Professional Documents

Culture Documents

DIN ISO Programming USer Manual 2010

Uploaded by

Reymondo BundocCopyright

Available Formats

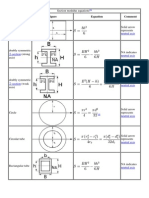

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DIN ISO Programming USer Manual 2010

Uploaded by

Reymondo BundocCopyright:

Available Formats

Users Manual

DIN/ISO

Programming

iTNC 530

NC Software

606 420-01

606 421-01

English (en)

6/2010

Controls of the TNC

Keys on visual display unit

Alphanumeric keyboard

Machine operating modes

Programming modes

Program/file management, TNC functions

Navigation keys

Potentiometer for feed rate and spindle speed

Cycles, subprograms and program section repeats

Key Function

Split screen layout

Toggle the display between machining

and programming modes

Soft keys for selecting functions on

screen

Shifts between soft-key rows

Key Function

File names, comments

DIN/ISO programming

Key Function

Manual Operation

Electronic Handwheel

smarT.NC

Positioning with Manual Data Input

Program Run, Single Block

Program Run, Full Sequence

Key Function

Programming and Editing

Test Run

Key Function

Select or delete programs and files,

external data transfer

Define program call, select datum and

point tables

Select MOD functions

Display help text for NC error messages,

call TNCguide

Display all current error messages

Show calculator

Key Function

Move highlight

Go directly to blocks, cycles and

parameter functions

Feed rate Spindle speed

Key Function

Define touch probe cycles

Define and call cycles

Enter and call labels for subprogramming

and program section repeats

Program stop in a program

150

0

50

100

F %

150

0

50

100

S %

Tool functions

Programming path movements

Special functions / smarT.NC

Coordinate axes and numbers: Entering and editing

Key Function

Define tool data in the program

Call tool data

Key Function

Approach/depart contour

FK free contour programming

Straight line

Circle center/pole for polar coordinates

Circle with center

Circle with radius

Circular arc with tangential connection

Chamfering/corner rounding

Key Function

Show special functions

smarT.NC: Select next tab on form

smarT.NC: Select first input field in

previous/next frame

Key Function

Select coordinate axes or

enter them into the program

Numbers

Decimal point / Reverse algebraic sign

Polar coordinate input / Incremental

values

Q parameter programming /

Q parameter status

Save actual position or values from

calculator

Skip dialog questions, delete words

Confirm entry and resume dialog

Conclude block and exit entry

Clear numerical entry or TNC error

message

Abort dialog, delete program section

. . .

. . .

A

b

o

u

t

t

h

i

s

M

a

n

u

a

l

HEIDENHAIN iTNC 530 5

About this Manual

The symbols used in this manual are described below.

Would you like any changes, or have you found

any errors?

We are continuously striving to improve documentation for you.

Please help us by sending your requests to the following e-mail

address: tnc-userdoc@heidenhain.de.

This symbol indicates that important notes about the

function described must be adhered to.

This symbol indicates that there is one or more of the

following risks when using the described function:

Danger to workpiece

Danger to fixtures

Danger to tool

Danger to machine

Danger to operator

This symbol indicates that the described function must be

adapted by the machine tool builder. The function

described may therefore vary depending on the machine.

This symbol indicates that you can find detailed

information about a function in another manual.

T

N

C

M

o

d

e

l

,

S

o

f

t

w

a

r

e

a

n

d

F

e

a

t

u

r

e

s

6

TNC Model, Software and Features

This manual describes functions and features provided by TNCs as of

the following NC software numbers.

The suffix E indicates the export version of the TNC. The export

version of the TNC has the following limitations:

Simultaneous linear movement in up to 4 axes

HSCI (HEIDENHAIN Serial Controller Interface) identifies the new

hardware platform of the TNC controls.

HeROS 5 identifies the new operating system of HSCI-based TNC

controls.

The machine tool builder adapts the usable features of the TNC to his

machine by setting machine parameters. Some of the functions

described in this manual may therefore not be among the features

provided by the TNC on your machine tool.

TNC functions that may not be available on your machine include:

Tool measurement with the TT

Please contact your machine tool builder to become familiar with the

features of your machine.

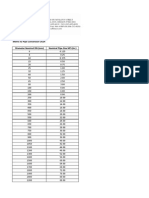

TNC model NC software number

iTNC 530, HSCI and HeROS 5 606 420-01

iTNC 530, HSCI and HeROS 5 606 421-01

T

N

C

M

o

d

e

l

,

S

o

f

t

w

a

r

e

a

n

d

F

e

a

t

u

r

e

s

HEIDENHAIN iTNC 530 7

Many machine manufacturers, as well as HEIDENHAIN, offer

programming courses for the TNCs. We recommend these courses as

an effective way of improving your programming skill and sharing

information and ideas with other TNC users.

Users Manual for Cycle Programming:

All of the cycle functions (touch probe cycles and fixed

cycles) are described in a separate manual. Please contact

HEIDENHAIN if you require a copy of this Users Manual.

ID: 670 388-xx

smarT.NC user documentation:

The smarT.NC operating mode is described in a separate

Pilot. Please contact HEIDENHAIN if you require a copy of

this Pilot. ID: 533 191-xx.

T

N

C

M

o

d

e

l

,

S

o

f

t

w

a

r

e

a

n

d

F

e

a

t

u

r

e

s

8

Software options

The iTNC 530 features various software options that can be enabled

by you or your machine tool builder. Each option is to be enabled

separately and contains the following respective functions:

Software option 1

Cylinder surface interpolation (Cycles 27, 28, 29 and 39)

Feed rate in mm/min for rotary axes: M116

Tilting the machining plane (Cycle 19, PLANE function and 3-D ROT

soft key in the Manual operating mode)

Circle in 3 axes with tilted working plane

Software option 2

Block processing time 0.5 ms instead of 3.6 ms

5-axis interpolation

Spline interpolation

3-D machining:

M114: Automatic compensation of machine geometry when

working with swivel axes

M128: Maintaining the position of the tool tip when positioning

with tilted axes (TCPM)

FUNCTION TCPM: Maintaining the position of the tool tip when

positioning with tilted axes (TCPM) in selectable modes

M144: Compensating the machines kinematic configuration for

ACTUAL/NOMINAL positions at end of block

Additional parameters for finishing/roughing and tolerance

for rotary axes in Cycle 32 (G62)

LN blocks (3-D compensation)

DCM Collision software option Description

Function that monitors areas defined by the

machine manufacturer to prevent collisions.

Page 329

DXF Converter software option Description

Extract contours and machining positions

from DXF files (R12 format).

Page 218

Additional dialog language software

option

Description

Function for enabling the conversational

languages Slovenian, Slovak, Norwegian,

Latvian, Estonian, Korean, Turkish, Romanian,

Lithuanian.

Page 576

T

N

C

M

o

d

e

l

,

S

o

f

t

w

a

r

e

a

n

d

F

e

a

t

u

r

e

s

HEIDENHAIN iTNC 530 9

Global Program Settings software option Description

Function for superimposing coordinate

transformations in the Program Run modes,

handwheel superimposed traverse in virtual

axis direction.

Page 347

AFC software option Description

Function for adaptive feed-rate control for

optimizing the machining conditions during

series production.

Page 358

KinematicsOpt software option Description

Touch-probe cycles for inspecting and

optimizing the machine accuracy.

Users Manual for

Cycles

3D-ToolComp software option Description

3-D radius compensation depending on the

tools contact angle for LN blocks.

Page 358

T

N

C

M

o

d

e

l

,

S

o

f

t

w

a

r

e

a

n

d

F

e

a

t

u

r

e

s

10

Feature content level (upgrade functions)

Along with software options, significant further improvements of the

TNC software are managed via the Feature Content Level (FCL)

upgrade functions. Functions subject to the FCL are not available

simply by updating the software on your TNC.

Upgrade functions are identified in the manual with FCL n, where n

indicates the sequential number of the feature content level.

You can purchase a code number in order to permanently enable the

FCL functions. For more information, contact your machine tool

builder or HEIDENHAIN.

All upgrade functions are available to you without surcharge

when you receive a new machine.

FCL 4 functions Description

Graphical depiction of the protected

space when DCM collision monitoring is

active

Page 333

Handwheel superimposition in stopped

condition when DCM collision

monitoring is active

Page 332

3-D basic rotation (set-up

compensation)

Machine Manual

FCL 3 functions Description

Touch probe cycle for 3-D probing Users Manual for

Cycles

Touch probe cycles for automatic datum

setting using the center of a slot/ridge

Users Manual for

Cycles

Feed-rate reduction for the machining of

contour pockets with the tool being in

full contact with the workpiece

Users Manual for

Cycles

PLANE function: Entry of axis angle Page 398

User documentation as a

context-sensitive help system

Page 146

smarT.NC: Programming of smarT.NC

and machining can be carried out

simultaneously

Page 108

smarT.NC: Contour pocket on point

pattern

smarT.NC Pilot

T

N

C

M

o

d

e

l

,

S

o

f

t

w

a

r

e

a

n

d

F

e

a

t

u

r

e

s

HEIDENHAIN iTNC 530 11

Intended place of operation

The TNC complies with the limits for a Class A device in accordance

with the specifications in EN 55022, and is intended for use primarily

in industrially-zoned areas.

Legal information

This product uses open source software. Further information is

available on the control under

U Programming and Editing operating mode

U MOD function

U LEGAL INFORMATION soft key

smarT.NC: Preview of contour

programs in the file manager

smarT.NC Pilot

smarT.NC: Positioning strategy for

machining point patterns

smarT.NC Pilot

FCL 2 functions Description

3-D line graphics Page 138

Virtual tool axis Page 498

USB support of block devices (memory

sticks, hard disks, CD-ROM drives)

Page 118

Possibility of assigning different depths

to each subcontour in the contour

formula

Users Manual for

Cycles

Touch-probe cycle for global setting of

touch-probe parameters

Users Manual for

Touch Probe Cycles

smarT.NC: Graphic support of block

scan

smarT.NC Pilot

smarT.NC: Coordinate transformation smarT.NC Pilot

smarT.NC: PLANE function smarT.NC Pilot

FCL 3 functions Description

N

e

w

f

u

n

c

t

i

o

n

s

6

0

6

4

2

x

-

0

1

s

i

n

c

e

t

h

e

p

r

e

d

e

c

e

s

s

o

r

v

e

r

s

i

o

n

s

3

4

0

4

9

x

-

0

5

12

New functions 606 42x-01 since the

predecessor versions 340 49x-05

Opening and Editing of externally created files is new (see

Additional tools for management of external file types on page

121)

New functions in the task bar added (see Soft-key row on page

80)

Enhanced functions for configuration of the Ethernet interface (see

Configuring the TNC on page 547)

Improvements regarding Functional Safety FS (option):

General information on Functional Safety FS (see General

Information on page 456)

Explanation of terms (see Explanation of terms on page 457)

Checking the axis positions (see Check axis positions on page

458)

Activating feed-rate limitation (see Activating feed-rate

limitation on page 460)

Improvements regarding the general status views of a TNC with

functional safety (see Additional Status displays on page 460)

The new HR 510, HR 520 and HR 550 FS handwheels are supported

(see Traversing with electronic handwheels on page 444)

New software option 3-D ToolComp: 3-D tool radius compensation

depending on the tools contact angle on blocks with surface normal

vectors (LN blocks)

3-D line graphics is now also possible in full-screen mode (see 3-D

Line Graphics (FCL2 Function) on page 138)

A file selection dialog for selecting files in different NC functions and

in the table view of the pallet table is available now (see Calling any

program as a subprogram on page 240)

DCM: Saving and restoring of fixture situations

DCM: The form for test program generation now also contains icons

and tooltips (see Check the position of the measured fixture on

page 340)

DCM, FixtureWizard: Touch points and probing sequence are shown

more clearly now

DCM, FixtureWizard: Designations, touch points and measuring

points can be shown or hidden as desired.(see Operating

FixtureWizard on page 337)

DCM, FixtureWizard: Chucking equipment and insertion points can

now also be selected by mouse click

DCM: A library with standard chucking equipment is available now

(see Fixture templates on page 336)

DCM: Tool carrier management (see Tool Holder Management

(DCM Software Option) on page 344)

N

e

w

f

u

n

c

t

i

o

n

s

6

0

6

4

2

x

-

0

1

s

i

n

c

e

t

h

e

p

r

e

d

e

c

e

s

s

o

r

v

e

r

s

i

o

n

s

3

4

0

4

9

x

-

0

5

HEIDENHAIN iTNC 530 13

In the Test Run mode, the working plane can now by defined

manually (see Setting a tilted working plane for the test run on

page 522)

On machines without encoders in the rotary axes, the rotary axis

coordinates to define the virtual axis direction VT can now be

specified via M114 (see Virtual axis VT on page 357)

In Manual mode the RW-3D mode for position display is now also

available (see Position Display Types on page 558)

Entries in the tool table TOOL.T (see Tool table: Standard tool data

on page 158)

New DR2TABLE column for definition of a compensation table for

tool radius compensation depending on the tools contact angle

New LAST_USE column, into which the TNC enters the date and

time of the last tool call

Q parameter programming: QS string parameters can now also be

used for jump addresses of conditional jumps, subprograms or

program section repeats (see "Calling a subprogram", page 238, see

"Calling a program section repeat", page 239 and see "Programming

If-Then decisions", page 264)

The generation of tool usage lists in the Program Run modes can be

configured in a form (see Settings for the tool usage test on page

175)

The behavior during deletion of tools from the tool table can now be

influenced via machine parameter 7263 (see Editing tool

tables on page 164)

In the positioning mode TURN of the PLANE function you can now

define a clearance height to which the tool is to be retracted before

tilting to tool axis direction (see Automatic positioning:

MOVE/TURN/STAY (entry is mandatory) on page 400)

The following additional functions are now available in the expanded

tool management (see Tool management (software option) on

page 178):

Columns with special functions are also editable now

The form view of the tool data can now be exited with or without

saving changed values

The table view now offers a search function

Indexed tools are now shown correctly in the form view

The tool sequence list includes more detailed information now

The loading and unloading list of the tool magazine can now be

loaded and unloaded by drag and drop

Columns in the table view can be moved simply by drag and drop

Several special functions (SPEC FCT) are now available in the MDI

operating mode (see Programming and Executing Simple

Machining Operations on page 500)

There is a new manual probing cycle that can be used to

compensate workpiece misalignments by rotating the rotary table

(see Workpiece alignment using 2 points on page 483)

N

e

w

f

u

n

c

t

i

o

n

s

6

0

6

4

2

x

-

0

1

s

i

n

c

e

t

h

e

p

r

e

d

e

c

e

s

s

o

r

v

e

r

s

i

o

n

s

3

4

0

4

9

x

-

0

5

14

New touch probe cycle for calibrating a touch probe by means of a

calibration sphere (see User's Manual for Cycle Programming)

KinematicsOpt: Better support for positioning of Hirth-coupled axes

(see User's Manual for Cycle Programming)

KinematicsOpt: An additional parameter for determination of the

backlash in a rotary axis was introduced (see User's Manual for

Cycle Programming)

New Cycle 275 for Trochoidal Slot Milling (see Users Manual for

Cycle Programming)

In Cycle 241 "Single-Fluted Deep-Hole Drilling" it is now possible to

define a dwell depth (see User's Manual for Cycle Programming)

The approach and departure behavior of Cycle 39 "Cylinder Surface

Contour" can now be adjusted (see User's Manual for Cycle

Programming)

C

h

a

n

g

e

d

f

u

n

c

t

i

o

n

s

6

0

6

4

2

x

-

0

1

s

i

n

c

e

t

h

e

p

r

e

d

e

c

e

s

s

o

r

v

e

r

s

i

o

n

s

3

4

0

4

9

x

-

0

6

HEIDENHAIN iTNC 530 15

Changed functions 606 42x-01 since

the predecessor versions 340 49x-06

In the calibration menus for touch probe length and radius, the

number and name of the active tool are also displayed now (if the

calibration data from the tool table are to be used, MP7411 = 1, see

"Managing more than one block of calibrating data", page 477).

During tilting in the Distance-To-Go mode, the PLANE function now

shows the angle actually left to be traversed until the target position

(see Position display on page 385).

The approach behavior during side finishing with Cycle 24 (DIN/ISO:

G124) was changed (see User's Manual for Cycle Programming).

C

h

a

n

g

e

d

f

u

n

c

t

i

o

n

s

6

0

6

4

2

x

-

0

1

s

i

n

c

e

t

h

e

p

r

e

d

e

c

e

s

s

o

r

v

e

r

s

i

o

n

s

3

4

0

4

9

x

-

0

6

16

HEIDENHAIN iTNC 530 17

Table of Contents

First Steps with the iTNC 530

1

Introduction

2

Programming: Fundamentals, File

Management 3

Programming: Programming Aids

4

Programming: Tools

5

Programming: Programming Contours

6

Programming: Miscellaneous Functions

7

Programming: Data Transfer from DXF

Files 8

Programming: Subprograms and Program

Section Repeats 9

Programming: Q Parameters

10

Programming: Miscellaneous Functions

11

Programming: Special Functions

12

Programming: Multiple Axis Machining

13

Programming: Pallet Editor

14

Positioning with Manual Data Input

15

Test Run and Program Run

16

MOD Functions

17

Tables and Overviews

18

HEIDENHAIN iTNC 530 19

1.1 Overview ..... 42

1.2 Machine Switch-On ..... 43

Acknowledge the power interruption and move to the reference points ..... 43

1.3 Programming the First Part ..... 44

Select the correct operating mode ..... 44

The most important TNC keys ..... 44

Create a new program/file management ..... 45

Define a workpiece blank ..... 46

Program layout ..... 47

Program a simple contour ..... 48

Create a cycle program ..... 50

1.4 Graphically Testing the Program ..... 52

Select the correct operating mode ..... 52

Select the tool table for the test run ..... 52

Choose the program you want to test ..... 53

Select the screen layout and the view ..... 53

Start the program test ..... 54

1.5 Tool Setup ..... 55

Select the correct operating mode ..... 55

Prepare and measure tools ..... 55

The tool table TOOL.T ..... 55

The pocket table TOOL_P.TCH ..... 56

1.6 Workpiece Setup ..... 57

Select the correct operating mode ..... 57

Clamp the workpiece ..... 57

Align the workpiece with a 3-D touch probe system ..... 58

Set the datum with a 3-D touch probe ..... 59

1.7 Running the First Program ..... 60

Select the correct operating mode ..... 60

Choose the program you want to run ..... 60

Start the program ..... 60

1 First Steps with the iTNC 530 ..... 41

20

2.1 The iTNC 530 ..... 62

Programming: HEIDENHAIN conversational, smarT.NC and ISO formats ..... 62

Compatibility ..... 62

2.2 Visual Display Unit and Keyboard ..... 63

Visual display unit ..... 63

Sets the screen layout ..... 64

Operating panel ..... 65

2.3 Operating Modes ..... 66

Manual Operation and Electronic Handwheel ..... 66

Positioning with Manual Data Input ..... 66

Programming and Editing ..... 67

Test Run ..... 67

Program Run, Full Sequence and Program Run, Single Block ..... 68

2.4 Status Displays ..... 69

General status display ..... 69

Additional status displays ..... 71

2.5 Window Manager ..... 79

Soft-key row ..... 80

2.6 Accessories: HEIDENHAIN 3-D Touch Probes and Electronic Handwheels ..... 81

3-D touch probes ..... 81

HR electronic handwheels ..... 82

2 Introduction ..... 61

HEIDENHAIN iTNC 530 21

3.1 Fundamentals ..... 84

Position encoders and reference marks ..... 84

Reference system ..... 84

Reference system on milling machines ..... 85

Polar coordinates ..... 86

Absolute and incremental workpiece positions ..... 87

Setting the datum ..... 88

3.2 Creating and Writing Programs ..... 89

Organization of an NC program in DIN/ISO ..... 89

Define the blank: G30/G31 ..... 89

Creating a new part program ..... 90

Programming tool movements in DIN/ISO format ..... 92

Actual position capture ..... 93

Editing a program ..... 94

The TNC search function ..... 98

3.3 File Management: Fundamentals ..... 100

Files ..... 100

Show externally created files on the TNC ..... 102

Data backup ..... 102

3.4 Working with the File Manager ..... 103

Directories ..... 103

Paths ..... 103

Overview: Functions of the file manager ..... 104

Calling the file manager ..... 105

Selecting drives, directories and files ..... 106

Creating a new directory (only possible on the drive TNC:\) ..... 109

Creating a new file (only possible on the drive TNC:\) ..... 109

Copying a single file ..... 110

Copying files into another directory ..... 111

Copying a table ..... 112

Copying a directory ..... 113

Choosing one of the last files selected ..... 113

Deleting a file ..... 114

Deleting a directory ..... 114

Marking files ..... 115

Renaming a file ..... 117

Additional functions ..... 118

Working with shortcuts ..... 120

Additional tools for management of external file types ..... 121

Data transfer to or from an external data medium ..... 125

The TNC in a network ..... 127

USB devices on the TNC (FCL 2 function) ..... 128

3 Programming: Fundamentals, File Management ..... 83

22

4.1 Adding Comments ..... 132

Function ..... 132

Entering comments during programming ..... 132

Inserting comments after program entry ..... 132

Entering a comment in a separate block ..... 132

Functions for editing of the comment ..... 133

4.2 Structuring Programs ..... 134

Definition and applications ..... 134

Displaying the program structure window / Changing the active window ..... 134

Inserting a structuring block in the (left) program window. ..... 134

Selecting blocks in the program structure window ..... 134

4.3 Integrated Pocket Calculator ..... 135

Operation ..... 135

4.4 Programming Graphics ..... 136

Generating / not generating graphics during programming ..... 136

Generating a graphic for an existing program. ..... 136

Block number display ON/OFF ..... 137

Erasing the graphic ..... 137

Magnifying or reducing a detail ..... 137

4.5 3-D Line Graphics (FCL2 Function) ..... 138

Function ..... 138

Functions of the 3-D line graphics ..... 138

Highlighting NC blocks in the graphics ..... 140

Block number display ON/OFF ..... 140

Erasing the graphic ..... 140

4.6 Immediate Help for NC Error Messages ..... 141

Displaying error messages ..... 141

Display HELP ..... 141

4.7 List of All Current Error Messages ..... 142

Function ..... 142

Show error list ..... 142

Window contents ..... 143

Calling the TNCguide help system ..... 144

Generating service files ..... 145

4.8 The Context-Sensitive Help System TNCguide (FCL3 Function) ..... 146

Function ..... 146

Working with the TNCguide ..... 147

Downloading current help files ..... 151

4 Programming: Programming Aids ..... 131

HEIDENHAIN iTNC 530 23

5.1 Entering Tool-Related Data ..... 154

Feed rate F ..... 154

Spindle speed S ..... 155

5.2 Tool Data ..... 156

Requirements for tool compensation ..... 156

Tool numbers and tool names ..... 156

Tool length L ..... 156

Tool radius R ..... 156

Delta values for lengths and radii ..... 157

Entering tool data into the program ..... 157

Entering tool data in the table ..... 158

Tool-carrier kinematics ..... 166

Using an external PC to overwrite individual tool data ..... 167

Pocket table for tool changer ..... 168

Calling tool data ..... 171

Tool change ..... 173

Tool usage test ..... 175

Tool management (software option) ..... 178

5.3 Tool Compensation ..... 182

Introduction ..... 182

Tool length compensation ..... 182

Tool radius compensation ..... 183

5 Programming: Tools ..... 153

24

6.1 Tool Movements ..... 188

Path functions ..... 188

Miscellaneous functions M..... 188

Subprograms and program section repeats ..... 188

Programming with Q parameters ..... 188

6.2 Fundamentals of Path Functions ..... 189

Programming tool movements for workpiece machining ..... 189

6.3 Contour Approach and Departure ..... 192

Starting point and end point ..... 192

Tangential approach and departure ..... 194

6.4 Path ContoursCartesian Coordinates ..... 196

Overview of path functions ..... 196

Straight line at rapid traverse G00

Straight line with feed rate G01 F ..... 197

Inserting a chamfer between two straight lines ..... 198

Corner rounding G25 ..... 199

Circle center I, J ..... 200

Circular path C around circle center CC ..... 201

Circular path G02/G03/G05 with defined radius ..... 202

Circular path G06 with tangential connection ..... 204

6.5 Path ContoursPolar Coordinates ..... 209

Overview ..... 209

Zero point for polar coordinates: pole I, J ..... 210

Straight line at rapid traverse G10

Straight line with feed rate G11 F ..... 210

Circular path G12/G13/G15 around pole I, J ..... 211

Circular path G16 with tangential connection ..... 212

Helical interpolation ..... 213

6 Programming: Programming Contours ..... 187

HEIDENHAIN iTNC 530 25

7.1 Processing DXF Files (Software Option) ..... 218

Function ..... 218

Opening a DXF file ..... 219

Basic settings ..... 220

Layer settings ..... 222

Specifying the reference point ..... 223

Selecting and saving a contour ..... 225

Selecting and storing machining positions ..... 228

Zoom function ..... 234

7 Programming: Data Transfer from DXF Files ..... 217

26

8.1 Labeling Subprograms and Program Section Repeats ..... 236

Labels ..... 236

8.2 Subprograms ..... 237

Operating sequence ..... 237

Programming notes ..... 237

Programming a subprogram ..... 237

Calling a subprogram ..... 238

8.3 Program Section Repeats ..... 239

Label G98 ..... 239

Operating sequence ..... 239

Programming notes ..... 239

Programming a program section repeat ..... 239

Calling a program section repeat ..... 239

8.4 Separate Program as Subprogram ..... 240

Operating sequence ..... 240

Programming notes ..... 240

Calling any program as a subprogram ..... 240

8.5 Nesting ..... 242

Types of nesting ..... 242

Nesting depth ..... 242

Subprogram within a subprogram ..... 243

Repeating program section repeats ..... 244

Repeating a subprogram ..... 245

8.6 Programming Examples ..... 246

8 Programming: Subprograms and Program Section Repeats ..... 235

HEIDENHAIN iTNC 530 27

9.1 Principle and Overview ..... 254

Programming notes ..... 256

Calling Q-parameter functions ..... 257

9.2 Part FamiliesQ Parameters in Place of Numerical Values ..... 258

Function ..... 258

9.3 Describing Contours through Mathematical Operations ..... 259

Function ..... 259

Overview ..... 259

Programming fundamental operations ..... 260

9.4 Trigonometric Functions ..... 261

Definitions ..... 261

Programming trigonometric functions ..... 262

9.5 If-Then Decisions with Q Parameters ..... 263

Function ..... 263

Unconditional jumps ..... 263

Programming If-Then decisions ..... 264

9.6 Checking and Changing Q Parameters ..... 265

Procedure ..... 265

9.7 Additional Functions ..... 266

Overview ..... 266

D14: ERROR: Displaying error messages ..... 267

D15 PRINT: Output of texts or Q parameter values ..... 271

D19 PLC: Transfer values to the PLC ..... 272

9.8 Entering Formulas Directly ..... 273

Entering formulas ..... 273

Rules for formulas ..... 275

Programming example ..... 276

9.9 String Parameters ..... 277

String processing functions ..... 277

Assigning string parameters ..... 278

Chain-linking string parameters ..... 279

Converting a numerical value to a string parameter ..... 280

Copying a substring from a string parameter ..... 281

Copying system data to a string parameter ..... 282

Converting a string parameter to a numerical value ..... 284

Checking a string parameter ..... 285

Finding the length of a string parameter ..... 286

Comparing alphabetic priority ..... 287

9 Programming: Q Parameters ..... 253

28

9.10 Preassigned Q Parameters ..... 288

Values from the PLC: Q100 to Q107 ..... 288

WMAT block: QS100 ..... 288

Active tool radius: Q108 ..... 288

Tool axis: Q109 ..... 289

Spindle status: Q110 ..... 289

Coolant on/off: Q111 ..... 289

Overlap factor: Q112 ..... 289

Unit of measurement for dimensions in the program: Q113 ..... 290

Tool length: Q114 ..... 290

Coordinates after probing during program run ..... 290

Deviation between actual value and nominal value during automatic tool measurement with the TT 130 ..... 291

Tilting the working plane with mathematical angles: rotary axis coordinates calculated by the TNC ..... 291

Measurement results from touch probe cycles (see also Users Manual for Touch Probe Cycles) ..... 292

9.11 Programming Examples ..... 294

HEIDENHAIN iTNC 530 29

10.1 Entering Miscellaneous Functions M and STOP ..... 302

Fundamentals ..... 302

10.2 Miscellaneous Functions for Program Run Control, Spindle and Coolant ..... 303

Overview ..... 303

10.3 Miscellaneous Functions for Coordinate Data ..... 304

Programming machine-referenced coordinates: M91/M92 ..... 304

Activating the most recently entered datum: M104 ..... 306

Moving to positions in a non-tilted coordinate system with a tilted working plane: M130 ..... 306

10.4 Miscellaneous Functions for Contouring Behavior ..... 307

Smoothing corners: M90 ..... 307

Insert rounding arc between straight lines: M112 ..... 307

Do not include points when executing non-compensated line blocks: M124 ..... 308

Machining small contour steps: M97 ..... 309

Machining open contours corners: M98 ..... 311

Feed rate factor for plunging movements: M103 ..... 312

Feed rate in millimeters per spindle revolution: M136 ..... 313

Feed rate for circular arcs: M109/M110/M111 ..... 314

Calculating the radius-compensated path in advance (LOOK AHEAD): M120 ..... 315

Superimposing handwheel positioning during program run: M118 ..... 317

Retraction from the contour in the tool-axis direction: M140 ..... 318

Suppressing touch probe monitoring: M141 ..... 319

Delete modal program information: M142 ..... 320

Delete basic rotation: M143 ..... 320

Automatically retract tool from the contour at an NC stop: M148 ..... 321

Suppress limit switch message: M150 ..... 322

10.5 Miscellaneous Functions for Laser Cutting Machines ..... 323

Principle ..... 323

Output the programmed voltage directly: M200 ..... 323

Output voltage as a function of distance: M201 ..... 323

Output voltage as a function of speed: M202 ..... 324

Output voltage as a function of time (time-dependent ramp): M203 ..... 324

Output voltage as a function of time (time-dependent pulse): M204 ..... 324

10 Programming: Miscellaneous Functions ..... 301

30

11.1 Overview of Special Functions ..... 326

Main menu for SPEC FCT special functions ..... 326

Program defaults menu ..... 327

Functions for contour and point machining menu ..... 327

Menu of various DIN/ISO functions ..... 328

11.2 Dynamic Collision Monitoring (Software Option) ..... 329

Function ..... 329

Collision monitoring in the manual operating modes ..... 331

Collision monitoring in Automatic operation ..... 332

Graphic depiction of the protected space (FCL4 function) ..... 333

Collision monitoring in the Test Run mode of operation ..... 334

11.3 Fixture Monitoring (Software Option) ..... 335

Fundamentals ..... 335

Fixture templates ..... 336

Setting parameter values for the fixture: FixtureWizard ..... 336

Placing the fixture on the machine ..... 338

Editing fixtures ..... 339

Removing fixtures ..... 339

Check the position of the measured fixture ..... 340

Manage fixtures ..... 342

11.4 Tool Holder Management (DCM Software Option) ..... 344

Fundamentals ..... 344

Tool-holder templates ..... 344

Set the tool holder parameters: ToolHolderWizard ..... 345

Removing a tool holder ..... 346

11.5 Global Program Settings (Software Option) ..... 347

Function ..... 347

Technical prerequisites ..... 349

Activating/deactivating a function ..... 350

Basic rotation ..... 352

Swapping axes ..... 353

Superimposed mirroring ..... 354

Additional, additive datum shift ..... 354

Axis locking ..... 355

Superimposed rotation ..... 355

Feed rate override ..... 355

Handwheel superimposition ..... 356

11 Programming: Special Functions ..... 325

HEIDENHAIN iTNC 530 31

11.6 Adaptive Feed Control Software Option (AFC) ..... 358

Application ..... 358

Defining the AFC basic settings ..... 360

Recording a teach-in cut ..... 362

Activating/deactivating AFC ..... 365

Log file ..... 366

Tool breakage/tool wear monitoring ..... 368

Spindle load monitoring ..... 368

11.7 Creating Text Files ..... 369

Application ..... 369

Opening and exiting text files ..... 369

Editing texts ..... 370

Deleting and inserting characters, words and lines ..... 371

Editing text blocks ..... 372

Finding text sections ..... 373

11.8 Working with Cutting Data Tables ..... 374

Note ..... 374

Applications ..... 374

Table for workpiece materials ..... 375

Table for tool cutting materials ..... 376

Table for cutting data ..... 376

Data required for the tool table ..... 377

Working with automatic speed / feed rate calculation ..... 378

Data transfer from cutting data tables ..... 379

Configuration file TNC.SYS ..... 379

32

12.1 Functions for Multiple Axis Machining ..... 382

12.2 The PLANE Function: Tilting the Working Plane (Software Option 1) ..... 383

Introduction ..... 383

Define the PLANE function ..... 385

Position display ..... 385

Reset the PLANE function ..... 386

Defining the machining plane with space angles: PLANE SPATIAL ..... 387

Defining the machining plane with projection angles: PROJECTED PLANE ..... 389

Defining the machining plane with Euler angles: EULER PLANE ..... 391

Defining the working plane with two vectors: VECTOR PLANE ..... 393

Defining the machining plane via three points: PLANE POINTS ..... 395

Defining the Machining Plane with a Single, Incremental Space Angle: PLANE RELATIVE ..... 397

Tilting the working plane through axis angle: PLANE AXIAL (FCL 3 function) ..... 398

Specifying the positioning behavior of the PLANE function ..... 400

12.3 Inclined-Tool Machining in the Tilted Plane ..... 405

Function ..... 405

Inclined-tool machining via incremental traverse of a rotary axis ..... 405

12.4 Miscellaneous Functions for Rotary Axes ..... 406

Feed rate in mm/min on rotary axes A, B, C: M116 (software option 1) ..... 406

Shorter-path traverse of rotary axes: M126 ..... 407

Reducing display of a rotary axis to a value less than 360: M94 ..... 408

Automatic compensation of machine geometry when working with tilted axes: M114 (software option 2) ..... 409

Maintaining the position of the tool tip when positioning with tilted axes (TCPM): M128 (software option

2) ..... 410

Exact stop at corners with nontangential transitions: M134 ..... 413

Selecting tilting axes: M138 ..... 413

Compensating the machines kinematics configuration for ACTUAL/NOMINAL positions at end of block: M144

(software option 2) ..... 414

12.5 Peripheral milling: 3-D radius compensation with workpiece orientation ..... 415

Function ..... 415

12 Programming: Multiple Axis Machining ..... 381

HEIDENHAIN iTNC 530 33

13.1 Pallet Editor ..... 418

Application ..... 418

Selecting a pallet table ..... 420

Leaving the pallet file ..... 420

Pallet datum management with the pallet preset table ..... 421

Executing the pallet file ..... 423

13.2 Pallet Operation with Tool-Oriented Machining ..... 424

Application ..... 424

Selecting a pallet file ..... 429

Setting up the pallet file with the entry form ..... 429

Sequence of tool-oriented machining ..... 434

Leaving the pallet file ..... 435

Executing the pallet file ..... 435

13 Programming: Pallet Editor ..... 417

34

14.1 Switch-On, Switch-Off ..... 438

Switch-on ..... 438

Switch-off ..... 441

14.2 Moving the Machine Axes ..... 442

Note ..... 442

Moving the axis using the machine axis direction buttons ..... 442

Incremental jog positioning ..... 443

Traversing with electronic handwheels ..... 444

14.3 Spindle Speed S, Feed Rate F and Miscellaneous Functions M..... 454

Function ..... 454

Entering values ..... 454

Changing the spindle speed and feed rate ..... 455

14.4 Functional Safety FS (Option) ..... 456

General Information ..... 456

Explanation of terms ..... 457

Check axis positions ..... 458

Overview of permitted feed rates and speeds ..... 459

Activating feed-rate limitation ..... 460

Additional Status displays ..... 460

14.5 Datum Setting without a 3-D Touch Probe ..... 461

Note ..... 461

Preparation ..... 461

Workpiece presetting with axis keys ..... 462

Datum management with the preset table ..... 463

14.6 Using the 3-D Touch Probe ..... 470

Overview ..... 470

Selecting probe cycles ..... 470

Recording measured values from the touch-probe cycles ..... 471

Writing the measured values from touch probe cycles in datum tables ..... 472

Writing the measured values from touch probe cycles in the preset table ..... 473

Storing measured values in the pallet preset table ..... 474

14.7 Calibrating a 3-D Touch Probe ..... 475

Introduction ..... 475

Calibrating the effective length ..... 475

Calibrating the effective radius and compensating center misalignment ..... 476

Displaying calibration values ..... 477

Managing more than one block of calibrating data ..... 477

14.8 Compensating Workpiece Misalignment with a 3-D Touch Probe ..... 478

Introduction ..... 478

Basic rotation using 2 points: ..... 480

Determining basic rotation using 2 holes/studs: ..... 482

Workpiece alignment using 2 points ..... 483

14 Manual Operation and Setup ..... 437

HEIDENHAIN iTNC 530 35

14.9 Datum Setting with a 3-D Touch Probe ..... 484

Overview ..... 484

Datum setting in any axis ..... 484

Corner as datumusing points that were already probed for a basic rotation ..... 485

Corner as datumwithout using points that were already probed for a basic rotation. ..... 485

Circle center as datum ..... 486

Center line as datum ..... 487

Setting datum points using holes/cylindrical studs ..... 488

Measuring Workpieces with a 3-D Touch Probe ..... 489

Using the touch probe functions with mechanical probes or dial gauges ..... 492

14.10 Tilting the Working Plane (Software Option 1) ..... 493

Application, function ..... 493

Traversing the reference points in tilted axes ..... 495

Setting the datum in a tilted coordinate system ..... 495

Datum setting on machines with rotary tables ..... 495

Datum setting on machines with spindle-head changing systems ..... 496

Position display in a tilted system ..... 496

Limitations on working with the tilting function ..... 496

Activating manual tilting ..... 497

Setting the current tool-axis direction as the active machining direction (FCL 2 function) ..... 498

36

15.1 Programming and Executing Simple Machining Operations ..... 500

Positioning with Manual Data Input (MDI) ..... 500

Protecting and erasing programs in $MDI ..... 503

15 Positioning with Manual Data Input ..... 499

HEIDENHAIN iTNC 530 37

16.1 Graphics ..... 506

Application ..... 506

Overview of display modes ..... 508

Plan view ..... 508

Projection in 3 planes ..... 509

3-D view ..... 510

Magnifying details ..... 513

Repeating graphic simulation ..... 514

Displaying the tool ..... 514

Measuring the machining time ..... 515

16.2 Functions for Program Display ..... 516

Overview ..... 516

16.3 Test Run ..... 517

Application ..... 517

16.4 Program Run ..... 523

Application ..... 523

Running a part program ..... 524

Interrupting machining ..... 525

Moving the machine axes during an interruption ..... 527

Resuming program run after an interruption ..... 528

Mid-program startup (block scan) ..... 529

Returning to the contour ..... 532

16.5 Automatic Program Start ..... 533

Application ..... 533

16.6 Optional Block Skip ..... 534

Application ..... 534

Erasing the / character ..... 534

16.7 Optional Program-Run Interruption ..... 535

Application ..... 535

16 Test Run and Program Run ..... 505

38

17.1 Selecting MOD Functions ..... 538

Selecting the MOD functions ..... 538

Changing the settings ..... 538

Exiting the MOD functions ..... 538

Overview of MOD functions ..... 539

17.2 Software Numbers ..... 540

Application ..... 540

17.3 Entering Code Numbers ..... 541

Application ..... 541

17.4 Loading Service Packs ..... 542

Application ..... 542

17.5 Setting the Data Interfaces ..... 543

Application ..... 543

Setting the RS-232 interface ..... 543

Setting the RS-422 interface ..... 543

Setting the OPERATING MODE of the external device ..... 543

Setting the baud rate ..... 543

Assignment ..... 544

Software for data transfer ..... 545

17.6 Ethernet Interface ..... 547

Introduction ..... 547

Connection possibilities ..... 547

Configuring the TNC ..... 547

17.7 Configuring PGM MGT ..... 553

Application ..... 553

Changing the PGM MGT setting ..... 553

Dependent files ..... 554

17.8 Machine-Specific User Parameters ..... 555

Application ..... 555

17.9 Showing the Workpiece in the Working Space ..... 556

Application ..... 556

Rotate the entire image ..... 557

17.10 Position Display Types ..... 558

Application ..... 558

17.11 Unit of Measurement ..... 559

Application ..... 559

17.12 Selecting the Programming Language for $MDI ..... 560

Application ..... 560

17.13 Selecting the Axes for Generating G01 Blocks ..... 561

Application ..... 561

17 MOD Functions ..... 537

HEIDENHAIN iTNC 530 39

17.14 Entering the Axis Traverse Limits, Datum Display ..... 562

Application ..... 562

Working without additional traverse limits ..... 562

Find and enter the maximum traverse ..... 562

Datum display ..... 563

17.15 Displaying HELP Files ..... 564

Application ..... 564

Selecting HELP files ..... 564

17.16 Displaying Operating Times ..... 565

Application ..... 565

17.17 Checking the Data Carrier ..... 566

Application ..... 566

Performing the data carrier check ..... 566

17.18 Setting the System Time ..... 567

Application ..... 567

Selecting appropriate settings ..... 567

17.19 TeleService ..... 568

Application ..... 568

Calling/exiting TeleService ..... 568

17.20 External Access ..... 569

Application ..... 569

17.21 Configuring the HR 550 FS Wireless Handwheel ..... 571

Application ..... 571

Assigning the handwheel to a specific handwheel holder ..... 571

Setting the transmission channel ..... 572

Selecting the transmitter power ..... 573

Statistics ..... 573

40

18.1 General User Parameters ..... 576

Input possibilities for machine parameters ..... 576

Selecting general user parameters ..... 576

List of general user parameters ..... 577

18.2 Pin Layouts and Connecting Cables for the Data Interfaces ..... 591

RS-232-C/V.24 interface for HEIDENHAIN devices ..... 591

Non-HEIDENHAIN devices ..... 592

RS-422/V.11 interface ..... 593

Ethernet interface RJ45 socket ..... 593

18.3 Technical Information ..... 594

18.4 Exchanging the Buffer Battery ..... 603

18 Tables and Overviews ..... 575

First Steps with the

iTNC 530

42 First Steps with the iTNC 530

1

.

1

O

v

e

r

v

i

e

w

1.1 Overview

This chapter is intended to help TNC beginners quickly learn to handle

the most important procedures. For more information on a respective

topic, see the section referred to in the text.

The following topics are included in this chapter

Machine Switch-On

Programming the First Part

Graphically Testing the Program

Tool Setup

Workpiece Setup

Running the First Program

HEIDENHAIN iTNC 530 43

1

.

2

M

a

c

h

i

n

e

S

w

i

t

c

h

-

O

n

1.2 Machine Switch-On

Acknowledge the power interruption and move

to the reference points

U Switch on the power supply for control and machine. The TNC starts

the operating system. This process may take several minutes. Then

the TNC will display the message Power interruption.

U Press the CE key: The TNC converts the PLC

program

U Switch on the control voltage: The TNC checks

operation of the emergency stop circuit and goes into

the reference run mode

U Cross the reference points manually in the displayed

sequence: For each axis press the machine START

button. If you have absolute linear and angle encoders

on your machine there is no need for a reference run

The TNC is now ready for operation in the Manual Operation mode.

Further information on this topic

Traversing the reference marks: See Switch-on on page 438

Operating modes: See Programming and Editing on page 67

Switch-on and crossing the reference points can vary

depending on the machine tool. Your machine manual

provides more detailed information.

44 First Steps with the iTNC 530

1

.

3

P

r

o

g

r

a

m

m

i

n

g

t

h

e

F

i

r

s

t

P

a

r

t

1.3 Programming the First Part

Select the correct operating mode

You can write programs only in the Programming and Editing mode:

U Press the operating modes key: The TNC goes into

the Programming and Editing mode

Further information on this topic

Operating modes: See Programming and Editing on page 67

The most important TNC keys

Further information on this topic

Writing and editing programs: See Editing a program on page 94

Overview of keys: See Controls of the TNC on page 2

Functions for conversational guidance Key

Confirm entry and activate the next dialog

prompt

Ignore the dialog question.

End the dialog immediately.

Abort dialog, discard entries.

Soft keys on the screen with which you select

functions appropriate to the active state

HEIDENHAIN iTNC 530 45

1

.

3

P

r

o

g

r

a

m

m

i

n

g

t

h

e

F

i

r

s

t

P

a

r

t

Create a new program/file management

U Press the PGM MGT key: the TNC displays the file

management. The file management of the TNC is

arranged much like the file management on a PC with

the Windows Explorer. The file management enables

you to manipulate data on the TNC hard disk

U Use the arrow keys to select the folder in which you

want to open the new file

U Enter a file name with the extension .I: The TNC then

automatically opens a program and asks for the unit

of measure for the new program. Please note the

restrictions regarding special characters in the file

name (see File names on page 101)

U To select the unit of measure, press the MM or INCH

soft key: The TNC automatically starts the workpiece

blank definition (see Define a workpiece blank on

page 46)

The TNC automatically generates the first and last blocks of the

program. Afterwards you can no longer change these blocks.

Further information on this topic

File management: See Working with the File Manager on page

103

Creating a new program: See Creating and Writing Programs on

page 89

46 First Steps with the iTNC 530

1

.

3

P

r

o

g

r

a

m

m

i

n

g

t

h

e

F

i

r

s

t

P

a

r

t

Define a workpiece blank

Immediately after you have created a new program, the TNC starts the

dialog for entering the workpiece blank definition. Always define the

workpiece blank as a cuboid by entering the MIN and MAX points,

each with reference to the selected reference point.

After you have created a new program, the TNC automatically initiates

the workpiece blank definition and asks for the required data:

U Spindle axis Z - Plane XY?: Enter the active spindle axis. G17 is

saved as default setting. Accept with the ENT key

U Coordinates?: Smallest X coordinate of the workpiece blank with

respect to the reference point, e.g. 0. Confirm with the ENT key

U Coordinates?: Smallest Y coordinate of the workpiece blank with

respect to the reference point, e.g. 0. Confirm with the ENT key

U Coordinates?: Smallest Z coordinate of the workpiece blank with

respect to the reference point, e.g. -40. Confirm with the ENT key

U Coordinates?: Largest X coordinate of the workpiece blank with

respect to the reference point, e.g. 100. Confirm with the ENT key

U Coordinates?: Largest Y coordinate of the workpiece blank with

respect to the reference point, e.g. 100. Confirm with the ENT key

U Coordinates?: Largest Z coordinate of the workpiece blank with

respect to the reference point, e.g. 0. Confirm with the ENT key

Example NC blocks

Further information on this topic

Defining the workpiece blank: (see page 90)

Y

X

Z

MAX

MIN

-40

100

100

0

0

%NEW G71 *

N10 G30 G17 X+0 Y+0 Z-40 *

N20 G31 X+100 Y+100 Z+0 *

N99999999 %NEW G71 *

HEIDENHAIN iTNC 530 47

1

.

3

P

r

o

g

r

a

m

m

i

n

g

t

h

e

F

i

r

s

t

P

a

r

t

Program layout

NC programs should be arranged consistently in a similar manner. This

makes it easier to find your place and reduces errors.

Recommended program layout for simple, conventional contour

machining

1 Call tool, define tool axis

2 Retract the tool

3 Pre-position the tool in the working plane near the contour starting

point

4 In the tool axis, position the tool above the workpiece, or pre-

position immediately to workpiece depth. If required, switch on

the spindle/coolant

5 Move to the contour

6 Machine the contour

7 Leave the contour

8 Retract the tool, end the program

Further information on this topic:

Contour programming: See Tool Movements on page 188

Recommended program layout for simple cycle programs

1 Call tool, define tool axis

2 Retract the tool

3 Define the fixed cycle

4 Move to the machining position

5 Call the cycle, switch on the spindle/coolant

6 Retract the tool, end the program

Further information on this topic:

Cycle programming: See Users Manual for Cycles

Example: Layout of contour machining programs

%BSPCONT G71 *

N10 G30 G71 X... Y... Z... *

N20 G31 X... Y... Z... *

N30 T5 G17 S5000 *

N40 G00 G40 G90 Z+250 *

N50 X... Y... *

N60 G01 Z+10 F3000 M13 *

N70 X... Y... RL F500 *

...

N160 G40 ... X... Y... F3000 M9 *

N170 G00 Z+250 M2 *

N99999999 BSPCONT G71 *

Example: Program layout for cycle programming

%BSBCYC G71 *

N10 G30 G71 X... Y... Z... *

N20 G31 X... Y... Z... *

N30 T5 G17 S5000 *

N40 G00 G40 G90 Z+250 *

N50 G200... *

N60 X... Y... *

N70 G79 M13 *

N80 G00 Z+250 M2 *

N99999999 BSBCYC G71 *

48 First Steps with the iTNC 530

1

.

3

P

r

o

g

r

a

m

m

i

n

g

t

h

e

F

i

r

s

t

P

a

r

t

Program a simple contour

The contour shown to the right is to be milled once to a depth of 5 mm.

You have already defined the workpiece blank. After you have initiated

a dialog through a function key, enter all the data requested by the

TNC in the screen header.

U Call the tool: Enter the tool data. Confirm each of your

entries with the ENT key. Do not forget the tool axis

U Retract the tool: Press the orange axis key Z in order

to get clear in the tool axis, and enter the value for the

position to be approached, e.g. 250. Confirm with the

ENT key

U Confirm Radius comp.: RL/RR/no comp? by pressing

the ENT key: Do not activate the radius compensation

U Confirm the Miscellaneous function M? with the

END key: The TNC saves the entered positioning

block

U Preposition the tool in the working plane: Press the

orange X axis key and enter the value for the position

to be approached, e.g. -20

U Press the orange Y axis key and enter the value for the

position to be approached, e.g. -20. Confirm with the

ENT key

U Confirm Radius comp.: RL/RR/no comp? by pressing

the ENT key: Do not activate the radius compensation

U Confirm the Miscellaneous function M? with the

END key: The TNC saves the entered positioning

block

U Move the tool to workpiece depth: Press the orange Y

axis key and enter the value for the position to be

approached, e.g. -5. Confirm with the ENT key

U Confirm Radius comp.: RL/RR/no comp? by pressing

the ENT key: Do not activate the radius compensation

U Feed rate F=? Enter the positioning feed rate, e.g.

3000 mm/min and confirm with the ENT key

U Miscellaneous function M? Switch on the spindle and

coolant, e.g. M13. Confirm with the END key: The TNC

saves the entered positioning block

U Move to the contour: Define the rounding radius of

the approaching arc

U Machine the contour and move to contour point 2: You

only need to enter the information that changes. In

other words, enter only the Y coordinate 95 and save

your entry with the END key

U Move to contour point 3: Enter the X coordinate 95

and save your entry with the END key

U Define the chamfer at contour point 3: Enter the

chamfer width 10 mm and save with the END key

X

Y

9 5

95

5

1

0

10

20

2

0

1 4

2

3

0

0

26

HEIDENHAIN iTNC 530 49

1

.

3

P

r

o

g

r

a

m

m

i

n

g

t

h

e

F

i

r

s

t

P

a

r

t U Move to contour point 4: Enter the Y coordinate 5 and

save your entry with the END key

U Define the chamfer at contour point 4: Enter the

chamfer width 20 mm and save with the END key

U Move to contour point 1: Enter the X coordinate 5 and

save your entry with the END key

U Depart the contour: Define the rounding radius of the

departing arc

U Retract the tool: Press the orange axis key Z in order

to get clear in the tool axis, and enter the value for the

position to be approached, e.g. 250. Confirm with the

ENT key

U Confirm Radius comp.: RL/RR/no comp? by pressing

the ENT key: Do not activate the radius compensation

U Miscellaneous function M? Enter M2 to end the

program and confirm with the END key: The TNC

saves the entered positioning block

Further information on this topic

Complete example with NC blocks: See Example: Linear

movements and chamfers with Cartesian coordinates on page 205

Creating a new program: See Creating and Writing Programs on

page 89

Approaching/departing contours: See Contour Approach and

Departure on page 192

Programming contours: See Overview of path functions on page

196

Tool radius compensation: See Tool radius compensation on page

183

Miscellaneous functions (M): See Miscellaneous Functions for

Program Run Control, Spindle and Coolant on page 303

27

0

50 First Steps with the iTNC 530

1

.

3

P

r

o

g

r

a

m

m

i

n

g

t

h

e

F

i

r

s

t

P

a

r

t

Create a cycle program

The holes (depth of 20 mm) shown in the figure at right are to be drilled

with a standard drilling cycle. You have already defined the workpiece

blank.

U Call the tool: Enter the tool data. Confirm each of your

entries with the ENT key. Do not forget the tool axis

U Retract the tool: Press the orange axis key Z in order

to get clear in the tool axis, and enter the value for the

position to be approached, e.g. 250. Confirm with the

ENT key

U Confirm Radius comp.: RL/RR/no comp? by pressing

the ENT key: Do not activate the radius compensation

U Confirm the Miscellaneous function M? with the

END key: The TNC saves the entered positioning

block

U Call the cycle menu

U Display the drilling cycles

U Select the standard drilling cycle 200: The TNC starts

the dialog for cycle definition. Enter all parameters

requested by the TNC step by step and conclude each

entry with the ENT key. In the screen to the right, the

TNC also displays a graphic showing the respective

cycle parameter

U Move to the first drilling position: Enter the

coordinates of the drilling position, switch on the

coolant and spindle, and call the cycle with M99

U Move to the subsequent drilling positions: Enter the

coordinates of the respective drilling positions, and

call the cycle with M99

U Retract the tool: Press the orange axis key Z in order

to get clear in the tool axis, and enter the value for the

position to be approached, e.g. 250. Confirm with the

ENT key

U Confirm Radius comp.: RL/RR/no comp? by pressing

the ENT key: Do not activate the radius compensation

U Miscellaneous function M? Enter M2 to end the

program and confirm with the END key: The TNC

saves the entered positioning block

X

Y

20

10

100

100

10

90

90 80

0

0

0

0

HEIDENHAIN iTNC 530 51

1

.

3

P

r

o

g

r

a

m

m

i

n

g

t

h

e

F

i

r

s

t

P

a

r

t Example NC blocks

Further information on this topic

Creating a new program: See Creating and Writing Programs on

page 89

Cycle programming: See Users Manual for Cycles

%C200 G71 *

N10 G30 G17 X+0 Y+0 Z-40 * Definition of workpiece blank

N20 G31 X+100 Y+100 Z+0 *

N30 T5 G17 S4500 * Tool call

N40 G00 G40 G90 Z+250 * Retract the tool

N50 G200 DRILLING Define the cycle

Q200=2 ;SETUP CLEARANCE

Q201=-20 ;DEPTH

Q206=250 ;FEED RATE FOR PLNGN

Q202=5 ;PLUNGING DEPTH

Q210=0 ;DWELL TIME AT TOP

Q203=-10 ;SURFACE COORDINATE

Q204=20 ;2ND SETUP CLEARANCE

Q211=0.2 ;DWELL TIME AT DEPTH

N60 X+10 Y+10 M13 M99 * Spindle and coolant on, call cycle

N70 X+10 Y+90 M99 * Call the cycle

N80 X+90 Y+10 M99 * Call the cycle

N90 X+90 Y+90 M99 * Call the cycle

N100 G00 Z+250 M2 * Retract in the tool axis, end program

N99999999 %C200 G71 *

52 First Steps with the iTNC 530

1

.

4

G

r

a

p

h

i

c

a

l

l

y

T

e

s

t

i

n

g

t

h

e

P

r

o

g

r

a

m

1.4 Graphically Testing the

Program

Select the correct operating mode

You can test programs only in the Test Run mode:

U Press the operating modes key: The TNC goes into

the Test Run mode

Further information on this topic

Operating modes of the TNC: See Operating Modes on page 66

Testing programs: See Test Run on page 517

Select the tool table for the test run

You only need to execute this step if you have not activated a tool

table in the Test Run mode.

U Press the PGM MGT key: the TNC displays the file

management

U Press the SELECT TYPE soft key: The TNC shows a

soft-key menu for selection of the file type to be

displayed

U Press the SHOW ALL soft key: The TNC shows all

saved files in the right window

U Move the highlight to the left onto the directories

U Move the highlight to the TNC:\ directory

U Move the highlight to the right onto the files

U Move the highlight to the file TOOL.T (active tool

table) and load with the ENT key: TOOL.T receives

that status S and is therefore active for the Test Run

U Press the END key: Leave the file manager

Further information on this topic

Tool management: See Entering tool data in the table on page 158

Testing programs: See Test Run on page 517

HEIDENHAIN iTNC 530 53

1

.

4

G

r

a

p

h

i

c

a

l

l

y

T

e

s

t

i

n

g

t

h

e

P

r

o

g

r

a

m

Choose the program you want to test

U Press the PGM MGT key: the TNC displays the file

management

U Press the LAST FILES soft key: The TNC opens a

pop-up window with the most recently selected files

U Use the arrow keys to select the program that you

want to test. Load with the ENT key

Further information on this topic

Selecting a program: See Working with the File Manager on page

103

Select the screen layout and the view

U Press the key for selecting the screen layout. The TNC

shows all available alternatives in the soft-key row

U Press the PROGRAM + GRAPHICS soft key: In the

left half of the screen the TNC shows the program; in

the right half it shows the workpiece blank

U Select the desired view via soft key

U Plan view

U Projection in three planes

U 3-D view

Further information on this topic

Graphic functions: See Graphics on page 506

Running a test run: See Test Run on page 517

54 First Steps with the iTNC 530

1

.

4

G

r

a

p

h

i

c

a

l

l

y

T

e

s

t

i

n

g

t

h

e

P

r

o

g

r

a

m

Start the program test

U Press the RESET + START soft key: The TNC

simulates the active program up to a programmed

break or to the program end

U While the simulation is running you can use the soft

keys to change views.

U Press the STOP soft key: The TNC interrupts the test

run

U Press the START soft key: The TNC resumes the test

run after a break

Further information on this topic

Running a test run: See Test Run on page 517

Graphic functions: See Graphics on page 506

Adjusting the test speed:See Setting the speed of the test run on

page 507

HEIDENHAIN iTNC 530 55

1

.

5

T

o

o

l

S

e

t

u

p

1.5 Tool Setup

Select the correct operating mode

Tools are set up in the Manual Operation mode:

U Press the operating modes key: The TNC goes into

the Manual Operation mode

Further information on this topic

Operating modes of the TNC: See Operating Modes on page 66

Prepare and measure tools

U Clamp the required tools in their chucks

U When measuring with an external tool presetter: Measure the tools,

note down the length and radius, or transfer them directly to the

machine through a transfer program

U When measuring on the machine: Place the tools into the tool

changer (see page 56)

The tool table TOOL.T

In the tool table TOOL.T (permanently saved under TNC:\), save the

tool data such as length and radius, but also further tool-specific

information that the TNC needs to conduct its functions.

To enter tool data in the tool table TOOL.T, proceed as follows:

U Display the tool table

U Edit the tool table: Set the EDITING soft key to ON

U With the upward or downward arrow keys you can

select the tool number that you want to edit

U With the rightward or leftward arrow keys you can

select the tool data that you want to edit

U To leave the tool table, press the END key

Further information on this topic

Operating modes of the TNC: See Operating Modes on page 66

Working with the tool table: See Entering tool data in the table on

page 158

56 First Steps with the iTNC 530

1

.

5

T

o

o

l

S

e

t

u

pThe pocket table TOOL_P.TCH

In the pocket table TOOL_P.TCH (permanently saved under TNC:\) you

specify which tools your tool magazine contains.

To enter data in the pocket table TOOL_P.TCH, proceed as follows:

U Display the tool table

U Display the pocket table

U Edit the pocket table: Set the EDITING soft key to ON

U With the upward or downward arrow keys you can

select the pocket number that you want to edit

U With the rightward or leftward arrow keys you can

select the data that you want to edit

U To leave the pocket table, press the END key

Further information on this topic

Operating modes of the TNC: See Operating Modes on page 66

Working with the pocket table: See Pocket table for tool changer

on page 168

The function of the pocket table depends on the machine.

Your machine manual provides more detailed information.

HEIDENHAIN iTNC 530 57

1

.

6

W

o

r

k

p

i

e

c

e

S

e

t

u

p

1.6 Workpiece Setup

Select the correct operating mode

Workpieces are set up in the Manual Operation or Electronic

Handwheel mode

U Press the operating modes key: The TNC goes into

the Manual Operation mode

Further information on this topic

Manual mode: See Moving the Machine Axes on page 442

Clamp the workpiece

Mount the workpiece with a fixture on the machine table. If you have

a 3-D touch probe on your machine, then you do not need to clamp the

workpiece parallel to the axes.

If you do not have a 3-D touch probe available, you have to align the

workpiece so that it is fixed with its edges parallel to the machine

axes.

58 First Steps with the iTNC 530

1

.

6

W

o

r

k

p

i

e

c

e

S

e

t

u

pAlign the workpiece with a 3-D touch probe

system

U Insert the 3-D touch probe: In the Manual Data Input (MDI) operating

mode, run a TOOL CALL block containing the tool axis, and then return

to the Manual Operation mode (in MDI mode you can run an

individual NC block independently of the others)

U Select the probing functions: The TNC displays the

available functions in the soft-key row

U Measure the basic rotation: The TNC displays the

basic rotation menu. To identify the basic rotation,

probe two points on a straight surface of the

workpiece

U Use the axis-direction keys to pre-position the touch

probe to a position near the first contact point

U Select the probing direction via soft key

U Press NC start: The touch probe moves in the defined

direction until it contacts the workpiece and then

automatically returns to its starting point.

U Use the axis-direction keys to pre-position the touch

probe to a position near the second contact point

U Press NC start: The touch probe moves in the defined

direction until it contacts the workpiece and then

automatically returns to its starting point.

U Then the TNC shows the measured basic rotation

U Press the END key to close the menu and then

answer the question of whether the basic rotation

should be transferred to the preset table by pressing

the NO ENT key (no transfer)

Further information on this topic

MDI operating mode: See Programming and Executing Simple

Machining Operations on page 500

Workpiece alignment: See Compensating Workpiece

Misalignment with a 3-D Touch Probe on page 478

HEIDENHAIN iTNC 530 59

1

.

6

W

o

r

k

p

i

e

c

e

S

e

t

u

p Set the datum with a 3-D touch probe

U Insert the 3-D touch probe: In the MDI mode, run a TOOL CALL block

containing the tool axis and then return to the Manual Operation

mode