Professional Documents

Culture Documents

EINTH13

Uploaded by

Raj ChavanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EINTH13

Uploaded by

Raj ChavanCopyright:

Available Formats

Rolta Academy: Engineering Design Services

CHAPTER 9

SCADA

9.1 SCADA Overview

SCADA is an acronym for Supervisory Control and Data Acquisition. SCADA

systems are used to monitor and control a plant or equipment in industries such

as telecommunications, water and waste control, energy, oil and gas refining and

transportation. These systems encompass the transfer of data between a

SCADA central host computer and a number of Remote Terminal nits !RTs"

and#or $rogrammable %ogic Controllers !$%Cs", and the central host and the

operator terminals. A SCADA system gathers information !such as where a lea&

on a pipeline has occurred", transfers the information bac& to a central site, then

alerts the home station that a lea& has occurred, carrying out necessary analysis

and control, such as determining if the lea& is critical, and displaying the

information in a logical and organi'ed fashion. These systems can be relatively

simple, such as one that monitors environmental conditions of a small office

building, or very comple(, such as a system that monitors all the activity in a

nuclear power plant or the activity of a municipal water system. Traditionally,

SCADA systems have made use of the $ublic Switched )etwor& !$S)" for

monitoring purposes. Today many systems are monitored using the infrastructure

of the corporate %ocal Area )etwor& !%A)"#*ide Area )etwor& !*A)". *ireless

technologies are now being widely deployed for purposes of monitoring.

SCADA systems consist of+

, -ne or more field data interface devices, usually RTs, or $%Cs, which

interface to field sensing devices and local control switchbo(es and valve

actuators

, A communications system used to transfer data between field data

interface devices and control units and the computers in the SCADA

central host. The system can be radio, telephone, cable, satellite, etc., or

any combination of these.

, A central host computer server or servers !sometimes called a SCADA

Center, master station, or .aster Terminal nit !.T"

, A collection of standard and#or custom software /sometimes called 0uman

.achine 1nterface !0.1" software or .an .achine 1nterface !..1"

software2 systems used to provide the SCADA central host and operator

terminal application, support the communications system, and monitor and

control remotely located field data interface devices

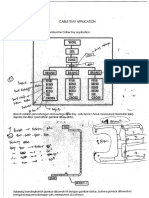

3igure 4.5 shows a typical SCADA system. 6ach of the above system

components will be discussed in detail in the ne(t sections.

nstr!mentation Engineering 1

Rolta Academy: Engineering Design Services

"ig 9.1: Ty#ical SCADA System

9.1.1 "ield Data nter$ace Devices

3ield data interface devices form the 7eyes and ears7 of a SCADA system.

Devices such as reservoir level meters, water flow meters, valve position

transmitters, temperature transmitters, power consumption meters, and pressure

meters all provide information that can tell an e(perienced operator how well a

water distribution system is performing. 1n addition, equipment such as electric

valve actuators, motor control switchboards, and electronic chemical dosing

facilities can be used to form the 7hands7 of the SCADA system and assist in

automating the process of distributing water.

0owever, before any automation or remote monitoring can be achieved, the

information that is passed to and from the field data interface devices must be

converted to a form that is compatible with the language of the SCADA system.

To achieve this, some form of electronic field data interface is required. RTs,

also &nown as Remote Telemetry nits, provide this interface. They are primarily

used to convert electronic signals received from field interface devices into the

language !&nown as the communication protocol" used to transmit the data over

a communication channel.

nstr!mentation Engineering 2

Rolta Academy: Engineering Design Services

The instructions for the automation of field data interface devices, such as pump

control logic, are usually stored locally. This is largely due to the limited

bandwidth typical of communications lin&s between the SCADA central host

computer and the field data a interface device. Such instructions are traditionally

held within the $%Cs, which have in the past been physically separate from

RTs. A $%C is a device used to automate monitoring and control of industrial

facilities. 1t can be used as a stand8alone or in con9unction with a SCADA or other

system. $%Cs connect directly to field data interface devices and incorporate

programmed intelligence in the form of logical procedures that will be e(ecuted in

the event of certain field conditions.

$%Cs have their origins in the automation industry and therefore are often used

in manufacturing and process plant applications. The need for $%Cs to connect

to communication channels was not great in these applications, as they often

were only required to replace traditional relay logic systems or pneumatic

controllers. SCADA systems, on the other hand, have origins in early telemetry

applications, where it was only necessary to &now basic information from a

remote source. The RTs connected to these systems had no need for control

programming because the local control algorithm was held in the relay switching

logic.

As $%Cs were used more often to replace relay switching logic control systems,

telemetry was used more and more with $%Cs at the remote sites. 1t became

desirable to influence the program within the $%C through the use of a remote

signal. This is in effect the 7Supervisory Control7 part of the acronym SCADA.

*here only a simple local control program was required, it became possible to

store this program within the RT and perform the control within that device. At

the same time, traditional $%Cs included communications modules that would

allow $%Cs to report the state of the control program to a computer plugged into

the $%C or to a remote computer via a telephone line. $%C and RT

manufacturers therefore compete for the same mar&et.

As a result of these developments, the line between $%Cs and RTs has blurred

and the terminology is virtually interchangeable. 3or the sa&e of simplicity, the

term RT will be used to refer to a remote field data interface device: however,

such a device could include automation programming that traditionally would

have been classified as a $%C.

9.1.% Comm!nications &etwor'

The communications networ& is intended to provide the means by which data

can be transferred between the central host computer servers and the field8

based RTs. The Communication )etwor& refers to the equipment needed to

transfer data to and from different sites. The medium used can either be cable,

telephone or radio.

The use of cable is usually implemented in a factory. This is not practical for

systems covering large geographical areas because of the high cost of the

nstr!mentation Engineering 3

Rolta Academy: Engineering Design Services

cables, conduits and the e(tensive labor in installing them. The use of telephone

lines !i.e., leased or dial8up" is a more economical solution for systems with large

coverage. The leased line is used for systems requiring on8line connection with

the remote stations. This is e(pensive since one telephone line will be needed

per site. Dial8up lines can be used on systems requiring updates at regular

intervals !e.g., hourly updates". 0ere ordinary telephone lines can be used. The

host can dial a particular number of a remote site to get the readings and send

commands.

Remote sites are usually not accessible by telephone lines. The use of radio

offers an economical solution. Radio modems are used to connect the remote

sites to the host. An on8line operation can also be implemented on the radio

system. 3or locations where a direct radio lin& cannot be established, a radio

repeater is used to lin& these sites.

0istorically, SCADA networ&s have been dedicated networ&s: however, with the

increased deployment of office %A)s and *A)s as a solution for interoffice

computer networ&ing, there e(ists the possibility to integrate SCADA %A)s into

everyday office computer networ&s.

The foremost advantage of this arrangement is that there is no need to invest in a

separate computer networ& for SCADA operator terminals. 1n addition, there is an

easy path to integrating SCADA data with e(isting office applications, such as

spreadsheets, wor& management systems, data history databases, ;eographic

1nformation System !;1S" systems, and water distribution modeling systems.

9.1.( Central Host Com#!ter

The central host computer or master station is most often a single computer or a

networ& of computer servers that provide a man8machine operator interface to

the SCADA system. The computers process the information received from and

sent to the RT sites and present it to human operators in a form that the

operators can wor& with. -perator terminals are connected to the central host

computer by a %A)#*A) so that the viewing screens and associated data can be

displayed for the operators. Recent SCADA systems are able to offer high

resolution computer graphics to display a graphical user interface or mimic screen

of the site or water supply networ& in question. 0istorically, SCADA vendors

offered proprietary hardware, operating systems, and software that was largely

incompatible with other vendors< SCADA systems. 6(panding the system

required a further contract with the original SCADA vendor. 0ost computer

platforms characteristically employed )1=8based architecture, and the host

computer networ& was physically removed from any office8computing domain.

0owever, with the increased use of the personal computer, computer networ&ing

has become commonplace in the office and as a result, SCADA systems are now

available that can networ& with office8based personal computers. 1ndeed, many of

today<s SCADA systems can reside on computer servers that are identical to

those servers and computers used for traditional office applications. This has

opened a range of possibilities for the lin&ing of SCADA systems to office8based

nstr!mentation Engineering 4

Rolta Academy: Engineering Design Services

applications such as ;1S systems, hydraulic modeling software, drawing

management systems, wor& scheduling systems, and information databases.

9.1.) O#erator *or'stations and So$tware Com#onents

-perator wor&stations are most often computer terminals that are networ&ed with

the SCADA central host computer. The central host computer acts as a server for

the SCADA application, and the operator terminals are clients that request and

send information to the central host computer based on the request and action of

the operators.

An important aspect of every SCADA system is the computer software used

within the system. The most obvious software component is the operator

interface or .an .achine 1nterface#0uman .achine 1nterface !..1#0.1"

pac&age: however, software of some form pervades all levels of a SCADA

system. Depending on the si'e and nature of the SCADA application, software

can be a significant cost item when developing, maintaining, and e(panding a

SCADA system. *hen software is well defined, designed, written, chec&ed, and

tested, a successful SCADA system will li&ely be produced. $oor performances

in any of these pro9ect phases will very easily cause a SCADA pro9ect to fail.

.any SCADA systems employ commercial proprietary software upon which the

SCADA system is developed. The proprietary software often is configured for a

specific hardware platform and may not interface with the software or hardware

produced by competing vendors. A wide range of commercial off8the8shelf

!C-TS" software products also are available, some of which may suit the

required application. C-TS software usually is more fle(ible, and will interface

with different types of hardware and software. ;enerally, the focus of proprietary

software is on processes and control functionality, while C-TS software

emphasi'es compatibility with a variety of equipment and instrumentation. 1t is

therefore important to ensure that adequate planning is underta&en to select the

software systems appropriate to any new SCADA system.

Software products typically used within a SCADA system are as follows+

, Central host computer operating system+ Software used to control the

central host computer hardware. The software can be based on )1= or

other popular operating systems.

, -perator terminal operating system+ Software used to control the central

host computer hardware. The software is usually the same as the central

host computer operating system. This software, along with that for the

central host computer, usually contributes to the networ&ing of the central

host and the operator terminals.

, Central host computer application+ Software that handles the transmittal

and reception of data to and from the RTs and the central host. The

software also provides the graphical user interface which offers site mimic

screens, alarm pages, trend pages, and control functions.

nstr!mentation Engineering 5

Rolta Academy: Engineering Design Services

, -perator terminal application+ Application that enables users to access

information available on the central host computer application. 1t is usually

a subset of the software used on the central host computers.

, Communications protocol drivers+ Software that is usually based within the

central host and the RTs, and is required to control the translation and

interpretation of the data between ends of the communications lin&s in the

system. The protocol drivers prepare the data for use either at the field

devices or the central host end of the system.

, Communications networ& management software+ Software required to

control the communications networ& and to allow the communications

networ&s themselves to be monitored for performance and failures.

, RT automation software+ Software that allows engineering staff to

configure and maintain the application housed within the RTs !or $%Cs".

.ost often this includes the local automation application and any data

processing tas&s that are performed within the RT.

The preceding software products provide the building bloc&s for the application8

specific software, which must be defined, designed, written, tested, and deployed

for each SCADA system.

9.% SCADA Arc+itect!res

SCADA systems have evolved in parallel with the growth and sophistication of

modern computing technology. The following sections will provide a description of

the following three generations of SCADA systems+

3irst ;eneration > .onolithic

Second ;eneration > Distributed

Third ;eneration > )etwor&ed

9.%.1 ,onolit+ic SCADA Systems

*hen SCADA systems were first developed, the concept of computing in general

centered on ?mainframe@ systems. )etwor&s were generally non8e(istent, and

each centrali'ed system stood alone. As a result, SCADA systems were

standalone systems with virtually no connectivity to other systems.

The *ide Area )etwor&s !*A)s" that were implemented to communicate with

remote terminal units !RTs" were designed with a single purpose in mind>that

of communicating with RTs in the field and nothing else. 1n addition, *A)

protocols in use today were largely un&nown at the time.

The communication protocols in use on SCADA networ&s were developed by

vendors of RT equipment and were often proprietary. 1n addition, these

protocols were generally very ?lean@, supporting virtually no functionality beyond

that required scanning and controlling points within the remote device. Also, it

was generally not feasible to intermingle other types of data traffic with RT

communications on the networ&.

Connectivity to the SCADA master station itself was very limited by the system

vendor. Connections to the master typically were done at the bus level via a

nstr!mentation Engineering 6

Rolta Academy: Engineering Design Services

proprietary adapter or controller plugged into the Central $rocessing nit !C$"

bac&plane.

Redundancy in these first generation systems was accomplished by the use of

two identically equipped mainframe systems, a primary and a bac&up, connected

at the bus level. The standby systemAs primary function was to monitor the

primary and ta&e over in the event of a detected failure. This type of standby

operation meant that little or no processing was done on the standby system.

3igure 4.B shows a typical first generation SCADA architecture.

9.%.% Distri-!ted SCADA Systems

The ne(t generation of SCADA systems too& advantage of developments and

improvement in system miniaturi'ation and %ocal Area )etwor&ing !%A)"

technology to distribute the processing across multiple systems. .ultiple stations,

"ig 9.%: "irst .eneration SCADA Arc+itect!re

each with a specific function, were connected to a %A) and shared information

with each other in real8time. These stations were typically of the mini8computer

class, smaller and less e(pensive than their first generation processors.

Some of these distributed stations served as communications processors,

primarily communicating with field devices such as RTs. Some served as

operator interfaces, providing the human8machine interface !0.1" for system

nstr!mentation Engineering 7

Rolta Academy: Engineering Design Services

operators. Still others served as calculation processors or database servers. The

distribution of individual SCADA system functions across multiple systems

provided more processing power for the system as a whole than would have

been available in a single processor. The networ&s that connected these

individual systems were generally based on %A) protocols and were not capable

of reaching beyond the limits of the local environment.

Some of the %A) protocols that were used were of a proprietary nature, where the

vendor created its own networ& protocol or version thereof rather than pulling an

e(isting one off the shelf. This allowed a vendor to optimi'e its %A) protocol for

real8time traffic, but it limited !or effectively eliminated" the connection of networ&

from other vendors to the SCADA %A). 3igure 4.C depicts typical second

generation SCADA architecture.

"ig 9.(: Second .eneration SCADA Arc+itect!re

Distribution of system functionality across networ&8connected systems served not

only to increase processing power, but also to improve the redundancy and

reliability of the system as a whole. Rather than the simple primary#standby

failover scheme that was utili'ed in many first generation systems, the distributed

architecture often &ept all stations on the %A) in an online state all of the time.

3or e(ample, if an 0.1 station were to fail, another 0.1 station could be used to

operate the system, without waiting for failover from the primary system to the

secondary.

nstr!mentation Engineering 8

Rolta Academy: Engineering Design Services

The *A) used to communicate with devices in the field were largely unchanged

by the development of %A) connectivity between local stations at the SCADA

master. These e(ternal communications networ&s were still limited to RT

protocols and were not available for other types of networ& traffic.

As was the case with the first generation of systems, the second generation of

SCADA systems was also limited to hardware, software, and peripheral devices

that were provided or at least selected by the vendor.

9.%.( &etwor'ed SCADA Systems

The current generation of SCADA master station architecture is closely related to

that of the second generation, with the primary difference being that of an open

system architecture rather than a vendor controlled, proprietary environment.

There are still multiple networ&ed systems, sharing master station functions.

There are still RTs utili'ing protocols that are vendor8proprietary. The ma9or

improvement in the third generation is that of opening the system architecture,

utili'ing open standards and protocols and ma&ing it possible to distribute

SCADA functionality across a *A) and not 9ust a %A). -pen standards eliminate

a number of the limitations of previous generations of SCADA systems. The

utili'ation of off8the8shelf systems ma&es it easier for the user to connect third

party peripheral devices !such as monitors, printers, dis& drives, tape drives, etc."

to the system and#or the networ&.

As they have moved to ?open@ or ?off8the8shelf@ systems, SCADA vendors have

gradually gotten out of the hardware development business. These vendors have

loo&ed to system vendors such as Compaq, 0ewlett8$ac&ard, and Sun

.icrosystems for their e(pertise in developing the basic computer platforms and

operating system software. This allows SCADA vendors to concentrate their

development in an area where they can add specific value to the system>that of

SCADA master station software.

The ma9or improvement in third generation SCADA systems comes from the use

of *A) protocols such as the 1nternet $rotocol !1$" for communication between

the master station and communications equipment. This allows the portion of the

master station that is responsible for communications with the field devices to be

separated from the master station ?proper@ across a *A). Dendors are now

producing RTs that can communicate with the master station using an 6thernet

connection. 3igure 4.E represents a networ&ed SCADA system.

nstr!mentation Engineering 9

Rolta Academy: Engineering Design Services

"ig 9.): T+ird .eneration SCADA System

Another advantage brought about by the distribution of SCADA functionality over

a *A) is that of disaster survivability. The distribution of SCADA processing

across a %A) in second8generation systems improves reliability, but in the event

of a total loss of the facility housing the SCADA master, the entire system could

be lost as well. Fy distributing the processing across physically separate

locations, it becomes possible to build a SCADA system that can survive a total

loss of any one location. 3or some organi'ations that see SCADA as a super8

critical function, this is a real benefit.

9.( SCADA Protocols

1n a SCADA system, the RT accepts commands to operate control points: sets

analog output levels, and responds to requests. 1t provides status, analog and

accumulated data to the SCADA master station. The data representations sent

are not identified in any fashion other than by unique addressing. The addressing

is designed to correlate with the SCADA master station database. The RT has

no &nowledge of which unique parameters it is monitoring in the real world. 1t

simply monitors certain points and stores the information in a local addressing

scheme. The SCADA master station is the part of the system that should ?&now@

that the first status point of RT number BG is the status of a certain circuit

brea&er of a given substation. This represents the predominant SCADA systems

and protocols in use in the utility industry today.

nstr!mentation Engineering 10

Rolta Academy: Engineering Design Services

6ach protocol consists of two message sets or pairs. -ne set forms the master

protocol, containing the valid statements for master station initiation or response,

and the other set is the RT protocol, containing the valid statements an RT

can initiate and respond to. 1n most but not all cases, these pairs can be

considered a poll or request for information or action and a confirming response.

The SCADA protocol between master and RT forms a viable model for RT8to8

1ntelligent 6lectronic Device !16D" communications. Currently, in industry, there

are several different protocols in use. The most popular are 1nternational

6lectrotechnical Commission !16C" HIJGI8K series, specifically 16C HIJGI8K85I5

!commonly referred to as 5I5" and Distributed )etwor& $rotocol version C

!D)$C".

"ig 9./: 0A1ER DA.RA,

nstr!mentation Engineering 11

Rolta Academy: Engineering Design Services

EC 234536/6131

16C HIJGI8K specifies a number of frame formats and services that may

be provided at different layers. 16C HIJGI8K is based on a three8layer 6nhanced

$erformance Architecture !6$A" reference model !see 3igure 4.K" for efficient

implementation within RTs, meters, relays, and other 1ntelligent 6lectronic

Devices !16Ds". Additionally, 16C HIJGI8K defines basic application functionality

for a user layer, which is situated between the -pen System 1nterconnection

!-S1" application layer and the application program. This user layer adds

interoperability for such functions as cloc& synchroni'ation and file transfers. The

following descriptions provide the basic scope of each of the five documents in

the base 16C HIJGI8K telecontrol transmission protocol specification set.

Standard profiles are necessary for uniform application of the 16C HIJGI8K

standards. A profile is a set of parameters defining the way a device acts. Such

profiles have been and are being created. The 5I5 profile is described in detail

following the description of the applicable standards. application data and basic

rules to specify application data units without specifying details about information

fields and their contents.

, 16C HIJGI8K8E !544C8IJ" provides rules for defining information data

elements and a common set of information elements, particularly digital and

analog process variables that are frequently used in telecontrol applications.

, 16C HIJGI8K8K !544K8IH" defines basic application functions that perform

standard procedures for telecontrol systems, which are procedures that reside

beyond layer G !application layer" of the 1S- reference model. These utili'e

standard services of the application layer. The specifications in 16C HIJGI8K8K

!544K8IH" serve as basic standards for application profiles that are then created

in detail for specific telecontrol tas&s.

6ach application profile will use a specific selection of the defined

functions. Any basic application functions not found in a standards document but

necessary for defining certain telecontrol applications should be specified within

the profile. 6(amples of such telecontrol functions include station initiali'ation,

cyclic data transmission, and data acquisition by polling, cloc& synchroni'ation,

and station configuration.

The Standard 5I5 $rofile provides structures that are also directly

applicable to the interface between RTs and 16Ds. 1t contains all the elements

of a protocol necessary to provide an unambiguous profile definition so vendors

may create products that interoperate fully.

At the physical layer, the Standard 5I5 $rofile additionally allows the

selection of 1nternational Telecommunication nion>Telecommunication

Standardi'ation Sector !1T8T" standards that are compatible with 6lectronic

1ndustries Association !61A" standards RS8BCB5 and RS8EJKB, and also support

fiber optics interfaces.

The Standard 5I5 $rofile specifies frame format 3T 5.B, chosen from

those offered in 16C HIJGI8K85 !544I8IB" to provide the required data integrity

together with the ma(imum efficiency available for acceptable convenience of

implementation. 3T 5.B is basically asynchronous and can be implemented using

nstr!mentation Engineering 12

Rolta Academy: Engineering Design Services

standard niversal Asynchronous Receiver#Transmitters !ARTs". 3ormats with

both fi(ed and variable bloc& length are permitted.

At the data lin& layer, the Standard 5I5 $rofile species whether an

unbalanced !includes multi8drop" or balanced !includes point8to8point"

transmission mode is used together with which lin& procedures !and

corresponding lin& function codes" are to be used. Also specified is an

unambiguous number !address" for each lin&.

The lin& transmission procedures selected from 16C HIJGI8K8B !544B8IE"

specify that S6)D#)- R6$%L, S6)D#C-)31R., and R6M6ST#R6S$-)D

message transactions should be supported as necessary for the functionality of

the end device. Additionally, The Standard 5I5 $rofile defines the necessary

rules for devices that will operate in the unbalanced !multi8drop" and balanced

!point8to8point" transmission modes.

The Standard 5I5 $rofile defines appropriate Application Service Data

nits !ASDs" from a given general structure in 16C HIJGI8K8C !544B8I4". The

si'es and the contents of individual information fields of ASDs are specified

according to the declaration rules for information elements defined in the

document 16C HIJGI8K8E !544C8IJ".

Type information defines structure, type, and format for information

ob9ect!s", and a set has been predefined for a number of information ob9ects. The

predefined information elements and type information do not preclude the

addition by vendors of new information elements and types that follow the rules

defined by 16C HIJGI8K8E !544C8IJ" and the Standard 5I5 $rofile. 1nformation

elements in the Standard 5I5 $rofile have been defined for protection

equipment, voltage regulators, and metered values to interface these devices as

16Ds to the RT.

The Standard 5I5 $rofile utili'es the following basic application functions,

defined in 16C HIJGI8K8K !544K8IH", within the user layer+

a" Station initiali'ation

b" Cyclic data transmission

c" ;eneral interrogation

d" Command transmission

e" Data acquisition by polling

f" Acquisition of events

g" $arameter loading

h" 3ile transfer

i" Cloc& synchroni'ation

9" Transmission of integrated totals

&" Test procedure

3inally, the Standard 5I5 $rofile defines parameters that support interoperability

among multi8vendor devises within a system. These parameters are defined in

HIJGI8K85IB and HIJGI8K85IK. The Standard 5I5 $rofile provides a chec&list

that vendors can use to describe their devices from a protocol perspective.

nstr!mentation Engineering 13

Rolta Academy: Engineering Design Services

These parameters include baud rate, common address of ASD field length, lin&

transmission procedure, basic application functions, etc., Also contained in the

chec& list is the information that should be contained in the ASD in both the

control and monitor directions. This will assist the SCADA engineers to configure

their particular system.

The Standard 5I5 $rofile application layer specifies the structure of the ASD,

as shown in 3igure 4.5. The fields indicated as being optional per system will be

determined by a system level parameter shared by all devices in the system. 3or

instance, the si'e of the common address of ASD is determined by a fi(ed

system parameter, in this case one or two octets !bytes".

The Standard 5I5 $rofile also defines two new terms not found in the 16C HIJGI8

K85 through HIJGI8K base documents. The control direction refers to

transmission from the controlling station to a controlled station. The monitor

direction is the direction of transmission from a controlled station to the

controlling station. 3igure 4.H shows the structure of ASDs as defined in the 16C

HIJGI8K85I5 specification.

nstr!mentation Engineering 14

Rolta Academy: Engineering Design Services

"ig 9.2 ASD7s

nstr!mentation Engineering 15

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Annexure For Pressure GaugeDocument2 pagesAnnexure For Pressure GaugeRaj ChavanNo ratings yet

- Pdms Cable TrayDocument10 pagesPdms Cable TrayRaj ChavanNo ratings yet

- Cs01304den 0112Document2 pagesCs01304den 0112Raj ChavanNo ratings yet

- XFDocument1 pageXFRaj ChavanNo ratings yet

- Drak A Mog CatalogDocument376 pagesDrak A Mog Catalogdadok999No ratings yet

- Why Has 4-20 Ma Gained So Much Acceptance and Survived So Long?Document2 pagesWhy Has 4-20 Ma Gained So Much Acceptance and Survived So Long?Raj ChavanNo ratings yet

- Marine Electrical KnowledgeDocument53 pagesMarine Electrical KnowledgeRhn RhnNo ratings yet

- Instrumentation Cables: BS 5308, Part 1 BS 5308, Part 2 and Gen. To BS 5308, Part 1Document88 pagesInstrumentation Cables: BS 5308, Part 1 BS 5308, Part 2 and Gen. To BS 5308, Part 1Raj ChavanNo ratings yet

- PL-2303 Windows XP Driver UpdateDocument1 pagePL-2303 Windows XP Driver UpdatePolo AlvarezNo ratings yet

- Proline Prosonic Flow 93W: Technical InformationDocument32 pagesProline Prosonic Flow 93W: Technical InformationRaj ChavanNo ratings yet

- What Does NAMUR NE 43 Do ForDocument1 pageWhat Does NAMUR NE 43 Do ForRaj ChavanNo ratings yet

- His AtlDocument7 pagesHis AtlRaj ChavanNo ratings yet

- DVR Vs NVRDocument3 pagesDVR Vs NVRGvds SastryNo ratings yet

- One NoteDocument11 pagesOne NoteRaj ChavanNo ratings yet

- NEMA Motor Manual Section on AccessoriesDocument16 pagesNEMA Motor Manual Section on AccessoriesDelfinshNo ratings yet

- and 330425 Accelerometer Acceleration Transducers - Datasheet - 141638 - Cda - 000 PDFDocument8 pagesand 330425 Accelerometer Acceleration Transducers - Datasheet - 141638 - Cda - 000 PDFdialixhNo ratings yet

- BN330500dt PDFDocument19 pagesBN330500dt PDFvvNo ratings yet

- SU-FMO Fire Alarm System Basics Presentation To Building Managers 7-28-2014Document30 pagesSU-FMO Fire Alarm System Basics Presentation To Building Managers 7-28-2014Ahmed MohamedNo ratings yet

- Surge Protec IIDocument14 pagesSurge Protec IIRaj ChavanNo ratings yet

- His AtlDocument7 pagesHis AtlRaj ChavanNo ratings yet

- Schneider Electric - Overload Relay Trip CurvesDocument84 pagesSchneider Electric - Overload Relay Trip CurvesMichael Parohinog GregasNo ratings yet

- Chapter 18 FiltrationDocument18 pagesChapter 18 FiltrationGMDGMD11No ratings yet

- Chem Earth PointsDocument65 pagesChem Earth PointsRaj ChavanNo ratings yet

- Area Classification: (IEC/EN 60529)Document1 pageArea Classification: (IEC/EN 60529)nestkwt1No ratings yet

- EINTH012Document32 pagesEINTH012Raj ChavanNo ratings yet

- Unitronics IdntolvurDocument24 pagesUnitronics IdntolvurRaj ChavanNo ratings yet

- Why Has 4-20 Ma Gained So Much Acceptance and Survived So Long?Document2 pagesWhy Has 4-20 Ma Gained So Much Acceptance and Survived So Long?Raj ChavanNo ratings yet

- Unit 6: Project EvaluationDocument12 pagesUnit 6: Project EvaluationRaj ChavanNo ratings yet

- Cost Estimation Techniques for Uncertain ProjectsDocument7 pagesCost Estimation Techniques for Uncertain ProjectsRaj ChavanNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- MS2420 / MS2430: Installation and User's GuideDocument81 pagesMS2420 / MS2430: Installation and User's GuideMauricio MatuteNo ratings yet

- Lindell SBC ManualDocument10 pagesLindell SBC ManualDiego DazaNo ratings yet

- Chapter 2: Hardware For Computer Operations: A. Computer-Based Information SystemDocument8 pagesChapter 2: Hardware For Computer Operations: A. Computer-Based Information SystemRabeel AhmadNo ratings yet

- 1N/FDLL 914/A/B / 916/A/B / 4148 / 4448: Small Signal DiodeDocument4 pages1N/FDLL 914/A/B / 916/A/B / 4148 / 4448: Small Signal DiodeRoad AdNo ratings yet

- A Three-Layer Privacy Preserving Cloud Storage Scheme Based On Computational Intelligence in Fog ComputingDocument40 pagesA Three-Layer Privacy Preserving Cloud Storage Scheme Based On Computational Intelligence in Fog ComputingdineshshaNo ratings yet

- ReleaseNotes Xxxyy.072.035 PDFDocument6 pagesReleaseNotes Xxxyy.072.035 PDFLaura CostacheNo ratings yet

- 560-0408-01a SL70R InstallDocument52 pages560-0408-01a SL70R InstalldanielNo ratings yet

- CGG PowerLogDocument2 pagesCGG PowerLogMuhNo ratings yet

- Iot Force Fsa Series Datasheet 32311096 B en Ciid 156697Document7 pagesIot Force Fsa Series Datasheet 32311096 B en Ciid 156697Florian OuvrardNo ratings yet

- Bandpass Filters Using Parallel Coupled Stripline Stepped ImpedaDocument3 pagesBandpass Filters Using Parallel Coupled Stripline Stepped Impedasrividhya ganesanNo ratings yet

- CFC For M7 Continuous Function ChartDocument88 pagesCFC For M7 Continuous Function ChartPradeep TripathiNo ratings yet

- Chapter 2newDocument134 pagesChapter 2newBelayneh TadesseNo ratings yet

- AcronisCyberProtect 15Document582 pagesAcronisCyberProtect 15Ivn Echegoyen RivasNo ratings yet

- 372.90 Win10 Win8 Win7 Desktop Release NotesDocument50 pages372.90 Win10 Win8 Win7 Desktop Release Notesanon_942724752No ratings yet

- Dpi Lpi ExpertDocument1 pageDpi Lpi ExpertReza AleeNo ratings yet

- Help VeriSensDocument228 pagesHelp VeriSensKanapot RitthapNo ratings yet

- Faster Image Compression using GPU Parallel ProcessingDocument2 pagesFaster Image Compression using GPU Parallel ProcessingSakib FahmidNo ratings yet

- Most SAP ABAP Module Pool Interview Questions and AnswersDocument9 pagesMost SAP ABAP Module Pool Interview Questions and AnswersRam Praneeth100% (1)

- Linked List Implementation of StackDocument3 pagesLinked List Implementation of StackEngr. AbdullahNo ratings yet

- An Oracle JD Edwards Enterpriseone Performance and Tuning Paper 8/2007Document23 pagesAn Oracle JD Edwards Enterpriseone Performance and Tuning Paper 8/2007RaveRaveNo ratings yet

- CH7 - Remote IO & Wireless Sensing ModulesDocument59 pagesCH7 - Remote IO & Wireless Sensing Modulesatif_aman123No ratings yet

- 1 Web Technology Assignment No 1Document5 pages1 Web Technology Assignment No 1RAtnaNo ratings yet

- PC Assembly and Software Installation RubricDocument2 pagesPC Assembly and Software Installation RubricEmerson NaderaNo ratings yet

- UG-2864HSWEG01 User Guide PDFDocument20 pagesUG-2864HSWEG01 User Guide PDFSachin KhandareNo ratings yet

- System Status Via EmailDocument9 pagesSystem Status Via EmailbabuiypeNo ratings yet

- RF 2.2.3.2 Local Server Setup GuideDocument19 pagesRF 2.2.3.2 Local Server Setup GuideHarid Luthfi Pratama100% (1)

- Control System Toolbox™ Release NotesDocument142 pagesControl System Toolbox™ Release Notesعبدالله جمالNo ratings yet

- Go For DevOps (151-200)Document50 pagesGo For DevOps (151-200)Matheus SouzaNo ratings yet

- 15GMK 6250 Super ElectricDocument17 pages15GMK 6250 Super ElectricВиталий РогожинскийNo ratings yet

- The Circuit Diagram of Three Phase Inverter Given Below. The Circuit Consists of Six Switching Devices Like MOSFETDocument11 pagesThe Circuit Diagram of Three Phase Inverter Given Below. The Circuit Consists of Six Switching Devices Like MOSFETKhadija HanifNo ratings yet