Professional Documents

Culture Documents

CAMD Assembly

Uploaded by

SameerKulkarniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CAMD Assembly

Uploaded by

SameerKulkarniCopyright:

Available Formats

Bench Vice Assembly 1

In this project, you will create the Bench Vice assembly. Figures B through E shows the views

and dimensions of the components of the Bench Vice assembly.

Bench Vice Assembly

Figure 2 Views and dimensions of the base

Figure 1 The Bench Vice assembly

CAMD_ProE_Assembly 1 MIT College of Engineering, Pune - 411038.

2 Student Project

Figure 4 Views and dimensions of various components of the Bench Vice assembly

Figure 3 Views and dimensions of the Vice Jaw

CAMD_ProE_Assembly 2 MIT College of Engineering, Pune - 411038.

Bench Vice Assembly 3

Figures 5 Views and dimensions of various components of the Bench Vice assembly

CAMD_ProE_Assembly 3 MIT College of Engineering, Pune - 411038.

Butterfly Valve Assembly 1

Create the components of the Butterfly Valve assembly and then assemble them, as shown in

Figure 1. The dimensions of the components are shown in Figures 2 through 7. Assume the

missing dimensions.

Butterfly Valve Assembly

Figure 1 The Butterfly Valve assembly

Figure 2 Dimensions of the Body

CAMD_ProE_Assembly 4 MIT College of Engineering, Pune - 411038.

2 Student Project

Figure 4 Dimensions of the Retainer Figure 3 Dimensions of the Shaft

Figure 6 Sectional front view of the Arm Figure 5 Top view of the Arm

Figure 7 Dimensions of the Plate, Nut, and Screw

CAMD_ProE_Assembly 5 MIT College of Engineering, Pune - 411038.

V-Block Assembly 1

Figure 2 Views and dimensions of the V-Block body

Create all the components of the V-Block assembly and then assemble them, as shown in

Figure 1. The dimensions of the components are shown in Figures 2 and 2.

V-Block Assembly

Figure 1 The V-Block assembly

CAMD_ProE_Assembly 6 MIT College of Engineering, Pune - 411038.

2 Student Project

Figure 3 Views and dimensions of the U-Clamp and Fastener

CAMD_ProE_Assembly 7 MIT College of Engineering, Pune - 411038.

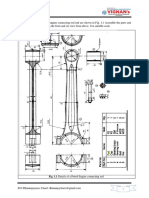

Crosshead Assembly 1

Crosshead Assembly

Figure 2 The exploded state of Crosshead assembly

Figure 1 The Crosshead assembly

In this project, you will create all components of the Crosshead assembly and then assemble

them, as shown in Figure 1. Also you will create an exploded state, shown in Figure 2. The

dimensions of the components are shown in Figures 3 through 7.

CAMD_ProE_Assembly 8 MIT College of Engineering, Pune - 411038.

2 Student Project

Figure 3 Front view and the right-side view of the Body

Figure 5 Dimensions of Piston Rod Figure 4 Dimensions of Keep Plate

Figure 6 Dimensions of the Brasses and Bolt

CAMD_ProE_Assembly 9 MIT College of Engineering, Pune - 411038.

Crosshead Assembly 3

Figure 7 Dimensions of Nut

CAMD_ProE_Assembly 10 MIT College of Engineering, Pune - 411038.

Double Bearing Assembly 1

In this project, you will create the Double Bearing assembly shown in Figure 1. The exploded

state of the assembly is shown in Figure 2 and the dimensions of the components of the

Double Bearing assembly are shown in Figures 3 through 7.

Double Bearing Assembly

Figure 4 Top view of the Cap Figure 3 Top view of the Base

Figure 2 The exploded view of the Double

Bearing assembly

Figure 1 The completed Double Bearing

assembly

Figure 6 Front view of the Cap Figure 5 Front view of the Base

CAMD_ProE_Assembly 11 MIT College of Engineering, Pune - 411038.

2 Student Project

Figure 7 Dimensions and drawing views of the Bushing and the Bolt

CAMD_ProE_Assembly 12 MIT College of Engineering, Pune - 411038.

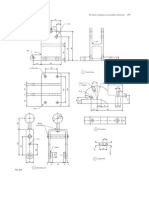

Fixture Assembly 1

Create all the components of the Fixture assembly and then assemble them, as shown in

Figure 1. The details of the components of the Fixture assembly are shown in

Figures 2 through 5.

Fixture Assembly

Figure 1 The Fixture assembly

Figure 2 Dimensions of the End Plate

CAMD_ProE_Assembly 13 MIT College of Engineering, Pune - 411038.

2 Student Project

Figure 3 Dimensions of the Disk

Figure 4 Dimensions of the Support Pin and the Bolt

CAMD_ProE_Assembly 14 MIT College of Engineering, Pune - 411038.

Fixture Assembly 3

Figure 5 Dimensions of the Spacer, Center Pin, and the Nut

CAMD_ProE_Assembly 15 MIT College of Engineering, Pune - 411038.

Plummer Block Assembly 1

Figure 2 Views and dimensions of the Casting

In this project, you will create the components of the Plummer Block assembly, as shown in

Figure 1 and then assemble them. The dimensions of the components are given in Figures 2

through 4.

Plummer Block Assembly

Figure 1 The Plummer Block assembly

CAMD_ProE_Assembly 16 MIT College of Engineering, Pune - 411038.

2 Student Project

Figure 3 Views and dimensions of the Cap

Figure 4 Views and dimensions of Brasses, Nut, Lock Nut, and Bolt

CAMD_ProE_Assembly 17 MIT College of Engineering, Pune - 411038.

Press Tool Assembly 1

In this project, you will create the Press Tool assembly shown in Figure 1. The exploded state

of the assembly is shown in Figure 2 and the dimensions of the components of the Press Tool

assembly are shown in Figures 2 through 5.

Press Tool Assembly

Figure 1 The completed Press Tool assembly after assembling the

Top Plate with the assembly

Figure 2 The exploded view of the Press Tool as-

sembly

Figure 3 Figure showing the Bottom Plate

CAMD_ProE_Assembly 18 MIT College of Engineering, Pune - 411038.

2 Student Project

Figure 5 Dimensions and views of the Guide Pillar

and Guide Bush

Figure 4 Dimensions and views of the Top

Plate

CAMD_ProE_Assembly 19 MIT College of Engineering, Pune - 411038.

Pulley Support Assembly 1

Figure 2 Exploded view of the Pulley Support assembly

Create the components of the Pulley Support assembly and then assemble them, as shown in

Figure 1. After creating the assembly, create its exploded view, as shown in Figure 2. The

dimensions of the components are given in Figures 4 through 8.

Pulley Support Assembly

Figure 1 The Pulley Support assembly

CAMD_ProE_Assembly 20 MIT College of Engineering, Pune - 411038.

2 Student Project

Figure 8 Dimensions of the Washer, Cap Screw, Turn Screw, and Nut

Figure 5 Dimensions of the Bushing Figure 4 Dimensions of the Pulley

Figure 7 Sectioned front view of the Figure 6 Left-side view of the Bracket

CAMD_ProE_Assembly 21 MIT College of Engineering, Pune - 411038.

Pulley Support Assembly 3

Figure 3 Parts list for the Pulley Support assembly

CAMD_ProE_Assembly 22 MIT College of Engineering, Pune - 411038.

Shock Assembly 1

Shock Assembly

Figure 1 The Shock assembly

In this project, you will create all components of the Shock assembly and then assemble

them, as shown in Figure 1. Also create an exploded state of the assembly, as shown in

Figure 2. The dimensions of the components are shown in Figures 3 through 10.

Figure 2 The exploded state of the Shock Assembly

CAMD_ProE_Assembly 23 MIT College of Engineering, Pune - 411038.

2 Student Project

Figure 4 Dimensions for Pivot Figure 3 Dimensions for Bracket

Figure 5 Dimensions for U-Support

CAMD_ProE_Assembly 24 MIT College of Engineering, Pune - 411038.

Shock Assembly 3

Figure 9 Dimensions for Hexagonal bolt Figure 8 Dimensions for Washer

Figure 6 Dimensions for Bushing Figure 7 Dimensions for Self-locking nut

Figure 10 Dimensions for Castle nut

CAMD_ProE_Assembly 25 MIT College of Engineering, Pune - 411038.

Wheel Support Assembly 1

Create all the components of the Wheel Support assembly and then assemble them, as shown

in Figure 1. The dimensions of the components are shown in Figures 2 through 6.

Wheel Support Assembly

Figure 1 The Wheel Support assembly

Figure 9-3 Dimensions of the Support Figure 2 Dimensions of the Base

Figure 5 Sectioned side view of the Wheel Figure 4 Front view of the Wheel

CAMD_ProE_Assembly 26 MIT College of Engineering, Pune - 411038.

2 Student Project

Figure 6 Dimensions of the Shoulder Screw, Bolt, Nut, Bushing,

and Washer

CAMD_ProE_Assembly 27 MIT College of Engineering, Pune - 411038.

Pipe Vice Assembly 1

In this Project, you will create all components of the Pipe Vice assembly, as shown in

Figure 1, and then assemble them. The dimensions of the components are given in

Figures 2 and 3.

Figure 1 The Pipe Vice assembly

Pipe Vice Assembly

Figure 2 Views and dimensions of the Base

CAMD_ProE_Assembly 28 MIT College of Engineering, Pune - 411038.

2 Student Project

Figure 3 Views and dimensions of the Screw, Handle, Movable Jaw, and Handle Screw

CAMD_ProE_Assembly 29 MIT College of Engineering, Pune - 411038.

Shaper Tool Head Assembly 1

Create the Shaper Tool Head assembly, as shown in Figure 1. After creating the assembly, create

its exploded view, as shown in Figure 2. The dimensions of the components are given in

Figures 3 through 7.

Shaper Tool Head Assembly

Figure 1 The Shaper Tool Head assembly

Figure 2 The exploded view of the Shaper Tool

Head assembly

CAMD_ProE_Assembly 30 MIT College of Engineering, Pune - 411038.

2 Student Project

Figure 3 Views and dimensions of the Swivel Plate

CAMD_ProE_Assembly 31 MIT College of Engineering, Pune - 411038.

Shaper Tool Head Assembly 3

Figure 4 Views and dimensions of the Back Plate

CAMD_ProE_Assembly 32 MIT College of Engineering, Pune - 411038.

4 Student Project

Figure 5 Views and dimensions of the Vertical Slide

CAMD_ProE_Assembly 33 MIT College of Engineering, Pune - 411038.

Shaper Tool Head Assembly 5

Figure 6 Views and dimensions of various components

CAMD_ProE_Assembly 34 MIT College of Engineering, Pune - 411038.

Stock Bracket Assembly 1

Figure 2 Top and front views of the Stock Support Base

In this project, you will create the Stock Bracket assembly shown in Figure 1. The details of

the components of the Stock Bracket assembly are shown in Figures 2 through 8.

Stock Bracket Assembly

Figure 1 The Stock Bracket assembly

CAMD_ProE_Assembly 35 MIT College of Engineering, Pune - 411038.

2 Student Project

Figure 4 Top and front views of the Adjusting Screw

Nut

Figure 3 Front and right-side views of the Stock

Support Roller

Figure 6 Views of the Adjusting Nut Handle and

Adjusting Screw Guide

Figure 5 Front and right-side views of the Support Roller Bracket

CAMD_ProE_Assembly 36 MIT College of Engineering, Pune - 411038.

Stock Bracket Assembly 3

Figure 8 Top and front views of the Thrust

Bearing

Figure 7 Views of the Support Adjusting Screw

CAMD_ProE_Assembly 37 MIT College of Engineering, Pune - 411038.

Motor Blower Assembly 1

In this project, you will create the Motor Blower assembly shown in Figure 1. The exploded

view of the assembly is shown in Figure 2. The details of the components of the Motor Blower

assembly are shown in Figures 3 through 8.

Figure 1 Motor Blower assembly

Figure 2 Exploded view of the Motor Blower assembly

Motor Blower Assembly

CAMD_ProE_Assembly 38 MIT College of Engineering, Pune - 411038.

2 Student Project

Figure 3 Dimensions of the Upper Housing

Figure 4 Dimensions of the Lower Housing

CAMD_ProE_Assembly 39 MIT College of Engineering, Pune - 411038.

Motor Blower Assembly 3

Figure 5 Dimensions of the Blower

Figure 6 Dimensions of the Motor

CAMD_ProE_Assembly 40 MIT College of Engineering, Pune - 411038.

4 Student Project

Figure 8 Dimensions of the Shaft

Figure 7 Dimensions of the Cover

CAMD_ProE_Assembly 41 MIT College of Engineering, Pune - 411038.

Radial Engine Assembly 1

In this project, you will create the Radial Engine assembly shown in Figures 1 and 2. The

Radial Engine assembly will be created in two parts, one will be the subassembly and the

other will be the main assembly. The dimensions of the components of the Radial Engine

assembly are shown in Figures 3 through 6.

Radial Engine Assembly

Figure 1 The Radial Engine assembly Figure 2 The exploded view of the assembly

Figure 3 Views and dimensions of the Piston

CAMD_ProE_Assembly 42 MIT College of Engineering, Pune - 411038.

2 Student Project

Figure 5 Views and dimensions of the Master Rod

Figure 4 Views and dimensions of the Articulated Rod

CAMD_ProE_Assembly 43 MIT College of Engineering, Pune - 411038.

Radial Engine Assembly 3

Figure 6 Views and dimensions of the Rod Bush Upper, Rod Bush Lower, Piston Pin Plug,

Piston Pin, Piston Rings, and Master Rod Bearing

CAMD_ProE_Assembly 44 MIT College of Engineering, Pune - 411038.

You might also like

- Student's Project InventorDocument10 pagesStudent's Project InventorSatish BollamNo ratings yet

- Create and assemble components of Tool Head assemblyDocument42 pagesCreate and assemble components of Tool Head assemblySaif RahmanNo ratings yet

- Student Project Pro-EDocument10 pagesStudent Project Pro-EAmit GoelNo ratings yet

- Student Projects SldwrksDocument6 pagesStudent Projects SldwrksPrithvi Harve100% (1)

- AssemblyDocument45 pagesAssemblyKaan Zumrutkaya100% (1)

- Assembly DrawingsDocument15 pagesAssembly DrawingsN Dhanunjaya Rao BorraNo ratings yet

- Assembly Drawing ExercisesDocument57 pagesAssembly Drawing Exercisesxitta00100% (10)

- Student Project Inv 2008Document16 pagesStudent Project Inv 2008Agus PrijantoNo ratings yet

- ME2257-Machine Drawing ManualDocument62 pagesME2257-Machine Drawing ManualVPSureshKumar100% (4)

- Press Tool AssemblyDocument2 pagesPress Tool Assemblyjaganmohanbits100% (6)

- Assembly Drawing Part 2Document5 pagesAssembly Drawing Part 2Graham MutumaNo ratings yet

- Assembly Drawing ExercisesDocument57 pagesAssembly Drawing ExercisesAli HassanNo ratings yet

- Machine Drawing Worked ExamplesDocument2 pagesMachine Drawing Worked Exampleseuclidl75% (4)

- Drafting ExercisesDocument12 pagesDrafting ExercisesJaime Andres Velez100% (3)

- Machine Drawing Work Sheet On Assembly Drawing@BikiDocument11 pagesMachine Drawing Work Sheet On Assembly Drawing@BikiAgnihothra Sarma OrugantiNo ratings yet

- CAMD USN 15ME36A/46A Third Semester B.E. Degree ExaminationDocument4 pagesCAMD USN 15ME36A/46A Third Semester B.E. Degree ExaminationVasim MansuriNo ratings yet

- Shaper Tool Head AssemblyDocument6 pagesShaper Tool Head AssemblykamelsuxNo ratings yet

- Stock Bracket AssemblyDocument3 pagesStock Bracket AssemblyAdam Gomez100% (1)

- Assembly Drawings Part-3Document19 pagesAssembly Drawings Part-3Parameswararao Billa100% (1)

- Fixture Assembly PDFDocument3 pagesFixture Assembly PDFAnonymous O1JbaDjPNNo ratings yet

- Autodesk Inventor - Using Splines and SurfacesDocument20 pagesAutodesk Inventor - Using Splines and SurfacesNdianabasi UdonkangNo ratings yet

- Bench Vice AssemblyDocument3 pagesBench Vice Assemblyom_prakash1986100% (1)

- DEMONSTRATION - Const. of A HelixDocument2 pagesDEMONSTRATION - Const. of A HelixNitin B maskeNo ratings yet

- CAD Manual Section ViewsDocument227 pagesCAD Manual Section ViewsAhmed BdairNo ratings yet

- Machine Drawing T-SheetDocument30 pagesMachine Drawing T-SheetIfham Shah100% (3)

- Double Bearing Assembly PDFDocument2 pagesDouble Bearing Assembly PDFM.Saravana Kumar..M.E50% (2)

- CATIA Drawings For Practice (Pune)Document36 pagesCATIA Drawings For Practice (Pune)Mr. Pradeep Wadkar91% (35)

- Plummer Block Assembly PDFDocument2 pagesPlummer Block Assembly PDFAnonymous O1JbaDjPN100% (2)

- Machine Drawing PDFDocument182 pagesMachine Drawing PDFPrasanth Kumar100% (1)

- Assembly Drawing AssignmentDocument3 pagesAssembly Drawing AssignmentSagar Dhage100% (1)

- Catia V5 TrainingDocument48 pagesCatia V5 TrainingPrasad Naik73% (11)

- Machine Drawing ManualDocument90 pagesMachine Drawing Manualmechanical 2017-2021No ratings yet

- Solid Works Lab ManualDocument57 pagesSolid Works Lab Manualbalusharma121288% (8)

- Autodesk Inventor - Sheet Metal Punch IfeaturesDocument6 pagesAutodesk Inventor - Sheet Metal Punch IfeaturesNdianabasi UdonkangNo ratings yet

- Mechanical Engineering Drawings and ProjectsDocument21 pagesMechanical Engineering Drawings and ProjectsRajueswar100% (4)

- Sample Midterm Problems - Engineering Graphics in DesignDocument5 pagesSample Midterm Problems - Engineering Graphics in Designmaterial manNo ratings yet

- Engineering Drawing: Mechanical Engineering Department L.J. PolytechnicDocument40 pagesEngineering Drawing: Mechanical Engineering Department L.J. PolytechnicTufel NooraniNo ratings yet

- CATIA V5-6R2015 Basics - Part II: Part ModelingFrom EverandCATIA V5-6R2015 Basics - Part II: Part ModelingRating: 4.5 out of 5 stars4.5/5 (3)

- CAD LAB - ExercisesDocument63 pagesCAD LAB - Exercisessarath761089% (9)

- Computer Aided Machine DrawingDocument9 pagesComputer Aided Machine DrawingChetan Gowda0% (1)

- Bench Vice Assembly Bench Vice Assembly PDFDocument3 pagesBench Vice Assembly Bench Vice Assembly PDFmayur kadamNo ratings yet

- S12.s12 - TAREA CAMD-AssemblyDocument44 pagesS12.s12 - TAREA CAMD-AssemblyELIZABETH COAGUILA AÑARINo ratings yet

- Imperial College of Engineering and Research: Jayawant Shikshan Prasarak Mandal'sDocument35 pagesImperial College of Engineering and Research: Jayawant Shikshan Prasarak Mandal'ssameertamboliNo ratings yet

- Part-B1-Petrol Engine Connecting RodDocument5 pagesPart-B1-Petrol Engine Connecting RodN Dhanunjaya Rao BorraNo ratings yet

- Computer Aided Modeling Design of External Gear PumpDocument6 pagesComputer Aided Modeling Design of External Gear Pump39SEAShashi KhatriNo ratings yet

- Shaping Machine Tool Head Assembly ProjectDocument5 pagesShaping Machine Tool Head Assembly ProjectBehailu FelekeNo ratings yet

- Proiect Catia V5Document5 pagesProiect Catia V5Claudiu ClassNo ratings yet

- Inventor Practical 5 Tutorial SheetDocument6 pagesInventor Practical 5 Tutorial SheetStefan XerriNo ratings yet

- Project 3 2014Document9 pagesProject 3 2014Daimen WilliamsNo ratings yet

- Design and Development of Tacking and Welding Fixture For Mixing Drum of 10/7 Concrete MixerDocument5 pagesDesign and Development of Tacking and Welding Fixture For Mixing Drum of 10/7 Concrete MixerIJIRSTNo ratings yet

- MCQ Aim/Principle/Apparatus Required/procedure Tabulation/Circuit/ Program/Drawing Dimensi Oning Result/ Output Viva-Voce TotalDocument21 pagesMCQ Aim/Principle/Apparatus Required/procedure Tabulation/Circuit/ Program/Drawing Dimensi Oning Result/ Output Viva-Voce TotalGeorge OliverNo ratings yet

- CW1 ReportDocument19 pagesCW1 ReportMohammad AzemNo ratings yet

- Jednostavni PrimeriDocument13 pagesJednostavni Primeridaka crtamNo ratings yet

- Experiment 1.3 Title of The ExperimentDocument11 pagesExperiment 1.3 Title of The ExperimentAB RanaNo ratings yet

- Glass TransitionDocument2 pagesGlass TransitionSameerKulkarniNo ratings yet

- EnglishDocument1 pageEnglishSameerKulkarniNo ratings yet

- Crystallinity in PolymerDocument2 pagesCrystallinity in PolymerSameerKulkarniNo ratings yet

- Polymer Crystallisation: ImportantDocument1 pagePolymer Crystallisation: ImportantSameerKulkarniNo ratings yet

- Mathemaical EquationDocument1 pageMathemaical EquationSameerKulkarniNo ratings yet

- Mechanical EffectsDocument1 pageMechanical EffectsSameerKulkarniNo ratings yet

- Cold CrystallisationDocument2 pagesCold CrystallisationSameerKulkarniNo ratings yet

- MeltingDocument2 pagesMeltingSameerKulkarniNo ratings yet

- CrystallisaitonDocument2 pagesCrystallisaitonSameerKulkarniNo ratings yet

- Effect of Crystalline BeahaviourDocument1 pageEffect of Crystalline BeahaviourSameerKulkarniNo ratings yet

- Crystallinity - Mechanical EffectsDocument3 pagesCrystallinity - Mechanical EffectsSameerKulkarniNo ratings yet

- MathsDocument1 pageMathsSameerKulkarniNo ratings yet

- Effect of Crystalline BeahaviourDocument3 pagesEffect of Crystalline BeahaviourSameerKulkarniNo ratings yet

- Effect of Crystalline BeahaviourDocument1 pageEffect of Crystalline BeahaviourSameerKulkarniNo ratings yet

- Your Site Is Not Processing My DocumentDocument7 pagesYour Site Is Not Processing My DocumentSameerKulkarniNo ratings yet

- Important KnowledgeDocument1 pageImportant KnowledgeSameerKulkarniNo ratings yet

- Science Is Physics, Chemistry and MathsDocument1 pageScience Is Physics, Chemistry and MathsSameerKulkarniNo ratings yet

- Important KnowledgeDocument1 pageImportant KnowledgeSameerKulkarniNo ratings yet

- SameerDocument1 pageSameerSameerKulkarniNo ratings yet

- Sameer JadhavDocument1 pageSameer JadhavSameerKulkarniNo ratings yet

- N-S EquationDocument1 pageN-S EquationSameerKulkarniNo ratings yet

- Solution To A 3d Flow Problem Using Navier Stokes EquationDocument1 pageSolution To A 3d Flow Problem Using Navier Stokes EquationSameerKulkarniNo ratings yet

- Naviers Stokes EquationDocument1 pageNaviers Stokes EquationSameerKulkarniNo ratings yet

- SameerDocument1 pageSameerSameerKulkarniNo ratings yet

- Metal Matrix Composites: Properties and AdvantagesDocument1 pageMetal Matrix Composites: Properties and AdvantagesSameerKulkarniNo ratings yet

- Micromax RepairDocument1 pageMicromax RepairSameerKulkarniNo ratings yet

- Figure 5-2.-Hotchkiss DriveDocument1 pageFigure 5-2.-Hotchkiss DriveSameerKulkarniNo ratings yet

- Seminar or TPP Registration FormDocument1 pageSeminar or TPP Registration FormSameerKulkarniNo ratings yet

- Info About Drive ShaftDocument1 pageInfo About Drive ShaftSameerKulkarniNo ratings yet

- Mechanical MeasurementsDocument1 pageMechanical Measurementsvikashranjan1987No ratings yet

- Hilton EMEA Energy Water-Efficient Design Companion Guide - Final - V - 1.0Document41 pagesHilton EMEA Energy Water-Efficient Design Companion Guide - Final - V - 1.0virtechNo ratings yet

- Selected Redox ReactionsDocument40 pagesSelected Redox ReactionsGliezl ImperialNo ratings yet

- Olive Oil InfrastructuresDocument5 pagesOlive Oil InfrastructuresShahzad ShameemNo ratings yet

- HammerDocument128 pagesHammerIulian MihaiNo ratings yet

- Grinding Aid Admixtures Improve Cement ProductionDocument3 pagesGrinding Aid Admixtures Improve Cement Productionjagrut100% (2)

- 2710 100 Series - Screw Side-Action GripsDocument4 pages2710 100 Series - Screw Side-Action GripsLitarmjNo ratings yet

- Enzo Nicolai T. Teves High School 1st Periodical Test in Automotive ServicingDocument4 pagesEnzo Nicolai T. Teves High School 1st Periodical Test in Automotive ServicingSylvia Aguilar RizaldoNo ratings yet

- Section 26 24 13-LV Power Distribution Boards PDFDocument15 pagesSection 26 24 13-LV Power Distribution Boards PDFmasoodaeNo ratings yet

- Learning Activity Sheet Science 8, Quarter 3, Week 1: Elements, Compounds, and MixturesDocument14 pagesLearning Activity Sheet Science 8, Quarter 3, Week 1: Elements, Compounds, and MixturesJoan MarieNo ratings yet

- Retrofilling Aging Transformers With Natural Ester Based Dielectric Coolant For Safety and Life ExtensionDocument7 pagesRetrofilling Aging Transformers With Natural Ester Based Dielectric Coolant For Safety and Life Extension王阳No ratings yet

- Claudia - Gavrilescu - XRAY Technology PDFDocument51 pagesClaudia - Gavrilescu - XRAY Technology PDFdangthNo ratings yet

- Coaching MDSP 02Document10 pagesCoaching MDSP 02jay dubouzetNo ratings yet

- Rotary Vane PumpDocument7 pagesRotary Vane PumpSanny HamdaniNo ratings yet

- Drag CoefficientDocument7 pagesDrag CoefficientAdrian John Soe Myint100% (1)

- CrackingDocument20 pagesCrackingNiaz Ali KhanNo ratings yet

- Anchorage To Concrete - Means and MethodsDocument28 pagesAnchorage To Concrete - Means and MethodsMustafaNo ratings yet

- Steel Coil AlignmentDocument1 pageSteel Coil AlignmentBalluff SensorsNo ratings yet

- Rock Proof: Liquid Water Integral WaterproofDocument2 pagesRock Proof: Liquid Water Integral Waterproofimran jamalNo ratings yet

- Tunnel Systems: Design & SupplyDocument8 pagesTunnel Systems: Design & SupplyJuan Luis Vilca YucraNo ratings yet

- Breaker Rack Out and Rack in (PB QBook)Document3 pagesBreaker Rack Out and Rack in (PB QBook)Ehsan Pappu33% (3)

- B4A3Document6 pagesB4A3ashokclineNo ratings yet

- 6001 FluorescentLightFittings EK00 III en PDFDocument9 pages6001 FluorescentLightFittings EK00 III en PDFarturonc100% (1)

- CT00022379 28288Document48 pagesCT00022379 28288Salim AshorNo ratings yet

- Rotary Switch PDFDocument4 pagesRotary Switch PDFasdfadgNo ratings yet

- Aniline Point & Diesel IndexDocument1 pageAniline Point & Diesel IndexSerena Serena0% (1)

- All Makes Filters Cross Reference GuidesDocument5 pagesAll Makes Filters Cross Reference GuidesJafet Israel RojasNo ratings yet

- Palm Kernel Oil Mill ProjectDocument8 pagesPalm Kernel Oil Mill Projectsjr141071100% (2)

- H1 SteeringDocument225 pagesH1 SteeringVinay Kumar NeelamNo ratings yet

- Datasheet Rockfon Medicare-StandardDocument7 pagesDatasheet Rockfon Medicare-Standardsirikhwan wonganuntNo ratings yet

- Underground Cables - 010954Document23 pagesUnderground Cables - 010954lawrence momanyiNo ratings yet