Professional Documents

Culture Documents

Bridge Formwork Without Anchors

Uploaded by

Mirjana Veljkovic100%(4)100% found this document useful (4 votes)

580 views35 pagesFormwork

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFormwork

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(4)100% found this document useful (4 votes)

580 views35 pagesBridge Formwork Without Anchors

Uploaded by

Mirjana VeljkovicFormwork

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 35

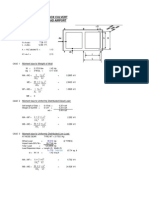

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 1 von 35

Calculation example

for bridge formwork

without anchors

Static department

static-amstetten@doka.com

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 2 von 35

List of contents

Calculation example for bridge formwork without anchors ................................... 1

Overview of the structure and calculation steps ............................................................ 3

Load assumption ........................................................................................................... 4

Design of parts .............................................................................................................. 5

1. Verification of plywood 3-SO 21mm ........................................................................ 5

2. Verification of H20 beam at the bottom formwork.................................................... 6

3. Verification of H20 beam for lateral panels.............................................................. 7

4. Verification of WS10 ............................................................................................... 8

5. Verification of spindle strut T7 (S1) ....................................................................... 10

6. Verification of vertical WS10 ................................................................................. 11

7. Verification of spindle strut T7 (S2) ....................................................................... 13

8. Verification of WS10 ............................................................................................. 14

9. Verification of spindle strut T7 (S3) ....................................................................... 16

10. Verification of vertical WS10 ................................................................................. 17

11. Verification of spindle strut T7 (S4) ....................................................................... 18

12. Verification of horizontal profile WS10 .................................................................. 19

Annex A ....................................................................................................................... 21

A.1 Verification of H20 beam at the bottom formwork .................................................. 21

A.2 Verification of H20 beam for lateral panels ............................................................ 23

A.3 Verification of WS10 .............................................................................................. 25

A.4 Verification of vertical WS10 .................................................................................. 27

A.5 Verification of WS10 .............................................................................................. 29

A.6 Verification of vertical WS10 .................................................................................. 31

A.7 Verification of horizontal profile WS10 ................................................................... 33

Remark: This calculation example doesnt contain the verification of the scaffolding

beneath the superstructure.

Anmerkung: Bei diesem Berechnungsbeispiel erfolgt kein Nachweis des Traggerstes

unter dem Oberbau.

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 3 von 35

Bridge formwork

Overview of the structure and calculation steps

12

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

1

2

3

4 8

5

6

10

9

7

11

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 4 von 35

Load assumption

Permanent actions (self-weight):

Formwork Top 50: 0,65 [kN/m]

(plywood, wooden parts, steel parts)

Posts and steel parts: 0,50 [kN/m]

Handrail post and planks: 0,50 [kN/m]

Variable imposed actions (variable loads):

Concrete weight: 25 [kN/m]

Concrete pressure: 50 [kN/m]

Live load while pouring: 1,50 [kN/m] < 10% of the concrete weight

(acc. EN 12812): + 0,75 [kN/m] for construction operations loading

O 2,50 [kN/m]

Live load on platform (acc. EN12812): 1,50 [kN/m]

Wind load (acc. DIN1055 part 4): 1,04 [kN/m]

(max. wind, height above ground <20m)

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 5 von 35

Design of parts

1. Verification of plywood 3-SO 21mm

(Nachweis Schalhaut im Betonbalkenbereich)

concrete pressure: max. 50 [kN/m]

max.M < perm. M

max.Def. < perm. Def. =l/500

The 3-SO 21mm has to be checked in all significant situations!

(Nachweis der Schalhaut ist in den magebenden Lastfllen zu fhren!)

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 6 von 35

2. Verification of H20 beam at the bottom formwork

(Nachweis H20 im Betonbalkenbereich, Schalung der Balkenunterseite)

Load assumption for influence e= 0,24m

(Lastannahme fr 0,24m Einflussbreite)

Live load while pouring (Nutzlast whrend Betonage):

Concrete weight (Betongewicht):

m kN m x m kN x m C

w

/ 60 , 9 24 , 0 / 25 60 , 1

Dead load (Eigengewicht):

m kN m x m kN D

l

/ 16 , 0 24 , 0 / 65 , 0

System:

max.Shear < perm. Shear

max.M < perm. Moment

max.Def. < perm. Deformation

For detailed calculation see Annex A, A.1

Pv =max. reaction force

for the WS10

(max. Auflagerreaktion WS10)

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

m kN m x m kN L

l

/ 60 , 0 24 , 0 / 5 , 2

C

w

=9.60kN/m

L

l

=0.60kN/m

D

l

=0.16kN/m

14.76 kN 14.76 kN

675mm

1500mm 675mm

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 7 von 35

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

3. Verification of H20 beam for lateral panels

(Nachweis H20 im Betonbalkenbereich, seitliche Schalung)

Load assumption for influence e= 0,284m

(Lastannahme fr 0,284m Einflussbreite)

Concrete pressure (Betondruck):

m kN m x m x m kN C

p

/ 31 , 9 284 , 0 31 , 1 / 25

System:

max.Shear < perm. Shear

max.M < perm. M

max.Def. < perm. Def.

The H20 has to be checked in all determining situations!

(Nachweis des H20 ist in den ausschlaggebenden Lastfllen zu fhren!)

For detailed calculation see Annex A, A.2

C

p

=9.31kN/m

13.27 kN 13.27 kN

675mm

1500mm 675mm

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 8 von 35

4. Verification of WS10

(Nachweis WS10)

The worst condition for WS10 see tipbeam calculation no. 2. H20 (concrete beam bottom formwork)

before.

(WS10 erhlt den grten Lasteinfluss wie in der vorherigen Tipbeam Berechnung Nr. 2. H20 (Schalung der

Balkenunterseite) ersichtlich).

max. influence of the WS10: (max. Einfluss von WS10)

max. reaction of H20 divided by max. linear load of H20.

(max. Auflagerreaktion dividieren durch die gesamte Linienlast).

l w l

D C L Pv e :

max

m m kN m kN m kN kN e 42 , 1 / 16 , 0 / 60 , 9 / 60 , 0 : 76 , 14

max

Load assumption for WS10: e= 1,42m

(Lastannahme fr WS10: e = 1,42m)

Live load while casting (Nutzlast whrend Betonage):

1,5kN/m < 1,35kN/m = 0,75kN/m + 0,10 x 25kN/m x 0,28m)/2 + (0,20m

l

L

m kN m x m kN L

l

/ 13 , 2 42 , 1 / 50 , 1

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 9 von 35

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Live load and dead load platform (Nutzlast und Eigengewicht Arbeitsbhne):

m kN m x m kN m kN L

p l

/ 84 , 2 42 , 1 / 50 , 0 / 50 , 1

Concrete weight 1 (Betongewicht 1) (0,20m):

m kN m x m kN x m C

w

/ 10 , 7 42 , 1 / 25 20 , 0

1

Concrete weight 2 (Betongewicht 2) (0,282m):

m kN m x m kN x m C

w

/ 01 , 10 42 , 1 / 25 282 , 0

2

Dead load (Eigengewicht):

m kN m x m kN D

l

/ 92 , 0 42 , 1 / 65 , 0

Hand rail (Schutzgelnder):

kN m x m kN H

R

71 , 0 42 , 1 / 50 , 0

Bending moment from wind (Moment aus Windlast):

kNm

m

x m x m x x m kN M

W

36 , 1

2

922 , 1

42 , 1 922 , 1 50 , 0 / 04 , 1

System:

max. Shear < perm. Shear

max. M < perm. M

max.Def. < perm. Def. the serviceability is given

For detailed calculation see Annex A, A.3

vertical load of

spindle strut S1

vertical load of

WS10 = Pv1

L

lp

=2.84kN/m

11.33 kN 5.50 kN

780mm

113mm

1171mm

C

w1

=7.10kN/m

C

w2

=10.01kN/m

L

l

=2.13kN/m

D

l

=0.92kN/m

H

R

=0.71kN

M

W

=1.36kNm

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 10 von 35

5. Verification of spindle strut T7 (S1)

(Nachweis der Spindelstrebe T7 (S1))

The inclined position of the WS10 is not considered. (Die Neigung des WS10 wird nicht bercksichtigt).

kN S

v

33 , 11

1

kN x kN S

h

28 , 0 4 , 1 tan 33 , 11

1

kN kN S 33 , 11 4 , 1 cos : 33 , 11

1

Spindle strut S1(T7):

Length: L=1,61m

max. Pspindle strut T7 < perm. Pspindle strut T7

11,33kN < 70kN

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 11 von 35

6. Verification of vertical WS10

(Nachweis des vertikalen WS10)

The inclined position of the WS10 is not considered. The spindle S2 is used as the

second bearing of the WS10.

(Die Neigung des WS10 wird nicht bercksichtigt. Die Spindelstrebe S2 dient als zweites Auflager des WS10.)

kN S

h

28 , 0 = the horizontal component of the spindle strut T7 (S1) see the calculation of T7

before.(= die horizontale Komponente aus der Spindelstrebe T7 (S1) wie in der Berechnung von T7 ersichtlich).

Concrete pressure (Betondruck):

m kN m x m x m kN C

p

/ 58 , 58 42 , 1 65 , 1 / 25

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 12 von 35

Force resulting from wind on the hand rail (Kraft aus Windlast auf das Schutzgelnder):

kN m x m x x m kN R

W

11 , 1 42 , 1 497 , 1 50 , 0 / 04 , 1

Wind load on the formwork (Windlast auf die Schalung):

m kN m x x m kN W

L

/ 48 , 1 42 , 1 0 , 1 / 04 , 1

System:

max. Shear < perm. Shear

max. M < perm. M

max.Def. < perm. Def.

For detailed calculation see Annex A, A.4

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

horizontal load of

spindle strut S2

horizontal load of

spindle strut S2

W

L

=1. 48kN/m

43.56 kN

558mm 320mm 1175mm

R

W

=1.11kN

C

p

=58.58kN/m

S

h

=0.28kN

9.67 kN

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 13 von 35

7. Verification of spindle strut T7 (S2)

(Nachweis der Spindelstrebe T7 (S2))

Horizontal force resulting from the calculation of vertical WS10. (Horizontale Kraft aus der Berechnung von WS10

vertikal ersichtlich).

kN S

h

56 , 43

2

kN kN S 15 , 60 6 , 43 cos : 56 , 43

2

Spindle strut S2 (T7):

Length: L=1,58m

max. Pspindle strut T7 < perm. Pspindle strut T7

60,15kN < 70kN

Vertical load on the horizontal WS10

(Vertikallast auf den WS10):

kN x kN S

v

70 , 44 0 , 42 cos 15 , 60

2

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 14 von 35

8. Verification of WS10

(Nachweis WS10)

Load assumption for WS10: e= 1,42m

(Lastannahme fr WS10: e = 1,42m)

Live load while pouring (Nutzlast Betonage):

1,5kN/m < 1,41kN/m = 0,75kN/m + 0,10 x 25kN/m x 0,275m)/2 + (0,25m

l

L

m kN m x m kN L

l

/ 13 , 2 42 , 1 / 50 , 1

Concrete weight 3 (Betongewicht 3) (0,275m):

m kN m x m kN x m C

w

/ 76 , 9 42 , 1 / 25 275 , 0

3

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 15 von 35

Concrete weight 4 (Betongewicht 2) (0,25m):

m kN m x m kN x m C

w

/ 88 , 8 42 , 1 / 25 25 , 0

4

Dead load (Eigengewicht):

m kN m x m kN D

l

/ 92 , 0 42 , 1 / 65 , 0

System:

5.54 kN

max. Shear < perm. Shear

max. M < perm. M

max.Def. < perm. Def. the serviceability is given

For detailed calculation see Annex A, A.5

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

vertical load of

WS10 = Pv3

C

w4

=8.88kN/m

5.54 kN

1148mm 598mm

C

w3

=9.76kN/m

15.42 kN

vertical load of

spindle strut S3

0.00 kN

L

l

=2.13kN/m D

l

=0.92kN/m

C

w4

=8.88kN/m

C

p

=58.58kN/m

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 16 von 35

9. Verification of spindle strut T7 (S3)

(Nachweis der Spindelstrebe T7 (S3))

The inclined position of the WS10 is not considered.

(Die Neigung des WS10 wird nicht bercksichtigt).

kN S

v

42 , 15

3

kN x kN S

h

65 , 0 4 , 2 tan 42 , 15

3

kN kN S 43 , 15 4 , 2 cos : 42 , 15

3

Spindle strut S3 (T7):

Length: L=1,47m

max. Pspindle strut T7 < perm. Pspindle strut T7

15,43kN < 70kN

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 17 von 35

10. Verification of vertical WS10

(Nachweis des vertikalen WS10)

The inclined position of WS10 is not considered. The spindle strut S4 and the horiz. WS10

are bearings of this vertical WS10 (because of the symmetry of the cross-section).

(Die Neigung des WS10 wird nicht bercksichtigt. Die Spindelstrebe S4 und der horizontale WS10 sind Auflager dieses vertikalen

WS10. (aufgrund der Symmetrie des Querschnitts))

kN S

h

65 , 0

3

= the horizontal component of spindle strut T7 (S3) see the calculation of T7

before.(= die horizontale Komponente aus der Spindelstrebe T7 (S3) wie in der Berechnung von T7 ersichtlich).

Concrete pressure (Betondruck):

m kN m x m x m kN C

p

/ 76 , 9 42 , 1 275 , 0 / 25

1

m kN m x m x m kN C

p

/ 16 , 57 42 , 1 61 , 1 / 25

2

System:

For detailed calculation see Annex A, A.6

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

horizontal load of

spindle strut S4

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

C

p2

=57.16kN/m

3.86 kN

501mm 583mm

C

p1

=9.76kN/m

34.45 kN 5.61 kN

523mm 409mm

S

3h

=0.65kN/m

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 18 von 35

11. Verification of spindle strut T7 (S4)

(Nachweis der Spindelstrebe T7 (S4))

Horizontal force see calculation of vertical WS10 before. (Horizontale Kraft aus der Berechnung von WS10 vertikal

ersichtlich).

kN S

h

45 , 34

4

kN kN S 10 , 45 2 , 40 cos : 45 , 34

4

Spindle strut S2 (T7):

Length: L=1,43m

max. Pspindle strut T7 < perm. Pspindle strut T7

45,10kN < 70kN

Vertical load on the horizontal WS10

(Vertikallast auf den WS10):

kN x kN S

v

16 , 31 3 , 46 cos 10 , 45

4

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 19 von 35

12. Verification of horizontal profile WS10

(Nachweis des horizontalen WS10- Profils)

Load assumption for continuous WS10 profile: e= 1,42m

(Lastannahme fr WS10 Profil: e = 1,42m)

Hand rail (Schutzgelnder):

kN m x m kN H

R

71 , 0 42 , 1 / 50 , 0

Vertical load spindle strut S1 (Vertikallast Spindelstrebe S1):

kN S

v

33 , 11

1

Vertical load spindle strut S2 (Vertikallast Spindelstrebe S2):

kN S

v

70 , 44

2

Vertical load spindle strut S3 (Vertikallast Spindelstrebe S3):

kN S

v

42 , 15

3

Vertical load spindle strut S4 (Vertikallast Spindelstrebe S4):

kN S

v

16 , 31

4

Reaction of the WS10 at the cantilever (Auflagerreaktion aus dem Nachweis WS10 im Kragarmbereich):

kN P

v

50 , 5

1

Reaction of the horizontal WS10 at the center of the bridge (Auflagerreaktion aus dem Nachweis horizontaler

WS10 in der Mitte des Brckenquerschnitts):

kN P

v

54 , 5

3

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 20 von 35

Concrete weight 1 (Betongewicht 1):

m kN m x m x m kN C

w

/ 01 , 10 42 , 1 282 , 0 / 25

1

Concrete weight 2 (Betongewicht 2):

m kN m x m x m kN C

w

/ 65 , 10 42 , 1 30 , 0 / 25

2

Concrete weight 3 (Betongewicht 3):

m kN m x m x m kN C

w

/ 80 , 56 42 , 1 60 , 1 / 25

3

Concrete weight 4 (Betongewicht 4):

m kN m x m x m kN C

w

/ 76 , 9 42 , 1 275 , 0 / 25

4

Live load 1 while pouring (Nutzlast Betonage 1):

m kN m x m kN L

l

/ 13 , 2 42 , 1 / 50 , 1

1

Live load 2 while pouring (Nutzlast Betonage 2):

m kN m x m kN L

l

/ 55 , 3 42 , 1 / 50 , 2

2

Dead load 1 inclined formwork (Eigengewicht 1 geneigte Schalung):

kN m x m x m kN D

l

24 , 1 44 , 1 32 , 1 / 65 , 0

1

Dead load 2 inclined formwork (Eigengewicht 2 geneigte Schalung):

kN m x m x m kN D

l

19 , 1 42 , 1 29 , 1 / 65 , 0

2

Dead load formwork (Eigengewicht Schalung):

m kN m x m kN D

l

/ 92 , 0 42 , 1 / 65 , 0

Dead load (Eigengewicht):

m kN m x m kN D

l

/ 71 , 0 42 , 1 / 50 , 0

System:

For detailed calculation see Annex A, A.7

Remark: The supporting reactions of this system are the loads per leg for the

scaffolding beneath, which is not considered in this calculation example.

(Anmerkung: Die Auflagerreaktionen dieses Systems sind die Stiellasten fr die darunterliegende

Tragkonstruktion, die in diesem Beispiel nicht berechnet wird.)

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 21 von 35

Annex A

A.1 Verification of H20 beam at the bottom formwork

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

L

l

=

C

w

=

D

l

=

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 22 von 35

Pv =max. reaction force

for the WS10

(max. Auflagerreaktion WS10)

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 23 von 35

A.2 Verification of H20 beam for lateral panels

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 24 von 35

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 25 von 35

A.3 Verification of WS10

HR =

MW =

LL =

LLP =

Cw1 =

DL =

Cw2=

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 26 von 35

vertical load of

spindle strut S1

vertical load of

WS10 = Pv1

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 27 von 35

A.4 Verification of vertical WS10

from spindle strut S1: Sh=

Rw=

C

P

=

W

L

=

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 28 von 35

horizontal load of

spindle strut S2

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 29 von 35

A.5 Verification of WS10

L

L

=

C

w3

=

C

w4

=

D

L

=

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 30 von 35

vertical load of

WS10 = Pv3

vertical load of

spindle strut S3

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 31 von 35

A.6 Verification of vertical WS10

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 32 von 35

horizontal load of

spindle strut S4

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 33 von 35

A.7 Verification of horizontal profile WS10

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 34 von 35

HR =

S1V =

S2V =

PV1 =

DL1 =

DL2 =

PV3 =

S4V =

S3V =

D

L

=

D

L

=

D

L

=

C

w1

=

C

w2

=

C

w3

=

C

w3

=

C

w2

=

L

L1

=

L

L2

=

L

L1

=

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

Calculation examples for formwork systems

Static Department 26.08.2011

The formwork experts Seite 35 von 35

max. Shear < perm. Shear

max. Moment < perm. Moment

max.Def. < perm. Def. the serviceability is given

Remark: The supporting reactions of this system are the loads per leg for the

scaffolding beneath, which is not considered in this calculation example.

(Anmerkung: Die Auflagerreaktionen dieses Systems sind die Stiellasten fr die darunterliegende

Tragkonstruktion, die in diesem Beispiel nicht berechnet wird.)

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

f

o

r

i

n

t

e

r

n

a

l

u

s

e

o

n

l

y

You might also like

- Chapter 15 - FormworkDocument14 pagesChapter 15 - Formworkmadhesamar100% (3)

- Special FormworkDocument14 pagesSpecial Formworkastra0007100% (4)

- Formwork TechnologyDocument24 pagesFormwork Technologyriefsaldy100% (1)

- Kwikstage Shoring GuideDocument21 pagesKwikstage Shoring GuideKallumRowlandsNo ratings yet

- Doka FormworkDocument80 pagesDoka FormworkKG Rohilla83% (6)

- Industry Guide For Formwork: Construction Industry South Australia JUNE 2012Document37 pagesIndustry Guide For Formwork: Construction Industry South Australia JUNE 2012tino3528100% (6)

- DG7 Gass Design Guide Rev G PDFDocument54 pagesDG7 Gass Design Guide Rev G PDFAnonymous BAYE9xVnLNo ratings yet

- Types of Formwork GuideDocument10 pagesTypes of Formwork GuideEngrdens Dela CruzNo ratings yet

- Concrete Formwork SystemsDocument318 pagesConcrete Formwork Systemscdnaveen100% (14)

- ScaffoldCouplers14Document8 pagesScaffoldCouplers14Guatemalan1979No ratings yet

- 53 TemporaryworksfinalDocument20 pages53 Temporaryworksfinalwhwy99No ratings yet

- Temp Works Part 4Document4 pagesTemp Works Part 4aliengineer953No ratings yet

- Doka Calculation GuideDocument70 pagesDoka Calculation GuideNuno Geirinhas67% (9)

- Design Repropping Beam 24FDocument11 pagesDesign Repropping Beam 24FNelson WongNo ratings yet

- Hunnebeck Formwork and Shoring Product Handbook UK0715Document112 pagesHunnebeck Formwork and Shoring Product Handbook UK0715Eugen LoghIn100% (2)

- Formwork DesignDocument17 pagesFormwork DesignEajaz Buzruk100% (3)

- Doka Calculation Guide PDFDocument70 pagesDoka Calculation Guide PDFboctraian55100% (2)

- Twf2014.01 Use of European Standards For TW Design 24 November 2014 FinalDocument18 pagesTwf2014.01 Use of European Standards For TW Design 24 November 2014 FinalgeraldNo ratings yet

- Scaffold Equipment BrochureDocument12 pagesScaffold Equipment BrochurejdfnortonNo ratings yet

- Flat Slab Formwork Falsework1Document80 pagesFlat Slab Formwork Falsework1Amin ZuraiqiNo ratings yet

- Wall Ties FormworkDocument96 pagesWall Ties FormworkJack Jeff0% (1)

- Investigation FalseworkDocument211 pagesInvestigation FalseworkRichard OonNo ratings yet

- Temporary Works - Principles of Design and Construction-ICE Publishing (2012)Document379 pagesTemporary Works - Principles of Design and Construction-ICE Publishing (2012)William Harrow100% (2)

- Formwork Health and SafetyDocument78 pagesFormwork Health and Safetylwin_oo2435100% (1)

- On Vertical Formwork: Concr Ete PressureDocument7 pagesOn Vertical Formwork: Concr Ete PressureatiNo ratings yet

- Build 145 30 Build Right Scaffolding in The FrameDocument3 pagesBuild 145 30 Build Right Scaffolding in The Frameanon_657324417100% (2)

- Ring Lock ScaffoldingDocument47 pagesRing Lock ScaffoldingYasserMohsen100% (1)

- Scaffold CatalogDocument16 pagesScaffold CatalogKrm ChariNo ratings yet

- Flat Slab Formwork & FalseworkDocument163 pagesFlat Slab Formwork & FalseworkAnonymous Mij5VUGvi675% (4)

- Back ProppingDocument6 pagesBack ProppingMihai CojocaruNo ratings yet

- Standard Scaffold Details SummaryDocument13 pagesStandard Scaffold Details Summarysreejit77No ratings yet

- Formwork PDFDocument27 pagesFormwork PDFKandarp Rajyaguru100% (1)

- Formwork A Practical GuideDocument447 pagesFormwork A Practical Guideraahul_n83% (6)

- PERI Presentation 1 - Formwork Handset-Domino-Trio PDFDocument98 pagesPERI Presentation 1 - Formwork Handset-Domino-Trio PDFHaris Omerika100% (1)

- Tower CraneDocument4 pagesTower Cranemordidomi50% (2)

- Formulas for Determining Lateral Pressures on Fresh ConcreteDocument3 pagesFormulas for Determining Lateral Pressures on Fresh Concreteshaikhaziz84100% (2)

- Safe Working Loads for Props Loaded Eccentrically or ConcentricallyDocument1 pageSafe Working Loads for Props Loaded Eccentrically or Concentricallykj55No ratings yet

- Calcaaulation of Alpha CRDocument9 pagesCalcaaulation of Alpha CRDenis DimićNo ratings yet

- Servicability LimitsDocument51 pagesServicability LimitsjadlouisNo ratings yet

- Bubble Pump Design Optimization for Single Pressure Absorption CyclesDocument77 pagesBubble Pump Design Optimization for Single Pressure Absorption CyclesThomas Ancco VizcarraNo ratings yet

- Maslov Guzeev 2011Document47 pagesMaslov Guzeev 2011George KaridisNo ratings yet

- Illinois Transient Model PDFDocument77 pagesIllinois Transient Model PDFGustavo LarenzeNo ratings yet

- CMC Ans 11013 EnuDocument27 pagesCMC Ans 11013 EnuWashington MunatsiNo ratings yet

- Static Pushover Analysis: Zsoil .PC 070202 ReportDocument55 pagesStatic Pushover Analysis: Zsoil .PC 070202 ReportHugo Ramirez CarmonaNo ratings yet

- Csi Etabs & Safe Manual: Part III: Model Analysis & Design of SlabsDocument83 pagesCsi Etabs & Safe Manual: Part III: Model Analysis & Design of SlabsAnonymous LJ1v8KKNo ratings yet

- Principles of Metal Forming TheoryDocument21 pagesPrinciples of Metal Forming TheoryAshok Kumar UppariNo ratings yet

- What Does That MeanDocument13 pagesWhat Does That MeanTeyib AbdiNo ratings yet

- Panciroli Riccardo TesiDocument126 pagesPanciroli Riccardo TesiA_saravanavelNo ratings yet

- Steel Case Structure Design CalculationDocument21 pagesSteel Case Structure Design CalculationDe Dao Van100% (1)

- Compressive Strength TestDocument8 pagesCompressive Strength TestBeaver CaraNo ratings yet

- Design For RC Flat SlabsDocument70 pagesDesign For RC Flat SlabsAil AafaaqNo ratings yet

- NCCI: Modelling of Portal Frames - Elastic AnalysisDocument5 pagesNCCI: Modelling of Portal Frames - Elastic AnalysisBobaru MariusNo ratings yet

- ICSAS 2011 SE 03-Rev DTMFDocument6 pagesICSAS 2011 SE 03-Rev DTMFVincenzo PilusoNo ratings yet

- Calcul de Alpha CritiqueDocument20 pagesCalcul de Alpha Critiquelahlou_d9216No ratings yet

- Example 8: Effects of Splice/Slack On Pile Stress: GRLWEAP Standard ExamplesDocument2 pagesExample 8: Effects of Splice/Slack On Pile Stress: GRLWEAP Standard ExamplesbozarromegustaNo ratings yet

- Milovan Ov IDocument14 pagesMilovan Ov ISaturnus PlutoNo ratings yet

- Eaves Connection Design and AnalysisDocument37 pagesEaves Connection Design and AnalysisHui LiuNo ratings yet

- MEL311Document281 pagesMEL311Shiri ShaNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- LandingToWall Installation GuideDocument6 pagesLandingToWall Installation GuideMirjana VeljkovicNo ratings yet

- LandingToWall Installation GuideDocument6 pagesLandingToWall Installation GuideMirjana VeljkovicNo ratings yet

- Paratop 2Document2 pagesParatop 2Mirjana VeljkovicNo ratings yet

- Paratop 2Document2 pagesParatop 2Mirjana VeljkovicNo ratings yet

- Memo 62 Earthquake TSS RVKDocument6 pagesMemo 62 Earthquake TSS RVKMirjana VeljkovicNo ratings yet

- AutoCAD 2013 Tutorial - 3D Modeling WireframeDocument26 pagesAutoCAD 2013 Tutorial - 3D Modeling WireframeYa Minn AyeNo ratings yet

- INSTALL PEIKKO AND DELTABEAM DWG SYMBOL LIBRARIESDocument1 pageINSTALL PEIKKO AND DELTABEAM DWG SYMBOL LIBRARIESMirjana VeljkovicNo ratings yet

- Technical Newsletter - 589: Adjusting Device For Forming Wagon TDocument2 pagesTechnical Newsletter - 589: Adjusting Device For Forming Wagon TMirjana VeljkovicNo ratings yet

- 14 BucklingDocument13 pages14 BucklingMirjana VeljkovicNo ratings yet

- Ties and Connector Pins PG-9-2010 PDFDocument16 pagesTies and Connector Pins PG-9-2010 PDFMirjana VeljkovicNo ratings yet

- Self C CDocument20 pagesSelf C CMirjana VeljkovicNo ratings yet

- Rock AnkerDocument5 pagesRock AnkerMirjana VeljkovicNo ratings yet

- 2009 10 OnlineDocument8 pages2009 10 OnlineMirjana VeljkovicNo ratings yet

- Fitting instructions for weldable couplersDocument4 pagesFitting instructions for weldable couplersMirjana VeljkovicNo ratings yet

- Pop UpDocument1 pagePop UpMirjana VeljkovicNo ratings yet

- Gear Machine ManualDocument20 pagesGear Machine ManualRuchira Chanda Indu100% (1)

- SOP For OLDocument9 pagesSOP For OLTahir Ur RahmanNo ratings yet

- Ethics Position PaperDocument8 pagesEthics Position Papercwise2100% (1)

- Top 100 Magazine - DB - FINALDocument31 pagesTop 100 Magazine - DB - FINALCharlesNo ratings yet

- 8a Codes and Q & CDocument35 pages8a Codes and Q & CDanem HalasNo ratings yet

- PostDocument203 pagesPostMichael NasiefNo ratings yet

- Elements of Masonry DesignDocument83 pagesElements of Masonry DesigndyetNo ratings yet

- AutoForm Software Solutions en PDFDocument3 pagesAutoForm Software Solutions en PDFBASKARAN SELVARAJNo ratings yet

- Skyscraper'S Glass Cleaning Automated Robot: Department of Mechanical EngineeringDocument7 pagesSkyscraper'S Glass Cleaning Automated Robot: Department of Mechanical Engineeringankur raiNo ratings yet

- Buet Prospectus 2022-23 FinalDocument10 pagesBuet Prospectus 2022-23 FinalProttoy BhattacharyaNo ratings yet

- Chap 1 Intro To Systems Analysis and Design 2Document50 pagesChap 1 Intro To Systems Analysis and Design 2Hai MenNo ratings yet

- New EM Graduate ProgramDocument18 pagesNew EM Graduate ProgramabofahadNo ratings yet

- HandbookDocument146 pagesHandbookbluishimageNo ratings yet

- Audit Checklist For PlantDocument16 pagesAudit Checklist For PlantNash C. UsopNo ratings yet

- AM TRIS Resume 2012Document5 pagesAM TRIS Resume 2012AMTRISNo ratings yet

- Two Cell Box CulvertDocument12 pagesTwo Cell Box CulvertAhmad Arslan Rafique71% (7)

- C3 - Process Selection, Design, and AnalysisDocument54 pagesC3 - Process Selection, Design, and AnalysisMinh Thuận VõNo ratings yet

- BbsDocument72 pagesBbsAkd DeshmukhNo ratings yet

- OEE Primer Understanding OverDocument483 pagesOEE Primer Understanding OverJorge Cuadros Blas100% (1)

- Offshore Process Design StandardsDocument10 pagesOffshore Process Design Standardssri9987No ratings yet

- APFC Relays Catalogue 2 1Document12 pagesAPFC Relays Catalogue 2 1Maulik PatelNo ratings yet

- Research HighlightDocument209 pagesResearch HighlightMuhammad Noor KholidNo ratings yet

- Emergency Generator Sizing and Motor Starting Analysis: Mukesh Kumar Kirar, Ganga AgnihotriDocument6 pagesEmergency Generator Sizing and Motor Starting Analysis: Mukesh Kumar Kirar, Ganga Agnihotribalwant_negi7520No ratings yet

- 2nd Year Weekly Attendance Even Sem 2020-2021Document608 pages2nd Year Weekly Attendance Even Sem 2020-2021Jos BatlarNo ratings yet

- AIA PA Contract Document Listing and Prices 1Document7 pagesAIA PA Contract Document Listing and Prices 1Pin VongphaiNo ratings yet

- Instruments Used in Engineering DrawingDocument15 pagesInstruments Used in Engineering Drawingasus nyahendraNo ratings yet

- ISO 12215 Technical Paper on Small Craft ConstructionDocument14 pagesISO 12215 Technical Paper on Small Craft Constructionval-ovidiu iordache100% (1)

- Test Case Report TemplateDocument2 pagesTest Case Report TemplateArjun SinghNo ratings yet