Professional Documents

Culture Documents

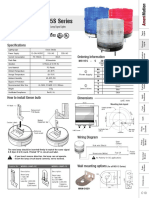

Grupo 3.5 "B" SERIES

Uploaded by

Sergio Belmar CrisostoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Grupo 3.5 "B" SERIES

Uploaded by

Sergio Belmar CrisostoCopyright:

Available Formats

E

0

.

1

8

.

0

7

0

3

.

0

2

.

0

1

GEAR PUMPS AND MOTORS ~B SERIES

GROUP 3.5

Technical catalogue

E

0

.

1

8

.

0

3

0

7

.

0

2

.

0

2

1

INDEX

GEAR PUMPS AND MOTORS

"B" SERIES

Page 2 - Features - Quick guide

Page 3 - Features - General - Working conditions - Fire resistent fluid

Page 4 - Features - Drive shaft - Pump rotation direction - Hydraulic pipe lines

Page 5 - Features - Filtration index recommended - Tightening torque - Common formulas

Page 6 - Features - Identification label

Page 7 - Features - Changing rotation instructions

Page 8 - 3.5P/MC GROUP 3.5

Page 9 - Assembling dimensions and values of pressure and speed

Page 11 - Flanged ports

Page 12 - Drive shafts

Page 13 - Mounting flanges

Page 14 - Outrigger bearing

Page 15 - Multiple gear pumps - Assembling dimensions

Page 16 - 3.5PC combination with 3PB

Page 18 - 19 - Pump performance curves

Page 20 - Port connectors

Page 21 - How to order - Single pumps/motors

Page 1 - GENERAL INDEX

Page 22 - How to order - Multiple pumps

Page 23 - WARRANTY

E0.18.0703.02.01

The data in this catalogue refers to the standard product.

The policy of Salami S.p.A. consists of a continuous improvement of its products.It reserves the right to change the

specifications of the different products whenever necessary and without giving prior information.

If any doubts, please get in touch with our sales departement.

Page 10 - Version interchangeable with 4PB

Page 17 - 3.5PC combination with 2PB (communicating inlet ports) -

- 3.5PC combination with 2PB with separated stages

E0.18.0307.02.02

2

Working conditions

GEAR PUMPS AND MOTORS

"B" SERIES

QUICK GUIDE TO SELECT THE RIGHT PUMP SIZE

To use the diagram shown above, select the pump displacement on the basis of flow required.

Then draw a vertical line to intersect the line representing the pump series.

Now you can select the group on the basis of required application pressure.

The diagram shown here below is used as a first dimensioning aid for the choice of pump group.

It is based on the value of displacements (horizontal coordinates)

and intermittent pressure P2 (vertical coordinates)

Example: 38 cm

3

/rev 2.5PB 38 220 bar (3140 psi)

If required application pressure is more than 220 bar, use a 3 PB

Definition of pressures

P1 = Continuos operating pressure

P2 = Intermittent operating pressure (1/3 of working time)

P3 = Peak pressure

max. 20 s

10 20 30 40 50 60 70 80 90 100 110

140

160

180

200

220

240

260

280

1.1

2.5

5.5

0.9

1.1

2.1

2.6 5.8

7.5

1.42.8

4.1

6.1

1PB 1.5PB 1.6PB 2PB

3.2

16

19

26

5.5

28

32

44

2.5PB

21

38

46

55

65

3PB

64 55

75

87

3.5PC

bar

cm

3

/rev

98

75

Features

GEAR PUMPS AND MOTORS

"B" SERIES

3

SALAMI gear pumps and motors are available in seven series giving options of displacements from 1.1 cm

3

/rev to

98 cm

3

/rev(from 0.06 cu.in./rev to 6.03 cu.in./rev).

All pumps are available as multiple units either of the same or different series.

With all sizes of pumps and motors there are options of shafts, flanges and ports as for European, German and

American standards.

SALAMI gear pumps and motors offer:

High volumetric efficiency by innovative design and accurate control of machining tolerances.

Axial compensation achieved by the use of floating bushes that allow high volumetric efficiency throughout the

working pressure range.

DU bearings ensure high pressure capability.

12 teeth integral gear and shaft.

Extruded alluminum body.

Die cast alluminum cover and flange - cast iron rear.

Double shafts seals in all pump series except Group 1.

Nitrile seals as standard and viton seals in high temperature applications.

All pumps and motors are hydraulic tested after assembly to ensure the high standard performance required by

SALAMI'S engineering.

GENERAL

WORKING CONDITIONS

FIRE RESISTENT FLUID

oil emulsion with 40% water

Water glycol

Phosphate esters

Type

HFB

HFC

HFD

Max pressure

130 bar/1880 psi

180 bar/2600 psi

Max speed (rpm)

2500

1500

1750

Temperature

3C +65C

-20C +65C

-10C +80C

Description

- Pump inlet pressure 0,7 to 2,5 bar

10 to 36 psi

- Return pipe line continuos pressure for motors MAX 2,5 bar - 36 psi

- Return pipe line intermit. pressure for motors MAX 6 bar for 15 sec - 85 psi

- Return pipe line peak pressure for motors MAX 15 bar - 215 psi

- Minimum operating fluid viscosity 12 mm

2

/ sec

- Max starting viscosity 800 mm

2

/ sec

- Suggested fluid viscosity range 17 - 65 mm

2

/ sec

- Fluid operating temperature range -15 to +85 C

- Hydraulic fluid mineral oil

Important:

in case of assembling of pumps without shaft seals (eg. B2 - B3....), you have to keep the value of

min. suction pressure ( 0.7 bar (abs)) in the vane between pump and coupling too.

Lower pressure can lead to suction of oil through the front flange (seat of the shaft without seal);

this can damage seriously the pump.

THE VALUES OF PRESSURE ARE ABSOLUTE

Features

GEAR PUMPS AND MOTORS

"B" SERIES

4

DRIVE SHAFT

Radi al and axi al l oads on the shafts must be avoi ded si nce they reduce the l i fe of the uni t.

Pumps driven by power take - off on engines must always be connected by placing an "Oldham" coupling or coupling

having convex toothed hub.

This is to ensure that inevitable misalignment during assembly is reduced to minimum.

HYDRAULIC PIPE LINE

To ensure favorable suction conditions it is important to keep pressure drop in suction pipe line to a minimum value

(see WORKING CONDITIONS).

To calculte hydraulic pipe line size, the designer can use; as an approximate guide, the following fluid speed figures:

From 1 to 2 m/sec on suction pipe line

From 6 to 10 m/sec on pressure pipe line

The lowest fluid speed values in pipe lines is recommended when the operating temperature range is high and/or for continuos

duty.

The hi ghest val ue i s recommended when the temperature di fference i s l ow and/or for i ntermi ttent duty.

When tandem pumps are supplied by 2 different reservoirs with 2 different fluids it is necessary to specify "AS" version.

In case of reversible motor allowance must be made to ensure the motor is not drained, through the case drain, when stationary.

From 3.28 to 6.36 ft/sec on suction pipe line

From 19.7 to 32.8 ft/sec on pressure pipe line

PUMP ROTATION DIRECTION VIEWED AT THE DRIVE SHAFT

Outlet Inlet

Anti - clockwise rotation Clockwise rotation Reversible rotation

Outlet Inlet

5

Features

GEAR PUMPS AND MOTORS

"B" SERIES

COMMON FORMULAS

FILTRATION INDEX RECOMMENDED

Contamination class NAS 1638

Contamination class ISO 4406

Achieved with filter

x

=75

> 200 bar / 2900 psi Working pressure

9

18/15

15 m

< 200 bar / 2900 psi

10

19/16

25 m

TIGHTENING TORQUE

OUR BOLTS AND TIE-RODS HAVE ALWAYS

HEATING TREATMENT OF BLACK BURNISHING

C = Input torque

P = Input power

Q = Outlet flow

=

=

=

(Nm)

(kW)

(l/min)

LEGENDA

Dp = Working pressure (bar)

q = Displacement (cm

3

/rev)

n = Speed (min

-1

)

h

m

= Mechanical eff. (0.92)

h

v

= Volumetric eff. (0.95)

PUMP TYPE BOLT TYPE

SIZE SERIE DIAMETER CLASS

TORQUE

Nm

2

B

SINGLE

M10x1. 5 8. 8 47- 51

2

B

MULTIPLE

M10x 1. 5 10. 9 50- 55

2.5

B

SINGLE

M1 2 8 . 8 7 0 - 7 5

2.5

B

MULTIPLE

M1 2 1 0 . 9 7 5 - 8 0

3 B M10 47- 51

3. 5 C M12 8. 8 74- 85

3 H M14 10. 9 1 5 0 - 1 6 0

1

B

SINGLE

M 8 x1.25 8. 8 20.5 - 25.5

1

B

MULTIPLE

M 8 x1.25 20.5 - 25.5

BOLT 180

TIE ROD F

O

R

S

C

R

E

W

S

Z

I

N

C

P

L

A

T

E

D

R

E

D

U

C

E

T

I

G

H

T

E

N

I

N

G

T

O

R

Q

U

E

O

F

1

0

%

8. 8

HEX. BOLT 10.9

HEX. SOCKET H.C.B. 12.9

Features

GEAR PUMPS AND MOTORS

"B" SERIES

6

A

B

C D

G F E

Based on the firm certification ISO 9001 - UNI EN 29001, section 4.8 (identification

and tracebility of the product), we have adopted a new identification label starting

from the 1

st

march 1995. Pls, see following example:

A = Product short descritpion (VD8A/FDD/U4G).

B = Customer part number.

C = Salami part number (6235 0025 0).

D = Production batch (for Salami management)

E = Rotation sense (only for pumps).

F = Manufacturing date (see data sheet here below)

G = Progressive number of assembling.

JANUARY

FEBRUARY

MARCH

APRIL

MAY

JUNE

JULY

AUGUST

SEPTEMBER

OCTOBER

NOVEMBER

DECEMBER

1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003

8M

8N

8P

8Q

8R

8S

8T

8U

8V

8Z

8X

8Y

0A

0B

0C

0E

0F

0G

0H

0I

0J

0K

0L

0D

1A

1B

1C

1E

1F

1G

1H

1I

1J

1K

1L

1D

2A

2B

2C

2E

2F

2G

2H

2I

2J

2K

2L

2D

3A

3B

3C

3E

3F

3G

3H

3I

3J

3K

3L

3D

4A

4B

4C

4E

4F

4G

4H

4I

4J

4K

4L

4D

5A

5B

5C

5E

5F

5G

5H

5I

5J

5K

5L

5D

6A

6B

6C

6E

6F

6G

6H

6I

6J

6K

6L

6D

7A

7B

7C

7E

7F

7G

7H

7I

7J

7K

7L

7D

9M

9N

9P

9Q

9R

9S

9T

9U

9V

9Z

9X

9Y

0M

0N

0P

0Q

0R

0S

0T

0U

0V

0Z

0X

0Y

1M

1N

1P

1Q

1R

1S

1T

1U

1V

1Z

1X

1Y

2M

2N

2P

2Q

2R

2S

2T

2U

2V

2Z

2X

2Y

3M

3N

3P

3Q

3R

3S

3T

3U

3V

3Z

3X

3Y

2004 2005

4M

4N

4P

4Q

4R

4S

4T

4U

4V

4Z

4X

4Y

5M

5N

5P

5Q

5R

5S

5T

5U

5V

5Z

5X

5Y

Only for pumps 2PB and 2PZ

(except triple 2PB) the identification product

is marked on the top of the pump body

as shown here below:

SALAMI 09/02

MADE IN ITALY 4010998

612271211 nr. 13

2PB 19S B25 B5

Month and year of made: maybe in the future you can find this

type of production date in the label beside too.

Production code (for Salami management).

Salami part number and progressive number of assembling.

Product short description.

Rotation sense.

Description of the product identification label

Features

GEAR PUMPS AND MOTORS

"B" SERIES

7

Before starting, be sure that the pump is

cleaned externally as well as the working

area to avoid that particles dangerous for

pump working can find their way into the

pump.

Pump represented is aclockwise rotation

pump.

To obtain an anti_clockwise rotation read

carefully the following instructions.

Picture "A"

1 - Loosen and fully unscrew the clamp

bolts.

2 - Lay the pump on the working area in

order to have the mounting flange

turned upside.

3 - Coat the shaft extension with grease to

avoid damaging the shaft seal.

4 - Remove the flange and lay it on the

working area;

verify that the seal is correctly located

in the body seat.

Picture "B"

1 - Mark the position of the bushing and

eventually the thrust plate, relative to

the body.

2 - Remove the bushing, thrust plate and

the driving gear taking care to avoid

driven gear axial shifts.

Picture "C"

1 - Draw out the driven gear from its housing,

taking care to avoid rear cover axial

shifts.

2 - Re-locate the driven gear in the position

previously occupied by the driving gear.

Picture "D"

1 - Re-locate the driving gear in the position

previously occupied by the driven gear.

Picture "E"

1 - Replace the bushing and thrust plate

taking care that:

- marks are located as on the picture

- surface containing the seal is visible

- seal and its protection are correctly

located

Picture "F"

1 - Clean body and mounting flange refaced

surfaces.

2 - Verify that the two plugs are located in

the body.

3 - Refit the mounting flange, turned 180

from its original position.

4 - Replace the clamp bolts and tighten

crosswise evenly to a torque of 40 - 45

Nm for 2PB, 2.5PB, 45 - 50 Nm for

3PB, 3.5PB.

5 - Check that the shaft rotates freely.

6 - Mark on the flange the new direction of

rotation.

Picture "B"

Picture "C"

Picture "D"

COVER

DRIVING GEAR

BODY

BUSHI NG

DRIVEN GEAR

Picture "A"

FLANGE

BOLT

THRUST PLATE

Pict. "F"

Pict. "E"

IMPORTANT: TO AVOID A PERFORMANCE LOSS DO NOT CHANGE MOTOR ROTATION

Rotation changing instructions for pumps GROUP 2 - 2.5 - 3 - 3.5

GEAR PUMPS AND MOTORS

"B" SERIES

8

3.5P/MC Group 3.5

GEAR PUMP IN DETAIL

1

2 3

4 5

7

6

9

8

11

10

12

13

12

8

9

7

8

7

9

14

4

1 - Shaft seals

2 - Washer

3 - Stop ring

4 - Bolts

5 - Flange

6 - Reference pin

7 - Bushings

9 - Plate

10 - Drive gear

11 - Driven gear

8 - Bushing seals and anti-extrusion

12 - Body seals

13 - Body

14 - Cover

This drawing can be considered an example

of standard components of group 3 pump.

3.5P/MC Group 3.5

GEAR PUMPS AND MOTORS

"B" SERIES

9

The pump shown is: 3.5PC 64D - P48 P3

Displacements up to 98 cm

3

/rev

Pressure up to 300 bar

ASSEMBLING DIMENSIONS AND VALUES OF PRESSURE AND SPEED

Displacements up to 5.98 cu.in./rev

Pressure up to 4300 psi

GEAR PUMPS AND

MOTORS

Drain hole G3/8 or 9/16-18 UNF

only for reversible pumps and motors

Tapered 1:8

Tightening torque 100 Nm

see pag. 5

Type

2750

55

10.7

23.54

230

3300

54.8

3.34

400

11.4

25.08

350

64 75 98*

63.2

3.85

300

4300

280

4000

250

3600

300

11.9

26.18

12.8

27.5

Displacement

Dimension A

Dimension C

Working pressure p1

Intermittent pressure p2

Peak pressure p3

Max. speed at p2

Min. speed at p1

Weight

cm

3

/ rev.

cu.in./rev.

mm.

in.

mm.

in.

bar

psi

bar

psi

bar

psi

rpm

rpm

kg

lbs

165

6.49

80

3.14

177

6.96

86

3.38

74.7

4.55

184

7.24

89.5

3.52

99

6.03

197

7.75

96

3.77

250

3600

280

4000

200

2900

220

3140

250

3600

2500 2000

87

12.5

27.5

88

5.36

192

7.55

93.5

3.68

210

3000

230

3300

260

3750

2250

*Available for quantity, please contact our sales dept.

3.5P/MC Group 3.5

GEAR PUMPS AND MOTORS

"B" SERIES

10

VERSION INTERCHANGEABLE WITH 4PB

Tapered 1:8

Tightening torque 140 Nm

see pag. 5

Drain hole G3/8 position only for

reversible pumps and motors

Type 75 87 98

300

Displacement

Dimension A

Dimension C

Working pressure p1

Intermittent pressure p2

Peak pressure p3

Max. speed at p2

Min. speed at p1

Weight

cm

3

/ rev.

cu.in./rev.

mm.

in.

mm.

in.

bar

psi

bar

psi

bar

psi

rpm

rpm

kg

lbs

230

3300

74.7

4.55

184

7.24

89.5

3.52

88

5.36

192

7.55

93.5

3.68

250

3600

280

4000

210

3000

230

3300

260

3750

99

6.03

197

7.75

96

3.77

200

2900

220

3140

250

3600

2500 2250 2000

12.5

27.5

13

28.6

14

30.8

GEAR PUMPS AND

MOTORS

The pump shown has: shaft "49" flange "P4"

3.5P/MC VERSION INTERCHANGEABLE WITH 4P/MB MEANS THAT THE FLANGE

HAS THE SAME DISTANCE BETWEEN CENTER HOLES OF 4P/MB

A

C

GEAR PUMPS AND MOTORS

"B" SERIES

11

3.5P/MC Group 3.5

FLANGED PORTS

code P

code S

d

For unidirectional motor inlet/outlet ports are reversed.

*For version 49 P4 (version interchangeable with 4PB see page 10)

Available for quantity, please

get in touch with our sales dept.

Depht e

7/16-14 UNC

Type INLET

55

64

75

87

98

D H

B

OUTLET

H d D d B

3/8-16 UNC

32

(1.26")

58.7

(2.31")

30.2

(1.26")

38

(1.50")

69.8

(2.75")

35.7

(1.41")

19

(0.75")

47.6

(1.87")

22.22

(0.87")

26

(1.02")

52.4

(2.06")

26.2

(1.03")

Tightening torque for different threads:

M10: 50 Nm

M12: 90 Nm

Type INLET

55

64

A C

d

OUTLET

A e C d

M10

M12

M10

51

(2.01")

62

(2.44")

27

(1.06")

33

(1.30")

16

(0.63")

22

(0.86")

e

51

(2.01")

22

(0.87")

16

(0.63")

75

87

98

M12

22

(0.86")

72.5

(2.85")

38

(1.50")

M10

16

(0.63")

51

(2.01")

22

(0.87")

GEAR PUMPS AND MOTORS

"B" SERIES

12

3.5P/MC Group 3.5

DRIVE SHAFTS

code 49

Tapered 1:8

Only with flange code P4

code 48

Max. torque 420 Nm

Woodruff key (4.7x10)

Tapered 1:8

code 56

SAE BB 15T-16/32DP-Ansi B92 1a 1976

Available for quantity, please contact

our sales dept.

Max. torque 460 Nm

2

5

.

4

code 55

SAE B 13T-16/32DP - Ansi B92 1a 1976

Available for quantity, please contact

our sales dept.

Max. torque 300 Nm

2

2

.

2

2

Max. torque 460 Nm

Woodruff key (6.3x10)

GEAR PUMPS AND MOTORS

"B" SERIES

13

3.5P/MC Group 3.5

MOUNTING FLANGES

code P3 code P4

With shaft code 49 With shaft code 48

code S3

With shaft code 55 - 56

Available for quantity, please contact

our sales dept.

GEAR PUMPS AND MOTORS

"B" SERIES

14

3.5P/MC Group 3.5

OUTRIGGER BEARING

Tightening torque 100 Nm

Distance from flange surface - Point at which the radial load acts F

r

The diagram shows the maximum

radial load with reference to a bearing

life of 3000 hours.

Example how to order: 3.5PC 87D - P48 P3 - CP

For dimension "A" and performance data,

see corresponding single pumps (pag. 9)

Available for quantity, please contact our sales department

Distance a (mm)

Radial loads (daN)

rpm

rpm

rpm

rpm

C(Nm)=

GEAR PUMPS AND MOTORS

"B" SERIES

15

Example to order : 3PC 75/64/55D - P48 P3

ASSEMBLING DIMENSIONS

3.5P/MC Group 3.5

The 3PB pumps can be easily transformed into front pump in the multiple units. All drive shafts

are pre-arranged and have a splined end according DIN 5482. The first unit must always be the

same size or bigger than following units. The features and performances are the same of the

corresponding single units: only in the case of simultaneous operating you have to verify that the

inlet torque is lower than the max. transmissible by the drive shaft.

kit multiple pumps 1 3 4 2

MULTIPLE

GEAR PUMPS

cm

3

/ rev.

cu.in./rev.

mm.

in.

Type

Displacement

Dimension A

Performance data

55 64 75 87 98

54.8

3.34

108

4.25

63.2

3.85

120

4.72

74.7

4.55

127

5.00

88

5.36

135

5.31

99

6.03

140

5.51

See corresponding single pumps

O Ring Max. torque 550 Nm see page 5 Centering

pin

Front pump Middle pump Rear pump

These units are pre-arranged for

multiple pumps, they have the drive shaft splined both sides

This is a Salami standard pump,

all drive shafts have a splined end

This is the cover

of Salami standard

pump

26

1.02 A

24

0.94

24

0.94 A

24

0.94

31

1.22

C (pag.9)

24

0.94 A

2

5

.

4

1

1 3 4 2

C (pag.9) C (pag.9)

GEAR PUMPS AND MOTORS

"B" SERIES

16

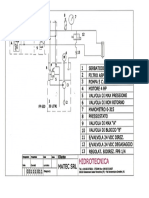

3.5P/MC Group 3.5

3.5PC COMBINATION WITH 3PB PUMP (COMMUNICATING INLET PORTS)

For dimensions (A C) see corresponding multiple pumps page 15

Order example:

3.5PC 64/3PB 21D - P48 P3

3.5PC 98/3PB 33S - P49 P4

3.5PC combination with

3PB (communicating inlet ports)

components kit:

1 3 2 4

Coupling O Ring see page 5

Front pump Rear pump

1 3 2

For dimensions rear pump

see catalogue:

GEAR PUMPS AND MOTORS

GROUP 3

26

1.02 A

48

1.89

27

1.06

C

2

5

.

4

1

4

2

2

0

.

8

7

17

3.5P/MC Group 3.5

3.5PC COMBINATION WITH 2PE PUMP WITH SEPARATED STAGES

3.5PC COMBINATION WITH 2PE PUMP (COMMUNICATING INLET PORTS)

GEAR PUMPS AND MOTORS

"B" SERIES

For dimensions (A C) see corresponding multiple pumps page 15

Order example:

3.5PC 46/2PE 16D - S55 S3

3.5PC 98/2PE 19S - P49 P4

Coupling O Ring see page 5

Front pump Rear pump

1 3 2

3.5PC combination with

2PE (communicating inlet ports)

components kit:

1 3 2

For dimensions rear pump

see catalogue:

GEAR PUMPS AND MOTORS

GROUP 2

26

1.02 A

45

1.77

24

0.94

C

2

5

.

4

1

1

5

.

9

0

.

6

3

4

4

code AS

For dimensions (A C) see corresponding multiple pumps page 15

Coupling O Ring

see page 5

Front pump Rear pump

Shaft seals

3.5PC combination with

2PE (separated stages)

components kit:

For dimensions and features

rear pump see catalogue:

GEAR PUMPS AND MOTORS

GROUP 2

1 4 2 3 5

As you can see in the 2PE

catalogue, drive shaft

and assembling screws

of the 2PE pump are longer

then standard 2PE.

1 3 2

26

1.02 A

61

2.40

24

0.94

C

2

5

.

4

1

1

5

.

9

0

.

6

3

4 5 6

6

Order example:

3.5PC 75/2PE 13.8D - P48 P3 - AS

PUMP PERFORMANCE CURVES

18

3.5P/MC Group 3.5

Performance curves carried out with oil viscosity at 16 cSt and oil temperature at 60C

3.5PC 55

3.5PC 64

3.5PC 75

19

3.5P/MC Group 3.5

Performance curves carried out with oil viscosity at 16 cSt and oil temperature at 60C

3.5PC 87

3.5PC 98

20

PORT CONNECTORS

Type G

AVAILABLE CONNECTORS - DIMENSIONS AND CODE

3.5P/MC Group 3.5

GEAR PUMPS AND MOTORS

"B" SERIES

MATERIAL: CAST IRON

Type C B l D F A

ORDERING CODE COMPLETE OF

SCREW - SPRING WASHER - O RING

3 G 4352 7013 0 43 27 51 21 10.5 G 1

4 G 4352 7017 0 55 34.5 62 27 12.5 G 1 1/4

5 G 4352 7018 0 56 34.5 72.5 27 12.5 G 1 1/2

Example to order a 3.5 PC standard pump: 3.5PC 64D - P48 P3

Example to order a 3.5 PC interchangeable with 4PB: 3.5PC 98D - P49 P4

21

GEAR PUMPS AND MOTORS

"B" SERIES

How to order/Group 3.5

SINGLE PUMPS/MOTORS

3.5

SERIES

D

MOUNTING FLANGES (pag. 13) CODES

European standard 60.3

European std. interchangeable with 4PB 63.5

SAE B 2 bolts 101.6

P2

P3 (pag.11)

S3*

P 64

FUNCTION CODE

Pump

Motor

P

M

ROTATION CODES

Clockwise

Anti-clockwise

Reversible

D

S

R

DIMENSION

48 P C P3

SEAL CODE

Buna Standard

Viton V

V CP

OUTRIGGER BEARINGS (pag. 14) CODES

European standard

CP*

PD2 - PD3

PD2=pre-arranged for 2PE rear

3.34 cu.in/rev.

3.85 cu.in/rev.

4.55 cu.in/rev.

5.36 cu.in/rev.

6.03 cu.in/rev.

TYPE DISPLACEMENTS

55

64

75

87

98*

54.8 cm

3

/rev.

63.2 cm

3

/rev.

74.7 cm

3

/rev.

88 cm

3

/rev.

99 cm

3

/rev.

PORTS (pag. 11) CODES

Flanged ports european standard P

DRIVE SHAFTS (pag. 12) CODES

Tapered 1:8 24.64

Tapered 1:8 31.75

SAE B splined 13 T

SAE BB splined 15 T

48

49

55*

56* SAE flanged ports (UNC) S*

PD3=pre-arranged for 3PB rear

*Available for quantity, please contact our sales department

How to order/Group 3.5

GEAR PUMPS AND MOTORS

"B" SERIES

MULTIPLE PUMPS

Example to order a 3.5 PC tandem pump: 3.5PC 75/64D - S56 S3

Example to order a tandem pump 3.5PC combination with 3PB: 3.5PC 75/3PB 38S - P48 P3

Example to order a tandem pump 3.5PC combination with 2PE separated stages:

3.5PC 64/2PE 16D - P49 P4 - AS

22

3.5PC D

MOUNTING FLANGES (pag. 13) CODES

European standard 60.3

European std. interchangeable with 4PB 63.5

SAE B 2 bolts 101.6

P2

P3 (pag.11)

S3*

75 55

ROTATION CODES

Clockwise

Anti-clockwise

Reversible

D

S

R

DIMENSION

55 S 64 S3

SEAL CODE

Buna Standard

Viton V

V CP

OUTRIGGER BEARINGS (pag. 14) CODES

European standard

CP*

PD2 - PD3

PD2=pre-arranged for 2PE rear

3.34 cu.in/rev.

3.85 cu.in/rev.

4.55 cu.in/rev.

5.36 cu.in/rev.

6.03 cu.in/rev.

TYPE DISPLACEMENTS

55

64

75

87

98*

54.8 cm

3

/rev.

63.2 cm

3

/rev.

74.7 cm

3

/rev.

88 cm

3

/rev.

99 cm

3

/rev.

PORTS (pag. 11) CODES

Flanged ports european standard P

DRIVE SHAFTS (pag. 12) CODES

Tapered 1:8 24.64

Tapered 1:8 31.75

SAE B splined 13 T

SAE BB splined 15 T

48

49

55*

56*

SAE flanged ports (UNC) S*

PD3=pre-arranged for 3PB rear

AS

SUCTION TYPE (pag. 17) CODES

3.5PC combination with 2PE with separated

stages

AS

3PB... / 2PE...

See catalogues:

GEAR PUMPS AND MOTORS

"B" SERIES GROUP 3

GEAR PUMPS AND MOTORS

"E"SERIES GROUP 2

*Available for quantity, please contact our sales department

WARRANTY

- We warrant products sold by us to be free from defects in material

and workmanship.

- Our sole obligation to buyer under this warranty is the repair or replacement,

at our option, of any products or parts thereof which, under normal use and

proper maintenance, have proven defective in material or workmanship, this

warranty does not cover ordinary wear and tear, abuse, misuse, averloading,

alteration.

- No claims under this warranty will be valid unless buyer notifies SALAMI in

writing within a reasonable time of the buyer's discovery of such defects,but

in no event later than twelve (12) mounths from date of shipment to buyer.

- Our obligation under this warranty shall not include any transportation charges

or cost of installation, replacement, field repair, or other charges related to

returning products to us; or any liability for directs, indirects or consequential

damage or delay.If requested by us, products or parts for which a warranty

claim is made are to be returned transportation prepaid to our factory. The risk

of loss of any products or parts thereof returned to SALAMI will be on buyer.

- No employee or representative is authorized to change any warranty in any

way or grant any other warranty unless such change is made in writing and

signed by an officer of SALAMI.

E

0

.

1

8

.

0

7

0

3

.

0

2

.

0

1

GEAR PUMPS AND MOTORS ~B SERIES

GROUP 3.5

Technical catalogue

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- W201 Wiring DiagramDocument290 pagesW201 Wiring Diagramilikemyfishbigandblue86% (44)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- EatonDocument157 pagesEatonMauro MonsalveNo ratings yet

- Operating Instructions, FormulaDocument35 pagesOperating Instructions, FormulaandymulyonoNo ratings yet

- G. ACI 360R-06 Brings Slabs On Ground Into The 21st Century - Art McKinney PDFDocument2 pagesG. ACI 360R-06 Brings Slabs On Ground Into The 21st Century - Art McKinney PDFinitbashNo ratings yet

- Timing Cover 190EDocument8 pagesTiming Cover 190ESergio Belmar CrisostoNo ratings yet

- Qi440 Manual EngDocument340 pagesQi440 Manual EngSergio Belmar CrisostoNo ratings yet

- 3 Phase Induction Motors Objective Questions With AnswersDocument3 pages3 Phase Induction Motors Objective Questions With AnswersMohan Raj0% (2)

- A320 Aircraft CharacteristicsDocument387 pagesA320 Aircraft CharacteristicsEder LucianoNo ratings yet

- ZXONE Quick Installation Guide - V1.0Document56 pagesZXONE Quick Installation Guide - V1.0kmad100% (2)

- IEEE STD C37.30.1 Estandar de Requisitos para Interruptores de Aire de AV AC para Nivelesmayores A 1000VDocument104 pagesIEEE STD C37.30.1 Estandar de Requisitos para Interruptores de Aire de AV AC para Nivelesmayores A 1000Valex100% (4)

- Digital Level - Display DA13Document16 pagesDigital Level - Display DA13Sergio Belmar CrisostoNo ratings yet

- DR System ConciseDocument37 pagesDR System ConciseJiten KarmakarNo ratings yet

- Leica 307 ManualDocument4 pagesLeica 307 ManualRaluca Sandu100% (2)

- Baliza Menics MS115S-S20 B-RDocument1 pageBaliza Menics MS115S-S20 B-RSergio Belmar CrisostoNo ratings yet

- SDC-3RS Revised Manual 4-05Document27 pagesSDC-3RS Revised Manual 4-05Sergio Belmar CrisostoNo ratings yet

- Motor TEDocument30 pagesMotor TESergio Belmar CrisostoNo ratings yet

- Válvula Sun Hydraulic CBCH-LCNDocument1 pageVálvula Sun Hydraulic CBCH-LCNSergio Belmar CrisostoNo ratings yet

- Alkitronic Eaf Akku en BDocument2 pagesAlkitronic Eaf Akku en BSergio Belmar CrisostoNo ratings yet

- Aluminium Gear Pumps Technical CatalogueDocument32 pagesAluminium Gear Pumps Technical CatalogueSergio Belmar CrisostoNo ratings yet

- Connect Directly To Your Computer: Px409-Usbh SeriesDocument4 pagesConnect Directly To Your Computer: Px409-Usbh SeriesSergio Belmar CrisostoNo ratings yet

- 5 Inch HDMI Display-B: User ManualDocument5 pages5 Inch HDMI Display-B: User ManualSergio Belmar CrisostoNo ratings yet

- SDE060 Uk-Kbs 216701Document4 pagesSDE060 Uk-Kbs 216701Sergio Belmar CrisostoNo ratings yet

- PS50 0907Document16 pagesPS50 0907Sergio Belmar CrisostoNo ratings yet

- Hydrowa Cyl PDFDocument44 pagesHydrowa Cyl PDFSergio Belmar CrisostoNo ratings yet

- Catálogo PARAMAX 9000 2Document352 pagesCatálogo PARAMAX 9000 2Car Alb Jose100% (1)

- Plano Centinela PuertoDocument1 pagePlano Centinela PuertoSergio Belmar CrisostoNo ratings yet

- Cilindro de Levante 3000 PsiDocument4 pagesCilindro de Levante 3000 PsiSergio Belmar CrisostoNo ratings yet

- Wren Hydraulic Pump Kwl4000Document6 pagesWren Hydraulic Pump Kwl4000Sergio Belmar CrisostoNo ratings yet

- P 1346 1Document8 pagesP 1346 1Sergio Belmar CrisostoNo ratings yet

- P 1346 1Document8 pagesP 1346 1Sergio Belmar CrisostoNo ratings yet

- Cisco 881 ManualDocument30 pagesCisco 881 ManualSergio Belmar CrisostoNo ratings yet

- Backstop Faja TransportadoraDocument12 pagesBackstop Faja TransportadoratayarinNo ratings yet

- CRS125 24G 1SDocument1 pageCRS125 24G 1SSergio Belmar CrisostoNo ratings yet

- 039 NG4 Prop LVDT eDocument1 page039 NG4 Prop LVDT eSergio Belmar CrisostoNo ratings yet

- UniFi AP AP-LR User GuideDocument57 pagesUniFi AP AP-LR User GuideSimón GarayNo ratings yet

- W201 PartsDocument543 pagesW201 PartsJuan Alejandro Reyes Bazan86% (7)

- 190E 16V C+D March-1986Document5 pages190E 16V C+D March-1986Sergio Belmar CrisostoNo ratings yet

- GaN technology powers bright LEDsDocument13 pagesGaN technology powers bright LEDsluciowwNo ratings yet

- Using Electricity SafelyDocument1 pageUsing Electricity SafelymariaNo ratings yet

- NUSTian Final July SeptDocument36 pagesNUSTian Final July SeptAdeel KhanNo ratings yet

- Gps VulnerabilityDocument28 pagesGps VulnerabilityaxyyNo ratings yet

- Bottom Ash HopperDocument8 pagesBottom Ash HopperBhargav ChaudhariNo ratings yet

- Structural Systems Engineering GuideDocument67 pagesStructural Systems Engineering Guidejucar fernandezNo ratings yet

- Lesson 7: Cylinders: Basic Hydraulic SystemsDocument12 pagesLesson 7: Cylinders: Basic Hydraulic Systemsoscar el carevergaNo ratings yet

- Struts by Kamalakar DanduDocument237 pagesStruts by Kamalakar DanduKamalakar DanduNo ratings yet

- Hit-Re 500 With Hit-V Has RodsDocument3 pagesHit-Re 500 With Hit-V Has RodsMKNo ratings yet

- Engine & Transmission ToolsDocument45 pagesEngine & Transmission Toolsabduallah muhammad100% (1)

- An Algorithm For Minimax Solution of Overdetennined Systems of Non-Linear EquationsDocument8 pagesAn Algorithm For Minimax Solution of Overdetennined Systems of Non-Linear EquationsDewi FitriyaniNo ratings yet

- Advantages & Disadvantages CITWDocument5 pagesAdvantages & Disadvantages CITWSreePrakashNo ratings yet

- QUS 303 CONSTRUCTION ECONOMICSDocument21 pagesQUS 303 CONSTRUCTION ECONOMICSjudexnams1on1No ratings yet

- Motorola's TQM Journey to Six Sigma QualityDocument19 pagesMotorola's TQM Journey to Six Sigma QualityKatya Avdieienko100% (1)

- Ultrasonic Testing Level 2 MCQsDocument8 pagesUltrasonic Testing Level 2 MCQspandab BkNo ratings yet

- Carimin Acacia Stability-Onhire Loading JerunDocument6 pagesCarimin Acacia Stability-Onhire Loading Jerunh2sbnj86b4No ratings yet

- Composite Repair PDFDocument13 pagesComposite Repair PDFNarendra PalandeNo ratings yet

- The Synergies of Hybridizing CNC and Additive ManufacturingDocument8 pagesThe Synergies of Hybridizing CNC and Additive ManufacturingdemuxNo ratings yet

- Operator Interface Hmi Touch Screen Cmore - 10Document54 pagesOperator Interface Hmi Touch Screen Cmore - 10QuantumAutomation100% (1)

- End All Red Overdrive: Controls and FeaturesDocument6 pagesEnd All Red Overdrive: Controls and FeaturesBepe uptp5aNo ratings yet

- Dow Corning (R) 200 Fluid, 50 Cst.Document11 pagesDow Corning (R) 200 Fluid, 50 Cst.Sergio Gonzalez GuzmanNo ratings yet

- Sad Thesis Guidelines FinalsDocument13 pagesSad Thesis Guidelines FinalsJes RamosNo ratings yet