Professional Documents

Culture Documents

Strengthening of Rinforced Concrete Beams

Uploaded by

Syed Mohd MehdiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Strengthening of Rinforced Concrete Beams

Uploaded by

Syed Mohd MehdiCopyright:

Available Formats

STRENGTHENING OF RINFORCED

CONCRETE BEAMS

Reinforced concrete beams need strengthening when the existing steel bars in the beam

are unsafe or insufficient, or when the loads applied to the beam are increased. In such

cases, there are different solutions that could be followed:

I-ADDING REINFORCEMENT STEEL BARS TO THE MAIN STEEL WITHOUT

INCREASING THE BEAMS CROSS SECTIONAL AREA

This solution is carried out when the reinforcing steel bars are not capable to carry the

stresses applied to the beam. The following steps should be followed:

1. The concrete cover is removed for both the upper and lower steel bars.

2. The steel bars are well cleaned and coated with an appropriate material that would

prevent corrosion.

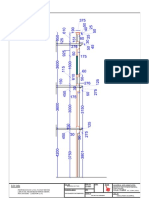

3. Holes are made, in the whole span of the beam under the slab, as shown in Fig.1, 15-

25cm apart, a diameter of 1.3cm and extend to the total width of the beam.

Fig.1: Holes in

the span of a beam

4. The holes are filled with an epoxy material with low viscosity and installing steel

connectors for fastening the new stirrups.

5. Steel connectors are installed into the columns in order to fasten the steel bars added

to the beam.

6. The added stirrups are closed using steel wires and the new steel is installed into

these stirrups.

7. The surface is then coated with a bonding epoxy material.

8. The concrete cover is poured over the new steel and the new stirrups.

The previous steps are illustrated in Fig 2.

Fig.2-

Strengthening a beam without increasing cross sectional area.

II-INCREASING BOTH THE REINFORCING STEEL BARS AND THE CROSS

SECTIONAL AREA OF CONCRETE

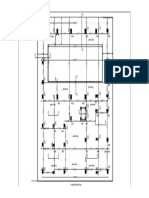

This solution is chosen when both the steel and concrete are not able to carry the

additional loads applied to the beam. In such cases the following steps should be

followed as in Fig 3.

1. Removing the concrete cover, roughing the beams surface, cleaning the reinforcement

steel bars and coating them with an appropriate material that would prevent corrosion.

2. Making holes in the whole span and width of the beam under the slab at 15-25cm.

3. Filling the holes with cement mortar with low viscosity and installing steel connectors

for fastening the new stirrups.

4. Installing the steel connectors into the columns in order to fasten the steel bars added

to the beam.

5. Closing the added stirrups using steel wires and the new steel is installed into these

stirrups.

6. Coating the concrete surface with an appropriate epoxy material that would guarantee

the bond between the old and new concrete, exactly before pouring the concrete.

7. Pouring the concrete jacket using low shrinkage concrete.

Fig.3:

Strengthening of beam by increasing the cross-sectional area and bars

III-ADDING STEEL PLATES TO THE BEAM

When it is required to strengthen the beams resistance against the applied moment or

shear stress, steel plates are designed with the appropriate size and thickness.

Then those plates are attached to the beam as follows:

1. Roughing and cleaning the concrete surfaces where the plates will be attached.

2. Coating the concrete surfaces with a bonding epoxy material.

3. Making holes in the concrete surfaces and plates.

4. Putting a layer of epoxy mortar on top of the plates with a 5mm thickness.

5. Attaching the steel plates to the concrete using bolts.

The previous steps are illustrated in Fig 4.

Fig.4: Strengthening of Beam by adding steel plates

In some cases, it is needed to reduce the load on the beam that needs strengthening

before implementing the previous steps, either partial or complete unloading.

This is made by putting steel beams on top or below the concrete beams, as shown

in Fig5.

Fig.5:

Reducing the load on the beam using steel beam.

The following photos were taken during strengthening an existing building; they present

the practical method of implementing some strengthening techniques.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Sublimation and Melting Point DeterminationDocument3 pagesSublimation and Melting Point DeterminationRhone RoqueNo ratings yet

- Solving The Simandoux EquationDocument15 pagesSolving The Simandoux Equationjose_rarmenta100% (1)

- REV01 CEILING ELECTRICAL-Model PDFDocument1 pageREV01 CEILING ELECTRICAL-Model PDFSyed Mohd MehdiNo ratings yet

- Furniture Layout Plan - ModelDocument1 pageFurniture Layout Plan - ModelSyed Mohd MehdiNo ratings yet

- Stone Dust & RubberDocument64 pagesStone Dust & RubberSyed Mohd Mehdi100% (1)

- ACI Journal - Evaluation of Ratio Between Splitting Tensile StrengthDocument10 pagesACI Journal - Evaluation of Ratio Between Splitting Tensile StrengthSyed Mohd MehdiNo ratings yet

- Time Extension Letter. (24.09.2016) DocxDocument1 pageTime Extension Letter. (24.09.2016) DocxSyed Mohd MehdiNo ratings yet

- Walls - Types, Features and Design ConceptDocument2 pagesWalls - Types, Features and Design ConceptSyed Mohd MehdiNo ratings yet

- Extra Item Rate HQDocument9 pagesExtra Item Rate HQSyed Mohd MehdiNo ratings yet

- Final Sustainable Sand Mining Management Guidelines 2016Document101 pagesFinal Sustainable Sand Mining Management Guidelines 2016Salil86No ratings yet

- Lighting Trade Price List w.e.f. 1st November, 2015Document80 pagesLighting Trade Price List w.e.f. 1st November, 2015Syed Mohd MehdiNo ratings yet

- Dissertation Phase 1Document33 pagesDissertation Phase 1Syed Mohd Mehdi100% (1)

- 1) MouldingDocument1 page1) MouldingSyed Mohd MehdiNo ratings yet

- A3 JAL NIGAM HEAD Office Last Final 12.08.15-ModelDocument1 pageA3 JAL NIGAM HEAD Office Last Final 12.08.15-ModelSyed Mohd MehdiNo ratings yet

- Green Building Site and Landscape PlanningDocument3 pagesGreen Building Site and Landscape PlanningSyed Mohd MehdiNo ratings yet

- Analysis of RatesDocument5 pagesAnalysis of Ratesakstrmec23No ratings yet

- BUILDING ORIENTATION FOR HOT AND DRY CLIMATESDocument2 pagesBUILDING ORIENTATION FOR HOT AND DRY CLIMATESSyed Mohd Mehdi75% (4)

- Green Roofing - A Step Towards SustainabilityDocument4 pagesGreen Roofing - A Step Towards SustainabilitySyed Mohd MehdiNo ratings yet

- Selection of Green Building MaterialsDocument3 pagesSelection of Green Building MaterialsSyed Mohd MehdiNo ratings yet

- Save Environment With Green BuildingsDocument2 pagesSave Environment With Green BuildingsSyed Mohd MehdiNo ratings yet

- Performance of Various Types of Buildings During EarthquakeDocument5 pagesPerformance of Various Types of Buildings During EarthquakeSyed Mohd Mehdi100% (1)

- Sustainability in Construction & Civil EngineeringDocument4 pagesSustainability in Construction & Civil EngineeringSyed Mohd MehdiNo ratings yet

- Concrete Mix Design Comparison Between BIS and ACIDocument7 pagesConcrete Mix Design Comparison Between BIS and ACIPraveen JainNo ratings yet

- How To Make A Building GreenDocument5 pagesHow To Make A Building GreenSyed Mohd MehdiNo ratings yet

- IS16(Part1):1991 Shellac SpecificationDocument6 pagesIS16(Part1):1991 Shellac SpecificationsdmelNo ratings yet

- Concrete Without CementDocument2 pagesConcrete Without CementSyed Mohd MehdiNo ratings yet

- Concrete Mix DesignDocument5 pagesConcrete Mix Designkom1984No ratings yet

- Cement Chemistry Guide: Types, Properties & ApplicationsDocument9 pagesCement Chemistry Guide: Types, Properties & ApplicationsSyed Mohd MehdiNo ratings yet

- Is 15109 (Part 2) - 2002 Iso 11269 - 1995 - Determination of The Effects of Pollutants On Soil Flora - Part 2 Effects of Chemicals On The Emergence and Growth Higher PlantsDocument10 pagesIs 15109 (Part 2) - 2002 Iso 11269 - 1995 - Determination of The Effects of Pollutants On Soil Flora - Part 2 Effects of Chemicals On The Emergence and Growth Higher PlantsPrapa KaranNo ratings yet

- CV PDFDocument4 pagesCV PDFSyed Mohd MehdiNo ratings yet

- Rules for Rounding Off Numerical Values in Technical DocumentsDocument18 pagesRules for Rounding Off Numerical Values in Technical Documentsসন্দীপ চন্দ্রNo ratings yet

- Determination of Specific Gravity of CementDocument1 pageDetermination of Specific Gravity of CementSyed Mohd MehdiNo ratings yet

- Fluid Mechanics II: Key Concepts of Fluid KinematicsDocument18 pagesFluid Mechanics II: Key Concepts of Fluid KinematicsYousef FarajNo ratings yet

- C-30 Concrete Mix Design RatiosDocument5 pagesC-30 Concrete Mix Design RatiosAtm Tjah Radix LoegoeNo ratings yet

- Strength of Materials 4th Ed by Ferdinand L Singer Andrew Pytel Www07MettkDocument287 pagesStrength of Materials 4th Ed by Ferdinand L Singer Andrew Pytel Www07Mettkluis morales100% (2)

- Hydrostatic Forces on SurfacesDocument12 pagesHydrostatic Forces on SurfacesPajhmanAwghanNo ratings yet

- Motion 1Document3 pagesMotion 1Fenil ShahNo ratings yet

- T3-Revision-Internal-ResistanceDocument22 pagesT3-Revision-Internal-Resistancejordan2gardnerNo ratings yet

- NTMM LAB: MATERIAL REMOVAL RATE TEST ON ULTRASONIC MACHINEDocument23 pagesNTMM LAB: MATERIAL REMOVAL RATE TEST ON ULTRASONIC MACHINETarundeep SinghNo ratings yet

- Review: Modeling Damping in Mechanical Engineering StructuresDocument10 pagesReview: Modeling Damping in Mechanical Engineering Structuresuamiranda3518No ratings yet

- NNPC Recruitment Past Questions GuideDocument64 pagesNNPC Recruitment Past Questions GuidenwabukingzNo ratings yet

- E-CAPS-28 - For CoE (XI) - Chemistry - (Que. - Answer Key)Document3 pagesE-CAPS-28 - For CoE (XI) - Chemistry - (Que. - Answer Key)darling deanNo ratings yet

- EVER11 Final ProgramDocument20 pagesEVER11 Final ProgramAdrian PopNo ratings yet

- Fluid MechanicsDocument29 pagesFluid Mechanicsaminur3rahman-1No ratings yet

- Electromagnetic SpectrumDocument74 pagesElectromagnetic SpectrumGuiller Lanuza100% (1)

- GE Gas Turbine IGV AngleDocument10 pagesGE Gas Turbine IGV AngleSamir BenabdallahNo ratings yet

- Energy in Somaliland Novia Thesis - Editing PDFDocument25 pagesEnergy in Somaliland Novia Thesis - Editing PDFAbdirahmanNo ratings yet

- Mercury Gemini Program Design Survey. NASA ERC Design Criteria Program Stability, Guidance and ControlDocument217 pagesMercury Gemini Program Design Survey. NASA ERC Design Criteria Program Stability, Guidance and ControlBob Andrepont100% (1)

- XI Maths - I Terminal ExamDocument2 pagesXI Maths - I Terminal ExamPurisai Rajamani KumarNo ratings yet

- Compressive Strength of Hydraulic Cement Mortars (Using 2-In. or (50-mm) Cube Specimens)Document9 pagesCompressive Strength of Hydraulic Cement Mortars (Using 2-In. or (50-mm) Cube Specimens)Jesús Luis Arce GuillermoNo ratings yet

- EE221 Solution Problem Set2Document10 pagesEE221 Solution Problem Set2srinivasanNo ratings yet

- Oversized Particles in Emulsified Asphalts (Sieve Test) : Standard Test Method ForDocument2 pagesOversized Particles in Emulsified Asphalts (Sieve Test) : Standard Test Method Forمحمد سليمان بن عمرNo ratings yet

- Topic 4 - Probability (Old Notes)Document22 pagesTopic 4 - Probability (Old Notes)Pradeep100% (1)

- CHY382-01 Ester Hydrolysis Lab ReportDocument5 pagesCHY382-01 Ester Hydrolysis Lab ReportJoshua AunNo ratings yet

- Light Class 7 Science Chapter 15Document11 pagesLight Class 7 Science Chapter 15Gaurav Sethi100% (1)

- Rectilinear Motion and Rotating VesselDocument4 pagesRectilinear Motion and Rotating VesselJack PresadoNo ratings yet

- Flux 10 4 New Features Presentation ValideDocument22 pagesFlux 10 4 New Features Presentation ValideleelNo ratings yet

- Signature RedactedDocument49 pagesSignature RedactedG Pavan KumarNo ratings yet

- GEC 104 Week 1 Lesson 1 Math Modern WorldDocument4 pagesGEC 104 Week 1 Lesson 1 Math Modern WorldJahnna Marie PomaresNo ratings yet

- TCL Air Conditioner Service ManualDocument138 pagesTCL Air Conditioner Service ManualFabian EtcheniqueNo ratings yet