Professional Documents

Culture Documents

Esdep Lecture Note (Wg15a)

Uploaded by

GhoozyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Esdep Lecture Note (Wg15a)

Uploaded by

GhoozyCopyright:

Available Formats

Previous | Next | Contents

ESDEP WG 15A

STRUCTURAL SYSTEMS: OFFSHORE

OBJECTIVE/SCOPE

To elaborate on structural steel concepts for integrated decks, module support frames, and modules. To show principles and methods of

construction (fromyard to offshore site).

PRE-REQUISITES

Lectures 1A & 1B: Steel Construction

Lecture 2.4: Steel Grades and Qualities

Lecture 2.5: Selection of Steel Quality

Lectures 3.1: General Fabrication of Steel Structures

Lecture 6.3: Elastic Instability Modes

Lecture 7.6: Built-up Columns

Lectures 8.4: Plate Girder Behaviour and Design

Lecture 11.2: Welded Connections

Lecture 12.2: Advanced Introduction to Fatigue

Lecture 15A: Offshore Structures

SUMMARY

Structural systems for each type of topside structure are introduced, i.e. truss, portal frame, box girder, and stressed skin.

Some special topics of design are addressed and the different construction phases are presented in more detail, i.e.:

fabrication 1.

weighing 2.

load out 3.

sea transport 4.

offshore installation especially deckmating 5.

module installation 6.

hook-up 7.

commissioning. 8.

A brief discussion on inspection and repair and on platformremoval concludes this lecture.

1. INTRODUCTION

This lecture deals with the structural design of jacket-based offshore deck structures, following the introduction in Lecture 15A.10.

Heavy decks, over 10.000 tons, are provided with a module support frame onto which a number of modules are placed, see Lecture 15A.1,

Figs. 4 and 5. Smaller decks, such as those located in the southern North Sea, are nowadays installed complete with all equipment in one lift

to minimize offshore hook-up. Most of this lecture refers to this type of integrated deck as described in Lecture 15A.10.

The selection of the concept for the structural deck is made in close cooperation with the other disciplines.

ESDEP LECTURE NOTE [WG15A] http://www.fgg.uni-lj.si/~/pmoze/ESDEP/master/wg15a/l1100.htm

1 of 18 9/2/2014 9:03 PM

For the design of the deck structure, the in-place condition has to be considered, together with the various previous stages such as

fabrication, load-out, transport and installation.

A structural systemfor a deck structure comprises several of the following elements:

Floors (steel plate or grating) }

Deck stringer (H beams, bulbs or troughs) } Discussed in

Horizontal bracing } Lecture 15A.10

Deck beams

}

Primary girders }

Vertical trusses or bracing } Discussed in

Deck legs } this lecture

2. MAIN STRUCTURE DESIGN

2.1 Introduction

Some major topics in topside structural design are reviewed below.

2.2 Main Structure-Portal Frame Design

A portal frame design has been used in recent major projects in the Dutch sector such as Amoco P15, Placid K12 [5] and Penzoil L8.

The main girder/column joint, as shown in Figure 1, is very important in determining the height. It is most practical to position the

longitudinal and transverse main girder flanges at the same elevation.

ESDEP LECTURE NOTE [WG15A] http://www.fgg.uni-lj.si/~/pmoze/ESDEP/master/wg15a/l1100.htm

2 of 18 9/2/2014 9:03 PM

Haunching of the transverse main girder , which is more lightly loaded-in-plane, however is not an option as these girders become highly

loaded during transport.

The severe restraint of welding a tubular in a diaphragmrequires the selection of TTP steel for the column section.

Due to the high importance of the diaphragmplates in the overall integrity of the structure and the welding constraints on the web plates in

between, TTP-steel is chosen also for the diaphragm.

Another option is to weld the girders directly onto the unstiffened can section of the column. The assessment of ultimate resistance as well as

fatigue strength has been the subject of recent research (see Lecture 15A.12).

Further improvement of the theoretical and experimental background is required. For lighter loaded truss structures, this non-stiffened type

of joint has been used successfully.

ESDEP LECTURE NOTE [WG15A] http://www.fgg.uni-lj.si/~/pmoze/ESDEP/master/wg15a/l1100.htm

3 of 18 9/2/2014 9:03 PM

A third solution is to weld the girders directly to the can section of the column, which is internally stiffened by rings. Its most severe

disadvantage is the difficulty of inspecting the column interior.

The disadvantage of both direct girder-column joints is that the girder sizing is governed by the very high moments at the column/beam

transition point.

Cast steel nodes forman alternative to the welded designs.

Member selection for portal frame structures with increasing section moduli usually includes:

300 mmwide rolled beam.

400 mmwide rolled beam.

450 mm/460 mmwide rolled beam.

castellated beams fabricated fromrolled beams, giving a height 1,5 times the original beamheight.

built-up girders fabricated fromrolled beamT-sections with a web plate welded-in-between.

plate girder.

The plate girder of course provides the greatest flexibility for design, material selection and procurement, though its cost per tonne is

approximately twice that of a rolled beam.

2.3 Main Structure-Truss Design

Most offshore structures of moderate size have been provided with a truss-type structure. Typically such trusses consist of rolled beams as

chords and tubulars as diagonals.

Truss design requires several choices which affect the structural efficiency and have impact on other disciplines:

number and configuration of braces

falling or rising braces

intermediate load carrying of chords

presence of external moments on joints

braces: tubulars or H-rolled sections

chords: rolled section or plate girders

truss joints: locally reinforced chord or prefabricated node section.

Figure 2 shows different arrangements of braces (basically N or W-type) obtained by variation of the number of nodes. It should be kept in

mind that all diagonals and verticals formobstructions for piping and cable routings of all kinds.

ESDEP LECTURE NOTE [WG15A] http://www.fgg.uni-lj.si/~/pmoze/ESDEP/master/wg15a/l1100.htm

4 of 18 9/2/2014 9:03 PM

For the transverse trusses, transparency is even more important, especially near the well area. The number of members required should

therefore be reduced to a minimum.

Providing a W-truss with light verticals should be evaluated against choosing a heavier chord section.

If a joint, e.g. at the top deck, is subject to severe moments due to lifting, ventstack, or crane pedestal for example, much of the bracing stress

would result fromunintended bending. Generally the deck leg restraint creates a similar problemin the lower deck. An evaluation should

yield a preferred location therefore for the node of the end brace.

The truss deflects under its vertical load which leads to restraint of the chord in the column and to bending of the chord. Both effects can

quite severely effect the efficiency. The chord section should be kept compact therefore and not given too much height.

Tubulars (circular, square or rectangular) or rolled sections can be chosen for the braces.

The choice depends primarily on the loads and the chord width. A chord width of 300mmcan accommodate a 10 in. brace only. Thus a wider

chord flange is preferred.

2.4 Main Structure-Stressed Skin Design

A third major structural option is the stressed skin concept, where full height plate walls take the function of the truss or the frame.

Modules for living quarters are frequently built to this concept. Other types of modules have not been built with stressed skin since the

obstruction they cause during construction is severe.

For smaller stressed skin modules, trapezoid corrugated plate can be used to provide a wall in a frame of square hollow sections.

For bigger modules, flat plate stiffened with through-stiffeners is used for the walls.

The detailed design can only be made with a clear plan for assembling the module which shows the panels that must be prefabricated.

2.5 Non-Load Bearing Walls

Blast or fire walls are provided in offshore platforms. Due to their function full welding to the main structure is often unavoidable, see Figure

3a.

ESDEP LECTURE NOTE [WG15A] http://www.fgg.uni-lj.si/~/pmoze/ESDEP/master/wg15a/l1100.htm

5 of 18 9/2/2014 9:03 PM

Special attention is required concerning:

the capability of the walls to comply with the deformation of the main structure during load-out, sea transport, lifting and in-service.

the strength of welds to the main structure being stronger than the plate to avoid rupture and potential crack initiation of the main

structure.

One solution is to provide a flexible detail, see Figure 3b and 3c, with stiffeners falling short.

2.6 Crane Pedestals

Crane pedestal, are discussed briefly below.

It is structurally economical to put the crane pedestal on top of a main column. For a truss type the main structure will be close to the

platformperiphery so a moderate length of crane boomis sufficient.

For a portal frame type with columns closer to the outer periphery, the pedestal requires a special column in order to avoid using a crane with

large boomlength. Figure 4 depicts such a solution.

ESDEP LECTURE NOTE [WG15A] http://www.fgg.uni-lj.si/~/pmoze/ESDEP/master/wg15a/l1100.htm

6 of 18 9/2/2014 9:03 PM

The functions of the main structure with respect to the crane pedestal are:

to provide torsional support preferable at top deck level

to provide lateral restraint at top deck level

to provide lateral restraint at the lower end of the pedestal

to provide vertical support, preferably at the lower end of the pedestal.

Bending restraint by deck beams and/or main structure girders is not required and should be reduced where possible. Torsion caused by

slewing of the crane should preferably be resisted by the floor plate, the stiffest element.

It has become practice to include the tapered top section of the pedestal in the supply package of the crane. The top section contains the

large flange for the slewing bearing.

Fatigue due to crane operations is a design criterion and requires careful detailing of the pedestal and the adjoining structure.

ESDEP LECTURE NOTE [WG15A] http://www.fgg.uni-lj.si/~/pmoze/ESDEP/master/wg15a/l1100.htm

7 of 18 9/2/2014 9:03 PM

3. ANALYSIS OF DECK STRUCTURES

3.1 Introduction

Although the analysis of deck structures is a standard task, several aspects require special attention:

Plate girder design

Strength of joints

Strength of the floor plate

Lifting points

Modelling of floor plates

Support of modules.

3.2 Plate Girder Design

Design of plate girders requires selection of many dimensional variables and of approaches for assessing load-carrying resistance. Lectures

8.4 deal in more detail with plate girder design.

Web buckling due to bending, normal force and shear restricts the slenderness of the web which is expressed as the height of the web (h)

divided by the web thickness (t).

API-RP2A [2] refers to the AISC manual [3] which gives the figures below for material with yield-stress of 355 MPa:

Allowable bending stress 0,66 Fy 0,60 Fy

Ratio web height h to thickness t 90 138

Ratio flange width b to thickness t 18 27

Instead of the above approach, more recent research, [3] and [6], allows use of the post-buckling strength. The depth/thickness limits given

above do not then apply.

3.3 Strength of Joints

The most important joints in a topside steel structure are:

the ring stiffened joint between rolled beams or plate girders with a circular column.

the non-stiffened joint between rolled beams or plate girders with a circular column.

the tubular brace joint to single web beams.

the non-overlapped tubular joint.

These joints are discussed in Lecture 15A.12.

3.4 Lifting Points

The effect of lifting points on deck design is considerable. For example the local forces that act on the lifting points (Figure 5) have to be

transmitted safely through to the deck structure.

ESDEP LECTURE NOTE [WG15A] http://www.fgg.uni-lj.si/~/pmoze/ESDEP/master/wg15a/l1100.htm

8 of 18 9/2/2014 9:03 PM

There are two types of lifting points, trunnions and padeye, Figure 6.

ESDEP LECTURE NOTE [WG15A] http://www.fgg.uni-lj.si/~/pmoze/ESDEP/master/wg15a/l1100.htm

9 of 18 9/2/2014 9:03 PM

Trunnions, though favourable fromother points of view, see Section 4, can generate considerable offset of the sling force with respect to the

topdeck systempoints. Significant bending is generated which is transferred to the topdeck girders to the extent that they contribute to joint

stiffness. It is most efficient to leave these bending moments in the column, by providing stiff columns.

Padeyes generally provide a good opportunity to minimize or eliminate offset, as far as they can be situated on top of the column. The

requirement of recessed padeyes (recessed padeyes are those which are positioned between the top and bottomflange elevation) or the

presence of other structures on the top deck can lead to very eccentric positioning and resulting heavy moments. For this reason the lifting

concept must be developed in the concept phase of the structural development.

API-RP2A [1] requires larger load factors to be used for members direct-loaded by padeyes or trunnions.

3.5 Modelling of Floor Plates

There are two points of major interest:

representation of the floorplate in the structural model

true elevation

There are several ways to model the plate. The most direct is to choose a computer-programwhich allows selection of plate elements. A

ESDEP LECTURE NOTE [WG15A] http://www.fgg.uni-lj.si/~/pmoze/ESDEP/master/wg15a/l1100.htm

10 of 18 9/2/2014 9:03 PM

second option is to define representative members which model the plate stiffness by diagonals.

The deck plate is often positioned in the model at the elevation of the centre line, i.e. the mid height of the main structure girders, in order to

save nodes in the model. It should however be recognised that this "error" of elevation, amounting to 0,5 - 1m, can affect the results. A

separate evaluation should then be performed on the effect to this deliberate "error" at least at some critical points.

3.6 Support of Modules

Modules and deck structures interact structurally. API-RP2A [1] requires that modules are modelled as elastic structures for the analysis of

the supporting deck. In the 1970's major difficulties arose in the decks for concrete gravity structures, because modules were represented as a

set of loads for the different load cases, acting at the support points, and neglecting structural interaction. The basic phenomenon of this

interaction is that the distribution of the support reactions of the module is quite unequal and varies with the load case. Dimensional control

of the module as well as the support, with corrective measures, further provide control over the module - deck interaction. Some modules,

such as living quarter modules, gas compressor and injection modules, are often placed on anti-vibration pads in order to isolate themfrom

vibrations.

4. CONSTRUCTION

4.1 Introduction

In Lecture 15A.1 the principal aspects of construction of offshore structures and their major equipment was introduced.

For topsides more specific aspects are discussed below.

4.2 Fabrication

4.2.1 Operations

The design should allow efficient prefabrication of major sections. Prefabrication will avoid congestion in one working area and it speeds up

the whole construction process.

Prefabrication and assembly shall properly incorporate the aspects of installation of major and smaller mechanical equipment, as well as

outfitting with piping, electrical and instrument cables and lines. It should be recognized that major mechanical and electrical equipment is

often not available at the start of assembly and must be brought in during fabrication.

4.2.2 Design aspects

Since the overhead space is well covered by extensive piping routes as well as cable trays during construction, "late" structural work should

preferably not be positioned overhead in that underfloor area.

Fabrication of offshore steel structures is principally assembly by welding.

The prefabrication concept and joint detailing should maximize welding productivity with many horizontal welds preferably made using

SMAW technology.

Support to the topside during construction should be well controlled to avoid settlement and to keep within construction tolerances.

Special consideration should be given to the selection of materials suitable for the fabrication. Where thick-walled elements are involved

requiring Post Weld Heat Treatment (PWHT), the design should position such welding and the PWHT in the prefabrication phase.

4.3 Weight Engineering

The topside must be kept under strict weight control, as explained in Lecture 15A.10. To that end the topside is usually weighed prior to load

out. The basic design of a weighing systemusually consists of a set of hydraulic jacks with electrical load cells on top, installed between the

topside and the shop floor. The accuracy of such systems is typically 0,5-1%.

Accuracy is necessary in order to check the actual position of the centre of gravity. Knowledge of the position is vital for the installation.

The systemfor support of the topside should be similar to the anticipated method of load out.

4.4 Load Out

ESDEP LECTURE NOTE [WG15A] http://www.fgg.uni-lj.si/~/pmoze/ESDEP/master/wg15a/l1100.htm

11 of 18 9/2/2014 9:03 PM

4.4.1 Operations

The load out usually combines two operations:

moving the topside fromthe fabrication hall to the nearby quay.

moving the topside fromthe quay onto the barge.

The short journey on land can be complicated when the track is not flat or curves have to be taken.

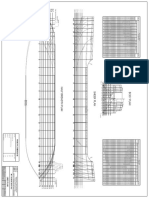

The most preferred option for load out is therefore to use a platformtrailer with individual suspended wheels, see Figure 7 and Slide 1.

Slide 1 : General arrangement of a load out through skidding

The trailer drives fromthe quay over a rocker flap resting on the quay and the barge and then slowly onto the barge. The barge is kept in

right trimby ballast pumping.

ESDEP LECTURE NOTE [WG15A] http://www.fgg.uni-lj.si/~/pmoze/ESDEP/master/wg15a/l1100.htm

12 of 18 9/2/2014 9:03 PM

When it reached the right position, the topside is set down on the beamgrid of the sea fastening.

4.4.2 Design aspects load out

When using platformtrailers the lower deck should be designed to meet three basic load-out requirements:

the bottomflange plates of the transverse beams should all be in one plane.

the distance of transverse beams should not exceed approximately 7 m.

the lower deck should be able to take an upward reaction typically in the range of 50-60 kN/m

2

of ground area.

A uniformdistribution of loads is assumed for platformtrailers. Skid systems which are not provided with a proper load sharing systemwill

lead to a non-uniformload distribution.

Design for load-out requires coordination with sea fastening design.

4.5 Sea Transport and Sea Fastening

4.5.1 Operations

Sea transport is a very critical operation, especially for topsides (see Slide 2).

Slide 2 : Seafastening of 105MN Brent C topside

After completion of the load out and full fastening to the barge, the barge is ballasted to its target draft and cleared for the transport.

The barge is towed by one or two tugs to the offshore location. There the barge is positioned close alongside the crane vessel.

Prior to lifting, the sea fastening is cut free.

Planning the sea transport contains several steps:

identification of critical clearances, e.g. (harbour depth, width of bridges or locks, etc inshore)

barge selection (a.o. stability, dynamic behaviour, location of bulkends).

evaluation of sea route (weather, length of tow).

assessment of barge motions in sea state.

development of a sea fastening concept.

assessment of deck/module integrity.

assessment of barge integrity.

There is also the option with some crane vessels to transport the top side on board. Usually an extra take over is required as the draft of the

crane vessel exceeds the depth at the fabricator's quay. The advantage however is that sea fastening requires less effort. Furthermore, the

offshore operation is simpler and quicker, as the most critical and weather sensitive operation - lift off the barge- is avoided.

4.5.2 Design aspects of sea transport and sea fastening

ESDEP LECTURE NOTE [WG15A] http://www.fgg.uni-lj.si/~/pmoze/ESDEP/master/wg15a/l1100.htm

13 of 18 9/2/2014 9:03 PM

Several elements of the structure are dominated by the load condition during transport, see Lecture 15A.1.

All equipment in or on the topside is also subject to heavy loads, e.g. control panels, generator skids, platformcrane, during transport.

Internal bracing of a topside for transport is not favoured since it creates obstacles and risk of damage or fire to cables, instruments, piping

and equipment during subsequent removal. External bracing is also not without problems. The width of the topside requires an extra wide

barge. It is difficult to find "strong" points on the topside exterior. The basic concept is therefore to fix the topside to the barge by its columns

only.

The designer should be aware that the bending stiffness of the topside often exceeds that of the barge. Considerable "composite" action can

result when the barge deflects in heavy head-on seas.

It is very important for any sea fastening concept to consider aspects of de-seafastening, i.e. cutting free, prior to lift off, and the need to

remain safe in a moderate sea state.

De-seafastening should not require any handling by cranes. Braces cut loose at one end should therefore remain stable and safe while fixed at

one end only.

Design of the sea fastening should not require any welding in the column joint, since the topside would not then be ready for immediate set

down onto the jacket.

When the tow is more than one or two days long, fatigue may have to be considered on critical nodes.

4.6 Installation

4.6.1 Operations

Installation on the substructure can be:

deck mating with a deep submerged floating GBS (Slide 3)

lifting onto an already installed jacket (Slide 4).

Slide 3 : Deckmating of the 500MN Gullfaks-C topside

ESDEP LECTURE NOTE [WG15A] http://www.fgg.uni-lj.si/~/pmoze/ESDEP/master/wg15a/l1100.htm

14 of 18 9/2/2014 9:03 PM

Slide 4 : Installation of 60MN K12-BP topside by floating crane

Deck mating is a floating operation in a sheltered location, e.g. a Norwegian fjord or Scottish loch. Deck mating requires that the deck is

temporarily supported with the final supports free. This requirement creates a very awkward load situation for the deck structure.

Lifting is the usual installation method for jacket-based topsides. During development of a platformconcept, the lift strategy should be

defined as part of the overall construction strategy. The lifting capacity of crane vessels is defined by hook-load and reach.

The required reach is determined mainly by the width of the topside and/or the transport barge.

The major steps are:

review of the weight report.

assessment of "critical" elevations.

assessment of feasible crane vessels.

development of a lift concept.

preliminary sizing of slings, shackles, trunnions, etc.

concept design of guides and bumpers.

analysis of deck or module structure for lift condition.

4.6.2 Design aspects of installation by lifting

The lift concept consists of several elements:

the single or dual crane lift

the sling configuration

choice of topside pick-up points

the necessity (or not) for spreader bars or even spreader frames

the single, double or paired slings

the choice of padeyes, or trunnions.

Crane vessels were listed in Lecture 15A.1. Slings are available up to over 400mmnominal diameter with safe working loads of 20-25 MN.

A basic element in all elevations is the inevitable tolerance in sling length which leads to an unequal distribution of sling forces (typically

25%-75%) in a four sling lift. The unequal sling forces lead to significant stresses in the module (see Figure 8).

ESDEP LECTURE NOTE [WG15A] http://www.fgg.uni-lj.si/~/pmoze/ESDEP/master/wg15a/l1100.htm

15 of 18 9/2/2014 9:03 PM

The use of spreader bars leads to a fully balanced lift without distorting the module. However the spreader bar is quite expensive and usually

leads to a requirement for a higher hook elevation.

The use of a spreader frame should only be considered in exceptional cases and does not prevent module distortion. The padeye/shackle

option is limited by the safe working load (maximum10MN) of the biggest shackle. The trunnion can accommodate higher loads.

4.7 Hook up

Hook up is the completion of all joints and connections after installation.

For economic reasons, the overall construction strategy should keep hook up work to a minimum. Critical hook up work is the work required

immediately to secure the object in order to survive the next storm.

4.8 Commissioning

Commissioning is not relevant to the structural design.

4.9 Inspection Maintenance and Repair (IMR)

These activities are a major source of operational expenditure, OPEX, as introduced in Lecture 15A.1.

Some requirements are:

inspection of the primary structure is a statutory, fully planned activity.

inspection is only possible when proper access to the area or joint is provided.

gaining access is costly and requires space to be left behind equipment.

minimumprovisions, e.g. small clamps under the deck, greatly speeds up scaffolding.

crack growth through fatigue is slow. A crack is usually detectable before one quarter of its life is passed.

dirt accumulation promotes corrosion damage.

ESDEP LECTURE NOTE [WG15A] http://www.fgg.uni-lj.si/~/pmoze/ESDEP/master/wg15a/l1100.htm

16 of 18 9/2/2014 9:03 PM

maximumuse should be made of the results of inspection. Evaluation should lead to modification of the inspection programme where

appropriate.

4.10 Removal

Removal requirements are different fromcountry to country. In some depths of water full removal is required in some countries fromthe

mudline upward. Elsewhere only the structure 75 mor more above the mudline must be removed.

Extensive engineering of removal is required to achieve a safe and effective operation. In the Gulf of Mexico removed structures are dumped

in the formof reefs. It is very difficult and inefficient at present to include conceptual removal engineering in the design phase. When re-use

of the facility is planned, then removal engineering should be developed early in the design.

5. CONCLUDING SUMMARY

Structural systems for each type of topside structure were introduced, i.e. truss, portal, box girder, and stressed skin systems.

In the section on design some topics were addressed in more detail.

In the section on construction the different phases were presented in more detail, i.e.

i. fabrication

ii. weighing

iii. load out

iv. sea transport

v. offshore installation especially deckmating

vi. module installation

vii. hook-up

viii. commissioning

A brief discussion on inspection and repair and on platformremoval concluded the lecture.

6. REFERENCES

[1] API-RP2A: Recommended practice for planning, designing and constructing fixed platforms.

American PetroleumInstitute, 18th ed., 1989.

The structural offshore code, governs the majority of platforms.

[2] AISC: Allowable stress design manual (ASD).

9th ed., American Institute of Steel Construction, 1989.

Widely used structural code for topsides.

[3] API-Bulletin 2V: Bulletin on design of flat plate structures.

American PetroleumInstitute, 1st ed., 1987.

Valuable specialist addendumto API-RP2A.

[4] API-Bulletin 2U: Bulletin on stability design of cylindrical shells.

American PetroleumInstitute, 1st ed., 1987.

Valuable specialist addendumto API-RP2A.

[5] D.v.d. Zee & A.G.J. Berkelder: Placid K12BP biggest Dutch production platform.

IRO Journal, nr. 38, 1987, pp 3-9.

Presents a recent example for a portal framed topside.

[6] R. Narayanan: Plated structures/Stability and Strength.

Applied Science Publishers, London, 1983.

ESDEP LECTURE NOTE [WG15A] http://www.fgg.uni-lj.si/~/pmoze/ESDEP/master/wg15a/l1100.htm

17 of 18 9/2/2014 9:03 PM

Good designers guide to plated structures design.

[7] ANON: Gullfaks C platformdeckmating.

Ocean Industry, April 1989, pp 24.

Good description of the actual mating of deck to GBS.

[8] A.G.J. Berkelder: Seafastening 105 MN Brent C deck.

Bouwen met Staal, nr.24 1979.

Presentation of seafastening design for GBS topside.

Previous | Next | Contents

ESDEP LECTURE NOTE [WG15A] http://www.fgg.uni-lj.si/~/pmoze/ESDEP/master/wg15a/l1100.htm

18 of 18 9/2/2014 9:03 PM

You might also like

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityFrom EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo ratings yet

- Lecture 15A.12-Connections in Offshore Deck StructuresDocument20 pagesLecture 15A.12-Connections in Offshore Deck StructuresLinh Tran100% (1)

- Semi Submersible PlatformsDocument11 pagesSemi Submersible PlatformsIlyaNo ratings yet

- Electromagnetic Well Logging: Models for MWD / LWD Interpretation and Tool DesignFrom EverandElectromagnetic Well Logging: Models for MWD / LWD Interpretation and Tool DesignRating: 5 out of 5 stars5/5 (1)

- Offshore Fixed Platform NotesDocument37 pagesOffshore Fixed Platform NotesAnkushkumar MaliNo ratings yet

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Subsea EngineeringDocument2 pagesSubsea Engineeringgupta_hemanshu1986252100% (1)

- Mechanics of Offshore Pipelines: Volume I: Buckling and CollapseFrom EverandMechanics of Offshore Pipelines: Volume I: Buckling and CollapseNo ratings yet

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyFrom EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyNo ratings yet

- Subsea Umbilical, Riser Flowline Installation: National Unversity of SingaporeDocument39 pagesSubsea Umbilical, Riser Flowline Installation: National Unversity of SingaporeYohanest ChandraNo ratings yet

- Underwater Technology: Offshore PetroleumFrom EverandUnderwater Technology: Offshore PetroleumL. AtteraasNo ratings yet

- QUE$TOR Training Examples - Offshore v2Document19 pagesQUE$TOR Training Examples - Offshore v2UTP PE Jan 17No ratings yet

- Offshore Operation Facilities: Equipment and ProceduresFrom EverandOffshore Operation Facilities: Equipment and ProceduresRating: 3 out of 5 stars3/5 (2)

- Saudi Aramco SR Proj Eng CVDocument2 pagesSaudi Aramco SR Proj Eng CVMoinuddin SahebNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Siri Jack-Up PlatformDocument7 pagesSiri Jack-Up Platformnaren_013No ratings yet

- Deepwater Sedimentary Systems: Science, Discovery, and ApplicationsFrom EverandDeepwater Sedimentary Systems: Science, Discovery, and ApplicationsJon R. RotzienNo ratings yet

- Kuliah 5 - Deck Structure of Offshore PlatformDocument36 pagesKuliah 5 - Deck Structure of Offshore Platformyusuf maulana yasin50% (2)

- Applied Gaseous Fluid Drilling Engineering: Design and Field Case StudiesFrom EverandApplied Gaseous Fluid Drilling Engineering: Design and Field Case StudiesNo ratings yet

- VCB4233 Sep2105 MetoceanDocument7 pagesVCB4233 Sep2105 MetoceanCyrus HongNo ratings yet

- Offshore Engineering - An OverviewDocument39 pagesOffshore Engineering - An Overviewkharade_a100% (1)

- Subsea StructureDocument2 pagesSubsea StructureobumuyaemesiNo ratings yet

- Ageing Offshore Well Structural Integrity Modelling Assessment and RehabilitationDocument16 pagesAgeing Offshore Well Structural Integrity Modelling Assessment and Rehabilitationvictor gerardoNo ratings yet

- Presentation On Offshore Structures and Offshore Engineering DeliverblesDocument26 pagesPresentation On Offshore Structures and Offshore Engineering DeliverblesPartha Sarathi100% (2)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- Modeling The Earth For Oil Exploration: Final Report of the CEC's Geoscience I Program 1990-1993From EverandModeling The Earth For Oil Exploration: Final Report of the CEC's Geoscience I Program 1990-1993No ratings yet

- Structural Design and Analysis of FPSO Topside Module SupportsDocument10 pagesStructural Design and Analysis of FPSO Topside Module SupportsSettuNo ratings yet

- Offshore StructureDocument35 pagesOffshore Structureईन्द्रनील रायNo ratings yet

- TechnicalPaper FloatingoffshoreplatformdesignDocument18 pagesTechnicalPaper FloatingoffshoreplatformdesignAriecandra MahesaNo ratings yet

- Mooring AnalysisDocument17 pagesMooring AnalysisIfediora GodsonNo ratings yet

- Diseño de Soporte Ductil en TunelesDocument7 pagesDiseño de Soporte Ductil en TunelesMario Andres Arias EstrellaNo ratings yet

- 2007 Sevan DrillingDocument54 pages2007 Sevan DrillingAjay V RamadasNo ratings yet

- Offshore Jacket and PilesDocument66 pagesOffshore Jacket and PilesMurad89No ratings yet

- Offshore Structure BasicsDocument3 pagesOffshore Structure Basicsafi1belle100% (1)

- Documents - Pub Case Study Sesamtm For Subsea Prepared by DNV GL Software TypicallyDocument23 pagesDocuments - Pub Case Study Sesamtm For Subsea Prepared by DNV GL Software TypicallyMiguel PereiraNo ratings yet

- Kamalakannan Resume (01!08!2018)Document5 pagesKamalakannan Resume (01!08!2018)Kamalakannan AyyaduraiNo ratings yet

- 01 Overview of Offshore PlatformDocument25 pages01 Overview of Offshore Platformtavis80No ratings yet

- Offshore Well ConstructionDocument34 pagesOffshore Well ConstructionИван Коровин100% (1)

- 20160126Document47 pages20160126SATRIONo ratings yet

- JacketDocument41 pagesJacketGarima Verma100% (2)

- Offshore Platforms Design OverviewDocument12 pagesOffshore Platforms Design OverviewΈνκινουαν Κόγκ ΑδάμουNo ratings yet

- Esdep Offshore Structures General IntroductionDocument187 pagesEsdep Offshore Structures General Introductiondfal13No ratings yet

- Oil Platform TypesDocument2 pagesOil Platform TypesandrejluigiNo ratings yet

- Shell Perdido Article PDFDocument72 pagesShell Perdido Article PDFhailay83100% (1)

- Subsea Engineering Case StudyDocument3 pagesSubsea Engineering Case StudyVenkatamanikandan RajendranNo ratings yet

- Oil and Gas GlossaryDocument8 pagesOil and Gas Glossaryina23ajNo ratings yet

- Introduction To Subsea Production SystemDocument42 pagesIntroduction To Subsea Production Systemmadonnite3781No ratings yet

- Rig Design Project ReportDocument12 pagesRig Design Project ReportEva BatrisyaNo ratings yet

- Well PlanningDocument4 pagesWell PlanningImranKabirNo ratings yet

- Offshore Platform TopsideDocument34 pagesOffshore Platform TopsideBen100% (4)

- Oil and Gas Offshore ProductionDocument9 pagesOil and Gas Offshore ProductionLao ZhuNo ratings yet

- Fixed PlatformsDocument98 pagesFixed Platformsusman nawazNo ratings yet

- Offshore Structures Design Construction and Maintenance - Online Course - 2019Document5 pagesOffshore Structures Design Construction and Maintenance - Online Course - 2019elreedymanNo ratings yet

- Kongsberg Oil and Gas Technology LimitedDocument1 pageKongsberg Oil and Gas Technology LimitedGhoozyNo ratings yet

- Liebherr STS Ship To Shore Container Gantry Cranes Technical Description 12469-0Document4 pagesLiebherr STS Ship To Shore Container Gantry Cranes Technical Description 12469-0sheron100% (2)

- Gantry Cranes Brochure PDFDocument40 pagesGantry Cranes Brochure PDFVince Bagsit PolicarpioNo ratings yet

- Offshore Process TechnologyDocument3 pagesOffshore Process TechnologyGhoozyNo ratings yet

- Liebherr STS Ship To Shore Container Gantry Cranes Technical Description 12469-0Document4 pagesLiebherr STS Ship To Shore Container Gantry Cranes Technical Description 12469-0sheron100% (2)

- Mechanical Completion & ComissioningDocument56 pagesMechanical Completion & ComissioningRustam Riyadi100% (1)

- PQ VendorsDocument0 pagesPQ VendorsGhoozyNo ratings yet

- Miniature Circuit Breaker Sizing - Electrical Engineering CentreDocument9 pagesMiniature Circuit Breaker Sizing - Electrical Engineering CentreGhoozyNo ratings yet

- Engineering Work Flow ChartDocument1 pageEngineering Work Flow ChartSanjib Deka83% (6)

- Project Control For Engineering PDFDocument35 pagesProject Control For Engineering PDFMasbooks100% (1)

- PSPC Ballast Tank IACS Procedural Requirments PDFDocument4 pagesPSPC Ballast Tank IACS Procedural Requirments PDFGhoozyNo ratings yet

- Green ITDocument14 pagesGreen ITGhoozyNo ratings yet

- Griffith Water Reclamation Plant Relocation OptionDocument42 pagesGriffith Water Reclamation Plant Relocation OptionGhoozyNo ratings yet

- Port Visit FinalDocument16 pagesPort Visit FinalSubhasish BhandariNo ratings yet

- K-Sim Engine MAK43C Container Feeder M11 Model DatasheetDocument2 pagesK-Sim Engine MAK43C Container Feeder M11 Model DatasheetStefano De SimoneNo ratings yet

- New Bunker Adjustment Factor (BAF) : Customer AdvisoryDocument4 pagesNew Bunker Adjustment Factor (BAF) : Customer AdvisoryJulius Eric PajarilloNo ratings yet

- Shipping Collusion BusinessDocument28 pagesShipping Collusion BusinessKeti AirportNo ratings yet

- Lines Plan AssignmentDocument1 pageLines Plan Assignmentyosef thio widyawanNo ratings yet

- Engleski IV 2.kolokvij KB (S.C) 2Document14 pagesEngleski IV 2.kolokvij KB (S.C) 2Petar GrginNo ratings yet

- ClassNK - PSC Annual Report (June 2019) PDFDocument57 pagesClassNK - PSC Annual Report (June 2019) PDFVu Tung Linh100% (1)

- Company Profile Bravo7Document14 pagesCompany Profile Bravo7RachmanNo ratings yet

- At The Helm 20Document20 pagesAt The Helm 20mfazioliNo ratings yet

- Daily Report Dry Dock 055705Document9 pagesDaily Report Dry Dock 055705Влад МойсеенкоNo ratings yet

- SAFETY FIRST TEST 180713.pdf-Revised-CalledoDocument5 pagesSAFETY FIRST TEST 180713.pdf-Revised-CalledoRosen Anthony0% (1)

- Shipping IndiaDocument2 pagesShipping IndiaSandipanBiswasNo ratings yet

- Container Losses in Rough Weather: Karan Doshi, Sharad DhavalikarDocument47 pagesContainer Losses in Rough Weather: Karan Doshi, Sharad DhavalikarDilip SarangdharNo ratings yet

- Week 5 International Maritime ConventionsDocument28 pagesWeek 5 International Maritime ConventionsZhean GreenwoodNo ratings yet

- Guidelines For Safe AnchoringDocument7 pagesGuidelines For Safe Anchoringziqiang liNo ratings yet

- Allowable Thickness Diminution For Hull StructuresDocument13 pagesAllowable Thickness Diminution For Hull Structuresjstoute100% (1)

- Three Years CCCCCCCCCCCCCCCCCCCDocument3 pagesThree Years CCCCCCCCCCCCCCCCCCCIvan DominguezNo ratings yet

- Transpo Midterms NotesDocument28 pagesTranspo Midterms NotesAriel Mark PilotinNo ratings yet

- Life Cycle Assessment in The Naval Sector: Between Certification and New MaterialsDocument8 pagesLife Cycle Assessment in The Naval Sector: Between Certification and New MaterialsLudovicoRuggieroNo ratings yet

- 0 POEAContract530690-05182022Document16 pages0 POEAContract530690-05182022jhon markNo ratings yet

- WWII 12th Air Force France ReportDocument219 pagesWWII 12th Air Force France ReportCAP History Library100% (3)

- Admiralty LawDocument576 pagesAdmiralty LawRihardsNo ratings yet

- Lights and Shapes Rule 26 Fishing VesselsDocument3 pagesLights and Shapes Rule 26 Fishing VesselsmarcNo ratings yet

- 0907 - A - Support Thruster 5 Year OverhaulsDocument21 pages0907 - A - Support Thruster 5 Year OverhaulsonlyourzNo ratings yet

- Performance AuditDocument78 pagesPerformance AuditKitsap SunNo ratings yet

- Princess Liner ScenariosDocument5 pagesPrincess Liner ScenariosMark AndersonNo ratings yet

- African Lark TC DESC 060511Document4 pagesAfrican Lark TC DESC 060511Duong TruongNo ratings yet

- Full Thrust Star WarsDocument79 pagesFull Thrust Star WarsHaggard72100% (2)

- Pub. 124 East Coast of South America 10ed 2007Document282 pagesPub. 124 East Coast of South America 10ed 2007joop12No ratings yet

- ONE P2P Schedule VNHPH To USLAX 20230710Document12 pagesONE P2P Schedule VNHPH To USLAX 20230710Amelie DuongNo ratings yet