Professional Documents

Culture Documents

Bobcat S130 Skidsteer

Uploaded by

Bruno PilieciCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bobcat S130 Skidsteer

Uploaded by

Bruno PilieciCopyright:

Available Formats

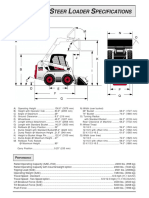

S130 SKID-STEER LOADER SPECIFICATIONS

DIMENSIONS

A) Operating Height .................................

B) Height with Operator Cab ..................

C) Angle of Departure ..............................

D) Ground Clearance ..............................

E) Wheelbase ..........................................

F) Length without Attachment .................

G) Length with Standard Bucket .............

H) Rollback @ Carry Position .................

I) Dump Height with Standard Bucket ....

J) Dump Reach @ Maximum Height .....

K) Height to Bucket Hinge Pin ................

L) Dump Angle @ Maximum Height .......

M) Rollback Fully Raised

@ Maximum Height ..........................

143.4" (3812 mm)

77.3" (1963 mm)

23

7.4" (188 mm)

35.5" (900 mm)

95.8" (2432 mm)

124.1" (3152 mm)

25

82.7" (2101 mm)

22.6" (575 mm)

109.5" (2781 mm)

40

96

Carry Position ........................................... 9.1" (231 mm)

N) Width (over bucket)

54" Bucket with offset rims ....... 54.0"

60" Bucket .................................. 60.0"

62" Bucket .................................. 62.0"

0) Turning Radius

with Standard Bucket ................ 68.7"

Rear Clearances ....................... 59.4"

P) Wheel Tread

10-16.5 ....................................... 48.1"

10-16.5 with offset rims ............ 42.5"

31.5x13-16.5 .............................. 48.5"

Q) Width (over tires)

10-16.5 ....................................... 58.7"

10-16.5 with offset rims ............ 53.8"

31.5x13-16.5 .............................. 59.4"

(1372 mm)

(1524 mm)

(1575 mm)

(1745 mm)

(1509 mm)

(1222 mm)

(1079 mm)

(1232 mm)

(1490 mm)

(1367 mm)

(1509 mm)

PERFORMANCE

Rated Operating Capacity (SAE J732) ...................................................................................... 1300 lbs. (590 kg)

Rated Operating Capacity with Counterweight option .............................................................. 1400 lbs. (635 kg)

Tipping Load (SAE) .................................................................................................................. 2634 lbs. (1195 kg)

Operating Weight (SAE) .......................................................................................................... 5235 lbs. (2375 kg)

Travel Speed ........................................................................................................................... 7.3 mph (11,8 km/hr)

Lift Breakout Force (SAE) ....................................................................................................... 2800 lbs. (1270 kg)

Tilt Breakout Force (SAE) ....................................................................................................... 3000 lbs. (1361 kg)

Push Force .............................................................................................................................. 3400 lbs. (1542 kg)

Bobcat S130 Skid-Steer Loader Specifications

March 11, 2008

ENGINE/ELECTRICAL

Make/Model .............................................. Kubota/V2403-MDI-E3

Fuel/Cooling .............................................. Diesel/Liquid

Horsepower (SAE Gross) ......................... 49 HP (36 kW)

Maximum Governed RPM ......................... 2700 RPM

Torque @ 1650 RPM (SAE Net) ............... 109.6 ft. lbs. (148,6 Nm)

Number of Cylinders ................................. 4

Displacement ............................................ 148.5 cu. in. (2,4 L)

Bore/Stroke ............................................... 3.43 in./4.03 in. (87 mm/102 mm)

Fuel Consumption ..................................... 1.8 gph (6,8L/h)

Estimated fuel consumption is based on testing by

Bobcat Company in high duty cycle digging applications.

Lubrication ................................................ Gear Pump Pressure System with Filter

Fuel Injection System ............................... Direct

Crankcase Ventilation ............................... Closed, breathing

Air Cleaner ................................................ Replaceable dry paper cartridge with separate safety element

Ignition ....................................................... Compression (Diesel)

Engine Coolant ......................................... Propylene glycol/water mix (53%-47%)

with freeze protection to -34F (-37C)

Starting Aid ............................................... Glow plugs

Alternator .................................................. 90 amps; ventilated

Battery ...................................................... 12 volt; 600 cold cranking amps @ 0F (-18C);

115 minute reserve capacity @ 25 amps

Starter ....................................................... 12 volt; gear reduction type; 4.02 HP (3,0 kW)

HYDRAULIC SYSTEM

Pump Type .............................................. Engine driven, gear type

Pump Capacity ....................................... 16.9 GPM (64 L/min) @ 3135 Pump RPM

System Relief @ Quick Couplers ........... 2650 - 2750 PSI (183 - 190 Bar)

Hydraulic Filter ....................................... Full flow replaceable, 3 micron synthetic media element

Hydraulic Cylinders ................................. Double-acting; tilt cylinders have cushioning feature on

dump & rollback

Control Valve ........................................... 3-Spool, open center type with spring detent on lift,

electric solenoid valves for auxiliary spool

Fluid Type ................................................ Bobcat Hydraulic/Hydrostatic Fluid (P/N 6563328)

Motor oil is not an acceptable alternative fluid.

Bore Diameter

Lift Cylinder (2) ................................. 2.00 in. (50,8 mm)

Tilt Cylinder (1) ................................. 3.50 in. (88,9 mm)

Rod Diameter

Lift Cylinder (2) ................................. 1.25 in. (31,8 mm)

Tilt Cylinder (1) ................................. 1.50 in. (38,1 mm)

Stroke

Lift Cylinder (2) ................................. 26.57 in. (674,9 mm)

Tilt Cylinder (1) ................................. 14.50 in. (368,3 mm)

Hydraulic Function Times

Raise Lift Arms ................................. 2.7 Seconds

Bucket Dump .......................... 2.2 Seconds

Lower Lift Arms ................................. 1.8 Seconds

Bucket Rollback ..................... 1.9 Seconds

Bobcat S130 Skid-Steer Loader Specifications

March 11, 2008

DRIVE SYSTEM

Main Drive ................. Fully hydrostatic, 4-wheel drive

Transmission ............ Infinitely variable tandem hydrostatic piston pumps, driving two fully reversing

hydrostatic motors

Final Drive Chains ..... Pre-stressed #80 HSOC endless roller chain (no master link)

and sprockets in sealed chaincase with oil lubrication. Chains do not require periodic

adjustments. Two chains per side with no idler sprocket

Axle Size .................. 2.0 in. (50,8 mm) heat treated

Wheel Bolts .............. (8) 9/16 in. wheel bolts fixed to axle hubs

CAPACITIES

Fuel Tank .................................... 13.3 gals. (50,4 L)

Cooling System without Heater ..... 9.8 qts. (9,18 L)

Engine Oil with Filter ........................ 9.5 qts. (9,0 L)

Hydraulic Reservoir ......................... 14 qts. (13,2 L)

Hydraulic/Hydrostatic System ......... 6 gals. (22,0 L)

Chaincase Reservoir ........................ 8 gals. (30,0 L)

CONTROLS

Vehicle Steering ....................

Loader Hydraulics

Lift & Tilt .........................

Front Auxiliary (Std.) ......

Rear Auxiliary (Opt.) ......

Auxiliary Pressure Release ..

Engine ...................................

Starting Aid ...........................

Service Brake ........................

Direction and speed controlled by two hand levers

Controlled by separate foot pedals or optional Advanced Control System (ACS)

Controlled by electrical switch on Right Hand steering lever

Controlled by electrical switch on Left Hand steering lever

Pressure is relieved through the coupler block, push in and hold for five seconds

Hand lever throttle; key-type starter switch and shutdown

Glow Plugs automatically activated by Standard or Deluxe Instrument Panel

Two independent hydrostatic systems controlled by two hand operated

steering levers

Secondary Brake .................. One of the hydrostatic transmissions

Parking Brake ....................... Mechanical disk, hand operated rocker switch on dash panel

SERVICEABILITY

Access is available to the following through the rear door/tailgate and rear screen

Air cleaner

Alternator

Battery

Cooling system (radiator and hydraulic oil cooler) for cleaning

Engine oil and fuel filters

Engine oil drain and dipstick

Starter

Axle hubs provide protection for the axle seals

Bobtach pivots have replaceable wear bushings

Easy access to all lift arm grease points

Rod end of the tilt cylinder has a replaceable bushing

Tailgate has an optional lock for vandal proofing

Tailgate is equipped with door stop to hold door open while servicing

Tip-up operator cab gives access to certain hydraulic system components

Bobcat S130 Skid-Steer Loader Specifications

March 11, 2008

INSTRUMENTATION

The following loader functions are monitored by a combination of gauges and warning lights in the operators

line of sight. The system shall alert the operator of monitored loader malfunctions by way of an audible alarm

and visual warning lights.

Standard Instrument Panel

Gauges

Engine Coolant Temperature

Fuel

Hourmeter

Indicators

Attachment Control Device

BICS Functions

Glow Plugs

Warning Lights

Advanced Control System (ACS)

Engine Air Filter

Engine Coolant Temperature

Engine Oil Pressure

General Warning

Hydraulic Filter

Hydraulic Oil Temperature

Hydrostatic Charge Pressure

Seat Belt

System Voltage

Deluxe Instrument Panel (Option)

Same gauges, warning lights and other features as Standard Instrument Panel plus:

Bar-type gauges ................................ Engine Oil Pressure, System Voltage, Hydrostatic Charge Pressure

and Hydraulic Oil Temperature

Additional features ............................ Keyless Start with password capability, Digital Clock, Job Clock,

Attachments Information, Digital Tachometer, Multi-Language Display,

Help Screens, Diagnostic Capability & Engine/Hydraulic Systems

Shutdown Function

ATTACHMENTS

Angle Broom*

Auger

Backhoe

Brush Saw

Brushcat Rotary Cutter

Buckets

Bucket Adapter

Chipper*

Combination Bucket

Concrete Mixer*

Digger

Dozer Blade

Dumping Hopper

Grapple, Farm/Utility

Grapple, Industrial

Grader*

Hydraulic Breaker

Landplane

Landscape Rake

Mower

Pallet Fork - Standard

Pallet Fork - Hydraulic

Planer

Rear Stabilizer

Scarifier

Seeder

Snow Blade

Snow V-Blade*

Snowblower*

Sod Layer

Soil Conditioner*

Spreader

Super Scraper

Sweeper

Three-Point Hitch

Tiller

See Bobcat Product Price List for specific attachment model availability.

*Requires Attachment Control Kit

Tilt-Tatch

Tracks, Steel

Trench Compactor

Trencher

Utility Forks

Utility Frame

Vibratory Roller

Water Kit

Whisker Broom

Bobcat S130 Skid-Steer Loader Specifications

March 11, 2008

FACTORY OPTIONS

Advanced Control System (ACS)

Selectable Joystick Control (SJC)

Back-up Alarm and Horn

Engine Block Heater

Hydraulic Bucket Positioning

DEALER ACCESSORIES

Attachment Control Kit

Back-up Alarm

Cab Accessory Harness

Cab Enclosure

Catalytic Exhaust Purifier

Fire Extinguisher Kit

FOPS Kit - Level II**

Four-point Lift Kit

Four-Way Flasher Light Kit

Horn

Hydraulic Bucket Positioning

Locking Fuel Cap

Power Bob-Tach

Radio

Rear Auxiliary Hydraulics

Ride Control

Rotating Beacon Light

Side Windows Kit

Single-point Lift Kit

Special Applications Kit

Strobe Light Kit

Tailgate Lock Kit

HEATED CAB PACKAGES

H71 Option Package

Cab Enclosure with Heat

Power Bobtach

Sound Reduction

Suspension Seat

Deluxe Instrumentation Panel

Cab Accessory Harness

Attachment Control Kit

H51 Option Package

Cab Enclosure with Heat

Power Bobtach

Suspension Seat

Cab Accessory Harness

H31 Option Package

Cab Enclosure with Heat

Suspension Seat

Cab Accessory Harness

OPEN CAB PACKAGES

O71 Option Package

Power Bobtach

Suspension Seat

Deluxe Instrumentation Panel

Cab Accessory Harness

Attachment Control Kit

O51 Option Package

Suspension Seat

Cab Accessory Harness

Deluxe Instrumentation Panel

O31 Option Package

Suspension Seat

Cab Accessory Harness

Bobcat S130 Skid-Steer Loader Specifications

March 11, 2008

SAFETY

Bobcat Interlock Control System

(BICS) (Std.) ....................................... Requires the operator to be seated in the loader with the

seat bar in place and the engine running. After the operator presses

the Press to Operate Loader button, the loaders hydraulic lift and tilt

functions and traction drive system can be operated.

Lift Arm Bypass Control (Std.) ........... Used to lower the lift arms in the event that the lift arms cannot be

lowered during normal operating conditions.

Seat Belt (Std.) ................................... Should always be worn when operating the loader.

Seat Bar (Std.) ................................... Secondary operator restraint, also serves as an arm rest.

Operator Cab (Std.) ............................ An enclosable operator cab with side screens with a minimal inside

cab width of 33" (838 mm) as standard equipment.

Meets SAE J1040 and ISO 3471 for Roll Over Protective Structure

(ROPS) and SAE J1043 and ISO 3449 Level I for Falling Object

Protective Structure (FOPS). Level II option is available.

Level I Acceptance is intended for protection from falling bricks, small concrete blocks and hand tools encountered

in operations such as highway maintenance, landscaping and other construction site services.

Level II Acceptance is intended for protection from falling trees or rocks for machines involved in site clearing,

overhead demolition or forestry.

Lift Arm Support (Std.) ................................ Use for servicing when lift arms are raised

Parking Brake (Std.) .................................... Always set brake when leaving loader

Grab Handles (Std.) .................................... Should always be used when entering/exiting loader

Safety Tread (Std.) ...................................... Slip resistant tread on lift arms and main frame to be used when

entering/exiting loader

Attachment Steps (Std.) .............................. Should always be used when entering/exiting loader

Rear Window (Std.) ..................................... For emergency exit

Front & Rear Working Lights (Std.) ............ Use for indoor and low light operation

Backup Alarm (Opt.) ................................... For use in jobs with low visibility

Lift Kits (Opt.) .............................................. Lift kits are available so loader may be lifted into remote areas

Special Applications Kit (Opt.) .................... Restricts objects and material from entering cab openings

Operators Handbook (Std.) ........................ Weather resistant operator handbook written in English will be

attached to inside of cab, providing operational instructions and

warnings by decals with pictorials and international symbols plus

some messages in four basic languages: English, French,

German and Spanish.

TRAINING RESOURCES

These optional videotapes and training courses are available through Bobcat Parts

Bobcat Skid-Steer Loader Operator Training Course

4-hour course provides video, classroom and hands-on training (also available in Spanish)

Bobcat Skid-Steer Loader Service Safety Training Course

2-hour course provides video, classroom and hands-on training

Bobcat Skid-Steer Loader Safety Video

Short and to-the-point video provides basic safety instructions for the Skid-Steer Loader

You might also like

- Incompressible Flow Turbomachines: Design, Selection, Applications, and TheoryFrom EverandIncompressible Flow Turbomachines: Design, Selection, Applications, and TheoryNo ratings yet

- S220 Skid-Steer Specs Dimensions Engine ControlsDocument3 pagesS220 Skid-Steer Specs Dimensions Engine ControlsCarlos100% (1)

- Valve GP Pump ControlDocument2 pagesValve GP Pump ControlglobalindosparepartsNo ratings yet

- SCZ Cheetah Manual Book 03363Document87 pagesSCZ Cheetah Manual Book 03363rob sullivan100% (1)

- Aeg Ewm 2500 2100Document60 pagesAeg Ewm 2500 2100Niknak68No ratings yet

- s220 Manual de ServDocument44 pagess220 Manual de ServMauro AntihualNo ratings yet

- Martillo Duraegon ManualDocument46 pagesMartillo Duraegon ManualJavier ChavezNo ratings yet

- A300/A300H All-Wheel Steer Loaders: DimensionsDocument10 pagesA300/A300H All-Wheel Steer Loaders: Dimensionsedwin quirozNo ratings yet

- Eaton: Medium Duty Piston PumpDocument20 pagesEaton: Medium Duty Piston PumpChristian StalinNo ratings yet

- Spare Parts Catalogue: Series 2000Document96 pagesSpare Parts Catalogue: Series 2000pascukintaNo ratings yet

- Skid-Steer Loader: Left Side Standard Instrument PanelDocument2 pagesSkid-Steer Loader: Left Side Standard Instrument PanelMario AguirreNo ratings yet

- Front Suspension Cylinder Purge and ChargeDocument14 pagesFront Suspension Cylinder Purge and ChargezhenyupanNo ratings yet

- Parts Catalogue YTO-500,554Document101 pagesParts Catalogue YTO-500,554Mathews Matos100% (1)

- 3RD CLUTCH - Wheel Loader Komatsu WA120-1 - TORQUE CONVERTER AND TRANSMISSION 777partsDocument2 pages3RD CLUTCH - Wheel Loader Komatsu WA120-1 - TORQUE CONVERTER AND TRANSMISSION 777partsashraf elsayedNo ratings yet

- CATALOG PROVISION CRANE (Type P 20-08) N Cargo Crane (Type 20-12) PDFDocument1 pageCATALOG PROVISION CRANE (Type P 20-08) N Cargo Crane (Type 20-12) PDFAdi MuhibNo ratings yet

- Service Manual: ForewordDocument1,324 pagesService Manual: ForewordredNo ratings yet

- Bobcat A 300Document2 pagesBobcat A 300wykarindaNo ratings yet

- Part - Kobelco SK07 N2Document3 pagesPart - Kobelco SK07 N2boy qsiNo ratings yet

- Nikon Total Station DTM-502 ManualDocument226 pagesNikon Total Station DTM-502 ManualAzzahraNo ratings yet

- Kubota GR2020G - GR2120 - GR2120AU Lawn and Garden Tractor Operators ManualDocument100 pagesKubota GR2020G - GR2120 - GR2120AU Lawn and Garden Tractor Operators ManualСвятослав ВороновNo ratings yet

- KATO NK-200H hydraulic crane chartDocument2 pagesKATO NK-200H hydraulic crane chartmeshahanNo ratings yet

- Vibrating roller for asphalt compactionDocument2 pagesVibrating roller for asphalt compactionphannaNo ratings yet

- Samyo MPR 714Document79 pagesSamyo MPR 714Anonymous D8ay3BMJ5No ratings yet

- 3640e Parts Manual PDFDocument196 pages3640e Parts Manual PDFسعيد عيسيNo ratings yet

- Part Book PC130F-7 PPC HoseDocument1 pagePart Book PC130F-7 PPC HoseChimanNo ratings yet

- F12 Spare Parts ListsDocument21 pagesF12 Spare Parts ListsWillian Ramon de Miranda CavalcanteNo ratings yet

- Eccentric Weight Housing Oil - Change: Operation and Maintenance ManualDocument3 pagesEccentric Weight Housing Oil - Change: Operation and Maintenance ManualLuis AugustoNo ratings yet

- SE220 英文产品单页Document2 pagesSE220 英文产品单页Karl KarlNo ratings yet

- Main Hydraulic Pump Air - PurgeDocument3 pagesMain Hydraulic Pump Air - Purgemekanicobucaro100% (1)

- Cat 307B Control JoystickDocument2 pagesCat 307B Control JoystickAtaa AssaadNo ratings yet

- TM 5 2410 233 34Document354 pagesTM 5 2410 233 34Abdalla gibril100% (1)

- Hydraulic Pump 120GDocument25 pagesHydraulic Pump 120GSteven Y.MNo ratings yet

- Low Idle RPM AdjustDocument4 pagesLow Idle RPM AdjustSteven ManuputtyNo ratings yet

- Caterpillar Hammer Failure Analysis GuideDocument69 pagesCaterpillar Hammer Failure Analysis GuideVP ErickNo ratings yet

- S590 Machine SpecsDocument6 pagesS590 Machine SpecsdilanNo ratings yet

- S510 S530 S550 S570 S590 T590 - enDocument12 pagesS510 S530 S550 S570 S590 T590 - enPepe AlfredNo ratings yet

- Service Manual: S/N 232511001 & Above S/N 232411001 & Above (D Series)Document798 pagesService Manual: S/N 232511001 & Above S/N 232411001 & Above (D Series)Mariaha100% (1)

- BOBCAT S250 - S300 6901926 SM Preview PDFDocument51 pagesBOBCAT S250 - S300 6901926 SM Preview PDFCristhian MejiaNo ratings yet

- Great Plains Parts Manual NTA-907 & NTA-3007Document170 pagesGreat Plains Parts Manual NTA-907 & NTA-3007a04205No ratings yet

- 02 Sistema de CR New Holland PDFDocument23 pages02 Sistema de CR New Holland PDFpitufo_75No ratings yet

- 939C ServicioDocument48 pages939C ServicioSotavento Construcciones Renta de MaquinariaNo ratings yet

- Eaton: Medium Duty Piston PumpDocument20 pagesEaton: Medium Duty Piston PumpjuampacervantesNo ratings yet

- Operation 31200354 09-19-11 ANSI EnglishDocument150 pagesOperation 31200354 09-19-11 ANSI EnglishWilliam RoarkNo ratings yet

- All-Track Service: AT-80HD Operator ManualDocument28 pagesAll-Track Service: AT-80HD Operator ManualDavid OrtegaNo ratings yet

- Hydraulic Control Valve (W-BICS Valve) - (S-N 5122 20298 & Abv, 5124 40721 & Abv, 5126 12258 & Ab - 763 PDFDocument5 pagesHydraulic Control Valve (W-BICS Valve) - (S-N 5122 20298 & Abv, 5124 40721 & Abv, 5126 12258 & Ab - 763 PDFRomusNo ratings yet

- EGS1200-6 Diesel Generator Set Performance and SpecificationsDocument8 pagesEGS1200-6 Diesel Generator Set Performance and Specificationspurnomno sidiNo ratings yet

- (SM Eng) PC340 LC (NLC) - 6K (EEAM008007)Document323 pages(SM Eng) PC340 LC (NLC) - 6K (EEAM008007)НиколайNo ratings yet

- Service Manual Series F12: Effective: April, 2011 Supersedes: March, 2011Document32 pagesService Manual Series F12: Effective: April, 2011 Supersedes: March, 2011Eduardo Alvarez HuizaNo ratings yet

- Kde5000ta PDFDocument36 pagesKde5000ta PDFJoaquim MoraisNo ratings yet

- 14H Motor Grader ASE00001-) - Document StructureDocument3 pages14H Motor Grader ASE00001-) - Document StructureAHMED2ALINo ratings yet

- JCB Hand Held Hydraulic Equipment: Service ManualDocument51 pagesJCB Hand Held Hydraulic Equipment: Service ManualEng-Mohammed SalemNo ratings yet

- Generator Power Application Guide: Blue Star 145/185 Bobcat 225Document16 pagesGenerator Power Application Guide: Blue Star 145/185 Bobcat 225Younus BakshiNo ratings yet

- HM 350-4Document12 pagesHM 350-4Mohan CharanchathNo ratings yet

- Hydraulic Hammer Sandvik BR 211 STD: Parts Manual PMBR211SENG.607Document16 pagesHydraulic Hammer Sandvik BR 211 STD: Parts Manual PMBR211SENG.607SMM ENTREPRISENo ratings yet

- 314Document65 pages314dim4erema100% (2)

- SM Pw170es-6k-962Document625 pagesSM Pw170es-6k-962Эрнест Бекиров100% (1)

- Demo Dynapac Ca222Document30 pagesDemo Dynapac Ca222Sri hartatiNo ratings yet

- SATCO Wiring Nov2010Document32 pagesSATCO Wiring Nov2010marceloNo ratings yet

- Bobcat S250Document6 pagesBobcat S250svcingNo ratings yet

- Buldozer - CASE 550H - Specs 1-18-2012 - ENDocument4 pagesBuldozer - CASE 550H - Specs 1-18-2012 - ENMaurizio De LucaNo ratings yet

- Greenfield Tap Drill Recommendations PDFDocument1 pageGreenfield Tap Drill Recommendations PDFSan Ban CastroNo ratings yet

- Strecher - Shrinker 8836249Document2 pagesStrecher - Shrinker 8836249Bruno PilieciNo ratings yet

- Air Drill 8843914 PDFDocument14 pagesAir Drill 8843914 PDFBruno PilieciNo ratings yet

- Thermal Imager: User ManualDocument14 pagesThermal Imager: User ManualBruno PilieciNo ratings yet

- 760mm/30 3-IN-1 MACHINE: User ManualDocument12 pages760mm/30 3-IN-1 MACHINE: User ManualBruno PilieciNo ratings yet

- 13 Fractional Tap and Drill Bit GuideDocument4 pages13 Fractional Tap and Drill Bit Guidewhitelizard2001No ratings yet

- Lightweight Reciprocating Air Saw User ManualDocument18 pagesLightweight Reciprocating Air Saw User ManualBruno PilieciNo ratings yet

- 760mm/30 3-IN-1 MACHINE: User ManualDocument12 pages760mm/30 3-IN-1 MACHINE: User ManualBruno PilieciNo ratings yet

- Metal Shear 8096000 PDFDocument7 pagesMetal Shear 8096000 PDFBruno PilieciNo ratings yet

- Project Cost Tracking ReportDocument1 pageProject Cost Tracking Reportbl4ck_revo08No ratings yet

- ChartsDocument1 pageChartsravikumarmgowdaNo ratings yet

- 2011 Mad PogDocument81 pages2011 Mad PogBruno Pilieci100% (1)

- 1996 KountryAire5thDocument18 pages1996 KountryAire5thBruno PilieciNo ratings yet

- 1999KSCAOGDocument113 pages1999KSCAOGBruno PilieciNo ratings yet

- Excel Gantt Chart TemplateDocument15 pagesExcel Gantt Chart TemplateBruno PilieciNo ratings yet

- Project Scheduling and Monitoring ToolDocument13 pagesProject Scheduling and Monitoring ToolBruno PilieciNo ratings yet

- Procurement Plan GoodsDocument3 pagesProcurement Plan GoodsLeizza Ni Gui DulaNo ratings yet

- PMX30 SM 805170r2 PDFDocument88 pagesPMX30 SM 805170r2 PDFBruno PilieciNo ratings yet

- Csi Masterformat 1995 Edition PDFDocument2 pagesCsi Masterformat 1995 Edition PDFrobelineNo ratings yet

- 064 439 448 561 638 985 5841 ManualDocument27 pages064 439 448 561 638 985 5841 ManualBruno PilieciNo ratings yet

- ENH202 User Manual PDFDocument88 pagesENH202 User Manual PDFEric LevinNo ratings yet

- Training Guide Excel Basics AcctReconDocument87 pagesTraining Guide Excel Basics AcctReconrijderunner100% (1)

- PowerPlasma 50Document25 pagesPowerPlasma 50Bruno PilieciNo ratings yet

- 9n PDFDocument66 pages9n PDFBruno PilieciNo ratings yet

- PowerPlasma 50S 2013Document2 pagesPowerPlasma 50S 2013Bruno PilieciNo ratings yet

- PCM 875 - F 15 335 eDocument48 pagesPCM 875 - F 15 335 eBruno PilieciNo ratings yet

- Craftsman 917257720Document60 pagesCraftsman 917257720Bruno PilieciNo ratings yet

- Princess Auto Full Catalogue 277Document300 pagesPrincess Auto Full Catalogue 277Bruno PilieciNo ratings yet

- 6500 Watt GeneratorDocument44 pages6500 Watt GeneratorBruno PilieciNo ratings yet

- DCT Dual Clutch TransmissionDocument16 pagesDCT Dual Clutch TransmissionSudharshan SrinathNo ratings yet

- Acids and Bases NotesDocument17 pagesAcids and Bases NotesNap DoNo ratings yet

- Basic C MCQ - FinalDocument51 pagesBasic C MCQ - FinalDhivya DharshniNo ratings yet

- CHEM F111: General Chemistry II-Semester Lecture 35 (12-04-2019Document20 pagesCHEM F111: General Chemistry II-Semester Lecture 35 (12-04-2019Rachit ShahNo ratings yet

- Mste 3.0 Plane Geometry Hand OutsDocument8 pagesMste 3.0 Plane Geometry Hand OutsJasmine MartinezNo ratings yet

- Innovative High Throw Copper Electrolytic ProcessDocument6 pagesInnovative High Throw Copper Electrolytic Processyonathan fausaNo ratings yet

- Math10 Week3Day4 Polynomial-EqnsDocument44 pagesMath10 Week3Day4 Polynomial-EqnsMark Cañete PunongbayanNo ratings yet

- Treatment of Electroplating Wastewater Containing Cu2+, ZN 2+ and CR (VI) by ElectrocoagulationDocument8 pagesTreatment of Electroplating Wastewater Containing Cu2+, ZN 2+ and CR (VI) by ElectrocoagulationAnonymous ZAr1RKNo ratings yet

- p-4500 Technical InformationDocument13 pagesp-4500 Technical InformationElhoiNo ratings yet

- Inductive TransducersDocument12 pagesInductive TransducersMUKESH SUNDARARAJANNo ratings yet

- Cork Properties Capabilities and ApplicationsDocument22 pagesCork Properties Capabilities and ApplicationsVijay AnandNo ratings yet

- UNIT3 - Introduction To IC Technology - 290617 - EditedDocument82 pagesUNIT3 - Introduction To IC Technology - 290617 - EditedKISHAN SHUKLANo ratings yet

- Fault Report - Inventory Cpf1 Vs Caño LimomDocument37 pagesFault Report - Inventory Cpf1 Vs Caño LimomJessica RiveraNo ratings yet

- Alcohols, Phenols and Ethers Worksheet Answer Grade 12Document6 pagesAlcohols, Phenols and Ethers Worksheet Answer Grade 12sethu100% (1)

- Ajmera - Treon - FF - R4 - 13-11-17 FinalDocument45 pagesAjmera - Treon - FF - R4 - 13-11-17 FinalNikita KadamNo ratings yet

- Z 80 HelptopicsDocument5 pagesZ 80 HelptopicsEverly NNo ratings yet

- Manuscript 123Document46 pagesManuscript 123Datuzuharto Sultan100% (1)

- Job 1 SksoDocument5 pagesJob 1 SksoFajAr OkTaNo ratings yet

- 1-Newton Second Law-ForMATDocument5 pages1-Newton Second Law-ForMATVAIBHAV KUMARNo ratings yet

- BIOLOGY Paper 1 Marking Scheme Asumbi Girls Final Prediction 2022Document4 pagesBIOLOGY Paper 1 Marking Scheme Asumbi Girls Final Prediction 2022balozi training InstituteNo ratings yet

- Conceptual Data Modeling and Database Design Volume 1 - The Shortest Advisable Path A Fully Algorithmic ApproachDocument662 pagesConceptual Data Modeling and Database Design Volume 1 - The Shortest Advisable Path A Fully Algorithmic ApproachErkan50% (2)

- Malpresentation and MalpositionDocument33 pagesMalpresentation and MalpositionPeprah Ondiba100% (1)

- Booklet Momentum BWFDocument22 pagesBooklet Momentum BWFReem AshrafNo ratings yet

- Matrix Structural Analysis of BeamsDocument28 pagesMatrix Structural Analysis of BeamsKristine May Maturan0% (1)

- Requirements Elicitation and AnalysisDocument74 pagesRequirements Elicitation and AnalysisSadam GebiNo ratings yet

- Cisco Certified Network Associate - CCNA (200-301) : Building Blocks of NetworkingDocument5 pagesCisco Certified Network Associate - CCNA (200-301) : Building Blocks of NetworkingShahnawaz SiddiqueNo ratings yet

- Modular Forms Exam - Homework RewriteDocument2 pagesModular Forms Exam - Homework RewritejhqwhgadsNo ratings yet

- Chemical Equilibrium ExplainedDocument42 pagesChemical Equilibrium ExplainedDedi WahyudinNo ratings yet

- The World of Chemistry Video Guide SetDocument10 pagesThe World of Chemistry Video Guide SetrkvNo ratings yet

- UNIT-1 Introduction To Emi: A Arunkumar GudivadaDocument47 pagesUNIT-1 Introduction To Emi: A Arunkumar GudivadaBhagya bhagiNo ratings yet