 pagesIndianOil Pipeline Types, Laying, Maintenance & InspectionNaveen SahrawatNo ratings yet

- Discussion - Stress Strain CurveDocument3 pagesDiscussion - Stress Strain CurveAnonymous UoHUagNo ratings yet

- BVS-01 Stress AnalysisDocument11 pagesBVS-01 Stress AnalysisSiva baalan100% (1)

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsFrom EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNo ratings yet

- 2015Document55 pages2015jptl6477No ratings yet

- Swivel CatalogDocument24 pagesSwivel Catalogjptl6477No ratings yet

- PressureDocument1 pagePressurekarmakar tpNo ratings yet

- Pipe Sizing Charts Tables.12890822Document29 pagesPipe Sizing Charts Tables.12890822forevertay2000No ratings yet

- Hazop Training GuideDocument9 pagesHazop Training GuideAdyBorsosNo ratings yet

- 1 - Modeling of Pipeline TransientsDocument154 pages1 - Modeling of Pipeline TransientsOmer TokhNo ratings yet

- FoundOcean Fabric Formwork Grout Bag CatalogueDocument20 pagesFoundOcean Fabric Formwork Grout Bag Cataloguejptl6477No ratings yet

- FoundOcean Fabric Formwork Grout Bag CatalogueDocument20 pagesFoundOcean Fabric Formwork Grout Bag Cataloguejptl6477No ratings yet

- Dynamic Characteristics Check ValvesDocument12 pagesDynamic Characteristics Check ValvesZoran DanilovNo ratings yet

- Surge AnalysisDocument30 pagesSurge AnalysisRadhakrishna MadabhushiNo ratings yet

- In The Pipeline - June 2011Document9 pagesIn The Pipeline - June 2011jptl6477No ratings yet

- In The Pipeline - June 2011Document9 pagesIn The Pipeline - June 2011jptl6477No ratings yet

- Excavation Safety GuideDocument47 pagesExcavation Safety GuideskilmagNo ratings yet

- Putro 2017Document93 pagesPutro 2017Yon tinyayaNo ratings yet

- 2018 Physical Metallurgy Principles and Design - Haidemenopoulos, Gregory N PDFDocument490 pages2018 Physical Metallurgy Principles and Design - Haidemenopoulos, Gregory N PDFPhạm Thịnh100% (1)

- Extended-Design and Analysis of A Network Arch BridgeDocument10 pagesExtended-Design and Analysis of A Network Arch BridgehansNo ratings yet

- Physics Nmat 2018Document66 pagesPhysics Nmat 2018KL Tongson50% (2)

- Lecture 4: Adsorption: The Islamic University of Gaza-Environmental Engineering Department Water Treatment (EENV - 4331)Document45 pagesLecture 4: Adsorption: The Islamic University of Gaza-Environmental Engineering Department Water Treatment (EENV - 4331)Anuja Padole100% (1)

- LensesDocument13 pagesLenseshelmi_tarmiziNo ratings yet

- NA To Sls en 1993-1-1Document16 pagesNA To Sls en 1993-1-1Shan Sandaruwan AbeywardeneNo ratings yet

- Understanding Chemical EquilibriumDocument22 pagesUnderstanding Chemical EquilibriumYuvrajNo ratings yet

- MP ProblemsDocument2 pagesMP Problemskartikesh prasadNo ratings yet

- RK330-01 Atmospheric Temperature, Humidity & Pressure SensorDocument2 pagesRK330-01 Atmospheric Temperature, Humidity & Pressure SensorRach ToyNo ratings yet

- Amptpl: Adani Murmugao Port Terminal Private LimitedDocument58 pagesAmptpl: Adani Murmugao Port Terminal Private LimitedMinh TríNo ratings yet

- Adama Science and Technology University School of Applied Natural Science Department of Applied MathematicsDocument9 pagesAdama Science and Technology University School of Applied Natural Science Department of Applied MathematicsALEMAYEHUNo ratings yet

- Corrosion SlidesDocument65 pagesCorrosion SlidesAnshul ShuklaNo ratings yet

- GK 3165 Serti̇fi̇kaDocument1 pageGK 3165 Serti̇fi̇kanedim cılızNo ratings yet

- Datasheet Uni Flex ASB Open Top RadiusDocument4 pagesDatasheet Uni Flex ASB Open Top RadiusIkki Muhammad AssidqiNo ratings yet

- p121 RWB CombinedDocument278 pagesp121 RWB CombinedeiufjojNo ratings yet

- A35 AnswersDocument15 pagesA35 AnswersSeanNo ratings yet

- Doppler Effect ExplainedDocument6 pagesDoppler Effect ExplainedBrandonNo ratings yet

- Cast iron component failure investigationDocument4 pagesCast iron component failure investigationdelta lab sangliNo ratings yet

- Efunda - Plate Calculator - Clamped Circular Plate With Uniformly Distributed Loading-12.06.2017Document2 pagesEfunda - Plate Calculator - Clamped Circular Plate With Uniformly Distributed Loading-12.06.2017vinay1999No ratings yet

- Reduction of Air Pollution Using Smog-Free-Tower A Review PaperDocument5 pagesReduction of Air Pollution Using Smog-Free-Tower A Review PaperVivace SystmNo ratings yet

- El Salvador SeismicDocument11 pagesEl Salvador SeismicMadNo ratings yet

- Design components of MHP for hydraulic dataDocument34 pagesDesign components of MHP for hydraulic dataSomprasad PradhanNo ratings yet

- VFR & 118Document1 pageVFR & 118Moeen Iqbal ShahNo ratings yet

- CalibrationDocument13 pagesCalibrationAmanjit SinghNo ratings yet

- The Idea That A Machine Can Be Decomposed Into Simple Movable Elements Led Archimedes To Define The LeverDocument2 pagesThe Idea That A Machine Can Be Decomposed Into Simple Movable Elements Led Archimedes To Define The LeverEndalkachew AbateNo ratings yet

- Kinematic ViscosityDocument4 pagesKinematic ViscosityAloka KarunarathneNo ratings yet

- Home Assignment 5 PHY 306/604 Statistical MechanicsDocument3 pagesHome Assignment 5 PHY 306/604 Statistical MechanicsSayan KuntiNo ratings yet

- Phase Equilibrium: Phases, Components, and Degrees of FreedomDocument69 pagesPhase Equilibrium: Phases, Components, and Degrees of FreedomSyahirah FazialNo ratings yet

- Factors Affecting PermeabilityDocument4 pagesFactors Affecting PermeabilityMahesh RamtekeNo ratings yet