Professional Documents

Culture Documents

Rnaiplinternship 140307120357 Phpapp02

Uploaded by

vijay_sudhaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rnaiplinternship 140307120357 Phpapp02

Uploaded by

vijay_sudhaCopyright:

Available Formats

PRESENTATION

ON

AUTOBILE MANUFACTRING

(IMPLANT TRAINING)

INTERNSHIP

AT

RENAULT NISSAN AUTOMOTIVE INDIA

PRIVATE LIMITED (RNAIPL)

PRESENTED BY

AVINISH KUMAR JAIN

06-02-2014

Avinish kumar Jain

Objectives of Internship

General objective

As partial fulfillment of the requirements of the B.Tech. program at XXX

University

Specific Objectives

To get exposed to functions, structures and operational activities of the organization.

To learn about various manufacturing & managerial concepts, tools and techniques

that are theoretically and applied in an industry.

To learn the manufacturing and assembly process of an automobile.

To experience the working process of an industry.

To contribute my effort to industry.

About RNAIPL

The first dedicated Alliance facility in which Nissans and Renaults are made side-by-side is a modern and

highly efficient plant producing top quality cars. But theres more. Its now officially one of Indias safest and

most environmentally-friendly factories, too. Thats according to the Confederation of Indian Industry (CII),

which has given the plant its top award for excellence in Environmental Health and Safety.

In February 2008, the Renault-Nissan Alliance signed a MOU with Government of Tamil Nadu to set up a

manufacturing plant at Oragadam, near Chennai with a minimum investment of Rs. 4500 Crore over a period

of 7 years. On March 17, 2010, the Renault-Nissan alliance plant was inaugurated in a record time of 21

months since its groundbreaking ceremony in June 2008.

RNAIPL thus achieved the unique milestone of starting operations in record time of 21 months from the date

of signing of MOU. The Plant has an initial capacity of 2, 00,000 units per year and planned to reach

4, 00,000 units per year in full capacity. Nissans first locally manufactured global compact hatchback The

Nissan Micra is manufactured at the plant and commercial production for the same began in May 2010.It

represents 1500 employs.

Vision Enriching Peoples Lives

Mission It provide unique and innovative automotive product

and services that deliver superior measurable values to all stack

holders.

Products manufactured at

RNAIPL

Renault

Renault Fluence (Launched 2011)

Renault Koleos (Launched 2011)

Renault Pulse (Launched 2012)

Renault Duster (Launched July-2012)

Renault Scala (Launched 2012)

Cont.

Nissan

Nissan X-Trail (Launched 2005)

Nissan Teana (Launched 2007)

Nissan 370Z (Launched 2010)

Nissan Micra (Launched 2010)

Nissan Sunny (Launched 2011)

Basic Ideology in Manufacturing

Preference-1 Safety

Preference-2

Quality

Preference-3

Cost

Hydraulics

All the shops of RNAIPL are automated. In each shop hydraulic and pneumatic machines

are installed. Most of the manufacturing work are done by robots. So for operating, and

maintaining these machines and robots with accuracy, good knowledge of hydraulic,

pneumatics and robotics is necessary.

Principle (Pascal Law)

Pressure applied to a confined fluid at any point is transmitted undiminished and

equally throughout the fluid in all directions and acts upon every part of the

confining vessel at right angles to its interior surfaces.

Cont. Pumps

A pump is a mechanical device that moves fluids (liquids and gases) or

sometimes slurries, by mechanical action.

Pumps

Positive Displacement Pump

Centrifugal

Non Positive Displacement Pump

Axial

Internal

Gear Pump External

Vane

Piston

Radial

Axial Piston

Control Valves

A mechanical device that is used to control the flow of a fluid.

Valves

Direction Control

Valve (DCV)

Flow Control

Valve (FCV)

Pressure Control

Valve (PCV)

Mechanical Utility System

There are five components of mechanical utility system.

1. Compressors

2. Driers

3. Heat Exchangers

4. Pumps

5. Cooling Towers

Compressed air and drier flow process chart

Schematic diagram for compressors

Schematic Diagram of plate heat exchanger

BMS (Building Management system)

In BMS all the mechanical utilities are controlled and monitored. All the information about utilities

(driers, compressors etc.) like operating status, present conditions (pressure, temperature, and flow rate)

is transmitted through sensors to BMS. In BMS five displays are using that display the operating status

of the all utilities. One main display is used for main control. All the utilities can be controlled from the

BMS. For safety automatic alarm system is there. If any problem occurs in any utility system then

alarm rings and displays show the place where problem occurs. It also display that what is the problem.

Alarm rings in all the areas. It is very fast and time saving system because where is the problem, it is

already known so only specific person go there and solve the problem so checking of all utilities is not

required.

In design of plant every system is designed according to specific industrial standards.

In firefighting system the circular distance between each fire extinguisher should be 30 meters. But here

at every 15 meters fire extinguisher is placed for more safety. For every danger and safety sign photo

luminescent material is used.

PROCESS TEAM

INPUT

PROJECT

ENGINEERING TEAM

VALIDATE & CHECK

DESIGN OF SYSTEMS

VALIDATE & CHECK &

PREPARE BOQ

PURCHASE TEAM

TENDER FLOATING TO

CONTRACTORS

TECHNICAL

ALIGNMENT MEETING

NO

YES

YES

YES

NO

TECHNICAL

ALIGNMENT MEETING

FINAL BOQ

(Technically aligned

BOQ)

RNPO

TENDER FLOATING

RESEND QUOTATION

NEGOTIATION BY

RNPO

SUPPLIER FINALISATION

PROJECT STRUCTURE (PHASE I)

KICK OF

MEETING

START OF

PROJECT

DRAWING APPROVAL

DESIGN APPROVAL

PROGRESS REVIEW MEET

SCHEDULE MONITORING

SCHEDULE

MODE OF WORKING

WORK METHOD

RULES &

REGULATIONS

PROJECT

COMPLETION

QC

&

PREPARING

SNAG LIST

SAFETY AUDIT

(PRIMARY &

SECONDARY)

PREPARE

REPORT

CLOSING OF

SNAG LIST

HAND OVER TO

MAINTANENCE

PROJECT STRUCTURE PHASE-2

Vehicle Chain

Stamping Shop Body Shop

Paint Shop

Trim and

Chassis shop

Stamping Shop

In stamping shop body parts of car are manufactured using steel

plate.

1. Blanking

2. Pressing and Piercing

3. Quality checking

Blanking Process

1. Coil-Car: Coil of steel plate is pick up by crane and transferred to coil-car that transfer the coil to

uncoiler.

2. Uncoiler and advance correction machine: It sets the inner diameter of coil to the center of the line

by holding device that remove rolling habit of the tip of the coil.

3. Washing: The device that removes the foreign material that has adhered to the coil.

4. Leveler: Device that corrects the shape of the steel plate and makes it smooth. It consist a

combination of rollers that level the plate.

5. Looping: In this process steel plate is stretched into the pit and all the bends are removed..

6. Feeder: Device that adjusts the coil material to press cycle and set the cutting length and sends it to

piler.

7. Press: It press the steel plate and cut the steel. Press can be rotated at required angle to cut the steel

plate at any angle.

8. Piler: The device that piles the cut material with accuracy. From here cut material are transferred to

pressing line. There are Two Piler zone here.

Pressing and piercing Line

Here are three pressing lines.

Pressing Lines

Line-3 (5400 ton)

L-Line (2400 ton)

XL-Line (5400 ton) For pressing of larger parts

For pressing of larger parts

For pressing of small parts

Pressing and piercing Line

Cont.

Each line have 4 presses.

PB: By this press shape is given to steel plate by using specific die

according to drawing.

PC: By this press side or extra material is removed.

PD: By this press Piercing is done.

PE: By this press specific holes is made.

XL LINE AND LINE-3

PB

PC

PD

PE

2400 ton

1000 ton

1000 ton

1000 ton

L-LINE

PB 1200 ton

PC 400 ton

PD 400 ton

PE 400 ton

Stamping Shop

In stamping shop body parts of car are manufactured using steel

plate.

1. Blanking

2. Pressing and Piercing

3. Quality checking

After the pressing quality inspection is manually done. If there is no fault then

part is transferred to body shop.

Stamped parts are transferred using fork lifter from stamping shop to body shop. Here various stamped

parts are welded to make various components of main body like doors, engine compartments and

mounting points, chassis, hood, front cabin, rare cabin etc.

Body Shop

Spot welding and MAG welding is done for making the components.

Manually some parts are welded and by robot some other parts are welded.

Almost all the doors are made by robots like ABB, FANUC using various

mechanical operations (bending, compression) at the edges of parts.

There are two main lines and six sub lines (three each). Both are same lines. At

present time at Line -1 Sunny and Duster are being manufactured and at Line-2

Micra is being manufactured. Production rate of the body shop is 40JPH (jobs per

hour).

Welding cars doors at body shop by robots

Cont.

Welding cars roof at body shop by robots

Cont.

In the first sub line the engine compartment, the front cabin and the rear cabin are

assembled using spot welding manually.

In the second sub line nearby parts of engine, doors, hoods are assembled using

welding and nuts.

In main assembly line side doors, back doors, hood is assembled using automatic

nut runner machine. Finally quality checking is done of car body.

Each car is given with the serial number which corresponds to the paint colour.

The car body is sent to the metal line, where bumps or the dent or spots are

inspected. If any defect is found the body is sent to the sideways where it is tested

for the faults and solutions.

Finally car body is transferred to paint shop.

Paint shop

In paint shop there are two lines i.e. Line: 1 and Line: 2. both lines are

same.

Car body comes here from body shop.

At Line: 1 bodies of sunny and duster are painted and at line: 2 Micra

body is painted.

In paint shop car body passes through following lines:

1. Pre-treatment line (PT-line)

2. Electro Deposit Line (ED-Line)

3. ED-Oven

4. Sealer Zone

5. ED sanding zone

6. Body arranging zone

7. Dust off zone

8. TOPCOAT zone

From the paint shop car body is transferred to Trim & Chassis shop.

Cont.

Pre-Treatment Line.

It has 8 stages.

1. Pre-Degreaser-Washing using chemicals and safely removal of oils, greases, fats and carbon deposited on the

car body.

2. Degreaser-2 (D/P).- Final washing with chemicals of cars body.

3. Pre-Raw water Rinse. -Here, car body is washed using raw water of specific ph.

4. Raw water Rinse (D/P).- Again washed with raw water of specific ph. (final raw water washing).

5. Conditioner- It is used to make the car body surface rough. Because at rough surfaces coating more adheres.

6. Phosphate treatment zone- car body is coated with phosphate for providing metal cleanliness and corrosion

protection to the surface of the car body.

7. Pre-DI (Deionized) water Rinse zone- DI water bath is given to car body. For DI Water rinse Fresh de-

ionized water is used that is cleaner than drinking water. If any contamination remains on the surface before

the ED coating, it will cause the application issue and raise the potential for product failure.

8. DI water Rinse (D/P). -Final DI water bath is given to car body.

Here Pre-Treatment line ends.

Electro Deposit Line (ED-Line)

It has 3 stages.

1. ED-Bath-At this stage car body is covered with ED Paint. ED (Electro-deposition)

paint (cationic) is used as a primer for car bodies. It imparts rust resistance and

chipping resistance to the car body.

2. UF-(Ultra Filtrate)-1-The paint bath can be contaminated with pre-treatment

chemicals like e.g. phosphates, chlorides, and chromates. So, a part of ultra-filtrate

has to be leaded out to avoid contamination of the paint bath with these chemicals.

3. Fresh water and Tilting stage-After UF stage car body is washed with fresh water.

After washing the car body is tilted to remove all the water and waste paint from the

car body. Then car is tilted back to its initial position.

Here ED Line ends.

Cont.

Cont.

ED-OVEN

Car body passes through the ED Oven for drying the ED paint. First, air is

heated and passed through oven chamber then car body passes through the

chamber. Thus ED paint is dried by hot air.

Sealant is applied at every exterior edge of the car. Sealant is used to resist

the leakage through the car body. Then car body passes through the Sealer

Oven for drying the sealant.

Sealer-Zone

Then car body passes through the ED Sanding Zone. Here, extra paint is removed to make

ED paint layer uniform. This process is completely manual. First workers check the ED

paint layer and then remove extra paint using Sanding paper.

ED sanding zone

Body arranging zone

It has 3 lines.

Side line

Main Line

Repair Line

Cont.

When car body enters at storage are then barcode of car body is scanned and data sent to the CCR

(central control room) panel. Bodies of the same color are arranged in the main line. In main line

bodies are arranged on the basis of color such that same color bodies are together. If any car body

of different color comes in that line then it will be shifted to side line till it groups with another

bodies of same color. It is fully automated process according to the color car bodies are arranged

automatically in their respective line.

If after the ED Sanding stage body paint is not uniform or if some other faults are found in ED

paint then car body is transferred to repair line. From here body is sent to repair zone for repairing.

Dust Off zone

Dust from the body is removed before painting. So that dust doesnt

contaminate the paint. Feathers of Emu bird are used as dust remover

ACC (Anti corrosion Coating)

Primer coat (Sprayed by robots)

Primer Paint (Manually for more accuracy)

Primer flash off zone (Drying of primer paint)

Base Zone (For main paint, first sprayed by robots ,then manually)

Base flash off zone (Drying of base paint)

Clear Zone (For clearing car surface for shining, First by robots then manually for

more shining purpose.)

Cont.

TOPCOAT Zone

In this zone car is painted through following zone.

Car body is transferred to Trim & Chassis shop

Plastic Shop

In this shop bumpers are manufactured by Injection Molding Process.

Small pieces of Poly Propylene are used as raw material.

Two Mechanical Injection Molding machine (MIMM) and one Electrical Injection Molding machine

(EIMM) are here.

Mechanical Injection Molding Machine is controlled by hydraulic cylinders and Electrical Injection

Molding machine is controlled by Servo motors.

Electrical molding machine is preferable because it requires less maintenance and works with good

accuracy. In both types of machines hydraulic forces are applied.

For changing the mold for different units QMC (Quick Mold Change) System is used. It is completely

automated.

QMC system is controlled by PLC. For changing a one mold it takes 8.2 minutes.

PLC has all the specification about all the molds. For each mold a number is given. So for changing a

mold, corresponding number is given to PLC.

Then according to the size and shape of mold, QMC automatically adjusts its process for change the die

Die also has heater for maintaining the die temperature. It takes 45 minutes for heating the die. So die is

pre heated before the installation for saving the time.

For both mechanical molding machines there is common QMC unit and electrical molding machine has its

own QMC unit

Weight of a die is about 28-30 ton. From here bumpers are forward to bumper paint shop for painting and

piercing

Bumper Paint Shop

In this process Rare and Front bumpers, and finishers are painted. Finishing process of bumpers

and finishers is also done in this shop. Here, punching and drilling operation are done for

generating holes in bumpers

In this zone bumper is painted through following zone.

Heating Zone (Low speed conveyor) (bumper is heated. For heating fire is applied by the two

robots. Fire flame length is 250 mm)

Dust off zone (air is applied to bumper surface for clean the dust.)

Primer coat (Sprayed by robots)

Primer Paint (Manually for more accuracy)

Primer flash off zone (Drying of primer paint)

Base Zone (For main paint, first sprayed by robots ,then manually)

Base flash off zone (Drying of base paint)

Clear Zone (For clearing car surface for shining, First by robots then manually for more

shining purpose.)

Backing Zone 1 & 2- (High Speed Conveyor) Both backing zones are maintained at 120

degree Celsius temperature. By passing hot air in banking chamber paint is dried. Then bumper

is shifted fromhigh speed conveyor to low speed conveyor

Bumper Paint Shop

Cont.

Quality checking-Here, quality inspection is done. If any fault found in

bumper then it is sent for repair. If no fault is found then bumper is

unloaded from low speed conveyor and sent to vehicle chain.

For finisher painting same process is followed but at dust off zone there is no

need of finisher heating.

After final painting process piercing robot is used to generate holes in

bumper

Robots generate small holes in bumper by drilling operation. Holes are used for placing small sensors in

bumper.

Rare punching machine: It is used to generate big holes in bumper. These holes are used for placing little

big sensors, lights and other components.

Front punching machine: It is used for generate big holes in rare bumper and Front punching machine is

used for generate big holes in front bumper

Trim and Chassis shop

Here all the components of car are assembled

There are two main lines Line-1 and Line-2. Both lines

are same

At each line total 31 stations are there.

At each station 3-4 parts are assembled in car body.

There are six sub lines in each main line:

Primary line

Trim Line

Chassis Trim line

Engine assembly

Pre final

Tester Line

Cont.

Primary line- Car body comes frompaint shop. Doors are separated.

Trim Line- Interior components are assembled manually. Ex. Seat belt, floor cover ,Front and

rear glass ,CMM(Speedometer, Tachometer etc.). CCR controls the assembly.

Chassis and Engine Assembly line Exterior parts are assembled. Ex. engine, suspension

system, exhaust system, fuel tank, exhaust heat observer, brake system

Chassis and Trimline- All assembled components are checked. front and rear wheels.

Pre-final line- pre final line brake oil, fuel and coolant are filled using combo filling machine.

Final Line- Doors are assembled.

Tester Line- wheel alignment, Speed, braking system, Leakage are tested.

Test Drive and Sale

Internal component assembly

Engine fitting in car at Trim and Chassis shop

Wheels fitting in car at Trim and Chassis shop

Tester Line

Cars final stretch inspection

Power Train Line

Three Lines are here

JXX gear box assembly line

Engine Line:1

Engine Line:2

Cont.

Gear box assembly Line Process

1. Gear box Scanning

2. Assembly of gears.

3. Gear shifter (for 1

st

and 2

nd

gear) attached to secondary shaft

4. Primary shaft, secondary shaft with gear shifter and differential are

assembled in clutch housing

5. Gear shifters for 3

rd

, 4

th

and reverse gear are assembled with both

shafts.

6. Differential housing is assembled with clutch housing

7. By using mechanical housing tire side of the gear box is closed

8. In gear box a magnet is placed

Cont.

Gear box assembly Line Process

9. Primary shaft thickness measurement

10. Sealant Deposition

11. Then mechanical and clutch gear boxes are fixed and closed using

nut

12. Gear Box leakage testing by pressurized air.

13. Final Testing of gear box by assemble it with engine.

14. First gear box is scanned.

15. All tests are control by a PC.

16. maximum speed at different gears, Noise level (Manually) Speed at

different torques, power required at different slops at different

speed are tested. It is a one time process.

17. unloaded at gearbox area.

18. Testing of machine by blue and red gear box.

19. All blocks for gear box are imported from Renault France

Cont.

Engine Shop Line

At line-1 K9K (Diesel) engine is manufactured.

At line-2 XH (petrol) engine is manufactured Gear

Box leakage testing by pressurized air.

Cont.

Process

1. Cylinder block scanning.

2. Oil jet is fixed in cylinder by Oil jet press (2 Hydraulic and 4

Pneumatic)

3. Marking of engine code on cylinder block.

4. Oil level indicator assembly.

5. metal pieces are assembled in cylinder block support the crank

shaft. These metal pieces work as a bearing.

6. Then D dimension machine measure the height between bottom

dead center and top dead center for selecting the proper piston.

7. then crankshaft, piston, connecting rod are assembled in cylinder

block

8. oil filter, oil pump and oil pan is fixed

9. In H dimension machine piston is inspected that the piston is

perfect or not for the corresponding bore.

Cont.

Process

10. cylinder head is fixed on the cylinder block using nut bolt.

11. Then Cam shaft is fixed. Then fuel injector and high pressure fuel pump is fixed.

12. Timing Pulley and Timing belt is fixed.

13. Timing belt and gear transfer the power or motion from crank shaft to other engine accessories like cam

shaft, high pressure fuel pump. Fuel pump, cam shaft and other accessories are synchronized with crank

shaft.

14. Flywheel, vacuum pump ,Fuel pipe line, EGI harness cable, Intake manifold, exhaust manifold , Then

EGR (exhaust gas recycle) unit stabilizer, exhaust air intake ,exhaust air filter, Clutch kit (clutch plate

and disk), friction plate are assembled.

15. Engine Testing

16. Then quality of engine is checked and visual inspection of engine is done. If any fault is found then

engine is sent for repair. Then finally engine is sent to the SCM(supply chain management).

Casting Shop

In casting shop cylinder head and cylinder blocks are manufactured by casting

process.

In this shop two casting machines are here.

1 HPDC (High Pressure Die casting): Cylinder blocks are

manufactured by High Pressure Die Casting because they are heavy in

weight.

2 LPDC (Low Pressure Die Casting): Cylinder heads are

manufactured by Low Pressure Die Casting Process.

HDPC process is same as LDPC. Only difference is that pressure and die

moving velocity is higher in HDPC i.e. 60-70 Mpa and 308 m/s.

Cont.

LPDC (Low Pressure Die Casting)

Total 16 machines (3 LPDC) are here.

Raw material (ACD 12 Al alloy Rectangular rods)is poured into Melting Furnace where it melts.

Then molten material is transferred to holding zone to maintain the molten material temperature.

Temperature of Holding Zone is maintained at 700 degree Celsius.

Melting rate is 1.5 ton/hr.

LPG (fuel for combustion) furnace is used for melting where burner melt the raw material.

LPG is supplied at 1bar and air is supplied by blower.

Melting and Holding zone individual air blower is used.

At degreasing zone unwanted trapped gasses are removed from the molten material.

Then molten material is poured into LPDC machine

Using LPG die is pre heated before install in LPDC machine

Then casting is done in LPDC.

The temperature of molten material is maintained by electrical heaters in LPDC machine.

Removing the sand from casting surface.

Finishing operation of casting.

Hardening of casting.

Quality checking for cracks.

Visual inspection.

Air leakage checking

Conclusion

On the whole, this internship was a very useful experience. I have gained new knowledge, skills

and met many new people. I achieved several of my learning goals, however for some the

conditions did not permit. I got insight into professional practice. I learned the different facets of

working. I experienced that work management, is an important factor for the progress of projects.

Related to my study I learned more about the casting, stamping, machining, and welding. The

safety arrangements are very effective. I really very impressed with safety arrangements. I have

seen that all the employees are very aware of safety.

It is a very important aspect of the conservation of energy. Energy saving arrangements is also

very effective. The internship was also good to find out what my strengths and weaknesses are.

This helped me to define what skills and knowledge I have to improve in the coming time. At last

this internship has given me new insights and motivation to pursue a career in automotive field.

References

RNAIPL DATA

http://automotivehorizon.sulekha.com/

http://businesstoday.intoday.in/

http://www.dmcnicholl-technology.com/

http://www.theautochannel.com/news/2010/10/05/499926.html

You might also like

- Seiri - Seiton - Seiso - Seiketsu - Shitsuke: Nra WP - Nra L LHD - Nra NRH - Nra NFL R - RPL RNFDocument36 pagesSeiri - Seiton - Seiso - Seiketsu - Shitsuke: Nra WP - Nra L LHD - Nra NRH - Nra NFL R - RPL RNFvijay_sudhaNo ratings yet

- (See Rule 66 (6) ) : Print BackDocument3 pages(See Rule 66 (6) ) : Print Backvijay_sudhaNo ratings yet

- Daily Stand Up Meetings - NSNoHUBDocument1 pageDaily Stand Up Meetings - NSNoHUBvijay_sudhaNo ratings yet

- Application Form For The Post of Assessor-H0362490Document2 pagesApplication Form For The Post of Assessor-H0362490vijay_sudhaNo ratings yet

- Main LinkDocument1 pageMain Linkvijay_sudhaNo ratings yet

- Question 1Document21 pagesQuestion 1vijay_sudhaNo ratings yet

- Edited 12Document2 pagesEdited 12vijay_sudhaNo ratings yet

- KNPS Shift Handover TemplateDocument1 pageKNPS Shift Handover Templatevijay_sudha100% (1)

- Voyager™ 1452g Series: Quick Start GuideDocument16 pagesVoyager™ 1452g Series: Quick Start Guidevijay_sudhaNo ratings yet

- CC Lecture Notes 1 PDFDocument13 pagesCC Lecture Notes 1 PDFvijay_sudhaNo ratings yet

- English Through TamilDocument90 pagesEnglish Through TamilKhalifullah100% (1)

- Iffco-Tokio General Insurance Co - LTD: Servicing OfficeDocument3 pagesIffco-Tokio General Insurance Co - LTD: Servicing Officevijay_sudha50% (2)

- 2011 IEEE Cloud-Computing 01-26-11Document40 pages2011 IEEE Cloud-Computing 01-26-11Kamlesh MehtaNo ratings yet

- Saidai Duraisamy's Manidha NaeyamDocument2 pagesSaidai Duraisamy's Manidha Naeyamvijay_sudhaNo ratings yet

- SAP Enabled RF GunDocument4 pagesSAP Enabled RF Gunvijay_sudha100% (1)

- AprojectreportononlinetradingDocument51 pagesAprojectreportononlinetradingHarshdeep SainiNo ratings yet

- P.R. No. 262 - Narikuravur Members Registration Application Invited Collector News Page1 - 4.9.2014Document1 pageP.R. No. 262 - Narikuravur Members Registration Application Invited Collector News Page1 - 4.9.2014vijay_sudhaNo ratings yet

- 600 Application FormatDocument4 pages600 Application FormatmmmonmissionNo ratings yet

- Online ShoppingDocument54 pagesOnline ShoppingVaryam Pandey50% (6)

- TNSPYB Anskey PDFDocument4 pagesTNSPYB Anskey PDFjamarnath05No ratings yet

- Pension Revision Application FormDocument6 pagesPension Revision Application Formvijay_sudhaNo ratings yet

- WWW - Tnpsc.gov - in Anskeys 29-06-2014 GeneralKnowledgeDocument51 pagesWWW - Tnpsc.gov - in Anskeys 29-06-2014 GeneralKnowledgeVijay NirmalNo ratings yet

- SEO-optimized title for document instructionsDocument21 pagesSEO-optimized title for document instructionsArvind Manokar100% (1)

- TNTET PAPER I TENTATIVE ANSWER KEYDocument9 pagesTNTET PAPER I TENTATIVE ANSWER KEYanand_dec84No ratings yet

- Ugc Bank ChallanDocument1 pageUgc Bank Challanvijay_sudhaNo ratings yet

- Current Affairs 2011 KCDocument96 pagesCurrent Affairs 2011 KCAMU SHAHUL HAMEEDNo ratings yet

- Pg-Assistants-Tamil-Paper Tentative-Answer-Key PDFDocument12 pagesPg-Assistants-Tamil-Paper Tentative-Answer-Key PDFSamuthi RamNo ratings yet

- Faq DBMSDocument2 pagesFaq DBMSShashank MohanNo ratings yet

- Railway Recruitment Board (RRB) NotificationDocument16 pagesRailway Recruitment Board (RRB) NotificationFreshers Plane India100% (2)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- BOSTIK Boscoprime 1 Rev1-MinDocument2 pagesBOSTIK Boscoprime 1 Rev1-MinBuana Paksa OfficialNo ratings yet

- Application of Internal Linings - Sample - PIPDocument15 pagesApplication of Internal Linings - Sample - PIPgbuckley9630100% (1)

- Clear and Pigmented Lacquers: Standard Test Methods ForDocument6 pagesClear and Pigmented Lacquers: Standard Test Methods ForHHans MSilvaNo ratings yet

- Design:: Steel Structures Applied To Facade Containment SolutionsDocument112 pagesDesign:: Steel Structures Applied To Facade Containment SolutionsLuísNo ratings yet

- Af 163-2Document10 pagesAf 163-2lacsmm982No ratings yet

- Univan Hs PrimerDocument1 pageUnivan Hs PrimerWorapat Puttakasem0% (1)

- Surface Coating GuideDocument11 pagesSurface Coating GuideJuganta280100% (2)

- Interzinc 52 TDSDocument4 pagesInterzinc 52 TDSDele TedNo ratings yet

- 07-Adhesion PromoterDocument36 pages07-Adhesion Promotercyclo DreamNo ratings yet

- 074213fl CitadelDocument58 pages074213fl CitadelabobeedoNo ratings yet

- Corus Prevention of Corrosion On Structural Steelwork PDFDocument28 pagesCorus Prevention of Corrosion On Structural Steelwork PDFvonipkoNo ratings yet

- Ultraglaze Ssg4000: Silicone Structural Glazing AdhesiveDocument8 pagesUltraglaze Ssg4000: Silicone Structural Glazing AdhesivesauloNo ratings yet

- Mastertop 1325Document3 pagesMastertop 1325Doby YuniardiNo ratings yet

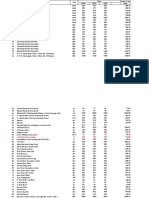

- Price List 2020 & 2021 From HardwareDocument48 pagesPrice List 2020 & 2021 From HardwareChinangNo ratings yet

- Sika Floorjoint PB 30pdrsDocument4 pagesSika Floorjoint PB 30pdrsRukmana's FamilyNo ratings yet

- Tulsi Paints RCM Presentation - P&aDocument32 pagesTulsi Paints RCM Presentation - P&aNagabhushan85% (13)

- SprayStone GT Series Paint TDSDocument5 pagesSprayStone GT Series Paint TDShilary9986No ratings yet

- Turbo3 A MAN B PDFDocument15 pagesTurbo3 A MAN B PDFjavierNo ratings yet

- Pentens ED FloorShieldDocument2 pagesPentens ED FloorShieldamelinda jocelinNo ratings yet

- Devchem 256: Chemical Resistant LiningDocument2 pagesDevchem 256: Chemical Resistant LiningMohamed NouzerNo ratings yet

- Painter (General) - ATS - NSQF-4Document36 pagesPainter (General) - ATS - NSQF-4azizNo ratings yet

- Food Grade Epoxy PaintsDocument5 pagesFood Grade Epoxy PaintsEdgar SerafinNo ratings yet

- DS385Document4 pagesDS385gabriel habibNo ratings yet

- SCG Catalog LowDocument42 pagesSCG Catalog LowNisay ArchineerNo ratings yet

- LATICRETEDocument164 pagesLATICRETEnap_carino100% (1)

- Military Standard: October 1,955Document22 pagesMilitary Standard: October 1,955MuazNo ratings yet

- Technical Data Sheet Jazeera Maxim Tex JA-26002: DescriptionDocument3 pagesTechnical Data Sheet Jazeera Maxim Tex JA-26002: DescriptionAhmad BougeisNo ratings yet

- Jotacoat UniversalDocument5 pagesJotacoat UniversalpcNo ratings yet

- General Guideline Sikasil Weather Sealants V2Document12 pagesGeneral Guideline Sikasil Weather Sealants V2Francisco BastidasNo ratings yet

- Guideline - Painting, Coating & Corrosion Protection - Dulux - Mild Steel - Surface PreparationDocument2 pagesGuideline - Painting, Coating & Corrosion Protection - Dulux - Mild Steel - Surface Preparationzinha_alNo ratings yet