Professional Documents

Culture Documents

Advanced Groove System: The Strongest and Most Dependable Mechanical Pipe Joining System For 14"-72"/350 - 1800 MM Pipe

Uploaded by

Jason WatersOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Advanced Groove System: The Strongest and Most Dependable Mechanical Pipe Joining System For 14"-72"/350 - 1800 MM Pipe

Uploaded by

Jason WatersCopyright:

Available Formats

The strongest and most dependable mechanical

pipe joining system for 14"- 72"/350 - 1800 mm pipe

TM

Advanced Groove System

VICTAULIC

Advanced Groove System

For demonstration only. Do not attempt.

When Victaulic designed the Advanced Groove System,

our customers set the criteria:

Contractors asked us for ease of installation, reliability and

inspectability, so we developed a new, robust two-piece housing.

Engineers wanted enhanced strength, so we created a revolutionary

wedge-shaped groove thats deeper and wider than that of any other

groove system to provide increased coupling-to-pipe engagement.

To reduce sensitivity to pipe end are, we located the groove further from the pipe end.

The fastest and most reliable

Victaulic joint system for

14"/350 mm to 72"/1800 mm pipe:

As shown in this actual

demonstration, a single

24"/600 mm AGS pipe

joint is strong enough to

support this payloader.

You can be condent that

its strong enough for your

piping applications.

It all adds up to the strongest Victaulic mechanical coupling

assembly system ever in this size range. Our patented

Advanced Groove System (AGS) delivers exceptional results.

AGS-joined pipe handles higher end loads and a higher

pressure rating up to 350 psi/2,410 kPa, depending on pipe

size and schedule, with a nominal three-to-one safety factor.

Chilled Water Systems

Distribution Piping

Industrial Process Piping

District Heating and Cooling

Non-Abrasive Mine Piping

(however external rings for

use with AGS Couplings

are available for Abrasive

Systems)

VICTAULIC

All AGS couplings, whether exible or rigid, have a two-

piece design and are secured with either two or four bolts

depending on joint size. This simplies and speeds assembly.

The housings are easy to position into the grooves. A wider,

wedge-shaped groove facilitates proper coupling positioning

by decreasing initial installation sensitivity. Tightening the

nuts to the proper specication completes the joint.

In addition, the surfaces of the two housings meet

solidly between the head of the bolt and the securing

nut, providing visual conrmation of proper assembly

and joint integrity once the nut is properly torqued.

Fast, simple, dependable assembly.

Visual conrmation of a proper joint

when these faces meet on both sides,

joint integrity is conrmed.

Coupling locks into place into a deeper,

wider groove for all-round rigidity.

Only two housings and two to four

bolts, depending on joint size, provide

360 contact with the groove and make

successful assembly easy.

Urban Outfitters PHILADELPHIA, PENNSYLVANIA

Urban Outfitters corporate headquarters needed an innovative piping

system solution in order to accommodate an accelerated renovation

schedule.

AGS couplings, fittings and valves were utilized on the 14"/350 mm

chilled water lines.

The center piece of the new office building is a glass-enclosed

heating/cooling central plant that occupies the lobby area.

William Osler Hospital BRAMPTON, ONTARIO

The Victaulic AGS system was utilized on heating, chilled and condenser

water piping for distribution and mechanical room systems at the William

Osler Hospital in Brampton, Ontario. Taking advantage of the quick

installation features, the contractor used the complete AGS system of

couplings, fittings, valves and pump accessories to help ensure the

project met both budget and project schedule requirements.

AGS couplings in 26 to 60 inch (660 to

1500 mm) sizes feature a two-piece housing

and four bolts and nuts.

Available as

rigid and flexible,

couplings.

AGS Vic-Flange

adapters are ANSI

CL. 125/150 Flanges.

Rigid couplings for

stainless steel rated to

300 psi/2065 kPa.

Butterfly and Check Valves

are available for a variety

of services. Size may vary.

Contact Victaulic for details.

Strainers and Suction

Diffusers are available

for protecting pumps.

AGS FITTINGS

Pre-grooved fittings include elbows,

tees and reducers. Available in

14-60"/600-1500 mm sizes.

Victaulic now offers flexible AGS couplings up to 72 inches (1800 mm) in size

making AGS an ideal solution for HVAC, district heating and cooling and indus-

trial process piping. Additionally, for abrasive services such as slurries and tail-

ings where full pipe wall thickness must be maintained on lined piping systems,

Victaulic offers external rings for use with AGS couplings.

Because the AGS coupling system provides great strength and dependability in

addition to speed, its an excellent choice over welding. Other advantages AGS

joints provide over welded joints include no flame, superior seismic-shock resis-

tance and a union at every joint for easy adjustment, system maintenance or sys-

tem expansion.

AGS couplings in 62 and 72 inch (1550 and

1800 mm) sizes feature a four-piece housing

and eight bolts and nuts.

Strength

TM

OGS Coupling

Coupling

Housing

Groove

Gasket

The FlushSeal gasket

delivers more contact

area for superior sealing.

Wider housing profile for greater end load capability

2-piece design

for faster installation

First flat-pad rigid coupling

design that installs

metal-to-metal for

visual inspection.

Patented coupling locks into

a deeper, wider, wedge-shaped

groove for extremely strong,

dependable joints.

Victaulic has developed a new, robust housing prole that increases the

distance from the groove to the end of the pipe to enhance strength.

AGS coupling housings make complete 360 contact with the groove.

The FlushSeal

gasket for AGS products, provides superior sealing.

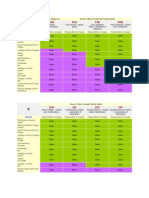

Actual Size Comparison

ORIGINAL GROOVE SYSTEM (OGS) COUPLING 24"/600 mm VS. AGS COUPLING 24"/600 mm

The above graphics are for illustration purposes only.

PB-285 3894 REV F UPDATED 05/2014

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

To learn more about the Victaulic Advanced Groove System,

visit www.victaulic.com/ags.

Designed to groove the Victaulic AGS groove prole.

VE872 VE414MC VE460 VE450FSD

VICTAULIC GLOBAL CONTACT INFORMATION

US & WORLD HEADQUARTERS

P.O. Box 31

Easton, PA 18044-0031 USA

4901 Kesslersville Road

Easton, PA 18040 USA

1 800 PICK VIC

1 800 742 5842

(within North America)

1 610 559 3300

1 610 250 8817 (fax)

pickvic@victaulic.com

CANADA

123 Newkirk Road

Richmond Hill, ON L4C 3G5

905 884 7444

905 884 9774 (fax)

viccanada@victaulic.com

EUROPE

Prijkelstraat 36

9810 Nazareth, Belgium

32 9 381 15 00

32 9 380 44 38 (fax)

viceuro@victaulic.be

MIDDLE EAST

P.O. Box 17683

Unit XB 8

Jebel Ali Free Zone

Dubai

United Arab Emirates

971 4 883 88 70

971 4 883 88 60 (fax)

INDIA

Victaulic Piping Products

India Priv. Ltd.

Indialand Global Industrial Park

Plot 4, Hinjewadi, Phase I,

Mulshi

Pune 411057 (India)

91 20 67 919 300

91 20 67 919 361 (fax)

ASIA

Unit 808, Building B,

Hongwell Plaza,

No.1602 West Zhongshan Road,

Shanghai, China 200235

86 21 6021 9400

86 21 6021 9500 (fax)

vicap@victaulic.com

AUSTRALIA AND NEW ZEALAND

7 Chambers Road

Unit 1

Altona North, Victoria

Australia 3025

1 300 PIC VIC

1 300 742 842

(within Australia)

61 3 9392 4000

61 3 9392 4096 (fax)

vicaust@victaulic.com

www.victaulic.com

CENTRAL AND

SOUTH AMERICA

P.O. Box 31

Easton, PA 18044-0031 USA

4901 Kesslersville Road

Easton, PA 18040 USA

610 559 3300

610 559 3608 (fax)

vical@victaulic.com

UNITED KINGDOM

Units B1 & B2, SG1 Industrial Park

Cockerell Close

Gunnels Wood Road

Stevenage

Hertfordshire, SG1 2NB (UK)

44 0 1438 310 690

44 0 1438 310 699 (fax)

viceuro@victaulic.be

Grooving Tools

VICTAULIC

You might also like

- D&D 3.5 Edition - Fiendish Codex I - Hordes of The Abyss PDFDocument191 pagesD&D 3.5 Edition - Fiendish Codex I - Hordes of The Abyss PDFIgnacio Peralta93% (15)

- Awo, Part I by Awo Fa'lokun FatunmbiDocument7 pagesAwo, Part I by Awo Fa'lokun FatunmbiodeNo ratings yet

- Mechatest SWAS SystemsDocument2 pagesMechatest SWAS SystemsKhan Ahmed MuradNo ratings yet

- Arabian Fal Holding: TUR DepartmentDocument34 pagesArabian Fal Holding: TUR DepartmentShams TabrezNo ratings yet

- Orlaco CatalogueDocument10 pagesOrlaco CataloguencthanhckNo ratings yet

- DS0411130 Set Monitor 12in RLED Serial R6 en R1-0Document2 pagesDS0411130 Set Monitor 12in RLED Serial R6 en R1-0cenicercNo ratings yet

- CVS Series 50 Chemical Injection Pump ManualDocument12 pagesCVS Series 50 Chemical Injection Pump Manualiqmpslab0% (1)

- Saudi Cement Sector - February 2023 - Riyadh CapitalDocument4 pagesSaudi Cement Sector - February 2023 - Riyadh Capitalikhan809No ratings yet

- SWCC PDFDocument43 pagesSWCC PDFSturovo TurboNo ratings yet

- Font Powerpoint DepDocument20 pagesFont Powerpoint DepThangqnNo ratings yet

- RTCC 1580 Sa MX 05458Document15 pagesRTCC 1580 Sa MX 05458Mohamed HaleemNo ratings yet

- IMRCE 4 Sponsorship and Exhibition Brochure 2023 (1) - CompressedDocument16 pagesIMRCE 4 Sponsorship and Exhibition Brochure 2023 (1) - CompressedHesham MahdyNo ratings yet

- HTPI Program AgendaDocument13 pagesHTPI Program AgendaOwais Manzoor MalikNo ratings yet

- Ebaa 1100Document6 pagesEbaa 1100sureshmaya88No ratings yet

- 2.2 - Pamphlet 6 Chlorine InstituteDocument16 pages2.2 - Pamphlet 6 Chlorine InstituteAdemilson Junior100% (1)

- Business PlanDocument17 pagesBusiness Plans kNo ratings yet

- Sales Pipeline Funnel Chart 1Document7 pagesSales Pipeline Funnel Chart 1Deden Andri Maulana SyamsudinNo ratings yet

- Brochure CMRPDocument2 pagesBrochure CMRPAwais KhanNo ratings yet

- 34 Moving Moulds PDFDocument68 pages34 Moving Moulds PDFAlexNo ratings yet

- Manual Derrick CCTV System - 0991560 PDFDocument4 pagesManual Derrick CCTV System - 0991560 PDFseanll2563No ratings yet

- Acid Pump Motor-Driven Diaphragm Dosing Pump ManualDocument80 pagesAcid Pump Motor-Driven Diaphragm Dosing Pump Manualatiq124No ratings yet

- GE in Saudi Arabia, Manufacturing Technology CenterDocument11 pagesGE in Saudi Arabia, Manufacturing Technology CenterAsif SajwaniNo ratings yet

- Incoterms 2012Document6 pagesIncoterms 2012Kevin Otieno0% (1)

- Quickcoup US Catalogue 2011 PDFDocument36 pagesQuickcoup US Catalogue 2011 PDFMihai NicoaraNo ratings yet

- ACROGEARS Portable Valve Actuators PETROL RED POWER LINE 1Document5 pagesACROGEARS Portable Valve Actuators PETROL RED POWER LINE 1JonesNo ratings yet

- Moody DiagramDocument4 pagesMoody DiagramRosy Vargas CaroNo ratings yet

- Oil Separator DimensionDocument2 pagesOil Separator DimensionislamakthamNo ratings yet

- Draft - JOB EX Presentation - HOP PH2 - Villa Construction PMC - Aug 2023Document28 pagesDraft - JOB EX Presentation - HOP PH2 - Villa Construction PMC - Aug 2023mekhtarNo ratings yet

- Stotme 2Document14 pagesStotme 2NadeemNo ratings yet

- SWOT PresentationDocument37 pagesSWOT PresentationmkpqNo ratings yet

- Ksa Cement Monthly Review - May 2013Document14 pagesKsa Cement Monthly Review - May 2013Olena Stanislavovna100% (1)

- Syspex-Catalogue 2020 PDFDocument82 pagesSyspex-Catalogue 2020 PDFWiki SetianaNo ratings yet

- HVAC Grooved Piping Systems 10-12Document6 pagesHVAC Grooved Piping Systems 10-12Mohammed ToemaNo ratings yet

- ONH AnalyzerDocument16 pagesONH AnalyzereddyewNo ratings yet

- AIMS-2024 BrochureDocument7 pagesAIMS-2024 BrochureTrajko GjorgjievskiNo ratings yet

- Pipeline Capacity IncreaseDocument8 pagesPipeline Capacity IncreaseElendu Emmanuel ChigozieNo ratings yet

- Equipments Catalog List VTD Gui Mr. DuyDocument3 pagesEquipments Catalog List VTD Gui Mr. DuyVu Van DaoNo ratings yet

- Gastech 2014 ProgrammeDocument23 pagesGastech 2014 Programmecristi_molinsNo ratings yet

- Multi Phase Flow Measurement: by S.ManickarajanDocument40 pagesMulti Phase Flow Measurement: by S.ManickarajanAli NasseriNo ratings yet

- Drag Reduction by Polymer AdditivesDocument55 pagesDrag Reduction by Polymer AdditivesMichael MedinaNo ratings yet

- 8b. EIS Attachment Well Drilling CostsDocument21 pages8b. EIS Attachment Well Drilling CostsDere HanNo ratings yet

- Lucky Cement Supply ChainDocument40 pagesLucky Cement Supply ChainMohammed UbaidNo ratings yet

- 3rd Asset Integrity O&G - May10 2023 - RemovedDocument18 pages3rd Asset Integrity O&G - May10 2023 - RemovedRahulNo ratings yet

- DLPS ProfileDocument39 pagesDLPS ProfileHarish Khatri100% (1)

- SchedulingDocument47 pagesSchedulingKonark PatelNo ratings yet

- Catalogo Basico (OTECO)Document8 pagesCatalogo Basico (OTECO)Ronal Borrero100% (1)

- Millennium Development GoalsDocument6 pagesMillennium Development GoalsSasha Perera100% (2)

- A Wicked Game by Kate BatemanDocument239 pagesA Wicked Game by Kate BatemanNevena Nikolic100% (1)

- Power Plant Simulator For OperatorsDocument2 pagesPower Plant Simulator For Operatorsalbert100% (1)

- Mech Cat PDFDocument169 pagesMech Cat PDFardi_a0uNo ratings yet

- Daily Progress Report-Kenz Co.30001592Document1 pageDaily Progress Report-Kenz Co.30001592daranivelNo ratings yet

- Walworth Corporate Profile 2011-2Document28 pagesWalworth Corporate Profile 2011-2eternalkhutNo ratings yet

- Odor ControlDocument1 pageOdor ControlDerek ColandunoNo ratings yet

- Job Safety Analysis - RIG DOWN OF GDS, CASCADE & SAFETY EQUIPMENTDocument3 pagesJob Safety Analysis - RIG DOWN OF GDS, CASCADE & SAFETY EQUIPMENTJun DandoNo ratings yet

- Project Summary - Final PresentationDocument28 pagesProject Summary - Final PresentationHesham AbbasNo ratings yet

- Shield Pipes Fittings PDFDocument36 pagesShield Pipes Fittings PDFilieoniciuc50% (2)

- Feniex Product Catalog 2013-2014Document56 pagesFeniex Product Catalog 2013-2014donald_wilson4741No ratings yet

- Project Execution Plan (GT GTD Oil Flushing)Document77 pagesProject Execution Plan (GT GTD Oil Flushing)Tao QuNo ratings yet

- Piping Hanger Presentation1Document85 pagesPiping Hanger Presentation1Parveen Nakwal100% (1)

- Dura Final CatalogueDocument20 pagesDura Final CataloguerudrabirNo ratings yet

- Yanbu: Export Refinery ProjectDocument6 pagesYanbu: Export Refinery ProjectJanakiraman MalligaNo ratings yet

- Grooved Piping System: Product DescriptionDocument4 pagesGrooved Piping System: Product DescriptionDGWNo ratings yet

- Victaulic W07 Rigid Cplg.20.02Document4 pagesVictaulic W07 Rigid Cplg.20.02dan_capitanNo ratings yet

- Style 22 Vic-Ring Coupling: Product DescriptionDocument2 pagesStyle 22 Vic-Ring Coupling: Product DescriptionDante2500No ratings yet

- Brochure 1100 PDFDocument6 pagesBrochure 1100 PDFDavid CarvalhoNo ratings yet

- How To Build Yam Chips Production PlantDocument11 pagesHow To Build Yam Chips Production PlantVu Thieu TuanNo ratings yet

- Theory of Construction of The Giza Plateau Pyramids (Original Title Hypothesis of Construction of The Pyramids of The Valley of Gizeh (Giza)Document15 pagesTheory of Construction of The Giza Plateau Pyramids (Original Title Hypothesis of Construction of The Pyramids of The Valley of Gizeh (Giza)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Unit 7 - Evolution and Classification: Regents BiologyDocument24 pagesUnit 7 - Evolution and Classification: Regents BiologyTalijah JamesNo ratings yet

- F. Moyra Allen: A Life in Nursing, 1921-1996: Meryn Stuart, R.N., PH.DDocument9 pagesF. Moyra Allen: A Life in Nursing, 1921-1996: Meryn Stuart, R.N., PH.DRose Nirwana HandayaniNo ratings yet

- The Evolution of Knowledge Management Systems Needs To Be ManagedDocument14 pagesThe Evolution of Knowledge Management Systems Needs To Be ManagedhenaediNo ratings yet

- Service Manual: NISSAN Automobile Genuine AM/FM Radio 6-Disc CD Changer/ Cassette DeckDocument26 pagesService Manual: NISSAN Automobile Genuine AM/FM Radio 6-Disc CD Changer/ Cassette DeckEduardo Reis100% (1)

- Northern Lights - 7 Best Places To See The Aurora Borealis in 2022Document15 pagesNorthern Lights - 7 Best Places To See The Aurora Borealis in 2022labendetNo ratings yet

- Security Policy 6 E CommerceDocument6 pagesSecurity Policy 6 E CommerceShikha MehtaNo ratings yet

- Quadratic SDocument20 pagesQuadratic SAnubastNo ratings yet

- Cultural AnthropologyDocument12 pagesCultural AnthropologyTRISH BOCANo ratings yet

- Dr. Babasaheb Ambedkar Technological UniversityDocument3 pagesDr. Babasaheb Ambedkar Technological UniversityalfajNo ratings yet

- Narrative FixDocument6 pagesNarrative Fixfitry100% (1)

- Design and Analysis of DC-DC Boost Converter: September 2016Document5 pagesDesign and Analysis of DC-DC Boost Converter: September 2016Anonymous Vfp0ztNo ratings yet

- Invenio Flyer enDocument2 pagesInvenio Flyer enErcx Hijo de AlgoNo ratings yet

- PUBLIC - Axie Origins Changelogs - Season 4Document2 pagesPUBLIC - Axie Origins Changelogs - Season 4Alef CarlosNo ratings yet

- A List of 142 Adjectives To Learn For Success in The TOEFLDocument4 pagesA List of 142 Adjectives To Learn For Success in The TOEFLchintyaNo ratings yet

- Deictics and Stylistic Function in J.P. Clark-Bekederemo's PoetryDocument11 pagesDeictics and Stylistic Function in J.P. Clark-Bekederemo's Poetryym_hNo ratings yet

- Language EducationDocument33 pagesLanguage EducationLaarni Airalyn CabreraNo ratings yet

- Evaluating Websites A Checklist - JOHN CARLO G. GAERLANDocument3 pagesEvaluating Websites A Checklist - JOHN CARLO G. GAERLANMarvin CincoNo ratings yet

- CBSE Class 12 Informatics Practices Marking Scheme Term 2 For 2021 22Document6 pagesCBSE Class 12 Informatics Practices Marking Scheme Term 2 For 2021 22Aryan BhardwajNo ratings yet

- Standalone Financial Results, Limited Review Report For December 31, 2016 (Result)Document4 pagesStandalone Financial Results, Limited Review Report For December 31, 2016 (Result)Shyam SunderNo ratings yet

- Higher Vapor Pressure Lower Vapor PressureDocument10 pagesHigher Vapor Pressure Lower Vapor PressureCatalina PerryNo ratings yet

- Actara (5 24 01) PDFDocument12 pagesActara (5 24 01) PDFBand Dvesto Plus CrepajaNo ratings yet

- Promoting Services and Educating CustomersDocument28 pagesPromoting Services and Educating Customershassan mehmoodNo ratings yet

- Agile in ISO 9001 - How To Integrate Agile Processes Into Your Quality Management System-Springer (2023)Document67 pagesAgile in ISO 9001 - How To Integrate Agile Processes Into Your Quality Management System-Springer (2023)j.paulo.mcNo ratings yet