Professional Documents

Culture Documents

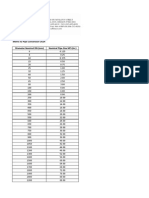

Heidenhain TNC Programming Notes

Uploaded by

Reymondo BundocOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heidenhain TNC Programming Notes

Uploaded by

Reymondo BundocCopyright:

Available Formats

Heidenhain

TNC410/426

Conversational

Programming

Arrow

Sabre

Lancer

TNC BASIC 01/01/2001

Index

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

11.0

12.0

13.0

14.0

15.0

Keys.

Introduction & M codes..

Absolute & Incremental Scale..

Cutter Compensation (APPR & DEP).

Program start

Toolchange

Linear programming

Blend Radius & Chamfers.

Circular Programming.

Working Planes & Polar Programming.

Hole canned cycles..

Milling canned cycles..

Co-ordinate Transformations

Sub-Programming....

Helical..

Tool Setting...

Datum Setting

Flex K..

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 1

CHAPTER 1

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 1

(Operation Keys)

Program & Editing select key

Select this key to create new programs or edit existing programs. After

selecting this key, a new program is created by selecting the PGM MGT

key, entering the new name and choosing metric or imperial from the on screen

prompts.

Program Run-Full Sequence select key

Select this key with the appropriate program from the file manager to Run

the program from the selected block (may require the use of the Go To

Block function) without single block.

Program Run-Single Block select key

Select this key with the appropriate program from the file manager to

Run the program from the selected block (may require the use of the Go

To Block function) one block at a time.

Test Run select key

Select this key with the appropriate program from the file manager to Test

run the selected blocks or full program. May require the use of the Go To

Block function. Can be used as a background function but will not test a program

being executed by the machine.

Manual Data Input (MDI)select key

Manual select key

Select this key for all types of manual machine executions i.e. any M or

S program functions, PLC movements, Datum Setting.

Electronic Handwheel select key

Select this key to use the handwheel or jog keys and for all some types of

manual machine executions i.e. any M or S program functions &

Datum Setting. Some Heidenhain controls will require a numerical number to be

entered for handwheel traverse speed (0 =fastest, 10 =slowest).

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 1

(Program Keys)

Linear (L)

Creates straight lines where the X & Y end co-ordinates are known. Can be used with

(I)Incremental and (P)Polar. Selecting this button in Program & Editing will prompt

the user for absolute:

1) End co-ordinates, R?(compensation), F?(feed), M?(miscellaneous functions).

Polar (Must be used in conjunction with Circle Centre)

1) Polar Angle, Polar Radius, R?(compensation), F?(feed), M?(miscellaneous functions).

Selecting (I)Incremental before the selected axis will define the movements in

incremental.

Circle Centre (CC) NOTE: MODAL

Used in conjunction with the (C)Circular or (L)Linear key . Selecting this button in

Program & Editing will prompt the user with circle centre or polar centre co-ordinates in

absolute.

Selecting (I)Incremental before the selected axis will define the circle centre co-

ordinates as incremental.

Circular (C) - (Must be used in conjunction with Circle Centre)

Creates circular movements where the end co-ordinates are known. Can be used with

(I)Incremental and (P)Polar and will create arcs or full circular movements. Selecting

this button in Program & Editing will prompt the user for absolute:

1) End co-ordinates, D?(direction),R?(compensation), F?(feed), M?(miscellaneous functions).

Polar:

1) PA?(polar angle), D?(direction),R?(compensation), F?(feed), M?(miscellaneous functions).

Selecting (I)Incremental before the selected axis will define the movements in

incremental.

Circular with a known radius(CR)

Creates circular movements (without the Circle Centre(CC) being specified) where the end

co-ordinates and radius are known. Can be used with (I)Incremental and will create arcs

only. Selecting this button in Program & Editing will prompt the user for absolute:

End co-ordinates, D?(direction), R?(radius), R?(compensation), F?(feed), M?(miscellaneous

functions).

Selecting (I)Incremental before the selected axis will define the movements in

incremental.

Circular movement Tangent to a line(CT)

Creates circular movements (without the Circle Centre(CC) being specified) tangent to the

last Linear(L) movement where the end co-ordinates are known. Can be used with

(I)Incremental and will create arcs only. Selecting this button in Program & Editing will prompt

the user for absolute:

End co-ordinates, R?(compensation), F?(feed), M?(miscellaneous functions).

Selecting (I)Incremental before the selected axis will define the movements in

incremental.

L

CC

C

CR

CT

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 1

Fillet Chamfer(CHF)

Creates fillet chamfers between two straight lines where the intersection point is known.

Selecting this button in Program & Editing will prompt the user for :

CHF?(chamfer length).

NOTE: Intersection point must be programmed as an X and Y co-ordinate before and

after the CHF prompt.

Blend Radius(RND)

Creates blend radius between two straight lines where the intersection point is known.

Selecting this button in Program & Editing will prompt the user for :

RND?(radius).

NOTE: Intersection point must be programmed as an X and Y co-ordinate before and

after the RND prompt.

Approach & Depart

Allows the user to start and finish, using compensation(RL / RR) if required, at specified

points when contouring.

Selecting this button in Program & Editing will prompt the user to select :

Linear tangential to next movement, Linear perpendicular (90deg) to next movement, Circular

tangential to next movement, or Linear circular tangential to the next movement.

APPR (Compensation(RL / RR) must be specified if required)

a) APPR LT : Define the contour start point as X & Y and the length of approach to create a

tangential approach.

b) APPR LN : Define the contour start point as X & Y and the length of approach to create a

perpendicular approach.

c) APPR CT : Define the contour start point as X & Y, the circular angle movement and the radius of

the circle to create a circular tangent approach.

d) APPR LCT : Define the contour start point as X & Y and the radius of circle to be the tangent arc

to create a linear circular tangent approach.

DEP (Compensation cancel (R0) is not specified and will cancel automatically)

a) DEP LT : Define the length of movement away from the end point to create a tangential departure

move.

b) DEP LN : Define the length of movement away from the end point to create a perpendicular

departure move.

c) DEP CT : Define the circular angle movement and the radius of the circle to create a circular

tangent departure move.

d) DEP LCT : Define the X & Y position to finish away from the contour and the radius of circle to

be the tangent arc to create a linear circular tangent departure move.

CHF

RND

APPR

DEP

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 1

Probe cycles select key (Optional)

Canned & Data cycle select key (Modal)

Cycle Call select key (Non-Modal)

Activates the last Modal Canned Cycle Definition (Not Data Definition)

Label Set select key (LBL ?)

Sets a Label around information which may be repeated. Label number

must be a unique number up to 3 digits long and the information following

this label start must be finished with LBL 0.

Label Call select key (CALL LBL ?)

Calls the required LBL ? and prompts the programmer for the amount of

required repeats.

NOTE: There is a procedure to how this works safely. If no repeats are necessary

the Call LBL ? can be input anywhere in the program. If there are repeats on the

Call LBL ? and do not follow straight after the specified label LBL 0 line then

the Call LBL ? MUST be enveloped around its own Label ?, the repeats taken

away from the repeated Call LBL ? line and then added to the 2nd Call LBL ?

with the same repeats less one. (As Follows)

LBL 1

program information in LBL 1

LBL 0

further program information

LBL 2

CALL LBL 1 (label requires repeating 10 times)

LBL 0

CALL LBL 2 REP 9 (9 times repeat because LBL 2 has been read once)

The easiest alternative is to program the CALL LBL 1 with no repeats 10

individual times one after the other or to ensure that the label is written in the

program after the program end M2.

Stop select key (Non- Modal)

Prompts the programmer for a Non-Modal miscellaneous M code

function.

TOUCH

PROBE

CYCL

DEF

CYCL

CALL

LBL

SET

LBL

CALL

STOP

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 1

Tool Definition select key (MODAL)

If the tool library is not set by parameters the program must contain

information with regard the tool length and the RADIUS. If the radius is

not necessary for the program i.e. a drill then it will be required if the graphics are

used.

Tool Call select key

Selecting this key will prompt the programmer for the required tool change

number, the spindle revolutions and the working spindle axis which would

be Z in X & Y axis programming.

Alternative Program Call select key

Selecting this key will prompt the programmer for the required program

number which exists in the program library.

Switch Table select key

Selecting this key will switch the display back and forth between the last

screen display and the current screen display.

Graphic / Text Display select key

Selecting this key, and selecting one of the prompt switches below the

screen will allow the programmer to view the Programmed Text, The

Graphics,Sections or Status.

TOOL

DEF

TOOL

CALL

PGM

CALL

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 1

(Other Program Keys)

Polar Key (P) NOTE: NON-MODAL

Selecting this key in conjunction with the other programming keys will transform the

selected axis co-ordinates into Polar or angular co-ordinates.

Incremental Key (I) NOTE: NON-MODAL

Selecting this key in conjunction with the programmed axis (X, Y or Z)keys will transform

the selected axis co-ordinates into Incremental co-ordinates.

X axis select Key

Y axis select Key

Z axis select Key

4th axis select Key

5th axis select Key (TNC426 or TNC430 only)

Clear numerical entry key

Delete Block key

Q Def. key (Parametric Expressions or Macro Programming)

Data Transfer key

Transfers the highlighted axis information into the selected program block.

P

I

X

Y

Z

IV

V

CE

DEL

Q

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 1

Data Skip key

End Of Block key

Enter Block Information key

Search Back key

Used in Editing, Test Run, Program Run & MDI.

Search Forward key

Used in Editing, Test Run, Program Run & MDI.

Search Right key

Used in Editing & MDI.

Search Left key

Used in Editing & MDI.

Search For Block Number key

Used in Editing, Test Run, Program Run & MDI. Must be used to

select the addressed block for program run.

Program Library select key

Select this key in program editing mode or program run mode to create

new programs or call existing programs. Only 1 directory exists in existing

Heidenhain controls except the TNC426 & TNC430 which has unlimited

directories. Highlighting the required program and depressing the Enter key will

transfer it to the appropriate menu (Run or Edit). Also data transfer and program

delete will be found here.

Modification select key

Selecting this key will allow the programmer or operator to change the

position display, change the data transfer parameters and also by using

special pass numbers allows the programmer to enter the main parameters table.

NO

ENT

END

ENT

GOTO

PGM

MGT

MOD

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 2

11

CHAPTER 2 CHAPTER 2 CHAPTER 2 CHAPTER 2

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 2

12

Process from Drawing to Product completion

1. Drawing

Examine drawing to determine fixturing,

machining origin, process and tooling.

.

.

.

.

2. Program preparation

Prepare a program while considering cutting

conditions as R.P.M., depth of cuts and feedrates.

T1 M6

G0 G90 G40 G17 G94

X0 Y0 S1000 M3

3. Program creation

Write the program in the control or another

editing source (P.C.) as per the program

preparation.

4. Test run

Test the mathematics of the program using the test

run facilities i.e. Graphics & program run.

(TEST RUN)

5. Machining

Set tools, set offset values and then process a trial

test workpiece.

VMC 500

6. Product completion and Inspection

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 2

13

Cutting Condition Commands

Cutting conditions should be carefully examined when preparing a program, since

these conditions greatly influence cutting efficiency and accuracy. The cutting

conditions that determine the rate of metal removal are the Cutting Speed, the

Feedrate, the Depth of Cut & the Width of Cut. These cutting conditions and

the nature of the material to be cut determine the power required to take the cut. The

cutting conditions must be adjusted to stay within the power available on the machine

tool to be used. These conditions also effect the tool life, which would need

consideration.

The following cutting conditions are required for all tooling used:

Spindle Speed R.P.M. (Revolutions per Minute)

Designated with an S command.

400 rpm S400

Formula

R.P.M. =Constant Surface Speed (C.S.S.) x 1000

x Diameter

C.S.S. can be found in all manufacturers tooling guides.

Feedrate mm/min. , inch/min. , feed/tooth, feed/rev.

Designated with an F command.

400 mm/min. F400

Formula

Feed =Number of teeth x feed/tooth (pitch) x R.P.M.

Feed/tooth can be found in all manufacturers tooling guides.

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 2

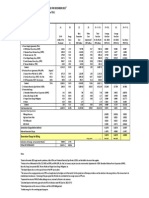

Table of Miscellaneous Codes (M Functions)

a) There are two types of programming codes:

Non-Modal - The programmed action code is active only in the block in which it is

specified & is self-canceling.

Modal - The programmed action code remains active when programmed for every

line of program and until it is replaced by another action code of the same group type.

M Code FUNCTION ( * Option) START

OF SPAN

END OF

SPAN

M00 Program Stop

M01 Program Stop by switch

M02 End Of Program

M03 Spindle Clockwise

M04 Spindle Anti-Clockwise

M05 Spindle Stop

M06 Toolchange

M08 External Coolant On

M09 Coolant Off

M10 4

th

Axis Unclamp *

M11 4

th

Axis Clamp *

M13 Spindle Clockwise With External Coolant

M14 Spindle Anti-Clockwise With External Coolant

M19 Spindle Orientates To Toolchange Position

M26 Z Axis Full Retract

M23 Thro Spindle Coolant +Spindle Clockwise *

M24 Thro Spindle Coolant +Spindle Anti-Clockwise *

M28 Thro Spindle Coolant *

M30 End Of Program Return Spindle tool to Drum

M89 Modal Cycle Call

M90 Constant Contour Speed at Corners

M91 Co-ordinates are referenced to machine co-ordinates

M94 Reduce rotary axis display to a value below 360 degrees

M97 Machine small contour steps

M99 Non-modal cycle call

M103 Reduce the feedrate during plunging to factor f

M109 Constant contour feed at cutting tool edge (increase and decrease)

M110 Constant contour feed at cutting tool edge (decrease only)

M111 Reset M109/M110

M00 Program Stop:

After executing the block where the M00 is commanded, automatic operation stops

the machine including the feed, spindle and coolant. Pressing the Cycle Start button

resumes all operations.

M01 Optional Program Stop:

M01 is identical to M00 but is actioned by a switch in the screen. When this switch is

ON then the code acts as M00, but when the switch is OFF the code is ignored

and operation continues as programmed. Applications include: Checks on dimensions,

Checks on tools and to remove chips during machining.

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 3

4

CHAPTER 3 CHAPTER 3 CHAPTER 3 CHAPTER 3

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 3

5

Absolute Scale

Tool motion assumes now that the spindle moves and not the table

10 30 50 70 90 -10 -30 -50 -70 -90

30

50

70

90

-10

-30

-50

-70

-90

X+ X-

Y-

Y+

10

30

50

70

90

-10

-30

-50

-70

-90

Z-

Z+

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 3

6

Absolute Programming

Y

X

40

80

120

160

90

30

50

80

X+ X-

Y-

Y+

L X40 Y90

L X80 Y30

L X120 Y80

L X160 Y50

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 3

7

Incremental (I) Scale

Tool motion assumes now that the spindle moves and not the table

10 30 50 70 90 -10 -30 -50 -70 -90

30

50

70

90

-10

-30

-50

-70

-90

X+ X-

Y-

Y+

10

30

50

70

90

-10

-30

-50

-70

-90

Z-

Z+

0

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 3

6

Incremental (I) Programming

Y

X

40 40 40 40

60

50

30

90

X+ X-

Y-

Y+

L X40 Y90

L IX40 IY-60

L IX40 IY50

L IX40 IY-30

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 4

CHAPTER 4

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 4

Cutter Compensation Application

Climb Milling (Radius Left - RL)

Conventional Milling (Radius Right - RR)

90 90

R

a

d

i

u

s

L

e

f

t

(

R

L

)

R

a

d

i

u

s

R

i

g

h

t

(

R

R

)

R

a

d

i

u

s

L

e

f

t

(

R

L

)

R

a

d

i

u

s

R

i

g

h

t

(

R

R

)

Note

All Compensated program data is created from information contained in the Radius

Offset column in the Tool tables (if used) or, the Radius Offset on a Tool Def.

program line.

Using Right Hand cutters (as above)

To leave material on the contour or pocket ADD the offset value to the value in the

Radius Offset data on the Tool Def program line or the radius column of the tool

table.

To remove material on the contour or pocket SUBTRACT the offset value to the

value in the Radius Offset data on the Tool Def program line or the radius column of

the tool table.

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 4

Compensation types

Circle Tangent Line Tangent Line Normal

1

1 2 1 RL R0

RL R0 RL R0

Circle Tangent LineTangent

1

RL

R0

LineNormal

1

RL R0

RL R0

1

1

RL

R0

Circle Tangent Line Tangent

Circle Tangent Line Normal

1

RL

R0

1

RL

R0

1

RL

R0

Line Normal

1

RL

R0

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 4

Approach Line Tangent

L X-10 Y+30 R0 FMAX M3

APPR LT X+40 Y+30 LEN+15 RL F200

L X+80 Y+80

APPR LT

40.00

10.00

30.00

15.00

30.00

RL

1

2

80.00

80.00

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 4

Approach Line Normal

L X-10 Y+30 R0 FMAX M3

APPR LN X+40 Y+30 LEN+15 RL F200

L X+80 Y+80

APPR LN

40.00

10.00

30.00 30.00

1

2

80.00

80.00

15

RL

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 4

Approach Circle Tangent

L X-10 Y+30 R0 FMAX M3

APPR CT X+40 Y+30 CCA+90 R15 RL F200

L X+80 Y+80

APPR CT

40.00

10.00

30.00 30.00

1

2

80.00

80.00

15

RL

90 Deg 15R

Rapid

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 4

Approach Line Circle Tangent

L X-10 Y+30 R0 FMAX M3

APPR LCT X+40 Y+30 R15 RL F200

L X+80 Y+80

APPR LCT

40.00

10.00

30.00 30.00

1

2

80.00

80.00

15

RL

90 Deg 15R

Feed

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 4

Depart Line Tangent

L Y+30 RL F100

DEP LT LEN+15

DEP LT

2

3

15.00

80.00

30.00

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 4

Depart Line Tangent

L Y+30 RL F100

DEP LN LEN+15

DEP LN

2

3

80.00

30.00

20.00

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 4

Depart Circle Tangent

L Y+30 RL F100

DEP CT CCA+90 R+15

DEP CT

2

3

80.00

30.00

90 Deg 15R

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 4

Depart Line Circle Tangent

L Y+30 RL F100

DEP LCT X+110 Y+30 CCA+90 R15

DEP LCT

2

3

80.00

30.00

90 Deg 15R

110.00

20.00

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 5

CHAPTER 5

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 5

Program Start:

Selecting this key in the Program and Editing mode will ask the operator for

the File Name which can be a file name up to 8 characters. Use Select

Type for choice of program (.H =Heidenhain, .I =ISO).

The total number of files is 64 or 128KB (410) or 1.5GB (426).

The operator will then be prompted for the choice of either metric or imperial

programming co-ordinates.

At the program start the operator will be prompted with the Blank Form Definition

or it can be searched for using the screen additional menus keys for the Blank form

setting key.

Toolchange: (without tool table)

TOOL DEF? L? R? ; Tool information line

TOOL CALL? Z S? F? DL? DR? DR2? ; Toolcall line

L M6 ; Toolchange line

The Tool File can be activated by setting Parameter 7260.0 to the required number

of tool rows in a file.

The Tool Def program line requires no values in the LENGTH and RADIUS

sections with the use of a tool table.

Tool information (Set by the programmer as required)

TOOL DEF? - Tool offset number

L? - Tool Length information.

R? - Tool Radius (Used for compensation & graphics).

Toolchange information (Set by the programmer as required)

TOOL CALL? - Tool number - 2 Digit number (pocket)

Z? - Axis the tool is aligned with.

S? - Tool Spindle Speed.

F? - Automatic feed selection. (Using material data base)

DL? - Additional tool length offset. (Roughing purposes)

DR? - Additional tool radius offset. (Roughing purposes)

DR2? - Second additional tool radius offset. (426 3D tool compensation)

Text messages (Set by the programmer as required)

; - Program Text - 55 characters limit.

Toolchange

L - Select the L key and continuous NO ENTER until M is reached (Automatic

load).

M6 - Toolchange code.

For manual load use a tool number greater than the number of automatic tool

pockets.

PGM

MGT

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 5

Program Creation

Edit Graphics

Selecting the GRAPHICS key as above will prompt the user with the following 3

keys:

Selecting the PGM +GRAPHICS key as above will prompt the user with the

following keys:

The GRAPHIC keys are as follows:

AUTO DRAW - Allows the pencil graphics to be used.

RESET + START - Will run the graphics in Full Run Mode.

CLEAR GRAPHICS - Clears the graphic screen.

START SINGLE BLOCK - Runs the graphics block by block on pressing this key.

SHOW/OMIT BLOCK NR. - Block number details shown on graphics.

<< >> - Graphic zoom.

WINDOW DETAIL - Redraws zoom area.

START - Restarts graphics after a program stop.

Selecting the PGM +SECTS key as above will allow the programmer to TAG

certain information to a specific area of program using the INSERT SECTION key

as below.

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 5

(LINE Exercise PGM 10101)

80mm Square

100mm Square

Plan

20

40

Side

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 5

(LINE Exercise PGM 10101)

0 BEGIN PGM 10101 MM

1 BLK FORM 0.1 Z X-50 Y-50 Z-40

2 BLK FORM 0.2 X+50 Y+50 Z+0

3 TOOL DEF 1

4 TOOL CALL 1 Z S1000

5 L M6

6 L X-70 Y-70 R0 FMAX M13

7 L Z-20 FMAX

8 APPR ?

9 L Y+40

10 L X+40

11 L Y-40

12 L X-40

13 DEP ?

14 TOOL CALL 0

15 L M6

16 M30

17 END PGM 10101 MM

80mm Square

100mm Square

Plan 20

40

Side

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 5

(LINE Exercise PGM 10102)

100mm Square

Plan

Side

20

40

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 5

(LINE Exercise PGM 10102)

0 BEGIN PGM 10102 MM

1 BLK FORM 0.1 Z X-50 Y-50 Z-40

2 BLK FORM 0.2 X+50 Y+50 Z+0

3 TOOL DEF 1

4 TOOL CALL 1 Z S1000

5 L M6

6 L X-20 Y-20 R0 FMAX M13

7 L Z-20 FMAX

8 APPR ?

9 L X+0 Y+50

10 L X+50 Y+0

11 L X-50 Y+0

12 L X-50 Y+0

13 DEP ?

14 TOOL CALL 0

15 L M6

16 M30

17 END PGM 10102 MM

100mm Square

Plan

Side

20

40

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 5

Chamfers & Blend Radii

Blend chamfers and Blend Radii can be created within a program with the aid of the CHF

& RND keys.

The CHF & RND values are Non-Modal values and are inserted into the program line after

the end point has been programmed (the known intersection programmed point)

1

2

3

80 mm

CHF =chamfer length

(1 to 2) L X0 Y80

CHF ? F?

(2 to 3) L X? Y0

1

2

3

8

0

m

m

RND =Blend radius

RND

(1 to 2) L X0 Y80

RND ? F?

(2 to 3) L X? Y0

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 5

(Chamfer Exercise PGM 10103)

100mm Square

Plan

Side

40

15

15

20

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 5

(Chamfer Exercise PGM 10103)

0 BEGIN PGM 10103 MM

1 BLK FORM 0.1 Z X-50 Y-50 Z-40

2 BLK FORM 0.2 X+50 Y+50 Z+0

3 TOOL DEF 1 L+0 R+10

4 TOOL CALL 1 Z S1000

5 L M6

6 L X-70 Y-20 R0 FMAX M13

7 L Z-20 FMAX

8 APPR ?

9 L X+0 Y+50

10 CHF 15

11 L X+50 Y+0

12 CHF 15

13 L X+0 Y-50

14 CHF 15

15 L X-50 Y+0

16 DEP ?

17 TOOL CALL 0

18 L M6

19 STOP M30

20 END PGM 10103 MM

100mm Square

Plan

Side

40

15

15

20

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 5

(Corner Rounding Exercise PGM 10104)

100mm Square

Plan

Side

40

20

15 R

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 5

(Corner Rounding Exercise PGM 10104)

0 BEGIN PGM 10104 MM

1 BLK FORM 0.1 Z X-50 Y-50 Z-40

2 BLK FORM 0.2 X+50 Y+50 Z+0

3 TOOL DEF 1

4 TOOL CALL 1 Z S1000

5 L M6

6 L X-70 Y-20 R0 FMAX M3

7 L Z-20 FMAX

8 APPR ?

9 L X+0 Y+50

10 RND R15

11 L X+50 Y+0

12 RND R15

13 L X+0 Y-50

14 RND R15

15 L X-50 Y+0

16 DEP ?

17 TOOL CALL 0

18 L M6

19 STOP M30

20 END PGM 10104 MM

100mm Square

Plan

Side

40

20

15 R

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 6

CHAPTER 6

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 6

(Circle Boss Exercise PGM 10105)

100mm Square

Plan

40

Side

20

35 R

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 6

(Circle Boss Exercise PGM 10105)

0 BEGIN PGM 10105 MM

1 BLK FORM 0.1 Z X-50 Y-50 Z-40

2 BLK FORM 0.2 X+50 Y+50 Z+0

3 TOOL DEF 1

4 TOOL CALL 1 Z S1000

5 L M6

6 L X+70 Y+0 R0 FMAX M3

7 L Z-20 FMAX

8 APPR ?

9 CC X+0 Y+0

10 C X+35 Y+0 DR-

11 DEP ?

12 TOOL CALL 0

13 L M6

14 STOP M30

15 END PGM 10105 MM

100mm Square

Plan

40

Side

20

35 R

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 6

(Circle Centre Arc (CC) Exercise PGM 10106)

100mmSquare

Plan

20

50

80

50

23.542

23.542

20

40

Side

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 6

(Circle Centre Arc (CC) Exercise PGM 10106)

0 BEGIN PGM 10106 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-40

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL DEF 1

4 TOOL CALL 1 Z S1000

5 L M6

6 L X-20 Y+50 R0 FMAX M3

7 L Z-20 FMAX

8 APPR ? F? M8

9 L X+23.542

10 CC X+50 Y+50

11 C X+23.542 Y+80 DR+

12 L X+0

13 DEP ?

14 TOOL CALL 0

15 L M6

16 STOP M30

17 END PGM 10106 MM

100mmSquare

Plan

20

50

80

50

23.542

23.542

20

40

Side

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 6

(Circle Arc (RAD) Exercise PGM 10107)

100mmSquare

Plan

20

80

23.542

23.542

20

40

Side

40 R

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 6

(Circle Arc (RAD) Exercise PGM 10107 text)

0 BEGIN PGM 10107 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-40

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL DEF 1

4 TOOL CALL 1 Z S1000

5 L M6

6 L X-20 Y+50 R0 FMAX M3

7 L Z-20 FMAX

8 APPR ?

9 L X+23.542

10 CR X+23.542 Y+80 R-40 DR+

11 L X+0

12 DEP ?

13 TOOL CALL 0

14 L M6

15 STOP M30

16 END PGM 10107 MM

100mmSquare

Plan

20

80

23.542

23.542

20

40

Side

40 R

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 6

(Tangential Arc Exercise PGM 10108)

100 SQR.

S

I

D

E

S

E

C

T

I

O

N

30

80

60

42.679

80

60

20 40

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 6

(Tangential Arc Exercise PGM 10108 text)

100 SQR.

S

I

D

E

S

E

C

T

I

O

N

30

80

60

42.679

80

60

20 40

0 BEGIN PGM 10108 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-40

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL DEF 1

4 TOOL CALL 1 Z S1000

5 L M6

6 L X+60 Y-20 R0 FMAX M3

7 L Z-20 FMAX

8 APPR ? F? M8

9 L Y+60

10 CT X+60 Y+80

11 L X+40

12 CT X+30 Y+42.679

13 L Y+0

14 DEP ?

15 TOOL CALL 0

16 L M6

17 L M30

18 END PGM 10108 MM

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 6

(Circular Arc Exercise PGM 10109)

100 SQR.

15

85

50

20

100 R

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 6

(Circular Arc Exercise PGM 10109)

100 SQR.

15

85

50

20

100 R

0 BEGIN PGM 10109 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-40

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL DEF 1

4 TOOL CALL 1 Z S1000

5 L M6

6 L X-20 Y-20 R0 FMAX M3

7 L Z-20 FMAX

8 APPR?

9 L Y+50

10 CR X+85 Y+50 R+100 DR-

11 L Y+0

12 DEP?

13 TOOL CALL 0

14 L M6

15 L M30

16 END PGM 10109 MM

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 6

(Circular Arc Exercise PGM 10110)

100

1

0

0

60

51.927

16.026

29.373

60.562

3

4

.

4

3

5

2

0

.

9

9

5

2

9

.

9

9

8

6

8

.

3

0

9

7

0

20 R

10 R

80 R

75 R

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 6

(Circular Arc Exercise PGM 10110 text)

0 BEGIN PGM 10110 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-40

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL DEF 1

4 TOOL CALL 1 Z S1000

5 L M6

6 L X+60 Y+120 R0 FMAX M3

7 L Z-20 FMAX

8 APPR?

9 CR X+60.562 Y+29.998 R+20 DR-

10 CR X+29.373 Y+20.995 R+75 DR+

11 CR X+16.026 Y+34.435 R+10 DR-

12 CR X+51.927 Y+68.309 R+80 DR-

13 CR X+60 Y+70 R+20 DR-

14 DEP?

15 TOOL CALL 0

16 L M6

17 L M30

18 END PGM 10110 MM

100

1

0

0

60

51.927

16.026

29.373

60.562

3

4

.

4

3

5

2

0

.

9

9

5

2

9

.

9

9

8

6

8

.

3

0

9

7

0

20 R

10 R

80 R

75 R

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 7

CHAPTER 7

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 7

44

Working Planes

XY Plane (Z)

Plan View Front View Side View

XZ Plane (Y) YZ Plane (X)

0

0

0

90

-270

180

-180

270

-90

+

+

+

-

- -

DR-

DR+

90

-270

90

-270

270

-90

270

-90

180

-180

180

-180

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 7

45

Polar Co-ordinate Command

The control has the ability to position itself to an endpoint in any plane using a P

code with an L code giving only the information regarding the radius of the move

from the PCD centre point with the angle of the line as that of a right angled triangle.

All angles are relative to the current plane.

LP PR? PA? R? F? M?

Where:

LP =PCD Polar command Line Polar

PR? =Radius of the PCD action

PA? =Angle of the move

R? =Radius compensation

F? =Feedrate

It is possible to use incremental to control the angle.

If the X & Y positions in the CC line of program to the PCD centre are omitted,

then the current tool position will become the pole PCD centre.

PA

PR

Required XY position

CC X?

CC Y?

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 7

46

(Linear Polar Exercise PGM 10111)

30

40

80

90

30

27

5

6

40

20

100 SQR.

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 7

47

(Linear Polar Exercise PGM 10111)

30

40

80

90

30

27

5

6

40

20

100 SQR.

0 BEGIN PGM 10111 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-40

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL DEF 1

4 TOOL CALL 1 Z S500

5 L M6

6 L X-20 Y+0 R0 FMAX M3

7 L Z-20 FMAX

8 L APPR ?

9 L Y+40

10 CC

11 LP PR+30 PA+60

12 CC

13 LP PR+40 IPA-27

14 CC

15 LP PR+80 IPA-90

16 L X+5 Y+6

17 DEP ?

18 L Z100 FMAX

19 TOOL CALL 0

20 L M6

21 L M2

22 END PGM 10110 MM

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 7

48

(Hexagon PGM 10111)

100 SQR.

R

4

0

6

0

D

e

g

.

20

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 7

49

(Hexagon PGM 10112)

100 SQR.

R

4

0

6

0

D

e

g

.

20

0 BEGIN PGM 10112 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-40

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL DEF 1

4 TOOL CALL 1 Z S1000

5 L M6

6 L X-20 Y-20 R0 FMAX M3

7 L Z-20 FMAX

8 APPR ?

9 CC X+50 Y+50

10 LP PR+40 PA+180

11 LP PA+120

12 LP PA+60

13 LP PA+0

14 LP PA-60

15 LP PA-120

16 LP PA-180

17 L Y+120

18 DEP ?

19 TOOL CALL 0

20 L M6

21 L M30

22 END PGM 10111 MM

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 7

50

Circular Polar Co-ordinate Command

The control has the ability to position itself to an endpoint in any plane using a P

code with a `C code giving only the information regarding the angle that the circle

stops at relative to zero degrees and around a specified Circle Centre position.

All angles are relative to the current plane.

CP PA? D? R? F? M?

Where:

CP =Circular Polar command

PA? =Stopping angle of the move

D? =Direction of circular move

R? =Radius compensation

F? =Feedrate

It is possible to use incremental to control the angle.

Using CP IPA? would control the angle from the starting position.

PA

Required XY position

CC X?

CC Y?

Start Point

PR

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 7

51

(Circle Boss Exercise (polar) PGM 10114)

100 SQR.

SIDE

20

35 R

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 7

52

(Circle Boss Exercise (polar) PGM 10114)

100 SQR.

SIDE

20

35 R

0 BEGIN PGM 10114 MM

1 BLK FORM 0.1 Z X-50 Y-50 Z-40

2 BLK FORM 0.2 X+50 Y+50 Z+0

3 TOOL DEF 1

4 TOOL CALL 1 Z S1000

5 L M6

6 L X+70 Y+0 R0 FMAX M3

7 L Z-20 FMAX

8 APPR ?

9 CC X+50 Y+50

10 CP IPA+360 DR- (or CP PA+0 DR-)

11 DEP ?

12 TOOL CALL 0

13 L M6

14 L M30

14 END PGM 10114 MM

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 7

53

(Circle Polar PGM 10115)

60

53.13

126.87

53.13

126.87

30 R

70 R

80

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 7

54

(Circle Boss Exercise (polar) PGM 10115)

60

53.13

126.87

53.13

126.87

30 R

70 R

80

0 BEGIN PGM 10115 MM

1 BLK FORM 0.1 Z X-90 Y-15 Z-40

2 BLK FORM 0.2 X+90 Y+15 Z+0

3 TOOL DEF 1

4 TOOL CALL 1 Z S1000

5 L M6

6 L X+0 Y-20 R0 FMAX M3

7 L Z-20 FMAX

8 APPR ?

9 CC X+0 Y-80

10 CP PA+126.87 DR+

11 CC X-60 Y+0

12 CP PA+53.13 DR-

13 CC X+0 Y+80

14 CP PA-53.13 DR+

15 CC X+60 Y+0

16 CP PA-126.87 DR-

17 CC X+0 Y-80

18 CP PA+90 DR+

19 DEP ?

20 TOOL CALL 0

21 L M6

22 L M30

23 END PGM 10115 MM

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 8

CHAPTER 8

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 8

Drilling cycles

The TNC offers machining cycles for all types of hole

operations.

Cycle Softkey

1 - Pecking without automatic pre-positioning.

200 - Drilling with automatic pre-positioning and

2nd setup clearance.

201 - Reaming with automatic pre-positioning and

2nd setup clearance.

202 - Boring with automatic pre-positioning and

2nd setup clearance.

203 - Universal Drilling with automatic pre-positioning,

2nd setup clearance, chip breaking and decrement.

204 - Back Boring with automatic pre-positioning and

2nd setup clearance.

2 - Tapping with a floating tap holder.

17 - Rigid Tapping without a floating holder.

18 - Thread Cutting (426).

209 Tapping with chip breaking.

1

200

201

202

203

204

2

17

18

209

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 8

Pecking (Cycle 1)

1) The tool drills from the Current Position to the first PECKING DEPTH at the

programmed FEED RATE F.

2) When it reaches the first pecking depth, the tool retracts in rapid traverse FMAX

to the starting position and advances again to the first PECKING DEPTH minus

the advanced stop distance t.

3) The advance stop distance is automatically calculated by the control:

At a total hole depth of up to 30mm :t =0.6mm

At a total hole depth exceeding 30mm :t =hole depth / 50.

Maximum advanced stop distance =7mm.

4) The tool then advances with another infeed at the programmed FEED RATE F.

5) The TNC repeats this process (1 - 4) until the programmed TOTAL HOLE

DEPTH is reached.

6) After a DWELL TIME at the bottom of the hole, the tool is returned to the

starting position in rapid traverse FMAX for chip breaking.

NOTE: Program a positioning block for the starting point (hole center) in the

working plane with RADIUS COMPENSATION RO.

Program a positioning block for the starting point in the tool axis (SET-UP

CLEARANCE above the workpiece surface).

The sign (+or -) for the cycle parameter TOTAL HOLE DEPTH determines the

working direction.

SETUP CLEARANCE - (Incremental) Distance between tool tip (at start

position) and workpiece surface.

TOTAL HOLE DEPTH - (Incremental) Distance between workpiece surface

and bottom of the hole (tool tip).

PECKING DEPTH - (Incremental) Infeed per cut. The tool will drill to the

DEPTH in one movement if :a) the PECKING DEPTH equals the TOTAL

HOLE DEPTH. b) the PECKING DEPTH is greater than the TOTAL HOLE

DEPTH.

DWELL TIME IN SECONDS - Amount of time the tool remains at the total

hole depth for chip breaking.

FEED RATE F - Traversing speed of the tool during drilling.

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 8

Drilling (Cycle 200)

1) The TNC positions the tool in the tool axis at rapid traverse FMAX to the SET-

UP CLEARANCE above the WORKPIECE SURFACE COORDINATE.

2) The tool drills to the first PLUNGING DEPTH at the programmed FEED

RATE F.

3) The tool is retracted to SET-UP CLEARANCE in FMAX, remains there - if

programmed - for the entered dwell time, and advances again in FMAX to 0.2mm

above the first PLUNGING DEPTH.

4) The tool then drills deeper by the PLUNGING DEPTH at the programmed

FEED RATE F.

5) The TNC repeats this process (2 - 4) until the programmed TOTAL HOLE

DEPTH is reached.

6) At the hole bottom, the tool is retracted to SET-UP CLEARANCE or - if

programmed - to the 2ND SET-UP CLEARANCE in rapid traverse FMAX.

NOTE: Program a positioning block for the starting point (hole center) in the

working plane with RADIUS COMPENSATION RO.

The sign (+or -) for the cycle parameter DEPTH determines the working direction.

SETUP CLEARANCE Q200 - (Incremental) Distance between tool tip (at

start position) and workpiece surface.

DEPTH Q201 - (Incremental) Distance between workpiece surface and bottom

of the hole (tool tip).

FEED RATE FOR PLUNGING Q206 - Traversing speed of the tool during

drilling.

PLUNGING DEPTH Q202 - (Incremental) Infeed per cut. The tool will drill to

the DEPTH in one movement if :a) the PECKING DEPTH equals the TOTAL

HOLE DEPTH. b) the PECKING DEPTH is greater than the TOTAL HOLE

DEPTH.

DWELL TIME AT TOP Q210 - Amount of time the tool remains at the SET-

UP CLEARANCE after having been retracted from the hole for chip release.

WORKPIECE SURFACE COORDINATE Q203 - (Absolute) Co-ordinate of

workpiece surface.

2ND SET-UP CLEARANCE Q204 - (Incremental) Co-ordinate in the tool

axis at which no collision between tool and workpiece (clamping devices) can

occur.

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 8

Reaming (Cycle 201)

1) The TNC positions the tool in the tool axis at rapid traverse FMAX to the SET-

UP CLEARANCE above the WORKPIECE SURFACE COORDINATE.

2) The tool reams to the entered DEPTH at the programmed FEED RATE F.

3) If programmed, the tool remains at the hole bottom for the entered dwell time.

4) The tool then retracts to SET-UP CLEARANCE at the FEED RATE F , and

from there - if programmed - to the 2ND SET-UP CLEARANCE in FMAX.

NOTE: Program a positioning block for the starting point (hole center) in the

working plane with RADIUS COMPENSATION RO.

The sign (+or -) for the cycle parameter DEPTH determines the working direction.

SETUP CLEARANCE Q200 - (Incremental) Distance between tool tip (at

start position) and workpiece surface.

DEPTH Q201 - (Incremental) Distance between workpiece surface and bottom

of the hole (tool tip).

FEED RATE FOR PLUNGING Q206 - Traversing speed of the tool during

drilling.

DWELL TIME AT DEPTH Q211 - Amount of time the tool remains at the

DEPTH.

RETRACTION FEEDRATE Q208 - Traversing feedrate of tool when

retracting from the hole. If zero is entered the tool retracts at the reaming FEED

RATE FOR PLUNGING.

WORKPIECE SURFACE COORDINATE Q203 - (Absolute) Co-ordinate of

workpiece surface.

2ND SET-UP CLEARANCE Q204 - (Incremental) Co-ordinate in the tool

axis at which no collision between tool and workpiece (clamping devices) can

occur.

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 8

Boring (Cycle 202)

1) The TNC positions the tool in the tool axis at rapid traverse FMAX to the SET-

UP CLEARANCE above the WORKPIECE SURFACE COORDINATE.

2) The tool bores to the entered DEPTH at the programmed FEED RATE F.

3) If programmed, the tool remains at the hole bottom for the entered dwell time.

4) The TNC then orientates the spindle to the zero degree position with an

orientated stop.

5) If retraction is selected, the tool retracts in the programmed direction by 0.2mm

(fixed value).

6) The tool then retracts to SET-UP CLEARANCE at the RETRACTION FEED

RATE , and from there - if programmed - to the 2ND SET-UP CLEARANCE in

FMAX.

NOTE: Program a positioning block for the starting point (hole center) in the

working plane with RADIUS COMPENSATION RO.

The sign (+or -) for the cycle parameter DEPTH determines the working direction.

SETUP CLEARANCE Q200 - (Incremental) Distance between tool tip (at

start position) and workpiece surface.

DEPTH Q201 - (Incremental) Distance between workpiece surface and bottom

of the hole (tool tip).

FEED RATE FOR PLUNGING Q206 - Traversing speed of the tool during

drilling.

DWELL TIME AT DEPTH Q211 - Amount of time the tool remains at the

DEPTH.

RETRACTION FEEDRATE Q208 - Traversing feedrate of tool when

retracting from the hole. If zero is entered the tool retracts at the reaming FEED

RATE FOR PLUNGING.

WORKPIECE SURFACE COORDINATE Q203 - (Absolute) Co-ordinate of

workpiece surface.

2ND SET-UP CLEARANCE Q204 - (Incremental) Co-ordinate in the tool

axis at which no collision between tool and workpiece (clamping devices) can

occur.

DISENGAGING DIRECTION Q214 - Direction to clear bore.

0 =Do not retract the tool

1 =Retract the tool in the negative main axis direction.

2 =Retract the tool in the negative secondary axis direction.

3 =Retract the tool in the positive main axis direction.

4 =Retract the tool in the positive secondary axis direction.

NOTE: Check the position of the tool tip when you program a spindle orientation to

zero degrees. Align the tool tip so that it is parallel to a coordinate axis. Select a

DISENGAGING DIRECTION in which the tool moves away from the edge of the

hole.

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 8

Universal Drilling (Cycle 203)

1) The TNC positions the tool in the tool axis at rapid traverse FMAX to the SET-UP

CLEARANCE above the WORKPIECE SURFACE COORDINATE.

2) The tool drills to the first PLUNGING DEPTH at the programmed FEED RATE.

3) If you have programmed chip breaking, the tool then retracts by 0.2mm. If you are

working without chip breaking, the tool retracts at the RETRACTION FEED RATE

to SET-UP CLEARANCE, remains there - if programmed - for the entered dwell

time, and advances again in FMAX to 0.2mm above the first PLUNGING DEPTH.

4) The tool then advances with another peck at the programmed FEED RATE F. If

programmed, the PLUNGING DEPTH is decreased after each peck by the

DECREMENT.

5) The TNC repeats this process (2 - 4) until the programmed TOTAL HOLE DEPTH

is reached.

6) The tool remains at the hole bottom - if programmed - for the entered DWELL

TIME to cut free, and then retracts to the SET-UP CLEARANCE at the

RETRACTION FEED RATE. If you have entered a 2ND SET-UP CLEARANCE,

the tool subsequently moves to that position in FMAX.

NOTE: Program a positioning block for the starting point (hole center) in the working

plane with RADIUS COMPENSATION RO.

The sign (+or -) for the cycle parameter DEPTH determines the working direction.

SETUP CLEARANCE Q200 - (Incremental) Distance between tool tip (at start

position) and work piece surface.

DEPTH Q201 - (Incremental) Distance between work piece surface and bottom of

the hole (tool tip).

FEED RATE FOR PLUNGING Q206 - Traversing speed of the tool during

drilling.

PLUNGING DEPTH Q202 - (Incremental) Peck depth. The tool will drill to the

DEPTH in one movement if :a) the PECKING DEPTH equals the TOTAL HOLE

DEPTH. b) the PECKING DEPTH is greater than the TOTAL HOLE DEPTH.

DWELL TIME AT TOP Q210 - Amount of time the tool remains at the SET-UP

CLEARANCE after having been retracted from the hole for chip release.

WORKPIECE SURFACE COORDINATE Q203 - (Absolute) Coordinate of

work piece surface.

2ND SET-UP CLEARANCE Q204 - (Incremental) Coordinate in the tool axis at

which no collision between tool and work piece (clamping devices) can occur.

DECREMENT Q212 (Increment) - Value by which the TNC decreases the

PLUNGING DEPTH after each peck.

NR OF BREAKS BEFORE RETRACTING Q213 - Number of chip breaks after

which the TNC is to withdraw the tool from the hole for chip release. For chip

breaking, the TNC retracts the tool each time by 0.2mm.

MINIMUM PLUNGING DEPTH Q208 (Incremental) - If a decrement was

entered, this limits the final plunging depth to this value.

DWELL TIME AT DEPTH Q211 - Amount of time the tool remains at the

DEPTH.

RETRACTION FEEDRATE Q208 - Traversing feed rate of tool when retracting

from the hole. If zero is entered the tool retracts at FMAX.

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 8

Back Boring (Cycle 204)

1) The TNC positions the tool in the tool axis at rapid traverse FMAX to the SET-

UP CLEARANCE above the WORKPIECE SURFACE COORDINATE.

2) The TNC then orientates the spindle to the zero degree position with an

orientated spindle stop, and displaces the tool by the OFF CENTER

DISTANCE.

3) The tool is then plunged into the already bored hole at the FEED RATE FOR

PRE-POSITIONING until the tooth has reached SET-UP CLEARANCE on

the underside of the work piece.

4) The TNC then centers the tool again over the bore hole, switches on the spindle

and the coolant and moves at the FEED RATE FOR BORING to the DEPTH

of bore.

5) If a DWELL TIME is entered, the tool will pause at the top of the bore hole and

will then be retracted from the hole again. The TNC carries out another

orientated spindle stop and the tool is once again displaced by the OFF

CENTER DISTANCE.

6) The TNC moves the tool at the FEED RATE FOR PRE-POSITIONING to the

SET-UP CLEARANCE and then, if entered, to the 2

ND

SET-UP

CLEARANCE with FMAX

NOTE: Program a positioning block for the starting point (hole center) in the

working plane with RADIUS COMPENSATION RO.

The sign (+or -) for the cycle parameter DEPTH determines the working direction.

The entered tool length is the total length to the underside of the boring bar and not

just to the tooth.

SETUP CLEARANCE Q200 - (Incremental) Distance between tool tip (at

start position) and work piece surface.

DEPTH Q249 - (Incremental) Depth of counter-bore from underside of work

piece.

MATERIAL THICKNESS Q250 - (Incremental)

OFF-CENTER DISTANCE Q251 - (Incremental) Off center shift distance.

TOOL EDGE HEIGHT Q252 - (Incremental) Tool nose thickness.

FEED RATE FOR PRE-POSITIONING Q253 - Feed for moving in and out

of bore (mm/min.).

FEED RATE FOR COUNTERBORING Q254 - Traversing speed of the tool

during counter boring (mm/min.).

DWELL TIME Q255 - Dwell time at counter bore finish depth.

WORKPIECE SURFACE COORDINATE Q203 - (Absolute) Coordinate of

work piece surface.

2ND SET-UP CLEARANCE Q204 - (Incremental) Coordinate in the tool axis

at which no collision between tool and work piece (clamping devices) can occur.

DISENGAGING DIRECTION Q214 - Direction to clear bore.

0 =Do not retract the tool

1 =Retract the tool in the negative main axis direction.

2 =Retract the tool in the negative secondary axis direction.

3 =Retract the tool in the positive main axis direction.

4 =Retract the tool in the positive secondary axis direction.

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 8

Tapping (Cycle 2)

1) The thread is cut in one pass.

2) Once the tool has reached the TOTAL DEPTH, the direction of spindle rotation is

reversed and the tool is retracted to the starting position at the end of the DWELL

TIME.

3) At the starting position, the direction of spindle rotation reverses once again.

NOTE: Program a positioning block for the starting point (hole center) in the

working plane with RADIUS COMPENSATION RO.

Program a positioning block for the starting point in the tool axis (SET-UP

CLEARANCE above the work piece surface).

The sign (+or -) for the cycle parameter DEPTH determines the working direction.

A floating tap holder is required for tapping. It must compensate the tolerances

between feed rate and spindle speed during tapping process.

When in cycle, the spindle speed override is disabled.

For tapping right hand threads activate the spindle with M3, for left hand threads use

M4.

SETUP CLEARANCE - (Incremental) Distance between tool tip (at start

position) and work piece surface. Standard value =4 times the thread pitch.

TOTAL HOLE DEPTH - (Incremental) Distance between work piece surface

and bottom of the hole (tool tip).

DWELL TIME IN SECONDS - Enter a value between 0 and 0.5 seconds to

avoid wedging of the tool during retraction.

FEED RATE F - Traversing speed of the tool during tapping.

The feed rate is calculated as follows: F = S x P

Where:

F is the feed rate.

S is the spindle speed in RPM.

P is the thread pitch.

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 8

Rigid Tapping (Cycle 17)

1) The thread is cut in one pass.

2) Once the tool has reached the TOTAL DEPTH, the direction of spindle rotation is

reversed and the tool is retracted to the starting position at the end of the DWELL

TIME.

3) At the starting position, the direction of spindle rotation reverses once again.

NOTE: Program a positioning block for the starting point (hole center) in the

working plane with RADIUS COMPENSATION RO.

Program a positioning block for the starting point in the tool axis (SET-UP

CLEARANCE above the workpiece surface).

The sign (+or -) for the cycle parameter DEPTH determines the working direction.

A floating tap holder is required for tapping. It must compensate the tolerances

between feedrate and spindle speed during tapping process.

When in cycle, the spindle speed override is disabled.

For tapping right hand threads activate the spindle with M3, for left hand threads use

M4.

The TNC calculates the feedrate from the spindle speed and the entered pitch. If the

feed override is adjusted during tapping, the feedrate will be adjusted automatically

to suit.

SETUP CLEARANCE - (Incremental) Distance between tool tip (at start

position) and workpiece surface. Standard value =4 times the thread pitch.

TOTAL HOLE DEPTH - (Incremental) Distance between workpiece surface

and bottom of the hole (tool tip).

PITCH - Thread pitch. Algebraic sign differentiates between right hand and left

hand threads.

+ = Right hand thread,

- = Left hand threads.

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 8

Thread Cutting (Cycle 18)

Cycle 18 THREAD CUTTING is performed by means of spindle control. The tool

moves with the active spindle speed from its current position to the entered DEPTH.

As soon as it reaches the end of thread, spindle rotation is stopped. Tool approach to

the hole surface and departure from the hole bottom must be programmed

separately.

NOTE: The TNC automatically activates and deactivates spindle rotation.

Do not program M3 or M4 before the cycle call.

When in cycle, the feed rate override is disabled.

The TNC calculates the feedrate from the spindle speed and the entered pitch. If the

spindle speed override is adjusted during threading, the feedrate will be adjusted

automatically to suit.

TOTAL HOLE DEPTH - (Incremental) Distance between current tool

position and the end of the thread.

PITCH - Thread pitch. Algebraic sign differentiates between right hand and left

hand threads.

+ = Right hand thread (M3 with negative depth)

- = Left hand threads (M4 with negative depth)

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 8

Tapping with chip breaking (Cycle 209)

1) The TNC positions the tool in the tool axis at rapid traverse FMAX to the SET-

UP CLEARANCE above the WORKPIECE SURFACE COORDINATE. There

it carries out an orientated spindle stop.

2) The tool moves to the programmed infeed depth, reverses the direction of the

spindle rotation and retracts by a specific distance or completely for chip release,

dependant on the definition.

3) It then reverses the direction of spindle rotation again and advances to the next in

feed depth.

4) The TNC repeats this process (2 3) until the programmed thread depth is

reached.

5) The tool is then retracted to SET-UP CLEARANCE, and if programmed, to the

2ND CLEARANCE with FMAX.

6) The TNC stops the spindle turning at SET-UP CLEARANCE

NOTE: Program a positioning block for the starting point (hole center) in the

working plane with RADIUS COMPENSATION RO.

The sign (+or -) for the cycle parameter THREAD DEPTH determines the working

direction.

At the end of the cycle the spindle comes to a stop. Before the next operation, restart

the spindle with M3 (or M4).

SETUP CLEARANCE Q200 - (Incremental) Distance between tool tip (at

start position) and work piece surface.

DEPTH Q201 - (Incremental) Distance between work piece surface and bottom

of the hole (tool tip).

THREAD PITCH Q239 Pitch of the thread (+=RH, - =LH)

WORKPIECE SURFACE COORDINATE Q203 - (Absolute) Co-ordinate of

work piece surface.

2ND SET-UP CLEARANCE Q204 - (Incremental) Co-ordinate in the tool

axis at which no collision between tool and work piece (clamping devices) can

occur.

DEPTH FOR CHIP BRKNG Q257 - (Incremental) In feed per cut. The tool

will tap to the DEPTH in one movement if a) the PECKING DEPTH equals the

TOTAL HOLE DEPTH. b) the PECKING DEPTH is greater than the TOTAL

HOLE DEPTH.

DIST FOR CHIP BRKNG Q256 Retraction rate for chip breaking. The TNC

multiplies the pitch by this value to retract the tap by this new amount before the

next peck. If Q256 =0 then the TNC retracts the tool fully for chip breakage.

ANGLE OF SPINDLE Q336 (Absolute) Angle at which the TNC positions

the tool before machining the thread.

** If the program is interrupted during cycle, the TNC will display the soft key

MANUAL OPERATION. By pressing this key, retraction of the tool is

possible. Simply press the positive axis direction button of the active tool

axis.**

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 8

(Drilling Cycle Exercises PGM 10116)

2

0

3

5

5

0

20

50

80

100

2

0

2

0

5

0

8mm Holes

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 8

(Drilling Cycle PGM 10116)

2

0

3

5

5

0

20

50

80

100

2

0

2

0

5

0

8mm Holes

0 BEGIN PGM 10116 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+50 Z+20

3 TOOL DEF 1

4 TOOL CALL 1 Z S1000

5 L M6

6 CYCL DEF 1.0 PECKING

7 CYCL DEF 1.1 SET UP 5

8 CYCL DEF 1.2 PLNGNG -20

9 CYCL DEF 1.3 DWELL 0

10 CYCL DEF 1.4 F???

11 L X+20 Y+20 R0 FMAX M3

12 L Z+5 FMAX

13 CYCL CALL M8

14 L Z+25 FMAX

15 L X+80 FMAX

16 L Z+5 FMAX

17 CYCL CALL

18 L Z+25 FMAX

19 CYCL DEF 1.0 PECKING

20 CYCL DEF 1.1 SET UP 5

21 CYCL DEF 1.2 PLNGNG -40

22 CYCL DEF 1.3 DWELL 0

23 CYCL DEF 1.4 F???

24 L X+50 Y+35 FMAX

25 CYCL CALL

26 TOOL CALL 0

27 L M6

28 L M30

29 END PGM 10116 MM

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 8

(Drilling Cycle Exercises PGM 10116B)

2

0

3

5

5

0

20

50

80

100

2

0

2

0

5

0

8mm Holes

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 8

(Drilling Cycle PGM 10116B)

2

0

3

5

5

0

20

50

80

100

2

0

2

0

5

0

8mm Holes

0 BEGIN PGM 10116B MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+50 Z+20

3 TOOL DEF 1

4 TOOL CALL 1 Z S1000

5 L M6

6 CYCL DEF 200 DRILLING

Q200 = 5 ;SET-UP CLEARANCE

Q201 = -20 ;DEPTH

Q206 = ??? ;FEED RATE FOR PLNGNG

Q202 = 5 ;PLNGNG DEPTH

Q210 = 0 ;DWELL TIME AT TOP

Q203 = 0 ;SURFACE COORDINATE

Q204 = 25 ;2ND SET-UP CLEARANCE

7 L X+20 Y+20 R0 FMAX M3

8 CYCL CALL M8

9 L X+80 FMAX

10 CYCL CALL

11 CYCL DEF 200 DRILLING

Q200 = 5 ;SET-UP CLEARANCE

Q201 = -40 ;DEPTH

Q206 = ??? ;FEED RATE FOR PLNGNG

Q202 = 5 ;PLNGNG DEPTH

Q210 = 0 ;DWELL TIME AT TOP

Q203 = 20 ;SURFACE COORDINATE

Q204 = 5 ;2ND SET-UP CLEARANCE

12 L X+50 Y+35 FMAX

13 CYCL CALL

14 TOOL CALL 0

15 L M6

16 L M30

17 END PGM 10116B MM

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 8

(Tapping Cycle PGM 10116C)

2

0

3

5

5

0

20

50

80

100

2

0

2

0

Centre hole tap 20mm deep

Other holes 10mm deep

M10 x 1.5 Tap

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 8

(Tapping Cycle PGM 10116C)

2

0

3

5

5

0

20

50

80

100

2

0

2

0

Centre hole tap 20mm deep

Other holes 10mm deep

M10 x 1.5 Tap

0 BEGIN PGM 10116C MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+50 Z+20

3 TOOL DEF 2

4 TOOL CALL 2 Z S100

5 L M6

6 CYCL DEF 2.0 TAPPING

7 CYCL DEF 2.1 SET UP 5

8 CYCL DEF 2.2 DEPTH -10

9 CYCL DEF 2.3 DWELL 0

10 CYCL DEF 2.4 F?

11 L X+20 Y+20 R0 FMAX M3

12 L Z+5 FMAX

13 CYCL CALL M8

14 L Z+25 FMAX

15 L X+80 FMAX

16 L Z+5 FMAX

17 CYCL CALL

18 L Z+25 FMAX

19 CYCL DEF 2.0 TAPPING

20 CYCL DEF 2.1 SET UP 5

21 CYCL DEF 2.2 DEPTH -20

22 CYCL DEF 2.3 DWELL 0

23 CYCL DEF 2.4 F?

24 L X+50 Y+35 FMAX

25 CYCL CALL

26 TOOL CALL 0

27 L M6

28 L M30

29 END PGM 10116C MM

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 8

(Rigid Tapping Cycle PGM 10116D)

2

0

3

5

5

0

20

50

80

100

2

0

2

0

Centre hole tap 20mm deep

Other holes 10mm deep

M10 x 1.5 Tap

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 8

(Rigid Tapping Cycle PGM 10116D)

2

0

3

5

5

0

20

50

80

100

2

0

2

0

Centre hole tap 20mm deep

Other holes 10mm deep

M10 x 1.5 Tap

0 BEGIN PGM 10116D MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+50 Z+20

3 TOOL DEF 2

4 TOOL CALL 2 Z S100

5 L M6

6 CYCL DEF 17.0 RIGID TAPPING

7 CYCL DEF 17.1 SET UP 5

8 CYCL DEF 17.2 PLNGNG -10

9 CYCL DEF 17.3 PITCH 1.5

10 L X+20 Y+20 R0 FMAX M3

11 L Z+5 FMAX

12 CYCL CALL M8

13 L Z+25 FMAX

14 L X+80 FMAX

15 L Z+5 FMAX

16 CYCL CALL

17 L Z+25 FMAX

18 CYCL DEF 17.0 RIGID TAPPING

19 CYCL DEF 17.1 SET UP 5

20 CYCL DEF 17.2 PLNGNG -20

21 CYCL DEF 17.3 PITCH 1.5

22 L X+50 Y+35 FMAX

23 CYCL CALL

24 TOOL CALL 0

25 L M6

26 L M30

27 END PGM 10116D MM

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 9

CHAPTER 9

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 9

Pocket , Stud & Slot Milling cycles

The TNC offers 9 cycles for all types of Milling operations.

Cycle Softkey

4 - Pocket Milling (rectangular) Roughing without automatic pre-

positioning.

212 - Pocket Finishing (rectangular) Finishing with automatic pre-

positioning and 2nd setup clearance.

213 - Stud Finishing (rectangular) Finishing with automatic pre-

positioning and 2nd setup clearance.

5 - Circle Pocket Milling - Roughing without automatic pre-

positioning.

214 - Circular Pocket Finishing - with automatic pre-positioning &

2nd setup clearance.

215 - Circular Stud Finishing - with automatic pre-positioning &

2nd setup clearance.

3 - Slot Milling - Roughing/finishing cycle with automatic pre-

positioning & vertical downfeed.

210 - Slot with reciprocating plunge cut - Roughing/finishing cycle

with automatic pre-positioning & reciprocating plunge milling.

211 - Circular Slot - Roughing/finishing cycle with automatic pre-

positioning & reciprocating plunge milling.

4

212

213

5

214

215

3

210

211

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 9

Linear Pocket Milling (Cycle 4)

1) The tool penetrates the workpiece at the starting position (pocket center) and

advances to the first PECKING DEPTH.

2) The cutter begins milling in the positive axis direction of the longer side (on

square pockets, always starting in the positive Y axis) and then roughs out the

pocket from the inside out.

3) This process (1 - 3) is repeated until the DEPTH is reached.

4) At the end of the cycle, the TNC retracts the tool to the starting position.

NOTE: Program a positioning block for the starting point (pocket center) in the

working plane with RADIUS COMPENSATION RO.

Program a positioning block for the starting point in the tool axis (SET-UP

CLEARANCE above the workpiece surface).

The sign (+or -) for the cycle parameter MILLING DEPTH determines the working

direction.

This cycle requires a center cutting endmill or a pilot hole drilled prior to the Pocket

milling cycle.

SETUP CLEARANCE - (Incremental) Distance between tool tip (at start

position) and workpiece surface.

MILLING DEPTH - (Incremental) Distance between workpiece surface and

bottom of the pocket.

PECKING DEPTH - (Incremental) Infeed per cut. The tool will advance to

the DEPTH in one movement if :a) the PECKING DEPTH equals the TOTAL

HOLE DEPTH. b) the PECKING DEPTH is greater than the MILLING DEPTH.

FEED RATE FOR PECKING - Pecking feedrateof the tool during penetration.

FIRST SIDE LENGTH - Pocket length parallel to the main axis of the working

plane.

SECOND SIDE LENGTH - Pocket width.

FEED RATE F - Milling feedrate.

DIRECTION OF THE MILLING PATH - DR+=Climb milling with M3,

DR- =Conventional milling with M3.

The stepover factor is parameter (7430) and is preset by the machine manufacturers.

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 9

Linear Pocket Finishing (Cycle 212)

1) The TNC automatically moves the tool in the tool axis to SET-UP

CLEARANCE, or - if programmed - to the 2ND SET-UP CLEARANCE, and

subsequently to the center of the pocket.

2) From the pocket center, the tool moves in the working plane to the starting point

for machining. The TNC takes the ALLOWANCE and the tool radius into account

for calculating the starting point. If necessary, the TNC plunge cuts into the pocket

center.

3) If the tool is at the 2ND SET-UP CLEARANCE, it moves in rapid traverse

FMAX to SET-UP CLEARANCE, and from there advances to the first PLUNGING

DEPTH at the FEED RATE FOR PLUNGING.

4) The tool then moves tangential to the contour of the finished part and, using

climb milling, machines one revolution.

5) After this, the tool departs the contour tangential and returns to the starting point

in the working plane.

6) This process (3 - 5) is repeated until the programmed DEPTH is reached.

7) At the end of the cycle, the TNC retracts the tool in rapid traverse to SET-UP

CLEARANCE, or - if programmed - to the 2ND SET-UP CLEARANCE, and

finally to the center of the pocket (end position =starting position).

NOTE: The sign (+or -) for the cycle parameter DEPTH determines the working

direction.

This cycle requires a center cutting endmill if it is being used to rough and finish (a

low plunging feedrate will be required).

Minimum size of pocket: 3 x tool radius.

SETUP CLEARANCE Q200 - (Incremental) Distance between tool tip (at

start position) and workpiece surface.

DEPTH Q201 - (Incremental) Distance between workpiece surface and bottom

of the pocket.

FEED RATE FOR PLUNGING Q206 - Traversing speed of the tool when

moving to DEPTH.

PLUNGING DEPTH Q202 - (Incremental) Infeed per cut.

FEED RATE FOR MILLING Q207 - Pecking feedrateof the tool during

milling.

WORKPIECE SURFACE COORDINATE Q203 - (Absolute) Coordinate of

workpiece surface.

2ND SET-UP CLEARANCE Q204 - (Incremental) Additional retract.

CENTER IN FIRST AXIS Q216 - (Absolute) Center of the pocket in the main

axis of the working plane.

CENTER IN SECOND AXIS Q217 - (Absolute) Center of the pocket in the

secondary axis of the working plane.

FIRST SIDE LENGTH Q218 - Pocket length parallel to the main axis of the

working plane.

SECOND SIDE LENGTH Q219 - Pocket width.

CORNER RADIUS Q220 - Radius of the pocket corners. No value entered here

will use tool radius value.

ALLOWANCE IN 1ST AXIS Q221 - (Incremental) Clearance value to allow

the tool diameter to rapid traverse close to the machined wall.

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 9

Linear Stud Finishing (Cycle 213)

1) The TNC automatically moves the tool in the tool axis to SET-UP

CLEARANCE, or - if programmed - to the 2ND SET-UP CLEARANCE, and

subsequently to the center of the stud.

2) From the stud center, the tool moves in the working plane to the starting point for

machining. The starting point lies to the right of the stud by a distance approx. 3.5

times the tool radius.

3) If the tool is at the 2ND SET-UP CLEARANCE, it moves in rapid traverse

FMAX to SET-UP CLEARANCE, and from there advances to the first PLUNGING

DEPTH at the FEED RATE FOR PLUNGING.

4) The tool then moves tangential to the contour of the finished part and, using

climb milling, machines one revolution.

5) After this, the tool departs the contour tangential and returns to the starting point

in the working plane.

6) This process (3 - 5) is repeated until the programmed DEPTH is reached.

7) At the end of the cycle, the TNC retracts the tool in rapid traverse to SET-UP

CLEARANCE, or - if programmed - to the 2ND SET-UP CLEARANCE, and

finally to the center of the pocket (end position =starting position).

NOTE: The sign (+or -) for the cycle parameter DEPTH determines the working

direction.

This cycle requires a center cutting endmill if it is being used to rough and finish (a

low plunging feedrate will be required).

SETUP CLEARANCE Q200 - (Incremental) Distance between tool tip (at

start position) and workpiece surface.

DEPTH Q201 - (Incremental) Distance between workpiece surface and bottom

of the stud.

FEED RATE FOR PLUNGING Q206 - Traversing speed of the tool when

moving to DEPTH.

PLUNGING DEPTH Q202 - (Incremental) Infeed per cut.

FEED RATE FOR MILLING Q207 - Feedrateof the tool during milling.

WORKPIECE SURFACE COORDINATE Q203 - (Absolute) Coordinate of

workpiece surface.

2ND SET-UP CLEARANCE Q204 - (Incremental) Additional retract.

CENTER IN FIRST AXIS Q216 - (Absolute) Center of the stud in the main

axis of the working plane.

CENTER IN SECOND AXIS Q217 - (Absolute) Center of the stud in the

secondary axis of the working plane.

FIRST SIDE LENGTH Q218 - Stud length parallel to the main axis of the

working plane.

SECOND SIDE LENGTH Q219 - Stud width.

CORNER RADIUS Q220 - Radius of the stud corners. No value entered here

will use tool radius value.

ALLOWANCE IN 1ST AXIS Q221 - (Incremental) Clearance value to allow

the tool diameter to rapid traverse close to the machined wall.

HEIDENHAIN TNC PROGRAMMING NOTES

Chapter 9

Circular Pocket Milling (Cycle 5)

1) The tool penetrates the workpiece at the starting position (pocket center) and

advances to the first PECKING DEPTH.

2) The tool subsequently follows a spiral path at the FEED RATE F .

3) This process is repeated until the DEPTH is reached.

4) At the end of the cycle, the TNC retracts the tool to the starting position.

NOTE: Program a positioning block for the starting point (pocket center) in the

working plane with RADIUS COMPENSATION RO.

Program a positioning block for the starting point in the tool axis (SET-UP

CLEARANCE above the workpiece surface).

The sign (+or -) for the cycle parameter MILLING DEPTH determines the working

direction.