Professional Documents

Culture Documents

Power Transformers Commissioning Procedure

Uploaded by

Sanjay Rout0 ratings0% found this document useful (0 votes)

58 views16 pagescommissioning procedure of PT

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentcommissioning procedure of PT

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

58 views16 pagesPower Transformers Commissioning Procedure

Uploaded by

Sanjay Routcommissioning procedure of PT

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 16

POWER TRANSFORMERS

Category: Electrical Installations, Power Transformers:

2.1:Introduction

Transformer is the most important unit in an electrical distribution networ! All

transformers are sub"ected to thorou#h tests at the manufacturer$s wors before

dispatch to the destination of erection! %ue to limitations in transport& lar#e capacit'

transformers are dis(assembled into )arious components before dispatch! At site& the

transformers are re(assembled with the )arious components lie bushin#s& coolers&

conser)ator etc! and then the internal bod' is dried out to remo)e the surface

moisture sticin# to the paper insulation durin# e*posure at site! As erection of

transformers in)ol)e assembl' of )arious components& pre(test inspection of

transformers ha)e #reater importance than other parts of an electrical s'stem! The

followin# para#raphs e*plain the pre(test inspections+pre(commission checs and the

pre(commission tests to be conducted on power transformers prior to ener#isation of

the unit!

2.2: Recording the Salient parameters

As the ser)ice life of a transformer is e*pected to co)er )er' man' 'ears& it is

necessar' to record the salient parameters of the transformer for future reference!

Rated capacit'& rated )olta#e ratio& connection& mae& maer$s serial number& 'ear of

manufacture& date of completion of erection& insulation dr' out details at site etc!

ma' be documented in a re#ister as permanent record! It is also necessar' to record

the serial number& ratin# and mae of )arious components lie bushin#s& tap

chan#er& tap chan#er control cubicle& cooler control cubicle& coolin# fans& oil pumps&

,uchholt- rela'& temperature indicators& heat e*chan#ers& oil .ow meter& water .ow

meter& pressure #au#es& oil le)el #au#e etc! For eas' reference& the details of the

main bod' and )arious components ma' be recorded in separate pa#es of a re#ister!

This re#ister will ser)e as a record of the ser)ice of the transformer! %etails of

replacement of components ma' also be recorded in the same re#ister!

2.3 Pre-commission checks

,efore commencin# the pre(commission tests& it is necessar' to )isuall' inspect

)arious parts& components and accessories of the transformer and also to conduct

operational chec for )arious protecti)e de)ices! /hec lists ma' be followed for the

)isual inspection and the operational checs so that the pre(commission checs are

conducted in a s'stematic manner and also that no chec+test is omitted! Model

chec lists for 0eneral checs and Functional checs are #i)en at the end of this

chapter in Appendi* 1!2 and 1!1 respecti)el'!

2.3.1 General checks

3i4 0eneral arran#ement

The 0eneral arran#ement of the electrical installation shall be checed for

concurrence with the

scheme appro)ed b' the %epartment of Electrical Inspectorate! Special emphasis

ma' be #i)en to thepfollowin#5

6 si-e of cables

6 si-e of bus bars

6 si-e of bus trunin#

6 si-e of earthin# conductors

6 ade7uac' of )arious clearances

6 spacin# between supports

6 )entilation

6 oil drain facilities

6 8re protection walls

6 8re 8#htin# arran#ements

3ii4 Terminations

The transformer terminal connections ma' be checed for the followin#5

6 .e*ibilit' and area of cross section of .e*ible connections at bushin#s

6 clearances of li)e "umper connections from transformer tan and accessories

6 socet si-e

6 perfection of crimpin#

6 tinnin# of contact surfaces to pre)ent bimetallic action

6 clearances inside cable end bo*

6 clearances of bus bar trunin#

6 conformit' of cable end bo* with the rele)ant IP3 In#ress Protection4 classi8cation

6 correctness of cable #landin# and ade7uac' of cable #land earthin# or pi# tail

6 support of cables at terminations and unsupported len#ths

3iii4 Perfection of connections

/onnections to the followin# shall be checed for proper surface contact& seatin# and

ti#htness!

6 to bushin#s 6 to the tap chan#er 6 to earth leads 6 to control and protecti)e

cables

6 to thermometers

3i)4 Earthin#

/hec the si-e of earthin# conductors& tinnin# of contact surfaces& area of contact

and seatin#& e9ecti)eness of boltin#& socetin#& ri)etin#& weldin# etc! for the earthin#

of the followin#5

6 %uplicate earthin# for neutral and bod'

6 Main tan and top co)er

6 Fan motors

6 Pumps

6 On :oad Tap /han#er 3O:T/4 chamber

6 Tap chan#er dri)in# #ear

6 %i)ertor switch

6 /able #lands+termination

6 Marshallin# bo*

3)4 /ontrol cable connections

/hec the control cable connections between the followin#

6 transformer accessories and marshallin# bo*

6 marshallin# bo* and sub(station panel

6 tap chan#er control cubicle and sub(station panel

3)i4 Radiator

/hec the radiator for release of air and position of )al)es! The )al)es shall be in

open position!

3)ii4 Main conser)ator and O:T/ conser)ator

/hec the oil le)el in the main conser)ator and O:T/ conser)ator! The conser)ator

shut o9 )al)e in the ,uchholt- rela' pipe line shall be in open position!

3)iii4 ,ushin#s

/hec the oil le)el in the bushin#s if sealed bushin#s are used! Release air from

bushin#s if air release plu#s are pro)ided!

3i*4 ,reather

/hec the oil le)el in the oil seal of the breather! /hec the colour of the silica #el in

the breather !

3*4 /ooler units& fans and pumps

/hec fans and pumps for proper mountin#! The number of fans and their position on

the radiators shall be in conformit' with the #eneral arran#ement drawin#s!

6 /hec the direction of rotation of coolin# fans and pumps

6 /hec the direction of oil .ow

6 /hec .ow of water in heat (e*chan#ers

6 Measure the Insulation Resistance 3IR4 of fans and pumps

6 /hec the settin#s for operation of fan motors and oil pumps

6 /hec the cooler unit for correct indication of oil .ow and settin# of the

thermometer

3*i4 Windin# Temperature Indicator 3WTI4 and Oil Temperature Indicator 3OTI4

6 /hec whether thermometer pocet is 8lled with oil

6 /hec whether the connections of the /T for windin# temperature indicator to the

thermometer pocet is properl' made as per the instructions #i)en on the WTI

terminal bo*!

6 /hec whether the contacts of WTI and OTI for alarm and trip are set at re7uired

temperatures dependin# upon ambient temperature and loadin# conditions! For oil

8lled transformers& the ma*imum permissible temperature rise abo)e the ambient

temperature is usuall' taen as ;<=/ for oil and <<=/ for windin#! In the case of cast

resin transformers& the alarm contact of the windin# temperature rela' is usuall'

desi#ned to operate at 2;== / and trip contact at 2>== / for transformers up to 2===

?@A! For hi#her ratin#s& the Temperatures are 2>== / and 2A==/ respecti)el'!

6 /alibration of the WTI+OTI ma' be checed with hot oil! Worin# of the WTI+RT%

repeaters shall be checed at the control room!

3*ii4 ,uchholt- rela's

6 /hec the an#le of mountin# of the ,uchholt- rela' usin# a spirit le)el

6 /hec the .oats for free mo)ement

6 Release air in the ,uchholt- rela'

6 In the case of forced oil cooled transformers& mae sure that the ,uchholt- rela'

does not operate when the pumps are switched on

*iii4 Ma#netic Oil :e)el 0au#e

Mo)e the .oat le)el of the oil le)el indicator up and down between the end positions

to ensure that the mechanism does not #et stuc at an' point! The low oil le)el alarm

of the #au#e shall be checed!

3*i)4 Arcin# horn #ap

/hec arcin# horn #aps of bushin#s for conformit' with standard )alues! The

standard )alues are #i)en below5

3*)4 Tap chan#er

/hec the se7uence of operation of the tap chan#er for the followin#5

6 manual operation

6 local electrical operation

6 remote electrical operation

6 parallel operation

3*)i4 0eneral inspection

i! Beaters in cubicles& conser)ator& etc! shall be checed

ii! An' other alarm+trip& contacts of .ow meters& di9erential pressure #au#es& etc!

shall be checed

iii! In the case of water cooled transformers& the pressure #au#e readin#s on water

and oil sides shall be checed to ensure that the water pressure is less than the oil

pressure! The 7uantit' of oil and water .ow shall not be less than what is speci8ed

i)! The an#le of protection of the li#htnin# shield pro)ided for outdoor transformers

shall be checed! The an#le shall be less than C= de#rees

)! /hec whether roller blocs are pro)ided for the rollers of the transformer

1!C!1 Functional checs

After the )isual inspection is complete& it is necessar' to test proper functionin# of

)arious protecti)e rela's and instruments! The followin# functional checs ma' be

carried out!

2! /hec the operation of the ,uchholt- alarm and trip b' in"ectin# air throu#h the

test pet coc!

1! Test the OTI for alarm and trip!

C! Test the WTI for alarm and trip!

;! /hec the worin# of the WTI + RT% 3Resistance Temperature %e)ice4 repeaters at

the

control room!

<! Test the O:T/ D Oil sur#e rela' for trip!

>! /hec alarm for low oil le)el!

E! /hec the REF rela' for current settin#

A! /hec the di9erential rela' for main and bias settin#s

F! /hec the bac up o)er current and earth fault rela's for current and time!

2=! /hec the o)er )olta#e rela' for )olta#e and time!

22! /hec the instantaneous o)er )olta#e rela' for )olta#e!

21! /hec the o)er .u*in# rela' for )olta#e& fre7uenc' and time!

2C! /hec the cooler unit for

6 o)er current settin# of fans

6 o)er current settin# of oil pumps

6 cooler suppl' failure alarm

6 fan+pump trip alarm

!an' mal( operation of the transformer ,uchholt- rela' when all the oil pumps are

switched on simultaneousl' in forced oil cooled transformers

2.4 Pre-commissioning tests

1!;!2 Insulation Resistance test

Insulation Resistance test is the simplest and most widel' used test to 8nd out the

soundness of insulation between two windin#s or between windin#s and #round!

Insulation resistance is measured b' means of insulation testers popularl' nown as

GMe##er$! The GMe##er$ consists of a %!/ power source 3hand operated or electricall'

dri)en %!/ #enerator or a batter' source with electronic circuit 4 and a measurin#

s'stem! Microprocessor based insulation testers are also now a)ailable! The

insulation test re)eals the condition of the insulation inside the transformer! The

insulation resistance )alues are a9ected b' temperature& humidit' and presence of

dirt on insulators and bushin#s!

Selection of Insulation Testers

Insulation testers with test )olta#e of <==& 2===& 1<== and <=== @ are a)ailable! The

recommended

ratin#s of the insulation testers are #i)en below5

Factors in.uencin# IR )alue

The IR )alue of transformers are in.uenced b'

2! surface condition of the terminal bushin#

1! 7ualit' of oil

C! 7ualit' of windin# insulation

;! temperature of oil

<! duration of application and )alue of test )olta#e

%i9erent IR )alues monitored in transformers

The followin# IR )alues are monitored in transformers

2! windin# to #round! e#! B@ to :@ and earth connected to#ether :@ to B@ and earth!

1! windin# to windin#! e#! B@ to :@

C! all windin#s to #round !e#! B@ and :@ to earth!

Steps for measurin# the IR

2! Shut down the transformer and disconnect the "umpers and li#htnin# arrestors!

1! %ischar#e the windin# capacitance!

C! Thorou#hl' clean all bushin#s

;! Short circuit the windin#s!

<! 0uard the terminals to eliminate surface leaa#e o)er terminal bushin#s!

>! Record the temperature!

E! /onnect the test leads 3a)oid "oints4!

A! Appl' the test )olta#e and note the readin#! The IR! )alue at >= seconds after

application of the test )olta#e is referred to as the Insulation Resistance of the

transformer at the test temperature!

Minimum )alue of IR

The followin# )alues of IR at C=de#! / can be considered to be the minimum

re7uirement for new oil 8lled transformers!

The transformer IR )alues in oil drained condition will be 2< to 1= times more than in

oil 8lled condition!

In.uence of temperature on IR

IR! )alues decrease sharpl' with the rise in temperature of the oil! The followin#

correction factors ma' be used for arri)in# at the IR )alue with di9erence in

temperature!

Interpretation of Insulation Resistance )alue!

While interpretin# IR )alues& importance shall be #i)en to the )ariation of the )alues

o)er a period of time rather than absolute )alues! For conclusi)e anal'sis& use onl'

results from tests performed at identical conditions as IR )alues are a9ected b' )alue

of test )olta#e& temperature of oil& duration of application of )olta#e& humidit'& e*tent

of stress applied etc! IR )alues recorded o)er a period of time ma' be plotted as a

cur)e to stud' the histor' of the insulation resistance! A cur)e showin# a downward

trend indicates a loss of IR due to unfa)ourable conditions such as oildeterioration&

e*cessi)e moisture in paper& deterioration+dama#e to terminal bushin#s etc! A )er'

sharp drop is a cause for concern and action shall be taen to ascertain the e*act

cause of insulation failure and for correcti)e steps!

Points to note

2! Transformers with O:T/ ha)e lower IR )alues when compared with transformers

with o9 circuit tap chan#er!

1! Auto transformers ha)e lower IR when compared to two windin# transformers!

C! Transformer windin#s with #raded insulation ha)e lower IR when compared to full'

insulated windin#s!

;! If the non(measured windin# terminals are not #uarded& the me##er will #i)e a low

readin#!

<! A)oid me##erin# when the transformer is under )acuum!

2.4.2 Dielectric asorption and polarisation inde! tests

%ielectric absorption and polari-ation inde* tests #i)e a #ood indication of the

condition of the insulation! This test is based on the comparison of absorption

characteristics of #ood insulation )ersus absorption characteristics of humid or

contaminated insulation!

Instruments+materials re7uired

Motorised or electronic insulation testers of appropriate )olta#e

Stop watch

:o#arithmic paper

Procedure for test

In this test& a test )olta#e is applied for an e*tended period of time& usuall' thirt'

minutes& usin# a me##er of appropriate )olta#e! The me##er readin#s are taen

e)er' 2= seconds for the 8rst minute and thereafter e)er' minute D up to C= minutes!

The procedure for measurement of IR under para 1!;!2! is followed here! Band

craned instruments are not suitable as continuous application of )olta#e is not

possible with such instruments! Motori-ed or batter' operated insulation testers are

used for the test! A cur)e is drawn showin# the )ariation in the )alue of IR! a#ainst

time on a lo#arithmic paper! The resultant cur)e is nown as dielectric absorption

cur)e! A t'pical dielectric absorption cur)e is shown in 8#! 1!2!

Polarisation Inde* is the ratio of Insulation Resistance at 2= minutes to Insulation

Resistance at 2 minute of application of test )olta#e!

Polarisation Inde! "Insulation Resistance at 1# minutes$Insulation

Resistance at 1 minute.

Interpretation of Polarisation Inde* and %ielectric Absorption /ur)e

A stead' increase in insulation resistance with continuous application of test )olta#e

indicates that the insulation is clean and dr'! Flat or ambulated cur)es demand

reconditionin# of the insulation! Polarisation inde* is a #ood appraisal of the condition

of the insulation!

The followin# are the #uidelines for e)aluatin# the condition of transformer insulation

with respect to Polarisation Inde* )alues!

Polarisation indices with respect to insulation resistance between B@ and :@ H earth &

:@ and B@H earth & earth and B@H:@ are e)aluated to ascertain the real condition of

the transformer insulation!

2.4.3 %&o 'oltage %est (Step 'oltage %est)

This test is an e*tension of the dielectric absorption test! This has been

recommended as a more conclusi)e indication of presence of moisture! Two separate

dielectric absorption tests made at di9erent )olta#es help to detect moisture in the

windin#! The hi#her test )olta#e should be about ; to < times the lower one&

3e#!1<== @ and <== @4 but should not be so hi#h as to dama#e the insulation! A wide

spread between the two dielectric absorption cur)es indicates presence of moisture!

If the insulation resistance )alue decreases substantiall' at a hi#her )olta#e& sa'

more than 1< percent& it is a reasonable indication of presence of moisture in the

insulation s'stem!

2.4.4 *easurement o+ %an delta

@arious insulation resistance tests e*plained abo)e indicate mainl' the surface

conditions and presence of moisture in the insulation! Measurement of loss factor&

commonl' referred to as tan delta re)eals the internal condition of the insulation!

With alternatin# currents& the absorption of the dielectric is intimatel' connected with

the loss of power in the dielectric! This loss within an insulation structure is

associated with the oscillation of polar molecules tr'in# to orient themsel)es with the

alternatin# electric 8eld! Bence current .owin# throu#h the insulation leads the

)olta#e b' some an#le which is sli#htl' less than F= de#rees! This small an#le

between pure capaciti)e current and actual current represented b' d 3delta4 is nown

as loss an#le! The dielectric loss in an insulation is #i)en b' @1 w / tan d and hence

proportional to tan d! If the insulation is perfect& the characteristic of tan delta )ersus

the applied )olta#e is almost a hori-ontal line! If )oids ha)e crept in the insulation

durin# manufacture or ser)ice& there will be substantial increase in tan delta with the

applied )olta#e! Bence the absolute )alues of tan delta in a commerciall'

manufactured e7uipment ha)e comparati)el' little practical si#ni8cance! ,ut the

)ariation in tan delta D ie! % tan delta D with respect to time is )er' important! The

)alues found durin# maintenance testin# should be compared with the initial )alues

recorded before commissionin# the e7uipment! A stable )alue of tan delta is

indicati)e of insulation stabilit' and small increase is indicati)e of normal a#ein#! Tan

delta is

measured usin# tan delta measurin# e7uipment!

2.4., %rans+ormer Ratio %est

Transformer ratio test is conducted to ensure that the turns ratio tall' with the name

plate details and also that tap chan#er connections are done correctl'! Ratio test is

done usin# a transformer turns ratio tester or with )oltmeters! With the turns ratio

tester& the turns ratio is directl' read on the tester for each tap and for each phase of

the windin#! The turns ratio can also be tested b' appl'in# a sin#le phase ac )olta#e

3appro*imatel' 1C=@4 on the B@ side and measurin# the )olta#e on the low )olta#e

side at all tap positions!

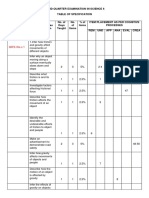

The results of the )olta#e ratio test ma' be recorded in tabular form as #i)en below5

'oltage ratio test ( - .oltmeter )

2.4./ Short circuit current measurement

This test is carried out as a chec for an' loose contact in the tap chan#er& lead

connections etc! In this test& all the C windin#s in the :@ side of the transformer are

short circuited! All contacts in the tap chan#er& lead connections and terminals are

checed for proper contact! From a )ariable )olta#e source& a C phase balanced low

)olta#e a!c suppl' is applied to the B@ windin# at rated tap and the current

measured! The current measured at rated tap should tall' with the calculated )alue

of B@ current at the applied )olta#e!

The )alue of B@ current at the applied )olta#e is calculated as follows5

Repeat the test at di9erent tap positions b' lowerin# and raisin# taps! The current

measured in the B@ windin# should tall' with the calculated )alue of B@ short circuit

current!

Wide di9erence between the measured and calculated )alues of B@ short circuit

current is an indication of loose contact in tap chan#er or lead connections!

2.4.0 *easurement o+ *agnetising current

The ma#netisin# current is measured to test an' fault in the ma#netic circuit and

windin#! The measured )alues are compared with the factor' test )alues! A balanced

three phase ;2<@ ac suppl' is applied to the :@ windin# and the simultaneous current

readin#s of the three phases are taen usin# low ran#e a!c ammeters of the same

accurac' class! For a core t'pe transformer& the middle phase ma#netisin# current

will be appro*imatel' half that in other windin#s! In I'O& %'2 and %'22 connections&

the currents in Gu$ and Gw$ phases will be nearl' double the current in G)$ phase! In a

Id2 connected transformer& currents in G)$ and Gw$ phases will be nearl' e7ual and

the current in Gu$ phase more than that in G)$ and Gw$ phases! In a Id22 connection&

currents in Gu$ and G)$ phases will be nearl' e7ual and the current in Gw$ phase more

than that in Gu$ and G)$ phases! If the measured )alues widel' di9er from the abo)e

)alues or from the factor' test )alues& there is reason to suspect some defect in the

transformer core and the manufacturer ma' be consulted! The

measured )alues of ma#netisin# current ma' be used as bench mars for the ser)ice

life of the transformer! Sample format for recordin# the ma#netisin# current is #i)en

below5

2.4.1 %est +or magnetic alance

This test is done to 8nd out the condition of stacin# of core laminations& ti#htness of

core bolts and perfection of ma#netic circuit! The B@ and :@ sides are isolated b'

remo)in# the bushin# connections! A sin#le phase suppl' of nearl' 1C=@ is applied to

one phase of the star connected windin# and the induced )olta#e in other two phases

are measured! The )olta#e ma' preferabl' be applied on the B@ windin#& as appl'in#

)olta#e to :@ windin# ma' induce )er' hi#h )olta#e in the B@ windin#! If the B@

windin# is connected in delta& the test ma' be conducted on the :@ side after tain#

necessar' precautions a#ainst accidental contact with the B@ bushin#s!

When the )olta#e is applied to the middle phase& the induced )olta#e measured on

the two other phases should be appro*imatel' e7ual! Where the )olta#e is applied to

an e*treme phase& the induced )olta#e on the middle phase should be substantiall'

hi#h when compared to the )olta#e induced in the other e*treme phase! In each test&

the sum of the induced )olta#es in two phases should be nearl' e7ual to the applied

)olta#e!

Tests ma' be carried out b' connectin# a series lamp 3sa' 1< watts4 at suppl' side to

restrict hi#her current& if an'! If the series lamp #lows bri#htl' or the induced )olta#e

readin#s in di9erent phases indicate -ero or )er' low )alue or if the induced )olta#es

show abnormal )ariation from the e*pected )alues& fault in the windin# can be

suspected!

For measurin# the )olta#es& hi#h impedance )oltmeter lie di#ital multimeter should

be used! The test ma' be repeated b' appl'in# )olta#e to the second and third

phases and measurin# the induced )olta#es in other phases! When the ma#netic

circuit is balanced& there would be s'mmetr' in the )alue of measured induced

)olta#es! The measured )olta#es ma' be recorded in the sample format #i)en below5

2.4.2 Phasor Group %est

Phasor relationship between B@ and :@ )olta#es is checed b' this test! Without

earthin# the windin# neutral points& interconnect one phase of B@ windin# D sa' 2J D

to the correspondin# phase of :@ windin# (1J and appl' a balanced C phase low

)olta#e to the B@ windin#! The phase se7uence of the suppl' should be the same as

the speci8ed phase se7uence of the transformer windin#! /onnections for %'22 and

%'2 transformers and the correspondin# )ector #roupin#s are #i)en in 8#ures 1!1

and 1!C! Measure the )olta#e between the primar' and the secondar' terminals! The

followin# re7uirements shall be ful8lled dependin# on the )ector #roup of the

transformers!

If two transformers are a)ailable for test& the phasor #roups can be compared easil'

b' appl'in# )olta#e from same source to identical bushin#s on the B@ side and b'

measurin# the )olta#e between identicall' mared terminals on the :@ sides with

sin#le interconnection between either the neutrals or an' one phase!

2.4.1# %est +or %rans+ormer 3il

Transformer oil is of petroleum ori#in and is used as a coolant and dielectric in

transformers! Transformer oil in #ood condition and conformin# to rele)ant standards

will pre)ent deterioration of transformer insulation! As the transformer oil is& to some

e*tent& e*posed to air at site& it is alwa's necessar' to test the oil for )arious

characteristics before the transformer is put to ser)ice! As the )arious tests for

transformer oil are laborator' tests& details of these tests are be'ond the scope of

this boo! Test procedures for )arious tests are #i)en in the rele)ant standards of ,IS&

list of which are #i)en at the end of this chapter in para 1!>!

From the point of )iew of 8eld tests& what is important is the method of and

precautions for collectin# the transformer oil and the limit )alues of )arious

characteristics! Bowe)er a rou#h test on the moisture content of the oil can be made

at site b' conductin# a simple test& popularl' called the cracle test! In this test& a

piece of steel tube of appro*imatel' 1< mm dia is closed at one end and the closed

end is heated to "ust under red hot ! Now the hot end is plun#ed into the oil sample

with the ear close to the open end! If the oil contains lar#e 7uantit' of moisture& a

sharp cracle will be heard! %r' oil will onl' si--le!

Samplin# of oil D 0eneral precautions

Since the results of the tests prescribed for transformer oil lar#el' depend on the

impurities in the sample sent for testin#& it is essential to eep the oil free from an'

contamination! The followin# precautions shall be taen while collectin# samples of

transformer oil!

2! For collectin# the sample& #lass containers with #lass stoppers are preferred o)er

metal t'pe! Wa* shall not be used for sealin# the containers! The stopper ma' be

co)ered with a piece of cloth paced with silica #el!

1! The container ma' be warmed to abo)e the ambient air temperature in order to

a)oid an' condensation of moisture!

C! ,efore collectin# the sample& all e7uipments used for handlin# the oil must be

washed with clean transformer oil! The oil used for washin# must be discarded!

;! Fle*ible steel hose ma' be used for handlin# the oil! Some inds of s'nthetic hoses

are also suitable! Ordinar' rubber hose should not be used as oil dissol)es the

sulphur in the rubber and thereb' #ets contaminated! The hose used must be clean

and free from dust& rust and scale!

<! The operator shall tae special care to see that his hands do not come in contact

with the sample or the internal surface of the container!

>! The transformer oil shall be protected a#ainst all inds of li#ht radiation durin#

transportation and stora#e!

Samplin# procedure

2! Remo)e the )al)e shield if 8tted!

1! Remo)e all )isible dirt and dust from the )al)e with a lintfree clean cloth!

C! Run o9 suKcient 7uantit' of oil( sa' 2 litre D to eliminate an' contaminant that

mi#ht ha)e accumulated in the drain coc!

;! Rinse the container with the oil bein# sampled!

<! Fill the container b' allowin# the oil to .ow a#ainst the side of the containers to

a)oid air traps!

>! /lose and seal the container and store the samples in a dar place!

E)aluation of test results

Three samples of oil from the top and bottom of the tan are tested for )arious

characteristics! For transformers of capacit' below 2 M@A and where )er' hi#h

reliabilit' is not e*pected the 8)e characteristics #i)en in table 1!2 shall be in)ariabl'

tested and it shall be ensured that the test results are within the minimum+ma*imum

limits!

In the case of transformers where )er' hi#h reliabilit' is re7uired and in all cases

where the capacit' is 2 M@A or abo)e& the additional characteristics #i)en in table 1!1

shall also be tested! The test results shall be within the #i)en limits!

2.4.11 Rela- %ests

All protecti)e rela's & /Ts& PTs and control wirin# shall be tested as e*plained under

the chapter for protecti)e rela's! The rela's shall be set to suit the operatin#

conditions and to coordinate with other sections of the s'stem! The rela' test results

shall be documented for future reference!

2., 4ommissioning

After completin# all the pre(commission tests #i)en under section 1!;& the pre(test

checs under section 1!C are redone once a#ain! All the protecti)e rela's and circuit

breaers are tested for proper worin#! The rela' settin#s are ept at a low )alue so

that the transformer will #et isolated if there is an' internal fault! Allow a settlin#

time of at least 1; hours for oil and then release air from all points! Now the

transformer ma' be test char#ed from the incomin# side on no(load and operated for

about two hours!

Obser)e the transformer hum for an' abnormalit'! An' )ibration or abnormal

ma#neti-in# current ma' also be obser)ed! After continuous operation for about two

hours& isolate the transformer and chec the #as operated ,uchholt- rela' for an'

#as collection! An' dissol)ed air or air bubble that ma' be collected in the ,uchholt-

rela' ma' be released and the transformer char#ed a#ain on no load! All connected

instruments ma' be checed for an' abnormal indication! Now #raduall' load the

transformer to full capacit' and eep it under constant obser)ation for at least 1;

hours of operation! /hec the oil and windin# temperature at full load and compare

with factor' test )alues! After four or 8)e da's of ser)ice& test the oil for )arious

characteristics& especiall' for ,%@! An' #as collection in the ,uchholt- rela' ma' also

be obser)ed! If the test results and obser)ations are found normal& the transformer

ma' be cleared for re#ular ser)ice! After the transformer is put in ser)ice for some

wees with normal worin# temperature& all sealed "oints shall be re (ti#htened!

The results of the )arious tests shall be recorded and ept in the station as a

permanent record for future reference! %etails such as place of erection& date of

commissionin#& protection #i)en to the transformer etc! ma' be furnished to the

manufacturer after commissionin#!

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Document2014 11 14 - 121GOODocument34 pagesDocument2014 11 14 - 121GOOSanjay RoutNo ratings yet

- 03 BJEF 15-21-28-S - Area LightingDocument2 pages03 BJEF 15-21-28-S - Area LightingSanjay RoutNo ratings yet

- Transmission LicenseDocument3 pagesTransmission LicenseSanjay RoutNo ratings yet

- SSR-2014-15 of Govt. of A.P.Document142 pagesSSR-2014-15 of Govt. of A.P.Vishnu VardhanNo ratings yet

- Report RajasthanDocument10 pagesReport RajasthanSanjay RoutNo ratings yet

- Transmission LicenseDocument3 pagesTransmission LicenseSanjay RoutNo ratings yet

- Smp-12 Testing of Induction Motor-21Document2 pagesSmp-12 Testing of Induction Motor-21Sanjay RoutNo ratings yet

- DG Inspection Orissa GazetDocument13 pagesDG Inspection Orissa GazetSanjay RoutNo ratings yet

- GETCO Substation SpecDocument76 pagesGETCO Substation SpecSaraswatapalit100% (1)

- Totl StationDocument8 pagesTotl StationSanjay RoutNo ratings yet

- Change Over Procedure From Wesco Supply To DG Supply and Vice VersaDocument2 pagesChange Over Procedure From Wesco Supply To DG Supply and Vice VersaSanjay Rout100% (2)

- Project Time ScheduleDocument2 pagesProject Time ScheduleSanjay RoutNo ratings yet

- DG Set and PanelDocument1 pageDG Set and PanelSanjay RoutNo ratings yet

- Transmission Line Planning, Coordination & MonitoringDocument3 pagesTransmission Line Planning, Coordination & MonitoringSanjay RoutNo ratings yet

- A Power Transmission Tower Consists of The Following PartsDocument3 pagesA Power Transmission Tower Consists of The Following PartsSanjay RoutNo ratings yet

- Standard Maintenance Procedure: Ferro Chrome Plant Doc - No VSL/FCP/SMP/7.5.1/01Document3 pagesStandard Maintenance Procedure: Ferro Chrome Plant Doc - No VSL/FCP/SMP/7.5.1/01Sanjay RoutNo ratings yet

- Smp-15 HT SystemDocument7 pagesSmp-15 HT SystemSanjay RoutNo ratings yet

- Quoted Price 1Document1 pageQuoted Price 1Sanjay RoutNo ratings yet

- Quoted PriceDocument15 pagesQuoted PriceSanjay RoutNo ratings yet

- PlatformDocument61 pagesPlatformAnonymous 48jYxR1CNo ratings yet

- Holiday Celebration Simple Corporate InvitationDocument1 pageHoliday Celebration Simple Corporate InvitationSanjay RoutNo ratings yet

- Change Over Procedure From Wesco Supply To DG Supply and Vice VersaDocument2 pagesChange Over Procedure From Wesco Supply To DG Supply and Vice VersaSanjay Rout100% (2)

- Baripadha MendhasalDocument92 pagesBaripadha MendhasalSanjay RoutNo ratings yet

- Transmission Line Planning, Coordination & MonitoringDocument3 pagesTransmission Line Planning, Coordination & MonitoringSanjay RoutNo ratings yet

- DocsDocument90 pagesDocsSanjay RoutNo ratings yet

- Zeck Eng FDocument48 pagesZeck Eng FAnonymous ExWAN2xjFJNo ratings yet

- IVRCL ManufacturingDocument37 pagesIVRCL ManufacturingSanjay RoutNo ratings yet

- To Avoid Accidents PLZ Follow This PointsDocument3 pagesTo Avoid Accidents PLZ Follow This PointsSanjay RoutNo ratings yet

- 33 KV T.P Analysis 14.01.2011Document2 pages33 KV T.P Analysis 14.01.2011Sanjay RoutNo ratings yet

- 5 MVA Trans EstimateDocument2 pages5 MVA Trans EstimateSanjay RoutNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Overview of Vertical Axis Wind Turbine VAWT Is OneDocument6 pagesOverview of Vertical Axis Wind Turbine VAWT Is OneAjeem DurraniNo ratings yet

- Electricity AssignmentDocument1 pageElectricity AssignmentSHANKARJEENo ratings yet

- Chem Form-6-Sem-1-01 PDFDocument44 pagesChem Form-6-Sem-1-01 PDFXuerong ChinNo ratings yet

- Composites For Machine Tool Beds: National Institute of Technology Rourkela (India)Document64 pagesComposites For Machine Tool Beds: National Institute of Technology Rourkela (India)kunalNo ratings yet

- Springs and The Balance WheelDocument2 pagesSprings and The Balance WheelNiels Kjaer-PedersenNo ratings yet

- Class: 9 Subject: Physics Chapter: Motion DPP No # 2: Questions Based On Graphical Representation of MotionDocument3 pagesClass: 9 Subject: Physics Chapter: Motion DPP No # 2: Questions Based On Graphical Representation of MotionshashwatNo ratings yet

- High Voltage Engineering by DR Suhail KhokharDocument43 pagesHigh Voltage Engineering by DR Suhail KhokharSuhail KhokharNo ratings yet

- Elevated Water Tank Design SpreadsheetDocument12 pagesElevated Water Tank Design SpreadsheetRuben Dario Posada B100% (3)

- Som QB PDFDocument32 pagesSom QB PDFvasanthmech092664No ratings yet

- What Is Philosophy For by Mary MidgleyDocument233 pagesWhat Is Philosophy For by Mary Midgleyлли про80% (5)

- Mechanical Properties of Undoped GaAs III Indentation ExperimentsDocument12 pagesMechanical Properties of Undoped GaAs III Indentation Experimentskelsiu1No ratings yet

- Maclaurin and Taylors SeriesDocument2 pagesMaclaurin and Taylors SeriesdssrwrtgwtgNo ratings yet

- Transmission Electron Microscopy and Its ApplicationsDocument12 pagesTransmission Electron Microscopy and Its ApplicationsMoayad TeimatNo ratings yet

- Power Electronics Prof. B.G. Fernandes Department of Electrical Engineering Indian Institute of Technology, Bombay Lecture - 15Document20 pagesPower Electronics Prof. B.G. Fernandes Department of Electrical Engineering Indian Institute of Technology, Bombay Lecture - 15sunitha vNo ratings yet

- Numerical Investigation of The Hydrothermal Performance of Novel Pin-FinDocument17 pagesNumerical Investigation of The Hydrothermal Performance of Novel Pin-FinTahmid SadiNo ratings yet

- Unit 4 Self Generating Sensors PDFDocument57 pagesUnit 4 Self Generating Sensors PDFHingula100% (1)

- Tesla Coils Plans PDFDocument153 pagesTesla Coils Plans PDFroseli100% (3)

- Sci 09 Sample QPDocument8 pagesSci 09 Sample QPkvindhraNo ratings yet

- Bulk Modulus of Air Content Oil in A Hydraulic CylinderDocument11 pagesBulk Modulus of Air Content Oil in A Hydraulic CylinderCamilo ManriqueNo ratings yet

- Full PDFDocument445 pagesFull PDFعلي مؤيد مطشر صدامNo ratings yet

- Smscom Manual Twin Controller Pro MK2 2017Document6 pagesSmscom Manual Twin Controller Pro MK2 2017saborespurpuraagroNo ratings yet

- Cengage Learning Stock Report 28th October 2014Document48 pagesCengage Learning Stock Report 28th October 2014kkp0650No ratings yet

- Underground Transmission Lines For High Power AC and DC TransmissionDocument4 pagesUnderground Transmission Lines For High Power AC and DC TransmissionSelf Study WorldNo ratings yet

- Stress-Constrained Topology Optimization With Design-Dependent LoadingDocument15 pagesStress-Constrained Topology Optimization With Design-Dependent LoadingLejla SelimovicNo ratings yet

- 3rd PT Science 6Document14 pages3rd PT Science 6Dhines CBNo ratings yet

- Dipole Antenna Solution2Document44 pagesDipole Antenna Solution2David GNo ratings yet

- Techteach - No Simview DC Motor IndexDocument3 pagesTechteach - No Simview DC Motor IndexDiabloNo ratings yet

- CHEM Part2Document90 pagesCHEM Part2Reiniel Cirujano AntonioNo ratings yet

- Meherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 27Document5 pagesMeherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 27amir moniriNo ratings yet

- Graphene Nano-Ribbon Waveguides: JORCEP, COER, Zhejiang University, Hangzhou 310058, ChinaDocument12 pagesGraphene Nano-Ribbon Waveguides: JORCEP, COER, Zhejiang University, Hangzhou 310058, Chinamsa_imegNo ratings yet