Professional Documents

Culture Documents

347

Uploaded by

adammzjinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

347

Uploaded by

adammzjinCopyright:

Available Formats

A

A

luminum, used for

major aboveground-

storage tank (AST)

components, has advantages

and disadvantages when

compared to the conventional

steel materials of construc-

tion.

For fixed-roof tanks, refin-

ers can save money and gain

improved quality if they con-

sider the advantages of alu-

minum over steel.

This article is the first of a

two-part series that discusses

the use of aluminum structur-

al components for ASTs. The

first article presents a compar-

ison of covered tanks vs. un-

covered tanks (tanks with a

floating roof but no fixed-

roof) as well as a comparison

of aluminum-dome roofs

(ADRs) vs. steel-cone roofs

(SCRs). The second article

compares various types of

aluminum and steel internal-

floating roofs.

For large ASTs, fixed roofs

should be aluminum because

the roof-support columns can

be eliminated when using alu-

minum domes (Fig. 1). Large

SCRs require columns. Alu-

minum domes maximize tank

capacity, reduce coating costs,

and have fire-safety advan-

tages.

For internal-floating roofs,

aluminum and steel each has

its own merits. Instead of just

bid prices, tank managers and

operators should consider the

long-term operational, safety,

environmental, and economic

issues of aluminum and steel

components in ASTs.

Although API 650 defines

a minimum standard of qual-

ity, in some cases, when safe-

ty and total cost of ownership

are considered, the standard

may not be adequate for de-

sired long-term performance.

Covered vs. uncovered

tanks

An AST that includes a

floating roof and is covered

by a fixed roof is considered

an internal-floating roof tank

(IFRT). An existing external-

floating roof tank (EFRT) can

be converted to a covered

IFRT by retrofitting it with a

fixed roof or cover.

Although the EFRT may

have a lower initial cost than

the IFRT, it may not have the

lowest total ownership cost

when long-term operating

costs, maintenance costs, and

potential risks are considered.

The factors which favor build-

ing or retrofitting EFRTs with

fixed roofs are incident pre-

vention, environmental pro-

tection, safety, and reduced

long-term maintenance and

operating costs.

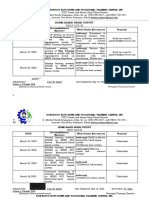

Table 1 summarizes the

considerations for the use of

covered tanks (IFRTs) vs. un-

covered tanks (EFRTs).

Overloading external-

floating roofs

External-floating roofs are

vulnerable to overloading.

The fixed roof eliminates the

intrusion of rainwater, snow,

ice, and dirt into the tank.

In EFRTs, precipitation can

sink the floating roofs during

heavy rainfalls or prolonged

winter storms. Historically,

several external-floating roofs

sink each year in the U.S. dur-

ing the winter or as a result of

extreme rainfall events. This

number may be underesti-

mated because these incidents

are not required to be report-

ed through any public chan-

nels.

Snow, ice, dirt, and debris

accumulation can render the

drains inoperable, resulting in

overloading. Overloading can

result when drain systems

freeze close or when drain ca-

pacities are inadequate.

In addition, heavy snow-

fall can result in an unbal-

anced load condition if the

snow collects on the wind-

ward and shaded surfaces. In

the Middle East, where rain-

water, snow, and ice are not a

concern, some users require

IFRTs to avoid accumulations

of windblown sand.

External-floating roofs are

especially vulnerable to over-

loading when the product

level is low or while the float-

ing roof is landed on its sup-

ports. There are several rea-

sons for this:

Per API 650-Appendix

C.3.4, the design buoyancy is

based on supporting 10 in. of

rainwater (or 52 psf); howev-

er, the supports are only de-

signed to support 25 psf, per

API 650-Appendix C.3.10.2.

When the roof is float-

ing at a low elevation, the

head pressure forcing rainwa-

ter through the drains is re-

duced. This head reduction

increases the amount and

weight of water on the deck

during rainfall.

In an annular-pontoon

floating roof (flat-center

deck), the center deck is high-

ly flexible and will rise when

vapors evaporate as the deck

is heated by solar energy. The

deck also deflects downward

at the center as it is loaded

with water. When the roof is

floating near the bottom,

loaded with water and sag-

ging at the center, the center

deck supports can contact the

bottom and fail as a result of

being overloaded. The float-

ing roof supports have also

been known to puncture the

FOCUS: REFINING

ALUMINUM TANK COMPONENTS1

Aluminuma good alternative

to steel for fixed-roof tanks

Philip E. Myers Chevron Products Co. San Ramon, Calif.

George L. Morovich Tank & Environmental Technologies Inc. The Woodlands, Tex.

Earl J. Crochet Plantation Pipe Line Co. Atlanta

Aluminum domes maximize usable tank capacity, avoid

coating costs, and avoid column problems. Photo courtesy

of Temcor (Fig. 1).

Reprinted with revisions to format, from the May 18, 1998 edition of OIL & GAS JOURNAL

Copyright 1998 by PennWell Corporation

bottom, resulting in serious

leaks.

The drain sizes of the ex-

ternal-floating roofs identified

in API 650-Appendix C3.8,

are minimal. The purchaser

should understand and iden-

tify the drain requirements for

each location, based on antici-

pated rainfall.

Water intrusion

The covered tank mini-

mizes rainwater entry into the

tank.

Rainwater can intrude into

the tank stock by seeping past

the seals. Water will mix with

or leach out certain additives

or components, which may

compromise product quality.

In addition, contaminated

water bottoms require the

long-term cost of collection

and disposal as a hazardous

waste.

Another problem associat-

ed with water entry into the

tank has to do with methyl

tertiary butyl ether (MTBE)

and other ether or alcohol-

based additives, which are

commonly used as a gasoline

additive to meet requirements

of the Clean Air Act.

Because MTBE and alcohol

are preferentially soluble in

water, remediation is more

complex for them than for hy-

drocarbons; therefore, it is im-

portant to minimize any in-

troduction of water into a

tank storing oxygenated gaso-

line.

Elimination

of EFRT drains

By covering a tank, the

need for an EFRT-rainwater

drain is eliminated. The re-

moval of the drain avoids the

risk of drain-line failure, re-

duces the initial tank equip-

ment cost, and results in sig-

nificant long-term operational

and maintenance savings. Fig.

2 shows how the drain is at-

tached to the EFRT.

The drain removal is envi-

ronmentally desirable be-

cause the potential for a major

spill or release as a result of a

roof-drain failure is eliminat-

ed. A substantial spill may

occur if the roof drain rup-

tures and the valve on the

roof drain has been left open.

Many companies require

EFRT-drain valves to be kept

closed. This policy, however,

increases the risk of overload-

ing the floating roof because it

requires manual intervention

to drain the floating roof dur-

ing rainfall. Some companies

have installed hydrocarbon-

sensing valves and other de-

tection devices on the roof-

drain outlets; however, these

devices have not proven effec-

tive to prevent the release of

hydrocarbons through a dam-

aged roof drain line under all

conditions.

In the long-term, avoid-

ance of maintenance costs

stems from eliminating the

manual-drain operation.

Maintenance can be annual

cold-climate protection or

eventual drain-line replace-

ment. To prevent drain-sys-

tem damage during pro-

longed winter conditions, ex-

ternal-floating roof drains are

often filled with antifreeze,

which introduces an addition-

al hazardous waste handling

and treatment cost.

Increased usable

tank capacity

For covered-floating roof

tanks (converted from an

EFRT) and for IFRTs, federal

regulations do not require a

secondary seal. The elimina-

tion of the secondary seal re-

duces the initial tank equip-

ment cost and associated

long-term maintenance and

inspection costs. Perhaps

most important, it increases

the usable capacity (or work-

ing volume) of the tank.

Because only a single liq-

uid-mounted primary seal is

required for an IFRT, floating

roofs can be operated at a

higher level, closer to the

fixed roof without interfer-

ence from the secondary seal.

The capacity savings from

eliminating the EFRT weath-

ershield-type secondary seal

can be in the range of 24-36

in.; however, eliminating a

secondary seal from an inter-

nal-floating roof will save

only 8-12 in. For new con-

struction, the lower design

loading of API 650-Appendix

H (Internal Floating Roof),

will further reduce outer rim-

profile clearance require-

ments by an additional 10-24

in. depending on the type of

internal-floating roof.

Corrosion

External-floating roofs cor-

rode and must be maintained

by initial and periodic recoat-

ing. Costs for recoating old

tanks with lead-based paints

can be significant. By covering

the tank, the need to coat the

floating roof is eliminated.

Even if the external-floating

roof is due for a coating re-

moval and paint job, it is not

necessary if the tank is cov-

ered.

The severity of internal-

FOCUS: REFINING

Covered tanks Uncovered tanks

Eliminates rainwater entry

(Environmental loading) Rainwater can:

Sink floating roofs if roofs are not drained or if drain

plugs

Add to water bottoms which may increase

disposal/treatment costs or cause product contamination

Accelerate bottom corrosion

Snow and freezing can cause floating-roof mechanical

failures or sinking

Eliminates roof drain Requires roof drain which:

Uses more vertical space to allow sufficient hydraulic

head

Is a potential for serious external spills if the drain is

not properly operated

Increases the potential for liquid on roof if roof drain is

damaged

Requires only a primary seal* Requires primary plus secondary seal which:

Requires secondary seal inspection and maintenance

Requires more vertical spacing to accommodate sec-

ondary seal

Seal fires rare Seal fires relatively common

* Although EPA 40 CFR 60 - U.S. EPA New Source Performance Standards does not require a secondary seal

for IFRTs, local air quality management districts (such as the Baaqmd in California) have stricter requirements In-

cidents of internal floating roof fires are far more rare than external floating roof fires; however, IFRT fires have

been extremely serious.

COVERED VS. UNCOVERED TANKS

Table 1

OGJ

Fig. 2

EFRT DRAIN

Drain hose

Rainwater

Plugging

Valve must be open

to drain rainwater

Secondary

seal

Water layer

shell corrosion is normally re-

duced by covering the tank.

For tanks which are fully coat-

ed on the internal shell, the

life of the coating will be in-

creased as a result of the re-

duced weather effects.

Safety and security

Fixed-aluminum dome

and steel roofs are less likely

than EFRTs to cause fire and

access problems.

Because an internal-float-

ing roof is within a closed

conductive structure, the

Faraday Cage Effect, which

isolates the interior from the

effects of external electrical

events such as lightning

strikes or static charges, re-

duces the risk of fire. Even di-

rect lightning strikes will not

cause sparks to discharge

from the floating roof to the

tank shell.

Fires or explosions involv-

ing internal-floating roof fires

are hundreds of times less

likely than those involving

uncovered EFRTs. Existing

EFRTs have also been covered

simply as a result of their

proximity to an ignition

source (such as a flare stack).

Despite increased potential,

rim fires on EFRTs are usually

quickly extinguished.

A fixed roof controls ac-

cess to the hazardous or con-

fined space environment in

the tank. The U.S. Occupa-

tional Safety and Health Ad-

ministration (OSHA) requires

that each facility designate

those areas that are confined

spaces, and entry must meet

all requirements under OSHA

29 CFR 1910.146. Typically,

for petroleum-storage tanks,

the space within the shell of

an EFRT is considered a con-

fined space if the roof is below

5 ft of the rim. For an IFRT,

however, any space within

the shell or under the fixed

roof is always considered a

confined space.

Many EFRTs in remote

areas have been covered due

to concerns of unauthorized

access. In one case, children

were found riding their bicy-

cles on the deck of a 200-ft di-

ameter EFRT slated for gaso-

line additive (MTBE) service;

spent bottle rockets were also

found on that same deck.

In the 1980s, the U.S. Air

Force Strategic Air Command

began a program to cover ex-

isting EFRTs, primarily to

eliminate water problems

with jet fuel and antifreeze

additives. A side benefit of

covers was to conceal base-

fuel inventory levels from aer-

ial surveillance.

Steel-cone roofs vs.

aluminum-dome roofs

Clear-span ADR tanks

have more advantages than

do column-supported SCR

tanks. Table 2 compares

ADRs and SCRs.

The ADR is usually the

FOCUS: REFINING

Steel cone Aluminum dome Additional comments

Corrosion Columns increase corrosion under No columns Corrosion will be more severe if a water-bottoms layer is

column bases. Poor coatings preparation present under the column bases. This is common for fin-

and application can aggravate corrosion. ished-fuel tanks.

Inspection Columns make inspection under No columns Inspection under column bases is typically not done due to

column bases difficult and often the difficulty of lifting the column and roof to visually inspect

overlooked. under the column bases.

Linings and coatings Columns tend to cause lining No columns Column bases rest flat on the tank bottom and are not

erosion and poor lining application at attached.Because of settlement, thermal expansion, and

column bases due to movement and small movements, the column base wears any coating on

sharp edges. the bottom. It is also very difficult to properly apply coatings

in areas such as around column bases.

Fire hazards Columns trap hydrocarbons which are No columns There have been many cases of injuries and fires

hazards when hotwork occurs during associated with liquid hydrocarbons trapped in roof

maintenance. columns. The problem is more serious with pipe columns

than built-up members. API 2015 has a complete discus-

sion of this topic.

Maintenance hazard Columns often have to be jacked up No columns The jacking process is a dangerous operation in which

to install double bottoms or to do improper procedures cause roof collapse as well as

other work. injuries.

Emissions Columns represent points of emissions. No columns The EPA program, Tanks 3.1, can be used to determine

the effect of emissions from fixed-steel roof tanks vs.

aluminum-dome roofs. This program is available to the

public on the internet.

Floating-roof binding Columns can bind on the floating roof No columns.

causing liquid to enter the roof or, in the

worst case, to sink it.

Frangible roof Frangible roof is possible. This is a Frangible roof not Although the frangible roof specified by API 650 is a

clear advantage. possible. valuable explosion and overpressure protection, it is not

known how the aluminum dome will perform under similar

overpressure situations.

Cost Typically, steel cone roofs have a Typically, aluminum- Proper cost analyses by competent personnel are required

lower initial cost. dome roofs have a to examine the true and total costs of ownership.

higher initial cost. If

coating costs are

included or if life span

is considered then

aluminum often gives

a better total cost of

ownership.

*Comparison does not apply to self-supported steel-roof tanks (usually 20 ft in diameter or smaller). Larger tanks have more columns.

STEEL CONE VS. ALUMINUM DOME CHARACTERISTICS*

Table 2

most favorable option for the

retrofit of an existing EFRT

with a new fixed roof. For

new tank construction, or re-

placement of an existing cone

roof, an evaluation should

consider the initial bid price

as well as other fundamental

variables:

Operating capacity sav-

ings

Initial coating cost and

long term maintenance

The elimination of

columns and their related

problems: emissions, penetra-

tion seal, bottom corrosion,

maintenance obstruction, set-

tlement, and incident risk

costs.

St eel , sel f - support ed

dome-roof tanks and small-

diameter tanks with self-sup-

ported fixed roofs are exclud-

ed from this evaluation; they

share, however, many of the

benefits of ADR tanks.

Similarities

Functionally, the roles of

the ADRs and the SCRs are

similar:

Both types protect the

floating roof from environ-

mental loading.

Both types minimize

dirt and water entry into the

tank.

Both types eliminate the

intrusion of rainwater into the

tank; however, the quality of

the aluminum-dome weather-

tight design will vary by man-

ufacturer. It is critical to spec-

ify a proven-ADR design

which is leaktight.

Both types reduce

weather-related corrosion on

the internal-shell surfaces.

Both types eliminate the

wind-related component of

tank emissions.

Both types improve fire

prevention, improve safety,

and enhance security.

Cost effectiveness

Technically, the ADRs and

SCRs have different require-

ments. When retrofitting an

existing EFRT with a new

fixed roof, the conversion to

an ADR tank is usually the

most cost effective, regardless

of tank size. This conversion

does not require removal

from service, tank cleaning, or

extensive downtime for hot-

work.

The aluminum dome is a

bolted structure that can be

assembled on the tank with

no hotwork. Steel roofs re-

quire hotwork because they

are field welded; therefore,

the hazards increase for steel

construction.

Today, new SCR construc-

tion should minimize the

number of SCR-support

columns to avoid penetra-

tions of the internal floating

roof and their related initial

costs, increased emissions,

and column-seal replacement

costs.

Without considering other

initial and long-term cost fac-

tors (listed below), the alu-

minum dome usually be-

comes cost effective for tank

diameters of 40 m or more,

the diameter for which multi-

ple rings of columns would be

required for an SCR. The alu-

minum-dome roof is cost ef-

fective for tanks larger than 20

m when compared to a steel-

dome roof and larger than 10

m if internal coatings are

needed for steel.

Capacity

The capacity of an SCR is

reduced because the cone-

roof support structure (in-

cluding roof rafter-to-shell at-

tachment gussets) extends 12-

18 in. below the top of the

tank shell, and the floating-

roof seal may run into the

fixed-steel roof. Although the

tank shell could be extended

upward, this is typically not

practical or cost effective for a

project to cover an EFRT. The

ADR tank does not usually re-

strict capacity because the at-

tachment of external framing

permits full travel of the seal

to the top of the tank shell.

Analyses should always be

performed to confirm clear-

ance with other deck obstruc-

tions (e.g., foam dams and

pressure/vacuum vent).

Larger-diameter domes have

a steep rise at the periphery,

which helps avoid interior-

deck obstructions. For addi-

tional clearance, the alu-

minum dome can be installed

with a skirt, which effectively

raises its base elevation.

Coatings

When comparing the dif-

ferences between steel and

aluminum, it is important to

consider the rather substantial

costs of surface preparation

and coating. Aluminum

domes are typically not coat-

ed, whereas steel roofs are al-

ways coated externally and

often coated internally in cor-

rosive environments.

ADRs are justified for

tanks with diameters as small

as 10 m for tanks which re-

quire internal coatings. This

conclusion is based on consid-

eration of the coating cost, the

special construction-detail re-

quirements, the internal seal-

welding requirement, and the

extensive preparation re-

quired for an effective inter-

nal coating. In addition, coat-

ings have maintenance costs

and recoating charges as a re-

sult of normal wear.

Beyond the initial roof

coating cost on an SCR, there

is the future maintenance. Of

FOCUS: REFINING

OGJ

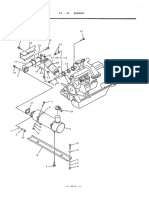

Fig. 3

GEODESIC DOME VS. CONE ROOF

Source: OGJ, July 10, 1989, p. 90.

Dome can be

easily elevated

to increase tank

capacity. Floating roof

Areas under

column supports

are prone to

corrosion and

hard to inspect.

Deck

penetrations

Columns

Geodesic dome

Cone roof

all the externally coated sur-

faces on a typical tank, the

cone-roof coating will fail first

as a result of horizontal expo-

sure to sunlight and ponding

of rainwater. These factors re-

sult in rust streaks that run

down the tank shell and cre-

ate a cosmetic problem.

The use of an ADR extends

the time interval between

tank-shell recoating and elim-

inates the cost of recoating the

roof-surface area.

Steel roofs often have un-

coated internal surfaces.

These roofs can produce tons

of corrosion products that

eventually delaminate from

the underside of the fixed roof

and collect on the bottom of a

tank. In one case, an estimated

70 tons of corrosion products

were removed from the bot-

tom of a 280 ft-diameter SCR

tank in crude oil service.

Had an internal-floating

roof been used, the exposure

of the fixed roof to corrosive-

sulfur compounds would

have been minimized. Pre-

ventive maintenance, howev-

er, would still have been re-

quired to remove some corro-

sion products from the deck.

The ADR would not have

generated corrosion products.

Emissions

The emission of organic or

hazardous vapors from an

ADR is lower than that of a

similar SCR. Unlike the cone

roof, the dome is a free-span

structure. The SCR tank has

columns that extend from the

fixed roof, through the float-

ing roof, and to the tank bot-

tom. The SCR has one or more

column penetrations from

which emissions escape to the

atmosphere. The use of an

aluminum dome reduces the

total facilities emissions in-

ventory by avoiding the emis-

sion factors for column pene-

trations.

Fig. 3 illustrates the differ-

ences between the ADR and

SCR tanks.

Chapter 19, Evaporative

Loss Measurement, of the API

Manual of Petroleum Mea-

surement Standards provides

a basis for the EPA emissions

calculation program. Al-

though not currently part of

the emission calculation for-

mula, the API Committee on

Petroleum Measurement is

considering better defining

the variables that influence

bulk and surface liquid tem-

peratures to improve accura-

cy. For example, although

bulk temperature is currently

based on ambient air condi-

tions, the method of delivery

and turnover rates are more

influential in determining the

bulk temperature.

Currently, there is only a

general paint factor to ad-

just bulk temperature for roof

variables. External-floating

roofs exposed to direct sun-

light should have higher sur-

face-liquid, shell-surface, and

deck-fitting temperatures than

covered-floating roofs. Cur-

rent bulk-temperature calcula-

tions, however, do not include

these solar-radiation effects.

Although not currently

considered in the emissions

calculation, the type of mater-

ial used in the tank should

also be considered. Because

aluminum has higher reflec-

tive and lower emissive prop-

erties than steel, emission cal-

culations should include the

following variables:

Adjustment of liquid-

surface temperature to reflect

the impact of heated-shell and

EFRT surfaces.

Addition of solar impact

and material variables to re-

flect reduced internal-surface

temperatures by either a steel

or aluminum fixed roof.

Addition of solar impact

and material variables to re-

flect reduced surface-liquid

temperatures by using vari-

ous types of aluminum inter-

nal floating roofs.

Corrosion caused

by columns

Roof-support columns in-

crease the potential for tank-

bottom corrosion and roof

corrosion.

API standards do not

allow columns to be attached

to the tank bottom so that the

tank bottom can settle with-

out distorting the roof. The

movement of the column base

on the tank bottom erodes

any coating on the tank bot-

tom and creates conditions

conducive to crevice corro-

sion.

Corrosion damage that oc-

curs near or under the column

bases is rarely inspected (even

during formal API 653 inter-

nal inspections) because the

base plate covers the corro-

sion damage. Column guides

and base plates, welded to the

tank bottom, make coating-

surface preparation and ap-

plication difficult, which in-

creases the potential for corro-

sion attack.

Because there is a higher

probability of tank-bottom

leaks as a result of corrosion

in SCR tanks, the potential for

resulting environmental cont-

amination increases.

Also, if the SCR support

columns vertically settle, the

cone roof surface plates will

deflect downward and pond

water (accelerating corro-

sion). A clear-span aluminum

dome is supported by the

tank shell, and uniform shell

settlement can be facilitated

by the use of a concrete ring-

wall foundation design.

More column problems

Columns can cause prob-

lems if they are out-of plumb,

trap hydrocarbons, or are im-

properly jacked during main-

tenance.

Columns which are out-of-

plumb with each other and

the tank shell can cause the

column-penetration seals to

wear. In severe cases, floating

roofs have hung up on

columns as the product level

rose.

Closed-shaped columns,

such as pipe columns, can

hold trapped hydrocarbons

even if they are designed to be

self draining. Many fires and

explosions have been initiated

by trapped hydrocarbons in

roof columns during internal-

tank work.

Tank columns are often

jacked up when new tank bot-

toms are being installed or

during maintenance.

Columns and jacking struc-

tures can collapse if improp-

erly jacked. The aluminum

dome, because it has no

columns, is not affected by in-

terior-bottom settlement and

offers no obstruction to bot-

tom inspection or mainte-

nance.

Roof frangibility

API 650 provides rules for

designing a frangible roof for

new CRTs. If a tank is inter-

nally overpressurized, a fran-

gible roof will fail at the roof-

to-shell joint and vent the ex-

cess pressure harmlessly to

the atmosphere.

In some instances, the

shell-to-bottom joint has failed

while overpressuring or over-

filling tanks without frangible

roofs. This failure causes the

tank to rocket upward,

spilling flammable contents or

releasing liquids. Frangible

roof failures historically have

not released liquid and have

resulted only in relatively

minor damage to the tank.

API 650-Appendix G,

which covers the design and

construction of ADR tanks,

states that the roof-to-shell

joint is not considered frangi-

ble. Certainly, the structural

attachments are not designed

to be frangible.

For all reported ADR-over-

pressurization incidents to

date (less than six), however,

the peripheral flashing has be-

haved as if it were a frangible

component. Even on ADR

tanks less than 40 ft in diame-

ter, in which frangible joints

are not considered reliable for

SCR tanks, the flashing has

behaved as a frangible com-

ponent.

The vent area of the alu-

minum-dome flashing should

exceed the vent area required

under API 2000, Section

2.4.3.2, which covers emer-

gency and normal venting for

Tanks Without Weak Roof-

to-Shell Attachment. There is

an open API agenda item to

allow the aluminum-dome

manufacturer to document

the frangibility of a panel

component and allow the

documented component to

contribute to the vent area as

required by API 2000.

Component frangibility is

not the same as a frangible

roof-to-shell joint, which is

defined under API 650, Sec-

tion 3.10.2.5 and API 2000,

Section 2.4.3.1. Component

frangibility is categorized sep-

arately under API 2000.

Safety access

In the rare event of a fire

within an IFRT, the alu-

minum dome panels provide

good access to the fire surface

for extinguishing. The panels

will melt away or allow an ax

to penetrate the surface. In

one incident concerning a

tank with an aluminum roof,

during a fire started by weld-

ing adjacent to a wastewater

basin, the panels quickly

melted away allowing the fire

to be promptly extinguished.

This same ability to re-

move ADR panels facilitates

access to the tank interior in

the event that personnel with-

in the tank require emer-

gency-vertical retrieval.

FOCUS: REFINING

Bibliography

Aluminum Design Manual: Specifica-

tions for Aluminum Structures,

the Aluminum Asssociation,

Washington, D.C.

API Manual of Petroleum Measure-

ment StandardsChapter 19,

Evaporative Loss Measurement,

American Petroleum Institute,

Washington, D.C.

API Publication 2026Safe

Access/Egress Involving Float-

ing Roof Tanks in Service, Amer-

ican Petroleum Institute, Wash-

ington, D.C.

API Standard 2000Venting Atmos-

pheric and Low-Pressure Storage

Tanks: Nonrefrigerated and Re-

frigerated, American Petroleum

Institute, Washington, D.C.

API Standard 650Welded Steel

Tanks for Oil Storage, Ninth

Edition, 1993, American Petrole-

um Institute, Washington, D.C.

Barrett, A.E., Geodesic-dome tank

roof cuts water contamination,

vapor losses, OGJ, July 10,

1989, p. 90.

EPA 40 CFR 60U.S. EPA New

Source Performance Standards

(Subpart Kb), 40 Code of Feder-

al Regulations, Washington,

D.C.

Myers, Philip E., Aboveground Stor-

age Tanks, McGraw-Hill, New

York, ISBN 0-07-044272-X.

OSHA 29 CFR 1910U.S. Occupa-

tional Safety and Health Admin-

istration, 29 Code of Federal

Regulations, Washington, D.C.

Myers Morovich Crochet

THE AUTHORS

Philip E. Myers is a senior standards

engineer at Chevron Products Co. He has

had experience in process and project en-

gineering in the utility, chemicals, petro-

chemicals, and refining businesses. In re-

cent years he has specialized in tanks and

pressure-vessel technology.

Myers serves as chairman of the sub-

committee for Tanks and Pressure Ves-

sels for the American Petroleum Institute

(API) and is vice-chairman of ASMEs

B96.1 Committee for Aluminum Tanks.

He holds a BS in chemical engineer-

ing from the University of California.

George L. Morovich is president of Tank & Environmental

Technologies Inc. (TETI), which he founded in 1991. TETI repre-

sents a group of companies offering engineering, manufacturing,

and contracting services related to industrial-liquids handling.

Morovichs primary focus is petroleum-storage tank equip-

ment, emission-control systems, water storage, and wastewater-

treatment equipment. He has 20 years of experience in the petro-

leum-storage tank industry. Since 1989, he has served the API as

a member of the subcommittee for Tanks and Pressure Vessels,

of the Task Force on Metrication of Standards, and of an envi-

ronmental technical assistance group.

Morovich holds a BS in geography from Sam Houston State

University. He is a recipient of an environmental science grant

from the National Science Foundation.

Earl J. Crochet is a senior engi-

neer at Plantation Pipe Line Co., re-

sponsible for corporate maintenance.

Plantation owns a refined products

pipeline with about 170 aboveground

storage tanks.

Crochet has been involved in all

aspects of aboveground storage tanks,

first as an inspector, and then later as

the leader of Plantations tank in-

tegrity program.

Crochet holds a BS in mechanical

engineering from Louisiana State

University.

Reprints Courtesy of:

TEMCOR

P.O. Box 48008, Gardena, CA90248

150 W. Walnut St, Suite 150, Gardena, CA90248

(310) 523-2322 Fax: (310) 523-2380

(800) 421-2263

e-mail: info@temcor.com

Website: www.temcor.com

You might also like

- TDS 8127-Eng PDFDocument2 pagesTDS 8127-Eng PDFadammzjinNo ratings yet

- Analytical Comparative Transport Cost Study On The Northern Corridor PDFDocument15 pagesAnalytical Comparative Transport Cost Study On The Northern Corridor PDFadammzjinNo ratings yet

- 6005 Servo Tank GaugeDocument10 pages6005 Servo Tank GaugeadammzjinNo ratings yet

- Approved List of Standards 30th March 2017Document13 pagesApproved List of Standards 30th March 2017adammzjinNo ratings yet

- Report On South Sudan Market Survey PDFDocument29 pagesReport On South Sudan Market Survey PDFadammzjinNo ratings yet

- Saturday, April 6, 2013 1330-1400 Hrs 1400-1600 Hrs. 1600-1630 Hrs. Venue: GTU Campus, Gandhinagar CampusDocument1 pageSaturday, April 6, 2013 1330-1400 Hrs 1400-1600 Hrs. 1600-1630 Hrs. Venue: GTU Campus, Gandhinagar CampusadammzjinNo ratings yet

- Clemco Clemvak III Owners ManualDocument4 pagesClemco Clemvak III Owners ManualadammzjinNo ratings yet

- 3LPE Coating SpecificationDocument20 pages3LPE Coating SpecificationadammzjinNo ratings yet

- Wasilatus ShafiDocument16 pagesWasilatus Shafiadammzjin100% (5)

- Hajj Umrah ChecklistDocument5 pagesHajj Umrah ChecklistadammzjinNo ratings yet

- Argon Liquid: Specification/gradeDocument1 pageArgon Liquid: Specification/gradeadammzjinNo ratings yet

- Tankguard SF Type: Tank Coating: Add To ListDocument2 pagesTankguard SF Type: Tank Coating: Add To ListadammzjinNo ratings yet

- E194-837 - 842 Gases Conversion ChartDocument3 pagesE194-837 - 842 Gases Conversion ChartadammzjinNo ratings yet

- ConversionDocument2 pagesConversionadammzjinNo ratings yet

- Pipe SwabsDocument2 pagesPipe SwabsadammzjinNo ratings yet

- Product Data Sheet: Argon (Ar)Document2 pagesProduct Data Sheet: Argon (Ar)adammzjin100% (1)

- Sect6 - Chapt2 - Mobile Internal Combustion EnginesDocument7 pagesSect6 - Chapt2 - Mobile Internal Combustion EnginesadammzjinNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Generator Relay Protection Setting Calculation REV 1.0Document18 pagesGenerator Relay Protection Setting Calculation REV 1.0SreekanthMylavarapuNo ratings yet

- SolarPro2 4Document100 pagesSolarPro2 4lgv2No ratings yet

- Cleaning of Pipes by Gas Discharge Back PuffingDocument1 pageCleaning of Pipes by Gas Discharge Back PuffingVamsi MahantiNo ratings yet

- NR-210803-Material and Energy BalanceDocument8 pagesNR-210803-Material and Energy BalanceSrinivasa Rao G100% (1)

- Welding HazardDocument1 pageWelding HazardErvinaNo ratings yet

- Ist 50 Smartletloose One 1x00 EngDocument2 pagesIst 50 Smartletloose One 1x00 EngMihai MecaNo ratings yet

- Shaffer Et Al. - 2003 - Foraging Effort in Relation To The Constraints ofDocument9 pagesShaffer Et Al. - 2003 - Foraging Effort in Relation To The Constraints ofBenjamin MendezNo ratings yet

- 1 Home Base Work March 19-MRCH 31Document3 pages1 Home Base Work March 19-MRCH 31Celso AmotoNo ratings yet

- NSGAFÖU 1,8/3 KV: Product InformationDocument3 pagesNSGAFÖU 1,8/3 KV: Product InformationAttila HorvathNo ratings yet

- Shell VOLUTA C 400: Neat Quenching OilDocument2 pagesShell VOLUTA C 400: Neat Quenching OilalmasNo ratings yet

- 100% NATEF Task Coverage: Automotive TechnologyDocument88 pages100% NATEF Task Coverage: Automotive TechnologynhathoaNo ratings yet

- Project On Global WarmingDocument22 pagesProject On Global WarmingHilda DsouzaNo ratings yet

- 434 02Document28 pages434 02Luiz Filipe Silva100% (1)

- Testing of Frost Free Ref. CompontntsDocument4 pagesTesting of Frost Free Ref. Compontntssantosh Indulkar100% (2)

- MaxxForce 9 Y 10Document5 pagesMaxxForce 9 Y 10Eduardo Alvarez100% (2)

- 6991 1767 01b - Diamec U4 - LRDocument4 pages6991 1767 01b - Diamec U4 - LRPABLONo ratings yet

- PDS655S 404 405Document59 pagesPDS655S 404 405Naing Min HtunNo ratings yet

- Decarbonization MagazineDocument86 pagesDecarbonization MagazineSynergy IndustriesNo ratings yet

- Filmwise and Dropwise ExperimentDocument16 pagesFilmwise and Dropwise ExperimentGoodMarissa100% (5)

- 2007-08 VodafonecrDocument378 pages2007-08 VodafonecrManisha BishtNo ratings yet

- Gmaw WQTDocument23 pagesGmaw WQTDera LesmanaNo ratings yet

- Снимок экрана 2023-03-01 в 09.16.43Document48 pagesСнимок экрана 2023-03-01 в 09.16.43Maksim ZolotarjovNo ratings yet

- Antibiotic Zone Reader KI 95Document1 pageAntibiotic Zone Reader KI 95Piyush A JoshiNo ratings yet

- Semester Syllabus For M. Sc. in Chemistry: School of Chemistry (AutonomousDocument22 pagesSemester Syllabus For M. Sc. in Chemistry: School of Chemistry (AutonomousDachou GeetuNo ratings yet

- Safe Handling of Petroleum ProductsDocument12 pagesSafe Handling of Petroleum ProductsMwkthangkwr BrahmaNo ratings yet

- All Clear kl8 Unit3 Extra Test ADocument3 pagesAll Clear kl8 Unit3 Extra Test AKaRtonEkNo ratings yet

- Determination of End Point of A Titration and Solubility Product of A Sparingly Soluble Salt Using Conductometry.Document12 pagesDetermination of End Point of A Titration and Solubility Product of A Sparingly Soluble Salt Using Conductometry.Chamith Herath33% (3)

- Southwark Schools For The FutureDocument59 pagesSouthwark Schools For The FuturewilliamsaminNo ratings yet

- 2D& 3D-Kate Susannah - Lindsay Sorin and Michelle Maranto-Option 2 - 22.03.23Document11 pages2D& 3D-Kate Susannah - Lindsay Sorin and Michelle Maranto-Option 2 - 22.03.23Miliausha KarimNo ratings yet

- OGAS Company ContactDocument4 pagesOGAS Company ContactrnoordinNo ratings yet