Professional Documents

Culture Documents

Erection Engineering - The Science Behind The Art

Uploaded by

Chris EvansOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Erection Engineering - The Science Behind The Art

Uploaded by

Chris EvansCopyright:

Available Formats

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

1

Thank you for joining our live webinar today.

We will begin shortly. Please standby.

Thank you.

Need Help?

Call ReadyTalk Support: 800.843.9166

AISC Live Webinars

Theres always a solution in Steel

AISC Live Webinars

Thank you for joining our live webinar today.

We will begin shortly. Please standby.

Thank you.

Need Help?

Call ReadyTalk Support: 800.843.9166

1

Theres always a solution in steel

Todays audio will be broadcast through the

internet.

Alternatively, to hear the audio through the

phone, dial 800 671 7004.

International callers, dial +1 303 223 4362.

For additional support, please press *0 and you

will be connected to a live operator.

AISC Live Webinars

AISC

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

2

Theres always a solution in steel

Todays live webinar will begin shortly.

Please standby.

As a reminder, all lines have been muted. Please type any

questions or comments through the Chat feature on the

left portion of your screen.

Todays audio will be broadcast through the internet.

Alternatively, to hear the audio through the phone,

dial 800 671 7004.

International callers, dial +1 303 223 4362.

For additional support, please press *0 and you will

be connected to a live operator.

AISC Live Webinars

AISC

4

Presented by

Erection Engineering:

The Science Behind the Art

Clint O. Rex,

Ph.D. P.E.

Will Jacobs, V,

P.E., S.E.

Stanley D. Lindsey & Associates

Atlanta

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

3

William P. Jacobs, V, P.E., S.E.

Clinton O. Rex, Ph.D., P.E.

Stanley D. Lindsey & Associates

Atlanta, Georgia, USA

Erection Engineering:

The Science Behind The Art

Theres always a solution in steel

The structure is stable only in its completed

form. Temporary supports required for stability

during all intermediate stages of construction

shall be designed, furnished and installed by the

contractor. Contractor is responsible for

construction analysis and erection procedures,

including design and erection of falsework,

temporary bracing, etc.

Typical General Structural Note:

What is Erection Engineering?

6

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

4

Theres always a solution in steel

Basket

Choker

Shackle

Clevis

Cable Dog

Spreader

The Lingo:

What is Erection Engineering?

Bridle Sling

Turnbuckle

Chain Fall

Col-Yoom

Foot-urr

7

Theres always a solution in steel

What are the rules to play by?

Is there any technical guidance?

What loads needs considered?

Stability Issues

Simple

Complex

Really Complex

Conveying the plan

Questions

Outline

Outline

8

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

5

Theres always a solution in steel

IBC 2012

The Rules

9

Theres always a solution in steel

2010 AISC Specification Section

M4.2

Code of Standard Practice Section

7.10.3

AISC 14

th

Ed. Manual

The Rules

10

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

6

Theres always a solution in steel

2010 AISC Specification Section M4.2

AISC

The Rules

11

Theres always a solution in steel

2010 AISC Code of Standard Practice Section 7.10.3

AISC

The Rules

12

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

7

Theres always a solution in steel

1926.755(a) 4 bolts required for column erection

1926.451(c)(1) Max height to width ratio of unbraced

scaffolding 4:1

1926.754(c)(1) Shear connectors in field only

1926.756(c)(1) Double connections sharing common

bolts

1926.756(d) Minimum load of 300lb at 18 from face

for column splice design

1926.756(e) Perimeter columns require 48 extension

for safety cables

OSHA

The Rules

13

Theres always a solution in steel

What are the rules to play by?

Is there any technical guidance?

What loads needs considered?

Stability Issues

Simple

Complex

Really Complex

Conveying the plan

Questions

Outline

Outline

14

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

8

Theres always a solution in steel

Guidance Is there Any?

Guidance

AISC Design Guide 10

15

Theres always a solution in steel

Guidance Is there Any?

Guidance

AISC Design Guide 10

BTH-1-2011 Design of

Below-the-Hook Lifting

Devices

16

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

9

Theres always a solution in steel

Guidance Is there Any?

Guidance

AISC Design Guide 10

BTH-1-2011 Design of

Below-the-Hook Lifting

Devices

WIRE Rope User Manual

4

th

Edition

17

Theres always a solution in steel

Guidance Is there Any?

Guidance

AISC Design Guide 10

BTH-1-2011 Design of

Below-the-Hook Lifting

Devices

WIRE Rope User Manual

4

th

Edition

Manufacturers Catalogs

(Certex / Crosby, etc).

18

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

10

Theres always a solution in steel

What are the rules to play by?

Is there any technical guidance?

What loads needs considered?

Stability Issues

Simple

Complex

Really Complex

Conveying the plan

Questions

Outline

Outline

19

Theres always a solution in steel

Dead and Live Loads

Loading

Loads are REAL

20

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

11

Theres always a solution in steel

Dead and Live Loads

Loading

Loads are REAL

21

Theres always a solution in steel

Dead and Live Loads

Loading

Deflection Limits

22

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

12

Theres always a solution in steel

Dead and Live Loads

Loading

Deflection Limits

23

Theres always a solution in steel

Dead and Live Loads

Loading

Deflection Limits

24

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

13

Theres always a solution in steel

ASCE 37-02

Loading

The ASCE 7 of

Construction Loading

Contains information on

construction dead, live,

wind, and seismic

loading

25

Theres always a solution in steel

Dead and Live Loads

Loading

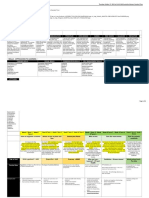

ASCE 37 Live Load Classes

26

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

14

Theres always a solution in steel

Wind Loads During Construction

Loading

Velocity Reductions

27

Theres always a solution in steel

Wind Loads During Construction

Loading

Force Reductions

28

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

15

Theres always a solution in steel

Wind Loads During Construction

Loading

Increase for Drag Factors

29

Theres always a solution in steel

Wind Loads During Construction

Loading

Reduce for Shielding Effects

30

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

16

Theres always a solution in steel

Wind Loads During Construction

Loading

31

Theres always a solution in steel

Wind Loads During Construction

Loading

AISC 14

th

Ed. Design Examples Chapter III

32

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

17

Theres always a solution in steel

Wind Loads During Construction

Loading

AISC 14

th

Ed. Design Examples Chapter III

ASCE 7-10 MWRS E-W

Base Shear from Design

Example = 167.6 kips

33

Theres always a solution in steel

Wind Loads During Construction

Loading

AISC 14

th

Ed. Design Examples Chapter III

ASCE 7-10 MWRS E-W

Base Shear from Design

Example = 167.6 kips

ASCE 37 = 602 kips??

34

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

18

Theres always a solution in steel

Any questions?

Questions

35

Theres always a solution in steel

What are the rules to play by?

Is there any technical guidance?

What loads needs considered?

Stability Issues

Simple

Complex

Really Complex

Conveying the plan

Questions

Outline

Outline

36

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

19

Theres always a solution in steel

Cribbing Beams

Simple

37

Theres always a solution in steel

AISC 360-10: Chapter F-Scope

Lateral Torsional Buckling

Simple

38

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

20

Theres always a solution in steel

AISC 360-10: Chapter F1 General Provisions

Lateral Torsional Buckling

Simple

39

Theres always a solution in steel

AISC 360-10: J10.7 / Part 2 of 14

th

Edition Manual

Lateral Torsional Buckling

Simple

40

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

21

Theres always a solution in steel

Connection Design for Steel Structures by Bo Dowswell

LTB Capacity is reduced as a result of web distortion

Lateral Torsional Buckling

Simple

Use modified LTB length (British Standard 5950, 1985)

' 2

beamdepth

l l d

d

= +

=

41

Theres always a solution in steel

Bolts

Welds

Clamps

But for what force?

Restraint of Flange

Simple

42

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

22

Theres always a solution in steel

AISC 360-10 Appendix 6

Restraint of Flange

Simple

0.024

r

rb

b b

M L

nC L

M =

For a typical simple span cribbing beam

1

Maximummoment along span

b

r

L L

n

M

=

=

=

0.024

r

rb

b

M

C

M =

43

Theres always a solution in steel

W8x31 Cribbing Beam

Example

Simple

45

u

P kips =

45 10/4 113

u

M Kip ft = =

b b b

104 (L =11.4 ft, C =1.0) Actual C =1.32

n

M Kip ft | =

114

p

M Kip ft | =

0.024113

2.05

1.32

rb

Kip ft M

= =

2.0512

3.08

8

Clamp Kips

= =

44

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

23

Theres always a solution in steel

What are the rules to play by?

Is there any technical guidance?

What loads needs considered?

Stability Issues

Simple

Complex

Really Complex

Conveying the plan

Questions

Outline

Outline

45

Theres always a solution in steel

Free Standing Trusses

Complex

46

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

24

Theres always a solution in steel

What are the issues?

Complex

Stability at time of lift not a concern

Stability after letting off the hook is concern

Self weight stability (i.e. can I connect the ends and

let it off the hook)

Self weight plus wind stability (i.e. will a good wind

cause the truss to fail if it survived being let off the

hook)

Determining what magnitude of wind will be a

problem

Sizing of temporary bracing when required

Determining temporary splice forces if final truss

splices are welded and made in the air

47

Theres always a solution in steel

How do you evaluate these issues?

Complex

Hand Methods

Direct Analysis Methods

48

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

25

Theres always a solution in steel

Hand Methods

Complex

Get truss weight from fabricator including connections

when possible

Simple beam and M/d truss analysis to get truss top

chord maximum compression

Treat top chord like a column with K=1 and L=Length of

Truss

Consider L/1000 out of straightness on top chord to

determine a gravity moment in the top chord

Evaluate B

1

factor for moment magnification

Determine wind loads

Review unity checks

Splice forces based on above simple forces

Bracing based on Appendix 6

49

Theres always a solution in steel

Direct Analysis

Complex

Model truss with weight modifications or lump loads to

allow for additional weight associated with connections

(bare model weight vs. actual fabricator takeoff

weight)- reduced stiffness

Sweep top and bottom chords

Top and bottom chords continuous members

Webs pins or continuous, depends...

Determine wind loads

Review unity checks, L = Panel point length

Splice forces directly from analysis

Bracing (if required) modeled in analysis

50

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

26

Theres always a solution in steel

Direct Analysis

Complex

Chord Sweep for Simple Truss, L/1000 Out-of-Straight

and bottom chord in opposite direction as top chord

If need brace, determine required braced based on the

above sweep

After sizing brace, need to revise sweep to match new

potential buckling shape

51

Theres always a solution in steel

The Truss

Complex Case Study 1

Simple span roof truss

120-ft Long, 11-ft Centerline to Centerline of Chords

W12x65 top chord, W12x53 bottom chord, W12x45

webs, webs up (all members)

Top & Bottom Chord Splices Near Midspan

52

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

27

Theres always a solution in steel

Hand Analysis

Complex Case Study 1

Truss weight from fabricator (with connections) = 31,960

lbs.

Analytical model of bare member truss (members going

node to node) = 27,516 lbs.

Connection Factor = 31,960/27,516=1.16

Typically on order of 1.1 to 1.25 for bolted

Top chord force

2

truss

d

31960

266 plf

120

266120

M = 479,400 lb-ft

8

479,400

P = 43.6 Kips

111000

w =

=

=

=

53

Theres always a solution in steel

Hand Analysis

Complex Case Study 1

Top chord moment from dead load

12012

1.44 inches

1000 1000

M =43.6 1.44 62.8 Kip-inch

d

L

=

=

=

W12x65 Top Chord, Slenderness, Moment Magnification

A=19.1 in

2

I

x

= 533 in

4

r

x

= 5.28 in

( )

( )( )( )

( )

1

r

1

2

2

e1 2 2

1.0120' 12

272

5.28

P

1

=1.0 for transverse load (wind, conservative)

29,000 533 0.8

*

P = 58.9 Kips

1.012012

x

m

e

m

KL

r

C

B

P

C

EI

KL

o

t

t

= =

=

= =

54

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

28

Theres always a solution in steel

Hand Analysis

Complex Case Study 1

B1 @ L.F. of 1.0

1.0

1.0

3.84

1.0 43.6

1

58.9

B = =

B1 @ L.F. of 1.2

1.2

1.0

8.95

1.2 43.6

1

58.9

B = =

B1 becomes unstable @ L.F. of 1.35<1.4 so bracing of the

top chord would be recommend before letting off the hook

55

Theres always a solution in steel

Hand Analysis

Complex Case Study 1

Required bracing, Appendix 6, Nodal Brace, w/o Wind

( )

r

r

br

0.01 P 0.011.4 43.6 0.61Kips

8P 81.4 43.6

1 1

= = 0.904 Kips/inch

6012

0.75

rb

b

P

L

|

|

= = =

| | | |

=

| |

\ . \ .

Wind loads for 68 MPH wind approximately 13 plf on top

chord + 12 plf from web members for total carried by top

chord of 25 plf

Additional brace force from wind

10

25 1.6 60 3.0 Kips

8 1000

rb

P = =

56

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

29

Theres always a solution in steel

Hand Analysis

Complex Case Study 1

Based on this analysis one would most likely recommend

some temporary bracing at mid-span of top chord

Likely cabling or possibly placement of a roof framing

member (roof beam) that could brace it back to a stable

portion of the roof

Bottom chord could be evaluated for wind loads to

determine if similar bracing is warranted to help reduce

bottom chord wind moments or deflections

What if the chord had passed the stability check; but, failed

the combination of dead plus wind?

_68

_30

25 plf

4 plf

wind

wind

W

W

=

=

57

Theres always a solution in steel

Direct Analysis

Complex Case Study 1

Insert nodes at the splice points

Scale member weights or add distributed point loads in

order to match the truss weight from the fabricator

Boundary conditions should represent what you expect to be

in place and connected

Build model of truss with nominal geometry & reduced

stiffness in accordance with direct analysis rules

Sweep top and bottom chords in a half sine curve in

opposite directions to match an L/1000 out of straightness

tolerance, 3D analysis, not 2D truss anymore

58

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

30

Theres always a solution in steel

Direct Analysis

Complex Case Study 1

Non-linear, P-A, P-A Large Deformation

Top and Bottom chord continuous members

Web members?

59

Theres always a solution in steel

Direct Analysis

Complex Case Study 1

Pinned Web Members

Buckles at a load factor of about 1.25

60

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

31

Theres always a solution in steel

Direct Analysis

Complex Case Study 1

Fixed Web Members

Buckles at a load factor of about 5.5

61

Theres always a solution in steel

Direct Analysis

Complex Case Study 1

Pin Webs

Truss moments @ L.F. of 1.25

62

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

32

Theres always a solution in steel

Direct Analysis

Complex Case Study 1

Fixed Webs

Truss Moments @ L.F. = 1.4

Max web member moment of 2.2 Kip-ft

63

Theres always a solution in steel

Direct Analysis

Complex Case Study 1

Wind V = 68 MPH (0.75 x 90MPH)

Wind deflection = 9-inches (L/160), strong axis into wind

Unity Check, 1.4 D = 0.08

Unity Check, 1.2 D + 1.6 W = 0.25

64

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

33

Theres always a solution in steel

The Truss

Complex Case Study 2

Pedestrian Bridge

Box Truss

65

Theres always a solution in steel

The Pick

Complex Case Study 2

11,000 lbs

76.25-feet long connection to connection

12-feet tall chord to chord

W14x38 Top Chord, Strong Axis Vertical

66

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

34

Theres always a solution in steel

The Numbers

Complex Case Study 2

Top Chord Axial Force, P

d

= M

d

/12-ft = 8.72 kips

KL/r

y

= 590

P

n

= 8.07 kips

P

d

/P

n

= 1.08

1.4P

d

/0.9P

n

= 1.68

No consideration of strong axis moment from

vierendeel action

No consideration of weak axis moment from wind

67

Theres always a solution in steel

The Result

Complex Case Study 2

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

35

Theres always a solution in steel

Any questions?

Questions

69

Theres always a solution in steel

What are the rules to play by?

Is there any technical guidance?

What loads needs considered?

Stability Issues

Simple

Complex

Really Complex

Conveying the plan

Questions

Outline

Outline

70

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

36

Theres always a solution in steel

On the Hook Stability

Really Complex

71

Theres always a solution in steel

On the Hook Stability

Really Complex

72

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

37

Theres always a solution in steel

On the Hook Stability

Really Complex

226 long barrel trusses

73

Theres always a solution in steel

Occurs all the time with Joists

Really Complex

74

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

38

Theres always a solution in steel

Determination of lifting points and

rigging techniques by a qualified

person is critically important for

[long span joists]. The erector

must be aware of the possibility

that the joist could fold-up under

its own weight if not lifted and

handled properly.

SJI Technical Digest 9

Really Complex

75

Theres always a solution in steel

Modeling

Really Complex

Enter in typical geometry and

select trial support locations

76

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

39

Theres always a solution in steel

Modeling

Really Complex

Enter in typical geometry and

select trial support locations

Add restraints (supports) at top of

cables for vertical loads and a

lateral restraint at top center to

prevent longitudinal translation

77

Theres always a solution in steel

Modeling

Really Complex

Now we need an initial shape

deformation to run a direct analysis

with but what shape?

Typical L/1000 not really applicable

to this on the hook case

78

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

40

Theres always a solution in steel

Modeling

Really Complex

One possibility is to run an elastic

(eigenvalue) buckling analysis to

determine the shape

Add small (0.01k/in) springs at all

nodes for analytical stability while

not interfering with buckling shape

79

Theres always a solution in steel

Setting up Direct Analysis

Really Complex

Review Buckling Modes

80

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

41

Theres always a solution in steel

Setting up Direct Analysis

Really Complex

Review Buckling Modes

81

Theres always a solution in steel

Setting up Direct Analysis

Really Complex

Export Nodal Deflections from Chosen Mode

82

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

42

Theres always a solution in steel

Setting up Direct Analysis

Really Complex

Modify Model Geometry to Match Deflections

83

Theres always a solution in steel

Setting up Direct Analysis

Really Complex

Now you have a new model with

an initial imperfection

Reduce member stiffness per

Direct Analysis Method

Replace uniform springs with

single springs at inflection points

(0.1 k/in)

Run second order analysis

with large deflections

84

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

43

Theres always a solution in steel

Setting up Direct Analysis

Really Complex

Now you have a new model with

an initial imperfection

Reduce member stiffness per

Direct Analysis Method

Replace uniform springs with

single springs at inflection points

(0.1 k/in)

Run second order analysis

with large deflections

Track deflections vs.

applied loads to see

softening of structure

85

Theres always a solution in steel

Analysis Results

Really Complex

86

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

44

Theres always a solution in steel

Really Complex

87

Theres always a solution in steel

Analysis Results

Really Complex

88

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

45

Theres always a solution in steel

Re-Analyzing

Really Complex

Repeat the process of choosing

support points, determining

initial shape from buckling mode,

and running a second-order

direct analysis until results are

satisfactory (stability under self

weight is achieved)

Check strength of members

89

Theres always a solution in steel

Re-Analyzing

Really Complex

90

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

46

Theres always a solution in steel

Really Complex

91

Theres always a solution in steel

The Real World

Really Complex

92

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

47

Theres always a solution in steel

The Real World

Really Complex

93

Theres always a solution in steel

The Real World

Really Complex

94

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

48

Theres always a solution in steel

The Real World

Really Complex

95

Theres always a solution in steel

The Real World

Really Complex

96

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

49

Theres always a solution in steel

The Real World

Really Complex

97

Theres always a solution in steel

The Real World

Really Complex

98

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

50

Theres always a solution in steel

The Real World

Really Complex

99

Theres always a solution in steel

What are the rules to play by?

Is there any technical guidance?

What loads needs considered?

Stability Issues

Simple

Complex

Really Complex

Conveying the plan

Questions

Outline

Outline

100

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

51

Theres always a solution in steel

Discuss with the Erector BEFORE starting work what the

final deliverable will be.

o Steps/Hand Sketches

o More Developed Steps with 2-D Details

o Full 3D Color-Coded Staged Construction BIM Models

Erection Plans

The Plan

The engineered erection sequence is generally in addition to

and works in conjunction with the fabricators E-Sheets.

Coordinate connection requirements with the Fabricator

101

Theres always a solution in steel

Steps / Hand Sketches

The Plan

102

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

52

Theres always a solution in steel

Standard primarily 2-D drawings with Steps and Details

One Sheeters

The Plan

103

Theres always a solution in steel

One Sheeters

The Plan

104

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

53

Theres always a solution in steel

Reasonable amount of detail

Adequate for a majority of jobs

Allows for some reasonable amount of flexibility

One Sheeters

The Plan

105

Theres always a solution in steel

Full 3-D BIM-Based Presentation of Each Step

The Works

The Plan

106

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

54

Theres always a solution in steel

The Works

The Plan

107

Theres always a solution in steel

Provides explicit direction for each sequence useful for

tracking progress (for all parties involved) and visualizing

erection procedures

Very little flexibility in the field can cause some issues

Owner Friendly

The Works

The Plan

108

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

55

Theres always a solution in steel

The Works

The Plan

109

Theres always a solution in steel

Talk through possible erection sequences with the erector

they have done this for a long time!

Use their ideas and verify / modify based on analysis.

Have the superintendent / field personnel that will be on the

job involved as early as possible.

Be realistic things change in the field an open dialog is

necessary

Erection Plans

The Plan

110

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

56

Theres always a solution in steel

What are the rules to play by?

Is there any technical guidance?

What loads needs considered?

Stability Issues

Simple

Complex

Really Complex

Conveying the plan

Questions

Outline

Outline

111

Theres always a solution in steel

Thank you!

Questions

Any questions?

Clint O. Rex,

Ph.D. P.E.

Will Jacobs, V,

P.E., S.E.

112

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

57

Theres always a solution in steel

Within 1 business day

You will receive an email on how to report attendance

from: ceu@aisc.org.

Be on the lookout: Check your spam filter! Check your

junk folder!

Completely fill out online form. Dont forget to check

the boxes next to each attendees name!

OR

CEU/PDH Certificates

AISC

Theres always a solution in steel

Access available in 24 hours

Go to:

http://www.wynjade.com/aiscfall12/webinarCEU.

Username: Your Web ID (found on your registration

receipt)

Password: Your Last Name

Completely fill out online form. Dont forget to check

the boxes next to each attendees name!

Questions? Please email us at webinars@aisc.org.

CEU/PDH Certificates

AISC

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

58

Theres always a solution in steel

AISC Night School

AISC

New curriculum of courses starts

January 14, 2013.

Each course consists of eight 90-

minute sessions

First course:

Fundamentals of Connection Design

by Dr. Tom Murray, Virginia Tech.

www.aisc.org/nightschool

Theres always a solution in steel

Over 80 hours of presentations

available anytime, online.

CEUs/PDHs are available.

www.aisc.org/elearning

AISC eLearning

AISC

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

59

Theres always a solution in steel

Live Webinars 2013

February 7, 2013 : Practical Use

of the Direct Analysis Method

Presented by Louis F. Geschwindner, Ph.D.

www.aisc.org/webinars

AISC Live Webinars

AISC

Theres always a solution in steel

Spring 2013

The NEW 14

th

Edition Manual

Seminar

Listen to the Steel - Welding

Seismic Braced Frames

Effective Building Design - Seismic

www.aisc.org/seminars

AISC Seminars

AISC

118

AISC Live Webinar Erection Engineering:

The Science Behind the Art

December 13, 2012

Copyright 2012

American Institute of Steel Construction

60

Theres always a solution in steel

Please give us your feedback!

Survey at conclusion of webinar.

Thank You!

AISC

You might also like

- Building Control Submissions June 2015 FinalDocument8 pagesBuilding Control Submissions June 2015 FinalChris EvansNo ratings yet

- CDM 2015Document90 pagesCDM 2015Tariq Akhtar67% (3)

- CDM 2015 Clients Printer FriendlyDocument22 pagesCDM 2015 Clients Printer FriendlyChris EvansNo ratings yet

- The Advantages of Using Structural Steel in ConstructionDocument11 pagesThe Advantages of Using Structural Steel in ConstructionChris EvansNo ratings yet

- Construction SafetyDocument4 pagesConstruction SafetyRajesh ParekhNo ratings yet

- Pyramus and Thisbe EbookDocument38 pagesPyramus and Thisbe EbookChris EvansNo ratings yet

- IG Intels BrochureDocument88 pagesIG Intels BrochureChris EvansNo ratings yet

- Designed & Detailed - BS 8110 (1997)Document32 pagesDesigned & Detailed - BS 8110 (1997)Chris Evans100% (1)

- Lintel Brochure 1Document18 pagesLintel Brochure 1Chris EvansNo ratings yet

- Edcl - Divers Vs Rovs & AuvsDocument10 pagesEdcl - Divers Vs Rovs & AuvsChris EvansNo ratings yet

- Westok Software User Guide - V5aDocument28 pagesWestok Software User Guide - V5aChris EvansNo ratings yet

- Approximate Methods of AnalysisDocument59 pagesApproximate Methods of AnalysisChris EvansNo ratings yet

- Wind Loads and Anchor Bolt Design For Petrochemical FacilitiesDocument82 pagesWind Loads and Anchor Bolt Design For Petrochemical FacilitiessanggythaNo ratings yet

- Dorman Long 1906 Handbook PDFDocument283 pagesDorman Long 1906 Handbook PDFturtlerexNo ratings yet

- Part 2 (Section 2) - Wind LoadingDocument70 pagesPart 2 (Section 2) - Wind LoadingChris EvansNo ratings yet

- Guide To Extending Your HomeDocument52 pagesGuide To Extending Your HomeChris EvansNo ratings yet

- Concrete Centre Spreadsheet User GuidesDocument32 pagesConcrete Centre Spreadsheet User GuidesChris Evans86% (14)

- Hilti Profis Anchor 2 User Guide (US)Document293 pagesHilti Profis Anchor 2 User Guide (US)Chris EvansNo ratings yet

- ARC Reinforcement Handbook - 6th EdDocument78 pagesARC Reinforcement Handbook - 6th EdChris EvansNo ratings yet

- Design of Crane Steel BeamsDocument134 pagesDesign of Crane Steel Beamsshak54383% (6)

- Structures To Resist The Effects of Blast Loading Ufc - 3 - 340 - 02 - PDFDocument1,943 pagesStructures To Resist The Effects of Blast Loading Ufc - 3 - 340 - 02 - PDFChris EvansNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Performance Appraisal Form From IndustryDocument2 pagesPerformance Appraisal Form From IndustryJaspal SinghNo ratings yet

- Model A360 CatalogDocument12 pagesModel A360 CatalogThomas StempienNo ratings yet

- Pinza Prova 5601Document2 pagesPinza Prova 5601Sublimec San RafaelNo ratings yet

- AllProducts catalogGREENHECKDocument52 pagesAllProducts catalogGREENHECKGenes Macalintal GalleneroNo ratings yet

- Strategic Human Resource Development I SlidesDocument26 pagesStrategic Human Resource Development I SlidesAbhiman Behera50% (2)

- Atmos GIGA N 32-160Document1 pageAtmos GIGA N 32-160Efril dilen franciscoNo ratings yet

- Design of Coin Sorter Counter Based On MCU: Articles You May Be Interested inDocument5 pagesDesign of Coin Sorter Counter Based On MCU: Articles You May Be Interested inArchana BenkarNo ratings yet

- Convert Tank to Wash Service Hazards ReviewDocument74 pagesConvert Tank to Wash Service Hazards ReviewMatthew Adeyinka0% (1)

- Datasheet TachogeneratorDocument4 pagesDatasheet TachogeneratorNurulHidayatNo ratings yet

- Food Safety ChecklistDocument5 pagesFood Safety ChecklistDenver Palingit Rimas100% (3)

- Ee8602 Protection and SwitchgearDocument2 pagesEe8602 Protection and SwitchgeararwinNo ratings yet

- ACAS II Operations in The European RVSM EnvironmentDocument45 pagesACAS II Operations in The European RVSM Environmentali4957270No ratings yet

- High Surge Energy Non-Inductive Compact Size: U Series ResistorsDocument2 pagesHigh Surge Energy Non-Inductive Compact Size: U Series ResistorsYouness Ben TibariNo ratings yet

- Perencanaan Produksi Dan Kebutuhan Material: Modul 4Document48 pagesPerencanaan Produksi Dan Kebutuhan Material: Modul 4Ivanca Earltina Miranda SimanungkalitNo ratings yet

- Sixth Sense Technology: Submitted By: Sushma Singh EC (B) 0906831087Document23 pagesSixth Sense Technology: Submitted By: Sushma Singh EC (B) 0906831087Swechha KambojNo ratings yet

- Approved List of Manufacturers: Line Pipes (Carbon/Alloy Steel)Document4 pagesApproved List of Manufacturers: Line Pipes (Carbon/Alloy Steel)Sourav Kumar GuptaNo ratings yet

- Stresses, Loads, and Factors of Safety in Structural ElementsDocument6 pagesStresses, Loads, and Factors of Safety in Structural ElementsMark Louies Mago VillarosaNo ratings yet

- Notice: Applications, Hearings, Determinations, Etc.: Southern Star Central Gas Pipeline, Inc.Document2 pagesNotice: Applications, Hearings, Determinations, Etc.: Southern Star Central Gas Pipeline, Inc.Justia.comNo ratings yet

- Form-HSE-TMR-006 Compressor, Genzet, Water Jet InspectionDocument2 pagesForm-HSE-TMR-006 Compressor, Genzet, Water Jet Inspectionkenia infoNo ratings yet

- EXCEL Formula DictionaryDocument1 pageEXCEL Formula Dictionarysprk4uNo ratings yet

- 2019 Planning OverviewDocument7 pages2019 Planning Overviewapi-323922022No ratings yet

- Hydraulic Excavator GuideDocument9 pagesHydraulic Excavator Guidewritetojs100% (1)

- Sensor Performance Characteristics DefinitionsDocument12 pagesSensor Performance Characteristics DefinitionsKhairul FahzanNo ratings yet

- School Paper Management: Dennis M. VidarDocument36 pagesSchool Paper Management: Dennis M. VidarMary Ann AysonNo ratings yet

- GRT8100 Product Guide Imperial PDFDocument32 pagesGRT8100 Product Guide Imperial PDFSijumon sijuNo ratings yet

- Wa0040Document3 pagesWa0040cia sin kwangNo ratings yet

- Rigging View Modular Overland ConveyorDocument84 pagesRigging View Modular Overland Conveyorrtyuibnm100% (2)

- Barangay Profile: (BP DCF No. 1 S. 2022)Document4 pagesBarangay Profile: (BP DCF No. 1 S. 2022)AiMae BaobaoenNo ratings yet

- Design of Water Cooled Electric Motors Using CFD and Thermography TechniquesDocument6 pagesDesign of Water Cooled Electric Motors Using CFD and Thermography TechniquesNicolas JerezNo ratings yet

- GM THM 4L80E ATRA MANUAL Repair Rebuild Book Transmission Guide 4L80 E PDFDocument100 pagesGM THM 4L80E ATRA MANUAL Repair Rebuild Book Transmission Guide 4L80 E PDFDaniel GonzalezNo ratings yet