Professional Documents

Culture Documents

Costs Associated With Airline

Uploaded by

asbadgCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Costs Associated With Airline

Uploaded by

asbadgCopyright:

Available Formats

The effect of Aircraft Ageing on Maintenance and related

Operating Costs

12 September 2013

Copyright TBE International Limited 2013

Aircraft

Trading

and

Lease

Management

Support

Physical

Maintenance

Management

and

Commercial

Support

Business

Planning

and

Advisory

Services

Master Class

Training

Seminars

Start-up Planning

and implementation

Economic

Analysis

Business

Improvement

Aero-political

Advisory Services

Maintenance

Management

PBH Agreement

Negotiation

Lease Return

Lease Mgt

Asset Health

Check Services

Lease/Sale/Purch

ase Services

Asset Valuations

Structured

knowledge transfer

Project based

learning

lean/6-sigma

mentoring

Our Services

Our People

Airline Executives

Airline Senior Managers

Six Sigma Black Belts

Professional Engineers

Accountants

Licensed Engineers

Who are we?

TBE international Limited (TBE) is a boutique Hong Kong based consulting and contracting

company incorporated in February 2007, specialising in Aviation and Aviation associated management

and advisory services.

2

Copyright TBE International Limited 2013

1. Why is understanding aircraft ageing important?

2. Drivers of aircraft ageing

3. Ageing and Direct Maintenance Cost

4. Ageing and Maintenance Influenced Costs

5. Ageing and Indirect Maintenance Costs

1. Summary

Agenda

This presentation focuses on a complex topic and is intended as an

overview rather than a detailed description of the aircraft ageing topic

3

Copyright TBE International Limited 2013 4

Why understand the Ageing Effect?

Airlines

Understand future maintenance costs

Understand future hull requirements

Plan for inventory requirements

Plan fleet renewal programmes

MROs

Understand future labour requirements

Understand market demand

Facilities planning

Firstly.. because its interesting!

But understanding aircraft ageing has a more practical use

Aircraft ageing can be considered the single most important maintenance cost variable

Copyright TBE International Limited 2013

What is aircraft ageing and what are the drivers?

Service Bulletins/AD, eg:

- Strut mod

- T/R lock gear box

- NGS

5

Engine Shop Visits

- Performance Restoration

- Life Limited Parts replacement

External damage

- FOD

- Hail

- Impact damage

Component Maintenance

- Wear out failures

- Hard time removals

Line Maintenance

Base Maintenance

- Routine inspections

- Non Routine rectification

- Corrosion

- Fatigue

Maint Influenced Costs

Decreased reliability

- Delay costs

Increase fuel burn

- Weight increase

Maintenance ground time

- Hull costs

Direct Maintenance Costs

External Factors

Operating parameters

Geographical location

Labour efficiency

Outsource / in-house

Indirect Maint Costs

Spare holding costs

Engineering Support

Infra-structure

- Tooling

- Hangars

Copyright TBE International Limited 2013

We will focus on these costs and their

influence on other elements

Aircraft Ageing Driver Tree

Operating

Costs

Associated

With

Aircraft

Ageing

6

Non Routine

factor

Routine

Maintenance

Maintenance

Influenced

Costs

Indirect

Maintenance

Costs

Infra-structure

(Tooling etc)

Engineering

Spares

Delay / Reliability

induced Costs

Fuel burn

Aircraft Hull / Maintenance

Ground time

Direct

Maintenance

Costs

On Aircraft

Line Maint

A/C Base

Maint

Off Aircraft

Component

Engine

Modifications

BER/Scrap

Routine wear out

Performance

Restoration

LLP / Hardtime

removals

External

Factors

- Operating

parameters

- Geographical

location

- Labour

efficiency

- Outsource /

in-house

Copyright TBE International Limited 2013

OEM Ageing Curve

7

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

M

a

t

u

r

i

t

y

/

A

g

e

i

n

g

F

a

c

t

o

r

Airframe Age

Pre-MSG3 MSG3 Millenium

Most people have seen the typical OEM ageing curve

Can this be used equally for all the aircraft operating cost elements?

Source: Boeing

Copyright TBE International Limited 2013

Direct Maintenance Costs

8

To understand how Direct Maintenance Costs are affected by ageing, consider

some real world examples..

Copyright TBE International Limited 2013 9

On Aircraft Maintenance

For all On Aircraft Maintenance the major cost driver is labour

so to simplify this presentation we will only consider Labour but in any full analysis material

should also be modeled.

To conduct any meaning full analysis the data needs to be normalised, so we need to

introduce some concepts

Non Routine Maintenance:

To understand how the amount of Non Routine changes with aircraft age

Actual Routine Labour Hours of the event

Actual Non Routine Labour Hours of the event

For each event, Non Routine Maintenance Factor =

Copyright TBE International Limited 2013

First consider Non Routine Maintenance.. Its more interesting!

Consider an actual example for a fleet of B744 aircraft..

NR increases at ~ 4% per year

Easy right?

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

N

R

/

R

F

a

c

t

o

r

Aircraft Age

NR/R Factor

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

N

R

/

R

F

a

c

t

o

r

Aircraft Age

4A Check C Check D Check

A different picture if check type

is considered!

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

N

R

/

R

F

a

c

t

o

r

Aircraft Age

4A Check C Check D Check

A checks do not show any increased NR findings with age

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

N

R

/

R

F

a

c

t

o

r

Aircraft Age

4A Check C Check D Check

A checks do not show any increased NR findings with age

C checks show the typical

ageing bump

But 2 different rates of

Increase of NR findings

10

On Aircraft Maintenance Non Routine Maintenance

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

N

R

/

R

F

a

c

t

o

r

Aircraft Age

4A Check C Check D Check

A checks do not show any increased NR findings with age

C checks show the typical

ageing bump

But 2 different rates of

Increase of NR findings

The rate of NR findings increase at the same rate

for D checks and C checks (~4.2% - 5% / year)

Magnitude of NR for each 1 hour of R is different

between C and D checks (due access and level

of inspection)

Copyright TBE International Limited 2013

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

R

o

u

t

i

n

e

L

a

b

o

u

r

M

a

t

u

r

i

t

y

F

a

c

t

o

r

Aircraft Age

4A Check C Check D Check

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

R

o

u

t

i

n

e

L

a

b

o

u

r

M

a

t

u

r

i

t

y

F

a

c

t

o

r

Aircraft Age

4A Check C Check D Check

A checks do not show any increased routine findings with age

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

R

o

u

t

i

n

e

L

a

b

o

u

r

M

a

t

u

r

i

t

y

F

a

c

t

o

r

Aircraft Age

4A Check C Check D Check

C checks show the typical

ageing bump

A checks do not show any increased routine findings with age

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

R

o

u

t

i

n

e

L

a

b

o

u

r

M

a

t

u

r

i

t

y

F

a

c

t

o

r

Aircraft Age

4A Check C Check D Check

A checks do not show any increased routine findings with age

C checks show the typical

ageing bump

The rate of Routine increase is the same for D

checks and C checks (~1.5% / year) but from

a different base

11

On Aircraft Maintenance Routine Maintenance

Consider the same fleet of B744 aircraft..

Copyright TBE International Limited 2013 12

On Aircraft Maintenance Routine and Non Routine

Putting together the Routine and Non Routine elements..

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

2.2

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

R

+

N

R

L

a

b

o

u

r

A

g

e

i

n

g

/

M

a

t

u

r

i

t

y

F

a

c

t

o

r

Aircraft Age

4A Check C Check D Check

A checks do not show any ageing effect

C and D checks exhibit an ageing effect of

~4.5% per year after maturity

Maturity at

5-10 years

Copyright TBE International Limited 2013 13

Component Maintenance

Component maintenance can be looked at via 2 mechanisms:

1. The number of removals or MBTUR/hard-time limit of each component

2. The cost of repair of each component when removed

Follow the process

1. Consider the MBTUR of each rotable / repairable component fitted

2. Consider the Quantity per Aircraft (QPA) fitted

This will give the quantity of removals per year

3. Dissect removals into 1

st

, 2

nd

, 3

rd

etc removals

4. Apply a cost to each removal type

This will give the cost ageing curve for the aircraft

Copyright TBE International Limited 2013

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

0

20

40

60

80

100

120

140

160

180

200

0

5

0

,

0

0

0

1

0

0

,

0

0

0

1

5

0

,

0

0

0

2

0

0

,

0

0

0

2

5

0

,

0

0

0

3

0

0

,

0

0

0

3

5

0

,

0

0

0

4

0

0

,

0

0

0

4

5

0

,

0

0

0

5

0

0

,

0

0

0

5

5

0

,

0

0

0

6

0

0

,

0

0

0

6

5

0

,

0

0

0

7

0

0

,

0

0

0

7

5

0

,

0

0

0

8

0

0

,

0

0

0

8

5

0

,

0

0

0

9

0

0

,

0

0

0

9

5

0

,

0

0

0

1

,

0

0

0

,

0

0

0

C

u

m

u

l

a

t

i

o

v

e

Q

t

y

C

o

m

p

o

n

e

n

t

s

(

%

)

Q

t

y

C

o

m

p

o

n

e

n

t

s

(

F

r

e

q

u

e

n

c

y

)

MBTUR

Cum Components Qty Components

The aircraft has ~ 1,000 Rotable and

Repairable components fitted with a

CMM and CLP > $5000

Component Maintenance, cont

Consider an example of an A330

Operating at a utilisation of 4000 FH p.a, 8 FH/FC

14

A/C TSN after 25 years =

100,000 FH

Now apply the QPA to obtain the quantity of removals

Copyright TBE International Limited 2013 15

Component Maintenance, cont

This is only an arisings measure, now dissect the type of arisings

Mature

at 4-6 yrs

0

50

100

150

200

250

300

350

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

C

o

m

p

o

n

e

n

t

R

e

m

o

v

a

l

s

p

e

r

Y

e

a

r

Aircraft Age

Avg increase in removals of

~0.2% per year

= effectively flat

Warranty

Period

Copyright TBE International Limited 2013

0

50

100

150

200

250

300

350

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

C

o

m

p

o

n

e

n

t

R

e

m

o

v

a

l

s

p

e

r

Y

e

a

r

Aircraft Age

5+ Removal 4th Removal 3rd Removal 2nd Removal 1st Removal

16

Component Maintenance, cont

Look at the type of removals.

~150 of the annual removals

will be very low MBTUR

items eg: wheels, filters etc

Why is this important?

The 1

st

removal is a lower cost than subs removals, ie: repair cost increases with age

Proportion of 1

st

/ 2

nd

etc removals

decreases as the aircraft ages

Now apply the different cost per event

Copyright TBE International Limited 2013

0.6

0.7

0.8

0.9

1

1.1

1.2

1.3

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

C

o

m

p

o

n

e

n

t

A

g

e

i

n

g

/

M

a

t

u

r

i

t

y

F

a

c

t

o

r

Aircraft Age

Avg increase in costs after maturity

is ~0.4% - 0.5% per year

Warranty

Period

17

Component Maintenance, cont

Putting together the quantity of events and the relative cost per event a component cost

ageing curve can be developed

Copyright TBE International Limited 2013 18

Engine Maintenance

Analysing engine ageing can be difficult as internal component deterioration is only

financially relised once the engine as a system is unserviceable

This is further compounded by different on-wing and in-shop inspection limits

A component (eg: blade) which is serviceable on-wing can be unserviceable if exposed in

the shop

To observe the effect of ageing use a process similar to that used for component

maintenance

Split Activity engine SVs, module exposure and LLP replacement

Apply Price increase in scrap rates as individual components age

Copyright TBE International Limited 2013 19

Engine Maintenance, cont

Consider a fleet of CFM56-7 engines

Operating at a rating of 24,000lbs, 3.0 EFH/EFC and 8% T/O derate

0

1

2

3

4

5

6

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

U

S

D

,

M

i

l

l

i

o

n

s

Aircraft/Engine Age (Years)

Core Refurb LPT Refurb LLP Replacement

Avg TOW

10,500cyc

Avg TOW

9,500cyc

Avg TOW

8,000cyc

Core Engine

LLP Limit

Booster/LPT

LLP Limit

Pull fwd to

align with SV

Copyright TBE International Limited 2013 20

Engine Maintenance, cont

Consider a different view..

0

0.5

1

1.5

2

2.5

3

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

U

S

D

,

M

i

l

l

i

o

n

s

Aircraft/Engine Age (Years)

Core Refurb Booster/LPT Refurb LLP Replacement

Core Refurb costs increase

over time due to increased

scrap/repair costs

LLPs generally do not

exhibit ageing as cost is

driven by a regulatory limit

Booster/LPT refurb costs

would also exhibit

ageing effects if

projected out far enough

Copyright TBE International Limited 2013

0

0.2

0.4

0.6

0.8

1

1.2

1.4

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

A

g

e

i

n

g

/

M

a

t

u

r

i

t

y

F

a

c

t

o

r

(

U

S

D

/

E

F

C

)

Aircraft/Engine Age (Years)

Core Booster/LPT LLP Total

21

Engine Maintenance, cont

Looking at a cost per EFC

The steps represent the

ageing effect

Copyright TBE International Limited 2013 22

Modifications

We havent addressed modifications in any of the previous examples

Modifications can be classified in 2 categories:

1. Safety

ADs and mandatory SBs

Risk reduction modifications

Ageing aircraft modifications

2. Economic

Any non safety modification should have

some form of economic break even for the

airline

Not necessarily from maintenance cost

These increase with age

But can affect young aircraft

Aircraft type specific or global

The magnitude of modifications

will increase with age

These should pay back within

a specific time hurdle

The key is to have a structured and robust modification evaluation process

within the airline

Copyright TBE International Limited 2013

Maintenance Influenced Costs

23

To understand how Maintenance Influenced Costs are affected by ageing, consider

some real world examples..

Copyright TBE International Limited 2013 24

Generally, maintenance ground time is proportional to labour hours spent on the aircraft

So it follows that a similar curve to the airframe labour ageing curve also applies to

ground time

Effect of Ground time

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

2.2

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

R

+

N

R

L

a

b

o

u

r

A

g

e

i

n

g

/

M

a

t

u

r

i

t

y

F

a

c

t

o

r

Aircraft Age

4A Check C Check D Check

Potential

120%

increase in

TAT in the

first 6 years

Potential 30% increase in

TAT in 7 years after

maturity

Variability increases as age

increases effecting turn time

Copyright TBE International Limited 2013 25

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 1 3 5 7 9 11

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

September June July August

98% 98% 98% 98% 98% 98% 98% 98% 98% 98% 98% 98% 98% 98% 98% 98% 98%

GREEN = check yield <98%, ORANGE = check yield 98-99%, RED = check yield 100%

1 2 3 4 5 6 8 9 10 12 13 14 16

7 11 15 100%

99%

100%

99% 99% 100%

100%

99% 98% 98% 98% 99% 99% 100% 99% 100%

With an extension of 2 days in TAT (6 to 8 days => 33% increase)

1 2 3 5 7 9 11 13 15 17 19

4 6 8 10 12 14 16 18 20 95%

96% 96%

97% 96% 96% 96% 95% 98% 97% 97%

98% 98% 98% 98% 98% 97% 97% 97% 96%

This generally turns into 2 lines of maintenance

Effect of Ground time, cont

This only considers a single check type obviously this will be compounded for every

D check cycle due to the addtional turn time associated with a D check

Consider a maintenance planning scenario simplified for illustration:

A single line of maintenance, 6 day TAT, 18 month maint interval and 98% interval utilisation

Copyright TBE International Limited 2013 26

Ground Time can be viewed in economic terms as:

1.Revenue Potential of Aircraft, but only count it if this is real

The measure is actual revenue $

2. Hull Cost, this is always real if a hull can be saved/deferred

The measure is the ownership cost of hull (lease costs etc)

Effect of Ground time, cont

When considering ground time in an economic sense it is effectively the opportunity cost

of an aircraft

The opportunity cost relates to:

The revenue making potential of the aircraft if it were in service

The value of an extra hull

Consider the dry lease rates of:

B738/A320 = US$180K-300K per mth (US$2.2M-3.6M p.a.)

A330 = US$490K-790K per mth (US$5.9M-9.5M p.a.)

B773ER = US$1M-1.2M per mth (US$13-14M p.a.)

Copyright TBE International Limited 2013

Management Strategy or

there is no age related DR decrease?

27

Dispatch Reliability

There are some issues when looking at long term Dispatch Reliability trends

1. The airplane can fly multiple mission types throughout its life

2. Schedule constraints vary over time

3. Availability of spare hulls in network is an issue

4. Availability of spares to recover the aircraft

But, there is a general feeling that Dispatch Reliability decreases with aircraft age

But by how much, if at all?

Although, consider that many airlines operate older fleets quite successfully where

dispatch reliability is critical

Delta

UPS / Fedex

Dispatch Reliability can be significantly affected by External Factors

Copyright TBE International Limited 2013 28

Dispatch Reliability, cont

93%

94%

95%

96%

97%

98%

99%

100%

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

D

i

s

p

a

t

c

h

R

e

l

i

a

b

i

l

i

t

y

<

1

5

m

i

n

Aircraft Age

Avg Dispatch Reliability / Qtr

Consider a long haul fleet which has which has been operating a similar route structure

for its life.

Poor EIS experience,

resulting in an OEM

working group

Mature stable region

~ up to 2

nd

D check

Ageing region where

variability increases and DR

decreases ~0.1% per year

Recall that Line Maintenance labour didnt exhibit ageing but dispatch reliability seems to

decrease in this case it was due to unique failures on the line rather than volume of work

Copyright TBE International Limited 2013

In-Direct Maintenance Costs

29

In-direct Maintenance costs do have a link to Direct Maintenance costs changes and can

be considered Direct Maintenance Support Costs

Spare holding costs

- Inventory acquisition and mgt

- Warehousing

- Obsolescence

Engineering Support

- Repair schemes

- Maintenance system content / hosting

- SB/AD review

Infra-structure

- Hangar costs

- Tooling

DMC Ageing Link

Component Ageing

- MBTUR

- Repair TAT

Airframe Ageing

- Routine elements

- Non routine elements

Airframe Ageing

- Routine elements

- Non routine elements

Copyright TBE International Limited 2013

No visible labour impact, but

reliability is impacted (see reliability)

Linked to ground time, non routine

factors

Both Routine and Non Routine

exhibit ageing effects (see graph)

Event / MBTUR and subsequent

repair cost driven

Costs are event driven, large impact

of external factors

Increases due to weight, non-flush

repairs, panel warping

Generally proportional to labour

increase + unusual defects

Dispatch reliability decreases with

age, unique defects

Linked to ground time, non routine

factors

Linked to MBTUR, repair TAT and

non routine

Putting it all together.

Operating

Costs

Associated

With

Aircraft

Ageing

Spares

Infra-structure

(Tooling etc)

Engineering

Fuel

Delay / Reliability

induced Costs

Aircraft Hull / Maintenance

Ground time

Line Maintenance

Base Maintenance

Component Maintenance

Engine Maintenance

30

Maintenance

Influenced

Costs

Indirect

Maintenance

Costs

Direct

Maintenance

Costs

Copyright TBE International Limited 2013 31

Summary

If conducting an ageing analysis for fleet renewal purposes dont forget to

include the Maintenance Influenced Costs

These can have a significant effect (sometime more than Direct Maintenance)

This IS NOT an exact science, all aircraft age differently, there is no one rule,

consider

Aircraft type

Your operating parameters

Your geographical location

Labour efficiency

Insource/outsource

There are multiple ageing mechanisms and each are different

There are commercial management strategies to limit / manage

exposure of ageing

But that will be a topic for another day !

Copyright TBE International Limited 2013

32

TBECapability through people

Thank You!

Copyright TBE International Limited 2013 33

For further information please contact:

Tom Bemstein

TBE International Limited

Level 19, Two International Finance Centre.

8 Finance Street,

Central. Hong Kong.

Phone: +852 3101 7286

Fax: +852 3101 7287

Email: enquiries@tbeinternational.com

or

tbemstein@tbeinternational.com (direct)

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- FLVS - AP Microeconomics: Final Study Guide With AnswersDocument13 pagesFLVS - AP Microeconomics: Final Study Guide With AnswersDescripteur100% (7)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Dundon Rollinson Sample ChapterDocument40 pagesDundon Rollinson Sample ChapterrhodaNo ratings yet

- Andrew Webster (Auth.) - Introduction To The Sociology of Development-Macmillan Education UK (1990)Document237 pagesAndrew Webster (Auth.) - Introduction To The Sociology of Development-Macmillan Education UK (1990)Bevs Dela CruzNo ratings yet

- BP Planning&Scheduling CaterpillarDocument35 pagesBP Planning&Scheduling CaterpillarOfelia Umpire Ruiz100% (4)

- Airbus FMCDocument89 pagesAirbus FMCceparis100% (2)

- Airbus FMCDocument89 pagesAirbus FMCceparis100% (2)

- Darden Case Book 2016 17Document147 pagesDarden Case Book 2016 17kr1zhna71% (7)

- Bombardier Aerospace 20140716 Business Aircraft Market Forecast - 2014 33Document43 pagesBombardier Aerospace 20140716 Business Aircraft Market Forecast - 2014 33asbadgNo ratings yet

- Gulfstream G550 BrochureV3Document26 pagesGulfstream G550 BrochureV3RAC1100% (1)

- Standard Costing and Variance AnalysisDocument6 pagesStandard Costing and Variance AnalysisBarby Angel100% (3)

- CAPE Economics 2014 U1 P1Document12 pagesCAPE Economics 2014 U1 P1C H LNo ratings yet

- Caie Igcse Economics 0455 Theory v1Document16 pagesCaie Igcse Economics 0455 Theory v1Mehri MustafayevaNo ratings yet

- Manpower PlanningDocument18 pagesManpower Planningtamim947No ratings yet

- Gulfstream G550 Specifications SheetDocument4 pagesGulfstream G550 Specifications Sheetasbadg100% (1)

- FAQ Saudi Labor Law by AttyChavez PHL Embassy RiyadhDocument21 pagesFAQ Saudi Labor Law by AttyChavez PHL Embassy RiyadhjonathandacumosNo ratings yet

- As 5045Document2 pagesAs 5045asbadgNo ratings yet

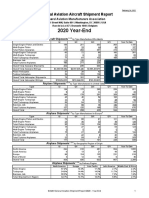

- 2014 Year End: General Aviation Aircraft Shipment ReportDocument7 pages2014 Year End: General Aviation Aircraft Shipment ReportasbadgNo ratings yet

- 2018 Year-End Report: General Aviation Aircraft Shipment ReportDocument7 pages2018 Year-End Report: General Aviation Aircraft Shipment ReportasbadgNo ratings yet

- GAMA 2017 General Aviation Shipment ReportDocument7 pagesGAMA 2017 General Aviation Shipment ReportasbadgNo ratings yet

- C 141 ADocument2 pagesC 141 AasbadgNo ratings yet

- GAMA 2016 General Aviation Aircraft Shipment ReportDocument7 pagesGAMA 2016 General Aviation Aircraft Shipment ReportasbadgNo ratings yet

- 2016 GAMA Databook - ForwebDocument60 pages2016 GAMA Databook - ForwebAnton100% (1)

- 2013 Year End: General Aviation Aircraft Shipment ReportDocument6 pages2013 Year End: General Aviation Aircraft Shipment ReportasbadgNo ratings yet

- 2015 Year End: General Aviation Aircraft Shipment ReportDocument7 pages2015 Year End: General Aviation Aircraft Shipment ReportasbadgNo ratings yet

- 2020 Year-End: General Aviation Aircraft Shipment ReportDocument7 pages2020 Year-End: General Aviation Aircraft Shipment ReportasbadgNo ratings yet

- Brochura Legacy 600Document17 pagesBrochura Legacy 600jtonetiNo ratings yet

- S102BDocument2 pagesS102BasbadgNo ratings yet

- 2017 Year End: General Aviation Aircraft Shipment ReportDocument7 pages2017 Year End: General Aviation Aircraft Shipment ReportasbadgNo ratings yet

- N 64215Document1 pageN 64215asbadgNo ratings yet

- S102SDocument2 pagesS102SasbadgNo ratings yet

- G550Performance ENG GS530EDocument8 pagesG550Performance ENG GS530Easbadg100% (1)

- C 5 ADocument2 pagesC 5 AasbadgNo ratings yet

- C 141 CDocument2 pagesC 141 CasbadgNo ratings yet

- E 864Document2 pagesE 864asbadgNo ratings yet

- C 141 FDocument2 pagesC 141 FasbadgNo ratings yet

- Ah 79100 CDocument2 pagesAh 79100 CasbadgNo ratings yet

- E 561Document2 pagesE 561asbadgNo ratings yet

- C 141 DDocument2 pagesC 141 DasbadgNo ratings yet

- Bacj 1Document2 pagesBacj 1asbadgNo ratings yet

- BacjDocument2 pagesBacjasbadgNo ratings yet

- Three Essays in MacroeconomicsDocument205 pagesThree Essays in MacroeconomicsGundeep ThethyNo ratings yet

- Class 3 4 5 6Document57 pagesClass 3 4 5 6GAURAV BHARDWAJNo ratings yet

- Test For WM Education-Aileen ArtiagaDocument2 pagesTest For WM Education-Aileen ArtiagaKade ArtiagaNo ratings yet

- Code of Conduct: Sourcing & Supply ChainDocument8 pagesCode of Conduct: Sourcing & Supply ChainPRAMODNo ratings yet

- Management Science BBA PabbiDocument70 pagesManagement Science BBA PabbiMuhammad Zeeshan KhanNo ratings yet

- Hotel Supervision IndividualDocument6 pagesHotel Supervision IndividualMohd YusufNo ratings yet

- William Clare RobertsDocument15 pagesWilliam Clare RobertsccssnniinnnnaaNo ratings yet

- The Future of Small FarmsDocument54 pagesThe Future of Small FarmsfischertNo ratings yet

- Department of Labor: CobbDocument41 pagesDepartment of Labor: CobbUSA_DepartmentOfLaborNo ratings yet

- Economics For Everyone: On-Line Glossary of Terms & ConceptsDocument43 pagesEconomics For Everyone: On-Line Glossary of Terms & Conceptsamira miroNo ratings yet

- Macroeconomics 7th Edition Hubbard Solutions Manual Full Chapter PDFDocument53 pagesMacroeconomics 7th Edition Hubbard Solutions Manual Full Chapter PDFhanhcharmainee29v100% (11)

- Large-Scale Migration and Remittance in Nepal: Issues, Challenges, and OpportunitiesDocument13 pagesLarge-Scale Migration and Remittance in Nepal: Issues, Challenges, and OpportunitiesChandan SapkotaNo ratings yet

- Coffee Bakery Project in KenitraDocument64 pagesCoffee Bakery Project in Kenitracristian123No ratings yet

- Location Strategies Factors and ModelsDocument6 pagesLocation Strategies Factors and ModelsNivedita ChoudharyNo ratings yet

- Taking The Basic Structure SeriouslyDocument7 pagesTaking The Basic Structure SeriouslyLorena FonsecaNo ratings yet

- Case Study - VET and National HRD in The Czech RepublicDocument3 pagesCase Study - VET and National HRD in The Czech Republicjugal adesaraNo ratings yet

- Social Insurance SyllabusDocument11 pagesSocial Insurance SyllabusrbugblatterNo ratings yet

- Malevich - Laziness As The Truth of Mankind 1921Document2 pagesMalevich - Laziness As The Truth of Mankind 1921lunaser100% (1)

- Feasibility Study, Financial and Economic Analysis of FeedmillDocument194 pagesFeasibility Study, Financial and Economic Analysis of Feedmillakuabata100% (3)

- Theory of Production and Cost: Chapter - 3Document50 pagesTheory of Production and Cost: Chapter - 3Arvind RamanujanNo ratings yet