Professional Documents

Culture Documents

07 0071 Unswhousing Ea Appsbcacompliance

Uploaded by

amazonfedOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

07 0071 Unswhousing Ea Appsbcacompliance

Uploaded by

amazonfedCopyright:

Available Formats

13 J une 2007

Our Ref: J 27088A-1 J S

Watpac NSW Pty Ltd

PO Box 6688

BAULKHAM HILLS NSW 2153

Fax: 9899 7681

Attention: Mr. Darren Skinner

Dear Sir,

Re: University of New South Wales

Student Accommodation BCA Compliance Report

Please find enclosed our BCA Compliance Report prepared in respect of the proposed

design contained within the architectural documentation provided.

In reviewing the content of this Report, particular attention is drawn to the content of

Parts 3 and 4, as:

Part 3 summarizes the compliance status of the proposed design in terms of each

prescriptive provision of the BCA.

The inclusion of this summary enables an immediate understanding of the

compliance status of the proposed design to be obtained.

Part 4 contains a detailed analysis of the proposed design, and provides

informative commentary & recommendation in respect of each instance of

prescriptive non-compliance and area of insufficient (design) detail, as

applicable.

This commentary enables the project team to readily identify and understand the

nature and extent of information required within the Building Permit (or other)

application to demonstrate the attainment of BCA compliance.

Should you require any further information, please do not hesitate to contact me on

the number provided.

Yours faithfully

J ason Storer

Technical Manager

for Trevor R Howse & Associates Pty Limited

B

B

C

C

A

A

C

C

O

O

M

M

P

P

L

L

I

I

A

A

N

N

C

C

E

E

A

A

S

S

S

S

E

E

S

S

S

S

M

M

E

E

N

N

T

T

PREPARED FOR

Watpac NSW Pty Ltd

REGARDING

University of New South Wales

Student Accommodation

(i)

R RE EP PO OR RT T R RE EG GI IS ST TE ER R

The following report register documents the development and issue of this report and

project as undertaken by this office, in accordance with the Quality Assurance policy

of Trevor R Howse & Associates Pty Ltd.

Our Reference Issue No. Remarks

Issue Date

J 27088A 1 DRAFT report issued to client. 13.6.07

The format, technical content and intellectual property associated with this report

remain the property of Trevor R. Howse & Associates Pty Limited, and has been

prepared and may only be used, for the development / buildings the subject of this

report.

(ii)

C CO ON NT TE EN NT TS S P PA AG GE E

1 1. .0 0 I IN NT TR RO OD DU UC CT TI IO ON N................................................................................... 1

1.1 General.............................................................................................................. 1

1.2 Report Basis...................................................................................................... 1

1.3 Exclusions ......................................................................................................... 2

1.4 Report Purpose................................................................................................. 2

2 2. .0 0 B BU UI IL LD DI IN NG G D DE ES SC CR RI IP PT TI IO ON N ................................................................... 4

2.1 General.............................................................................................................. 4

2.2 Rise in Storeys (Clause C1.2) .......................................................................... 4

2.3 Building Classification (Clause A3.2)............................................................. 4

2.4 Effective Height (Clause A1.1)........................................................................ 4

2.5 Type of Construction (Table C1.1)................................................................. 4

2.6 General Floor Area Limitations (Table C2.2)............................................... 4

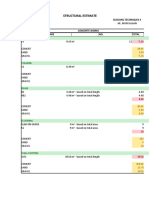

3 3. .0 0 B BC CA A A AS SS SE ES SS SM ME EN NT T S SU UM MM MA AR RY Y ...................................................... 5

3.1 General.............................................................................................................. 5

3.2 Section B Structure....................................................................................... 5

3.3 Section C Fire resistance .............................................................................. 5

3.4 Section D Access and Egress ........................................................................ 6

3.5 Section E Services and Equipment.............................................................. 7

3.6 Section F Health and Amenity..................................................................... 7

3.7 Section G Ancillary Provisions .................................................................... 8

3.8 Section H Special Use Buildings .................................................................. 8

3.9 Section J Energy Efficiency.......................................................................... 9

4 4. .0 0 B BC CA A A AS SS SE ES SS SM ME EN NT T D DE ET TA AI IL LE ED D A AN NA AL LY YS SI IS S.................................. 10

4.1 General............................................................................................................ 10

4.2 Section B Structure..................................................................................... 10

4.3 Section C Fire Resistance ........................................................................... 10

4.4 Section D Access and Egress ...................................................................... 16

4.5 Section E Services and Equipment............................................................ 21

4.6 Section F Health and Amenity................................................................... 22

4.7 Section G Ancillary provisions .................................................................. 24

4.9 Section J Energy Efficiency........................................................................ 24

1 1. .0 0 I IN NT TR RO OD DU UC CT TI IO ON N

1 1. .1 1 G GE EN NE ER RA AL L

This BCA Compliance Assessment report has been prepared at the request of

Watpac Pty Ltd, and relates to the development known as Student

Accommodation, to be located within the grounds of the University of New

South Wales, Kensington.

This report is based upon, and limited to, the information depicted in the

documentation provided for assessment, and does not make assumptions

regarding design intention or the like.

From this documentation, it is understood that the proposed development

encompasses:

(a) Construction of new residential accommodation for the university

students, with a total of 1030 bedrooms being provided across the

development. The development also has ancillary basement carparking, a

retail shop and kiosk, as well as laundry and e-learning facilities.

1 1. .2 2 R RE EP PO OR RT T B BA AS SI IS S

The content of this report reflects

(a) The principles and provisions of Building Code of Australia 2007.

(b) Architectural documentation prepared by Architectus :

Numbered Titled Dated

A20-01 Room schedule 1 18.5.07

A01-01 Level ground 1/2 1.6.07

A01-02 Level ground 2/2 1.6.07

A01-03 Level 1 1/2 1.6.07

A01-04 Level 1 2/2 1.6.07

A01-05 Level 2 1/2 1.6.07

A01-06 Level 2 2/2 1.6.07

A01-07 Level 3 1/2 1.6.07

A01-08 Level 3 2/2 1.6.07

A01-09 Level 4 1/2 1.6.07

A01-10 Level 4 2/2 1.6.07

A01-11 Level 5 1/2 1.6.07

A01-12 Level 5 2/2 1.6.07

A01-13 Level 6 1/2 1.6.07

A01-14 Level 6 2/2 1.6.07

A01-15 Level 7 1/2 1.6.07

A01-16 Level 7 2/2 1.6.07

A01-17 Level 8 1/2 1.6.07

- 2 -

Numbered Titled Dated

A01-18 Level 8 2/2 1.6.07

A01-19 Level roof 1/2 1.6.07

A01-20 Level roof 2/2 1.6.07

A02-01 North elevation 1.6.07

A02-02 South elevation 1.6.07

A02-03 East and West elevation 1.6.07

A03-01 Section A 1.6.07

A03-02 Section B 1.6.07

A03-04 Section C & D 1.6.07

A03-05 Section E & F 1.6.07

1 1. .3 3 E EX XC CL LU US SI IO ON NS S

It is conveyed that this report should not construed to infer that an assessment

for compliance with the following has been undertaken

(a) Structural and services design documentation;

(b) General building services;

(c) The individual requirements of service providers (i.e. Telstra, Water

Supply, Energy Australia);

(d) The individual requirements of the Workcover Authority;

(e) Disability Discrimination Act 1992 (DDA).

1 1. .4 4 R RE EP PO OR RT T P PU UR RP PO OS SE E

The purpose of this report is to identify the extent to which the architectural

design documentation complies with the relevant prescriptive provisions of BCA

2007.

Assessment of the proposed design considers each prescriptive BCA provision,

and identifies such as either:

(a) Being complied with; or

(b) Not being complied with; or

(c) Requiring the provision further detail with the future Building Permit or

other application or

(d) Not being relevant to the particular building works proposal.

The status of the design, in terms of these four (4) categories, is summarised

within Part 3 of this report.

Where prescriptive non-compliance is identified, suitable recommendations to

remedy the non-compliance shall be detailed in Part 4.

Trevor R Howse & Associates Pty Ltd

- 3 -

In instances where insufficient detail exists, summary of the information

required from the project team for inclusion within future applications (i.e.

Building Permit) shall also be outlined in Part 4.

Trevor R Howse & Associates Pty Ltd

- 4 -

2 2. .0 0 B BU UI IL LD DI IN NG G D DE ES SC CR RI IP PT TI IO ON N

2 2. .1 1 G GE EN NE ER RA AL L

In the context of the Building Code of Australia (BCA), the subject development

is described within items 2.2 2.6 below.

2 2. .2 2 R RI IS SE E I IN N S ST TO OR RE EY YS S ( (C CL LA AU US SE E C C1 1. .2 2) )

Having a rise in storeys of nine (9) for the larger building and one (1) for the

smaller stand alone buildings.

2 2. .3 3 B BU UI IL LD DI IN NG G C CL LA AS SS SI IF FI IC CA AT TI IO ON N ( (C CL LA AU US SE E A A3 3. .2 2) )

The building shall be of the following classifications:

(a) Class 3 Residential student accommodation

(b) Class 6 Retail

(c) Class 7a Carparking

(d) Class 9b E-learning facility

2 2. .4 4 E EF FF FE EC CT TI IV VE E H HE EI IG GH HT T ( (C CL LA AU US SE E A A1 1. .1 1) )

The buildings have an effective height not exceeding 25-metres

2 2. .5 5 T TY YP PE E O OF F C CO ON NS ST TR RU UC CT TI IO ON N ( (T TA AB BL LE E C C1 1. .1 1) )

Required to be of Type A for the nine storey building and Type C Construction

for the single storey buildings.

2 2. .6 6 G GE EN NE ER RA AL L F FL LO OO OR R A AR RE EA A L LI IM MI IT TA AT TI IO ON NS S ( (T TA AB BL LE E C C2 2. .2 2) )

(a) Class 3 (Type A and C) Not Applicable

(b) Class 6 (Type A)

(i) Maximum floor area 5,000 m

2

(ii) Maximum volume 30,000 m

3

(c) Class 7a & 9b (Type A)

(i) Maximum floor area 8,000 m

(ii) Maximum volume 48,000 m

Trevor R Howse & Associates Pty Ltd

- 5 -

3 3. .0 0 B BC CA A A AS SS SE ES SS SM ME EN NT T S SU UM MM MA AR RY Y

3 3. .1 1 G GE EN NE ER RA AL L

The tables contained within items 3.2 3.9 below summarise the compliance

status of the proposed architectural design in terms of each prescriptive

provision of the Building Code of Australia.

For those instances of either prescriptive non-compliance or insufficient

detail, a detailed analysis and commentary is provided within Part 4.

3 3. .2 2 S SE EC CT TI IO ON N B B S ST TR RU UC CT TU UR RE E

BCA reference Complies Does not

comply

Detail

required

Not

relevant

B1.1 resistance to actions

B1.2 determination of individual actions

B1.3 loads

B1.4 materials and form of construction

3 3. .3 3 S SE EC CT TI IO ON N C C F FI IR RE E R RE ES SI IS ST TA AN NC CE E

BCA reference Complies Does not

comply

Detail

required

Not

relevant

Spec. C1.1 fire resisting construction

C1.3 buildings of multiple classification

C1.4 mixed types of construction

C1.5 two storey Class 2 or 3 buildings

C1.6 Class 4 parts of a building

C1.7 open spectator stands & indoor sports stadiums

C1.8 lightweight construction

C1.10 fire hazard properties

C1.11 performance of external walls

C1.12 non-combustible materials

C2.2 general floor area & volume limits

C2.3 large isolated buildings

C2.4 requirements for open spaces & vehicular access

C2.5 Class 9a and 9c buildings

C2.6 vertical separation of openings in external walls

C2.7 separation of firewalls

C2.8 separation of classifications in same storey

C2.9 separation of classifications in different storeys

C2.10 separation of lift shafts

C2.11 stairways and lifts in one shaft

C2.12 separation of equipment

C2.13 electricity supply system

C2.14 public corridors in Class 2 and 3 buildings

C3.2 openings in external walls

C3.3 separation of external walls & associated openings

C3.4 acceptable methods of protection

C3.5 doorways in firewalls

C3.6 sliding fire doors

C3.7 doorways in horizontal exits

C3.8 openings in fire-isolated exits

C3.9 service penetrations in fire-isolated exits

Trevor R Howse & Associates Pty Ltd

- 6 -

BCA reference Complies Does not

comply

Detail

required

Not

relevant

C3.10 openings in fire-isolated lift shafts

C3.11 bounding construction: Class 2, 3, 4 and 9 buildings

C3.12 openings in floors & ceilings for services

C3.13 openings in shafts

C3.15 openings for service installations

C3.16 construction joints

C3.17 columns protected with f/r lightweight construction

3 3. .4 4 S SE EC CT TI IO ON N D D A AC CC CE ES SS S A AN ND D E EG GR RE ES SS S

BCA reference Complies Does not

comply

Detail

required

Not

relevant

D1.2 number of exits required

D1.3 when fire-isolated exits are required

D1.4 exit travel distances

D1.5 distance between alternative exits

D1.6 dimensions of exits and paths of travel to exits

D1.7 travel via fire-isolated exits

D1.8 external stairways or ramps in lieu of fire- isolated exits

D1.9 travel via non-fire isolated stairways or ramps

D1.10 discharge from exits

D1.11 horizontal exits

D1.12 non-required stairways or ramps

D1.13 number of persons accommodated

D1.16 plant rooms and lift motor rooms: concession

D1.17 access to lift pits

D2.2 fire-isolated stairways and ramps

D2.3 non-fire isolated stairways and ramps

D2.4 separation of rising and descending stair flights

D2.5 open access ramps and balconies

D2.6 smoke lobbies

D2.7 installations in exits and paths of travel

D2.8 enclosure of space under stairs and ramps

D2.9 width of stairways

D2.10 pedestrian ramps

D2.11 fire-isolated passageways

D2.12 roof as open space

D2.13 goings and risers

D2.14 landings

D2.15 thresholds

D2.16 balustrades

D2.17 handrails

D2.18 fixed platforms, walkways, stairways and ladders

D2.19 doorways and doors

D2.20 swinging doors

D2.21 operation of latch

D2.22 re-entry from fire-isolated exits

D2.23 signs on doors

D2.101 doors in path of travel in a POPE

D3.2 general building access requirements

D3.3 parts of buildings to be accessible

D3.4 concessions

D3.5 car parking

D3.6 identification of accessible facilities

D3.7 hearing augmentation services and features

D3.8 tactile indicators

Trevor R Howse & Associates Pty Ltd

- 7 -

3 3. .5 5 S SE EC CT TI IO ON N E E S SE ER RV VI IC CE ES S A AN ND D E EQ QU UI IP PM ME EN NT T

BCA reference Complies Does not

comply

Detail

required

Not

relevant

E1.3 fire hydrants

E1.4 fire hose reels

E1.5 sprinklers

E1.6 portable fire extinguishers

E1.8 fire control centres

E1.9 fire precautions during construction

E1.10 provision for special hazards

E2.2a general provisions

E2.2b specific provisions

E2.3 provision for special hazards

E3.2 stretcher facility in lifts

E3.3 warning against use of lifts in fire

E3.4 emergency lifts

E3.5 landings

E3.6 facilities for people with disabilities

E3.7 fire service controls

E3.8 aged care buildings

E4.2 emergency lighting

E4.4 design and operation of emergency lighting

E4.5 exit signs

E4.6 direction signs

E4.7 Class 2 and 3 buildings and Class 4 parts: exemptions

E4.8 design and operation of exit signs

E4.9 emergency warning and intercommunication systems

3 3. .6 6 S SE EC CT TI IO ON N F F H HE EA AL LT TH H A AN ND D A AM ME EN NI IT TY Y

BCA reference Complies Does not

comply

Detail

required

Not

relevant

F1.1 stormwater drainage

F1.5 roof coverings

F1.6 sarking

F1.7 water proofing of wet areas

F1.9 damp proofing

F1.10 damp proofing of floors on ground

F1.11 floor wastes

F1.12 sub-floor ventilation

F1.13 glazed assemblies

F2.1 facilities in residential buildings

F2.3 facilities in Class 3 to 9 buildings

F2.4 facilities for people with disabilities

F2.5 construction of sanitary compartments

F2.7 microbial (legionella) control

F2.8 waste management

F3.1 height of rooms

F4.1 provision of natural light

F4.2 methods and extent of natural lighting

F4.3 natural lighting borrowed from adjoining room

F4.4 artificial lighting

F4.5 ventilation of rooms

F4.6 natural ventilation

F4.7 ventilation borrowed from an adjoining room

Trevor R Howse & Associates Pty Ltd

- 8 -

BCA reference Complies Does not

comply

Detail

required

Not

relevant

F4.8 restriction on position of water closets and urinals

F4.9 airlocks

F4.11 car parks

F4.12 kitchen local exhaust ventilation

F5.2 sound transmission class: interpretation

F5.3 sound transmission of floors between units

F5.4 sound insulation of walls between units

F5.5 sound insulation rating of walls

F5.6 sound insulation rating of services

F5.7 sound insulation of pumps

3 3. .7 7 S SE EC CT TI IO ON N G G A AN NC CI IL LL LA AR RY Y P PR RO OV VI IS SI IO ON NS S

BCA reference Complies Does not

comply

Detail

required

Not

relevant

G1.1 swimming pools

G1.2 refrigerated chambers, strong-rooms & vaults

NSW G1.101 Provision for cleaning windows

G2.2 installation of appliances

G2.3 open fireplaces

G2.4 incinerator rooms

G3.2 dimensions of atrium well

G3.3 separation of atrium bounding walls

G3.4 construction of bounding walls

G3.5 construction at balconies

G3.6 separation at roofs

G3.7 means of egress

G3.8 fire and smoke control systems

G4.3 external doorways

G4.4 emergency lighting

G4.5 external ramps

G4.6 discharge of exits

G4.7 external trafficable structures

G4.8 fire-fighting services and equipment

G4.9 fire orders

G5.2 protection (in bushfire prone areas)

3 3. .8 8 S SE EC CT TI IO ON N H H S SP PE EC CI IA AL L U US SE E B BU UI IL LD DI IN NG GS S

BCA reference Complies Does not

comply

Detail

required

Not

relevant

H101.2 fire separation

H101.3 foyer space

H101.4 sprinkler systems for common foyers

H101.5 conventional stages

H101.6 non-conventional stages

H101.7 flying scenery

H101.8 load notice

H101.10 safety curtains

H101.11 seating in rows

H101.12 continental seating

H101.13 provision of guardrails

H101.14 guardrails

H101.15 dressing rooms

H101.16 storerooms

H101.17 projection suites

Trevor R Howse & Associates Pty Ltd

- 9 -

BCA reference Complies Does not

comply

Detail

required

Not

relevant

H101.18 basement storeys

H101.19 electric mains installation

H101.20 lighting

H101.22 automatic smoke-and-heat vents for stages

H101.23 solid fuel burning stoves & open fireplaces

H101.24 fuel gas cylinders

3 3. .9 9 S SE EC CT TI IO ON N J J E EN NE ER RG GY Y E EF FF FI IC CI IE EN NC CY Y

BCA reference Complies Does not

comply

Detail

required

Not

relevant

J 1.2 thermal construction general

J 1.3 roof and ceiling construction

J 1.4 roof lights

J 1.5 walls

J 1.6 floors

J 2.3 glazing

J 2.4 glazing

J 2.5 shading

J 3.2 chimneys and flues

J 3.3 roof lights

J 3.4 external windows and doors

J 3.5 exhaust fans

J 3.6 construction of roofs, walls and floors

J 3.7 evaporative coolers

J 4.2 air movement

J 4.3 ventilation openings

J 4.4 ceiling fans and evaporative coolers

J 5.2 air conditioning and ventilation systems

J 5.3 time switch

J 5.4 heating and cooling systems

J 5.5 ancillary exhaust systems

J 6.2 interior artificial lighting

J 6.3 interior artificial lighting and power control

J 6.4 interior decorative and display lighting

J 6.5 artificial lighting to the perimeter of a building

J 6.6 boiling water/chilled water storage units

J 7.2 hot water supply

J 8.2 access for maintenance

Trevor R Howse & Associates Pty Ltd

- 10 -

4 4. .0 0 B BC CA A A AS SS SE ES SS SM ME EN NT T D DE ET TA AI IL LE ED D A AN NA AL LY YS SI IS S

4 4. .1 1 G GE EN NE ER RA AL L

With reference to the BCA Assessment Summary contained within Part 3

above, the following detailed analysis and commentary is provided.

This commentary is formulated to enable the design documentation to be further

progressed, for the purpose of evidencing the attainment of compliance with the

relevant provisions of the BCA.

4 4. .2 2 S SE EC CT TI IO ON N B B S ST TR RU UC CT TU UR RE E

Cl. B1.1 The resistance of a building or structure must be greater than the most critical

action effect determined by BCA Clauses B1.2 & AS/NZS 1170.02002, and

B1.4.

Cl. B1.2 The structural design of the building must be determined in accordance with the

varying action considerations contained within this clause (i.e. permanent

actions, imposed actions, wind / earthquake actions).

Cl. B1.3 The structural design of the building must accord with:

Dead & Live Loads & AS 1170.12002

load combinations

Permanent, imposed & AS 1170.22002

other actions

Cl. B1.4 Materials and forms of construction must comply (where proposed) with the

following:

Masonry AS 37002001

Piling AS 2159 1995

Concrete AS 36002001

Timber construction AS 1684.2,3 or 4 2006

Cold formed steel structures AS 41001998

Aluminum AS/NZS 1664.1 or 21997

Metal sheet roof covering AS 1562.11992

Glazing AS 12882006 & AS 20471999

4 4. .3 3 S SE EC CT TI IO ON N C C F FI IR RE E R RE ES SI IS ST TA AN NC CE E

Cl. C1.1 Specification C1.1 Requirements for Type A Construction (applicable

to the 9 storey part of the building)

The proposed building works must incorporate the following AS 1530.42005

compliant fire resistance levels and characteristics:

* External Walls

External Walls

(class 3)

(Within 1.5m of the fire source feature)

Loadbearing 90/90/90

Non Loadbearing /90/90

(Between 1.5m & 3m of a fire source feature)

Loadbearing 90/60/60

Non Loadbearing /60/60

Trevor R Howse & Associates Pty Ltd

- 11 -

Cl. C1.1

contd

(Greater than 3m from a fire source feature)

Loadbearing 90/60/30

Non Loadbearing /30/30

External Walls

(class 6)

(Within 1.5m of the fire source feature)

Loadbearing 180/180/180

Non Loadbearing /180/180

(Between 1.5m & 3m of a fire source feature)

Loadbearing 180/180/120

Non Loadbearing /180/120

(Greater than 3m from a fire source feature)

Loadbearing 180/120/90

Non Loadbearing //

External Walls

(class 7a & 9b)

(Within 1.5m of the fire source feature)

Loadbearing 120/120/120

Non Loadbearing /120/120

(Between 1.5m & 3m of a fire source feature)

Loadbearing 120/90/90

Non Loadbearing /90/90

(Greater than 3m from a fire source feature)

Loadbearing 120/60/30

Non Loadbearing //

* External Columns

(less than 3m from a fire source feature)

Class 3 90//

* Internal Walls

Bounding fire stairs and lift shafts

Class 3

Loadbearing 90/90/90

Non Loadbearing /90/90

Class 6

Loadbearing 180/180/180

Non Loadbearing /180/180

Class 7a

Loadbearing 120/120/120

Non Loadbearing /120/120

NB: Stair shafts must also be fire separated at the top and bottom of the

shaft with fire rated construction achieving an FRL equivalent to that of the

stair or lift shaft.

Trevor R Howse & Associates Pty Ltd

- 12 -

Cl. C1.1

contd

Bounding vent / pipe/ garbage / and the like shafts

Class 3

Loadbearing 90/90/90

Non Loadbearing /90/90

Class 7a

Loadbearing 120/90/90

Non Loadbearing /90/90

NB: Any shafts must either extend through the roof cover, or be provided

with a lid having a fire resistance not less than the walls of the shaft. Note

that concrete is the simplest form of construction as the lid must achieve a

fire rating from both above and below, (as required in clause 2.7).

Class 3

Bounding sole occupancy units 90/90/90 (loadbearing)

& public lobbies /60/60 (non-loadbearing)

Between sole occupancy units 90/90/90 (loadbearing)

/60/60 (non-loadbearing)

Class 3

Internal load bearing walls, 90//

beams, trusses & columns

Class 6

Internal load bearing walls, 180//

beams, trusses & columns

Class 7a

Internal load bearing walls, 120//

beams, trusses & columns

* Firewalls

Between the Restaurant and Office 180/180/180

Between the Office 120/120/120

and Accommodation

* Floors

Class 3 generally 90/90/90

Between the carpark and the 120/120/120

Residential/retail above

Between retail and residential 180/180/180

Between e-learning and 120/120/120

residential

Trevor R Howse & Associates Pty Ltd

- 13 -

Cl. C1.1

contd

* Roofs

As the buildings are less than 25m in height and of mixed classification it is

required to be fire rated to achieve a 60 minute resistance to the incipient spread of

fire. Please advise if anything other than a concrete roof is proposed as a

performance based solution can be utilised to remove the fire rating where

necessary.

* Lintels

Clause 2.4

Lintels within the external walls of the building are required to have an FRL

equivalent to that of the part of the building within which it is located. Note the

concessions in clause 2.3 of Specification C1.1 re concessions for fire ratings

requirements for lintels.

* Fire Rated Wall Construction

Table 3(e)

All walls required to be fire rated must be constructed of non-combustible

construction. The same is applicable for the flooring and floor framing of lift pits.

Specification C1.1 Requirements for Type C Construction (class 3

single storey stand alone buildings)

*External Walls

Within 1.5m of a fire source feature

/90/90

More than 1.5m from fire source feature

/60/60

* External Columns

Within 1.5m of a fire source feature

90/--/--

More than 1.5m from fire source feature

/--/--

* Internal Walls

Between units and bounding a fire rated stair shafts.

An FRL of not less than 60/60/60.

Note: the fire rated party walls must extend to the underside of the ceiling above if

that ceiling has a 60 minute rating, or to the underside of the roof covering if it is

non-combustible (and the fire rated walls must not be crossed by timber other than

roof battens 75mm x 50mm maximum).

* Roofs

No fire rating required.

Trevor R Howse & Associates Pty Ltd

- 14 -

Cl. C1.8 If lightweight plasterboard is to be used in a fire rated application please provide

a copy of the manufacturers data sheet detailing the static load and resistance

achieved for the systems proposed within this building.

Cl. C1.10 The fire hazard properties of any materials other than floor, wall and ceiling

linings should accord with the following:

Have a spread of flame index exceeding 9

Have a smoke developed index exceeding 8, if the spread of flame index

exceeds 5

Floor, wall and ceiling linings must have fire hazard properties accordant with

BCA Specification C1.10a for a non-sprinkler protected building, which

specifies that:

Floor Materials.

Must have a critical radiant heat flux for the building not less than 2.2 and a

maximum smoke developed rate of 750 % minutes.

Class 3 Wall and ceilings.

For wall and ceiling linings a group number of 1 for fire stairs, 1 and 2 for public

corridors and 1, 2 and 3 for specific area and other areas.

Class 6, 7a and 9b Wall and ceilings.

For the class 6, 7a and 9b parts a group number of 1 for fire stairs, 1 and 2 for

public corridors and 1, 2 and 3 for specific areas and other areas, except the

ceilings of specific areas which are limited to groups 1 and 2.

Cl. C2.6 We have tried to assess the spandrel separation proposed for the building but due

to the lack of detail on the elevations it is difficult to determine where glazing

stops and a spandrel panel starts, e.g. grid 3-4, south elevation, as there may be

spandrels panels behind but this part of the elevation appears to be glazing.

As such this issue should be discussed at a design meeting to ensure that this

issue has been considered in respect to the provision of either a 1.1m wide

horizontal spandrel that extends a minimum of 450mm past the edge of any

openings or a vertical spandrel not less than 900mm high. Both types of

spandrels are required to be 60 minute fire rated.

We also note from our review of the plans that some of the spandrels do not

appear to extend the required 450mm past the end of the openings when a

horizontal spandrel has been used to achieve compliance, e.g. balconies to unit

E2.2, E3.3, F2.2, F2.1.

Cl. C2.7 Where walls are used to fire separate sole-occupancy units from each other or

from public corridors, they must:

Have an FRL not less than that specified in Clause C1.1 above.

Not be crossed by elements other than timber battens of 75x50-mm in size.

Extend to the underside of a floor having the same FRL as the wall, or to

the underside of the roof cover.

Cl. C2.8 Classifications located in the same storey (i.e. Ground floor - Class 6 retail, class

9b E-learning and Class 3 residential accommodation) must either be separated

using firewalls as described in Clauses C1.1 and C2.7 above, or the entire floor

constructed to the higher FRL applicable to the classification concerned.

Where separation is not possible the FRL of elements within the ground floor

would need to be increased to a minimum three (3) hour rating.

Trevor R Howse & Associates Pty Ltd

- 15 -

Cl. C2.9 As mentioned within Clause C2.8, similarly, if no firewall is provided to

separate classifications, then the floor between the ground floor and Level 1

would need an FRL of 180/180/180. Refer to Specification C1.1 above in

relation to the fire rating requirements for floors.

Cl. C2.10 The walls of the lift shaft need have a fire rating as specified in Clause C1.1

above. As mentioned within Clause C2.8 throughout the ground floor where the

separate classifications are not fire isolated the lift shaft need be constructed to

the higher FRL.

Cl. C2.12 Any proposed lift motor rooms and any onsite fire pumps must be fire separated

from the remainder of the building using construction having a 2-hour fire

resistance level, and a /120/30 self-closing fire door set.

Cl. C2.13 The existing sub-station will need to be two hour fire separated from the

remainder of the building by 2-hour construction (including self-closing two

hour rated door set).

Where the main switchboard controls emergency equipment operating in the

emergency mode, the switchboard must be separated from the remainder of the

building by 2-hour construction (including self-closing two hour rated door set).

Electrical conductors within the building that supply a main switchboard (see 1

above) must have a classification in accordance with AS/NZS 3013 of not less

than:

if in a position where subject to motor vehicle damage WS53W; or

otherwise WS52W; or

be enclosed in construction with an FRL of 120/120/120.

Where emergency equipment is required in a building all switchboards in the

electrical distribution system must provide full segregation by wall of enclosed

metal partitions designed to prevent the spread of faults between emergency and

non-emergency switchgear.

Cl. C3.2 Please provide clarification as to whether the external walls of the building are

proposed to be loadbearing or non-loadbearing. Once this clarification is

provided we will review the plans and indicate which windows/doors are

required to be fire rated due to their proximity to adjoining buildings on the site.

Cl. C3.4 Permissible protectives that may be required by clause C3.2 above:

Doors

(i) Self-closing or automatic closing 1-hour fire door sets; or

(ii) External wall-wetting sprinklers over self-closing or automatic

closing door sets.

Windows

(i) External wall-wetting sprinklers over fixed or automatic closing

windows; or

(ii) Fixed or automatic closing 1-hour fire rated glazing; or

(iii) External automatic closing 1-hour fire shutters.

Other openings

Internal or external wall wetting sprinklers as appropriate or construction

having an FRL of not les than /60/.

NB: any fire doors, fire windows or fire shutters must comply with

Specification C3.4.

Cl. C3.8 Doorways openings into the fire-isolated stairs must be fitted with door sets

having:

A fire resistance level not less than /60/30; and

Automatic or self-closing devices.

Trevor R Howse & Associates Pty Ltd

- 16 -

Cl. C3.9 The fire-isolated stairs must not be penetrated by any new building services

other than:

Water pipes for fire services (i.e. fire hydrants).

Wiring as permitted by clause D2.7(e).

Cl. C3.10 The lift landing doors must have a fire resistance level not less than /60/

Lift indicator panels greater than 35,000m

2

must also be fire rated to an FRL of

/60/60.

Cl. C3.11 Door openings to the sole occupancy units need be protected with self-closing

/60/30 fire doors.

Door from areas other than sole-occupancy units that open to public corridors.

need be protected with self-closing /60/30 fire doors.

Please advise if units AA6-1 has access to the stair to the west for egress.

We note that we may need to provide additional fire separation requirements for

units located in the north west corner of the development that currently appear to

have access to a single stair, as detailed within clause D1.4.

Cl. C3.12 New service openings through any floors in the building must be either fire

sealed or enclosed in a fire rated shaft, using materials having an FRL not less

than that of the floor concerned.

Cl. C3.13 Openings to shafts must be protected in accordance with the following:

For sanitary compartments a door or panel which together with the frame

is non-combustible or has an FRL of not less than /30/30; or

A /60/30 fire rated protective covering (i.e. access panels, or self-closing

doors and hoppers); or

For garbage shafts a door or hopper of non-combustible construction.

Cl. C3.15 Any services (mechanical ventilation, air conditioning, electrical etc) that pass

through the any wall required to have an FRL shall be protected by a prototype

device in accordance with AS 1530.42005 or as per Spec C3.15.

Cl. C3.16 Construction joints between fire resistant elements must be fire sealed with a

material having a fire resistance level not less than the elements being joined.

4 4. .4 4 S SE EC CT TI IO ON N D D A AC CC CE ES SS S A AN ND D E EG GR RE ES SS S

Cl. D1.3 Please advise what the door is for on the roof of the building at grid 12-13/E2

roof level, 2/2.

Please also clarify which areas of the roof are accessible.

The egress stair to building F3 appears to be a non-fire isolated stair. As such it

can only connect two stories. The stair currently connects 3 stories. 2 options are

available:

provide a separate entrance to the lower floor unit and remove the door that

connects it to the stair shaft; or

utilise a performance based solution to justify the connection of the third

floor. This would require smoke seals to the fire door to the unit on the

lowest level as well as a thermal detector within the unit linked to the smoke

detection system for the building.

Trevor R Howse & Associates Pty Ltd

- 17 -

Cl. D1.4 There are numerous travel distance non-compliances throughout the building (in

so far as exceeding 6 metres):

For level 8 the maximum distance to an exit is 6.6m, from unit D8.2.

For level 7 please advise if the stair to the west of units AA7-1 to AAA7-2 is

accessible. Same re units AA6-1 to 3 below.

On level 7, the maximum distance to an exit is 6.4m, from unit B7-2.

On level 6, the maximum distance to an exit is 6.4m, from unit DD6-4.

On level 5, the maximum distance to an exit is 6.4m, from unit C5-2.

On level 4, the maximum distance to an exit is 8m, from unit E4.1.

On level 3, the maximum distance to an exit is 8m, from unit E3.1.

On level 3 1/2, from units A3.1 to A 3.4, where is the 2

nd

exit from these

units, same re units A 2.1 to A 2.4, level 2-1/2.

Level 2, the maximum distance to an exit is 9m, from unit DD2-2

Please note that the door to the fire stair is missing level 2 near unit B2-1.

How is egress from units A01-A04 and A1- 1 achieved. There appears to be

an egress path in excess of 6m to a point of choice to 2 exits. Please discuss.

Note that the fire stairs are considered as the nearest exit.

Cl. D1.6 In terms of the dimensions of exits and paths of travel, the unobstructed

height of new doorways must not be less than 1980-mm, while the

unobstructed width must not be less than 750-mm.

Confirmation is also required that egress stairs and paths of travel will be a

minimum of 1m clear width.

Cl. D1.7 The fire stairs for the main foyers all discharge within the foyer area on the

lowest level and do not discharge directly to outside. As such this method of

discharge does not comply with the deemed-to-satisfy requirements as the foyer

areas are enclosed and thus the 2/3

rd

of the perimeter open concession available

in the BCA cannot be utilised.

As such is it proposed that a performance-based solution be sought in respect to

this issue. This should be discussed at a meeting with the architects.

We also note that egress from the southern foyers of the building appears to

require occupants to pass within 6m of the facade of the building. Please

comment as to whether egress is available in both an east and west direction via

an egress path that has a gradient not more than 1:8 or that has egress stairs

provided where the gradient exceeds 1:8.

Cl. D1.8 Please also advise what type of stair the stair at grid 2E is. It appears to be

designed as an external stair in lieu of a fire stair. Please clarify.

Cl. D1.10 The egress path from the Fig Tree Theatre to the street should not have a

gradient no more than 1:8, or have egress stairs provided, should the gradient

exceed 1:8. Please discuss.

All egress paths from the new parts of the building must also have an egress path

from the building to the street as per that required for the Fire Tree Theatre

above.

CL. D1.13 Please provide revised plans of the e-learning and retail area parts of the building

as noted on the plans submitted. We will then review re occupant load, toilet

facilities and egress.

Cl. D1.17 Where the depth of the lift pit is not more than 3m, access to the lift pit must be

through the lowest landing doors.

Where the pit depth is more than 3m access must be through an access doorway

complying with part (b) of this clause.

Trevor R Howse & Associates Pty Ltd

- 18 -

Cl. D2.2 Fire isolated stairways must be constructed:

Of non-combustible material; and

Such that local failure will not cause structural damage to the enclosing

shaft

Cl. D2.3 Non-fire isolated stairways and ramps must be constructed of either:

Reinforced concrete; or

6-mm thick steel; or

44-mm thick timber having an average density not less than 800 kg/m

3

at a

moisture content of 12%, and not joined by any formaldehyde based glues.

Cl. D2.4 The stairs from the carpark connect directly to the stairs from the residential

areas above. As such a performance based solution will be necessary to justify

this connection.

This will involve the provision of smoke seals to the carpark fire stair doors and

directional signage within the stair to ensure there is no confusion during egress.

Cl. D2.7 Electrical ducts, meter or distribution boards, and communication boards or

equipment, and electrical motors, must be separated from an exit or path of

travel by smoke sealed non-combustible construction.

Access to services and service shafts must not be via a fire stair.

Gas or fuel services must not be located within the egress stairs.

Cl. D2.8 Please indicate clearly on plans if it is proposed to create an enclosure beneath

any non-fire isolated stair within the development.

Please also note that enclosures under fire stairs are prohibited.

Cl. D2.13 Please ensure that stair treads will have a non-slip finish, and the going, riser and

steepness dimension of new stairs will be within the following range:

Riser 115-190-mm

Going 250-350-mm

Steepness 2R +G

No opening between risers shall permit a 125-mm sphere to pass through

between the treads.

Cl. D2.14 Landings must have the following characteristics;

Have a maximum gradient of 1:50; and

Have a non-slip finish throughout or an adequate non-skid strip near the

edge of the landing.

Cl. D2.15 A doorway may not incorporate a step at a point closer to the doorway than the

width of the door leaf, unless the door opens to a road, open space, external

balcony, or stair landing, and the step does not exceed 190mm.

Trevor R Howse & Associates Pty Ltd

- 19 -

Cl. D2.16 The following areas will be required to be provided with balustrading as the fall

indicated may be more than 1m and/or 4m.

The fire stairs will require balustrading with a rail at not more than 150mm

above the nosing of the tread then no gaps greater than 460mm between

rails, with the top rail not less than 865mm above the nosing of the treads.

If a landing in the fire stair exceeds 500mm, the top rail must be not less

than 1m above the floor of the landing.

The non-fire isolated stairs will require a balustrade not less than 865mm

high above the nosing of the treads with no gaps greater than 125mm. For

the landing of this stair, (greater than 500mm in length), the balustrading is

required to be a minimum of 1m in height with no gaps greater than

125mm. If the fall from the side of the stairs exceeds 4m at any point,

(measured from the landing floor), there shall be no climbable elements

between 150mm and 760mm above the floor of the landing.

For the balustrade to the balcony / terrace areas, where the fall is more than

1m but less than 4m the balustrade should be 1m high with no gaps greater

than 125mm. Where the fall from the floor to the ground level exceeds 4m

to the ground below, there shall be no climbable elements between 150mm

and 760mm above the floor.

Along any path or other trafficable area such as a roof, where the fall

exceeds 1m, a balustrade not less than 1m must be provided with no gaps

greater than 125mm.

For any window openings with sill heights less than 865mm and where the

fall from the sill exceeds 1m to the external part of the building a rail/s

must be installed to at a height not less than 865mm with no gaps greater

than 125mm.

Cl. D2.17 Handrails must be provided to at least one side of all stairways and ramps and

must:

Be continuous between stair flight landings; and

Have no obstruction that would cause a break in the hand hold; and

Have a rail fixed at a height not less than 865-mm.

Cl. D2.20 For the retail, laundry and e-library area the doors must be provided with a

device allowing them to be held in the open position.

Cl. D2.21 Doors must be provided with lever action hardware located 900-1200-mm above

the floor that does not require the use of a key to operate from the side seeking

egress, and involves a single handed downward or pushing action.

This is not applicable within the units, the retail area or laundries.

Cl. D2.23 Doors to the fire-isolated exits must be provided with signage stating,

FIRE DOOR

DO NOT OBSTRUCT

DO NOT HOLD OPEN

Doors discharging from fire-isolated exits must be provided with signage stating,

FIRE SAFETY DOOR

DO NOT OBSTRUCT

In each instance, the lettering must not be less than 20-mm high and be in a

colour that contrasts with the background.

Signage in respect to Clause 183 of the Environmental Planning and Assessment

Regulations 2000, Offences relating to fire stairs, must also be installed to the

outside face of the doors to the fire stairs.

Trevor R Howse & Associates Pty Ltd

- 20 -

Cl. D3.2 In terms of access for people with disabilities we note the following potential

non-compliances:

As there are a total of 304 sole-occupants units a total of 15.2 disabled

SOUs are required. Only 15 are provided on the plans. Please indicate the

location of a 16

th

unit.

Please indicate the gradients of the ramps on site that allow for access into

some of the residential foyers from the street, e.g. foyers AA, BB.

All doors to and within the access paths as well as to any common areas,

retail, laundries and e-learning all need to be a minimum of 800mm clear

width. This will required 870mm door leafs to be installed.

Certification will be required that all bathrooms have been designed as per

AS 1428.1 as insufficient detail is provided on the plans. However we note

that the size of the facility indicated is compliant with the requirements of

AS 1428.1.

How is foyer DD accessed as there appear to be stairs to both sides and

access is needed to unit DD6-5, level 6-2/2? Please plot the proposed

access path including gradients.

Please plot the access from the various foyers that are required to be

accessible to the retail/laundry/e-learning facilities including gradients.

Please advise how foyer E is access re unit E1.2.

Disabled access unit FF1.1 does not comply as the front door is not AS

1428.1 compliant. Please reconfigure.

Please advise how foyer C is accessed.

Unit CC0-10 has no front door indicated. Please add. Also north west bed

is not accessible as has no 470mm clearance to latch side of the door.

Please advise how foyers AA and BB are accessed.

North west bed of unit E4-3, level 4-2/2 is not accessible as has no 470mm

clearance to latch side of the door. Also has no disabled WC indicated.

North west bed of unit E3-3, level 3-2/2 is not accessible as has no 470mm

clearance to latch side of the door.

North west bed of unit E2-2, level 2-2/2 is not accessible as has no 470mm

clearance to latch side of the door. Also has no disabled WC indicated.

The door to the disabled bathroom of unit FF1-1, level 1-2/2, does not

appear to have a 470mm nib to the latch side of the door.

We will review disabled access to the retail, laundries and e-learning once

the revised plans are received.

Cl. D3.5 The disabled carspaces must be a minimum of 2.5m clear height and the path to

the spaces from the street must be a minimum of 2.3m clear height, as per AS

2890.1. Signage is also required to the disabled spaces as per AS 2890.1.

Cl. D3.6 AS 1428.12001 compliant International Symbols of Access and Braille signage

must be provided to the disabled sanitary facility as well as to indicate the

disabled accessible lifts to enable their locations to the identified.

Trevor R Howse & Associates Pty Ltd

- 21 -

Cl. D3.8 Type B tactile indicators must be provided to the top and bottom of the non-fire

isolated stairways. They may also be required to the ramps depending on their

proposed gradients. We will comment once the access paths are clarified.

4 4. .5 5 S SE EC CT TI IO ON N E E S SE ER RV VI IC CE ES S A AN ND D E EQ QU UI IP PM ME EN NT T

Cl. E1.3 AS 2419.12005 compliant fire hydrant coverage must be provided throughout

the building.

If a hydrant pump room is to be provided it must be fire rated with construction

achieving a fire resistance level of 120/120/120. The door into the room should

be a /120/30 self-closing fire door.

Cl. E1.4 AS 24412005 compliant fire hose reel coverage must be provided throughout

the area of the proposed works.

Please ensure that the fire hose reels are within 4-metres of the exit and do not

need to pass through any fire or smoke doors to cover the floor plate (other than

doors to units).

Cl. E1.5 AS 2118.11999 sprinkler coverage is required to the carpark. In addition any

sprinkler system must comply with specification E1.5 and any sprinkler valve

room must be located at a level where direct access to a road is available, as such

locating it within the carpark area does not comply with the deemed-to-satisfy

provisions of the BCA.

If the location must be within the carpark a performance-based solution is

required, this will also need fire brigade approval.

Cl. E1.6 AS 24442001 compliant portable fire extinguishers must be provided;

Within any retail kitchen to cover Class F fire risks, or where more than

50-litres of combustible liquid is stored (i.e. cooking oils);

To cover Class AE or E fire risks associated with emergency switchboards.

Cl. E1.9 Fire precautions during construction must be undertaken in respect to the

provision of fire extinguishers, hose reels and hydrants at the relevant stages of

construction. Certification to be provided at Construction Certificate stage.

Cl. E2.2a The proposed building must be provided with:

Automatic shut-down of any air handling system that recycles air between

fire compartments, and that does not form part of a smoke exhaust system,

on activation of AS/NZS 1668.11998 Clause 4.10 smoke detectors, and

incorporating smoke and fire dampers where penetrating firewalls; and

An automatic smoke detection and alarm system in accordance with AS

1670.12004 except for Clause 3.26(f), and needs to activate a building

occupant warning system in accordance with Clause 6 as well as be linked

to a monitoring station as per AS 1670.3.

The carpark must be designed to have a mechanical ventilation system in

accordance with AS 1668.2 1991 as well as clause 5.5 of AS 1668.1

1998. In addition note that fans with metal blades suitable for operation at

normal temperature may be used and the electrical power and control

cabling need not be fire rated.

Cl. E3.2 As the building is more than 12m in height each unit within the building must

have access to a lift that has minimum internal dimensions of not less than 2m

long x 600mm wide for stretcher use.

Trevor R Howse & Associates Pty Ltd

- 22 -

Cl. E3.3 Warning signage DO NOT USE LIFTS IF THERE IS A FIRE will be required

adjacent to every lift call button with dimensions as detailed in this clause.

Cl. E3.6 As disabled access is required to the building all lifts must be provided with

disabled controls as per AS 1735.121999.

Cl. E3.7 All lifts are required to be provided with fire services controls as per AS 1735.1

2003 or AS 1735.22001.

Cl. E4.2 AS 2293.12005 compliant emergency lighting must be provided throughout the

proposed building.

Cl. E4.4 Refer Clause E4.2 above for emergency lighting requirements.

Cl. E4.5 AS 2293.12005 compliant exit signage must be provided over each of the exit

doors.

It need be noted that the most recent amendment to the applicable standard

requires the installation of the pictorial running man symbol in lieu of the

word EXIT.

Cl. E4.6 AS 2293.12005 compliant directional exit signage must be provided throughout

the building to direct occupants to the exits.

Cl. E4.8 Refer Clauses E4.5 and E4.6 above for exit signage requirements.

Cl. E 4.9 An EWIS system is required to the building as per AS 16780.4 2004 and AS

4428.4 2004. Note that EWIS is not required to the single storey buildings.

4 4. .6 6 S SE EC CT TI IO ON N F F H HE EA AL LT TH H A AN ND D A AM ME EN NI IT TY Y

Cl. F1.1 Stormwater drainage must be AS/NZS 3500.3.22003 compliant.

Cl. F1.5 The roof material is not indicated on the plans. As such please indicate the type

of roofing material proposed to all parts of the building.

Cl. F1.6 Please certify that sarking will be installed to roof and walls for weatherproofing

as per AS/NZS 4200.1 and 2 - 1994.

Cl. F1.7 Wet areas must be water proofed in accordance with AS 37402004.

Cl. F1.9 Please certify that damp proofing will be provided as per this clause and AS

2904 1995 or AS 3660.1 - 2000.

Cl. F1.10 Please certify that damp proofing will be installed as per AS 2870 2003.

Cl. F1.11 Each bathroom/laundry area needs to be graded to permit drainage to a floor

waste.

Cl. F1.13 Refer Clause B1.4 above for the glazing in external walls

Cl. F2.3

& Cl.

F2.4

A disabled toilet facility need be provided for staff within the retail and e-

learning areas. This will be assessed once the revised plans for this area are

provided. Please also note that doors to a disabled WC must either open out or

be fitted with removable hinges to allow ease of removal.

Trevor R Howse & Associates Pty Ltd

- 23 -

Cl. F2.5 Where sanitary facilities are to be wholly enclosed, and the distance between the

WC pan and the nearest part of the doorway is less than 1200-mm, the doors

must either swing out, be fitted with removable hinges, or slide.

There are numerous toilets within the units of the building that do not comply

such as:

1. unit F1-3, level 1-2/2.

2. unit E1-3, level 1-2/2.

Please note that due to the large number of non-complying WCs we have not

listed them all.

Where doors to toilet cubicles are to be less than full height the doors must be a

minimum of 1.8m above the ground.

C1. F4.2 Please provide a window and door schedule for the openings within the external

faade so that we can undertake an assessment of the level of compliance of

natural lighting to the building for the residential units as the 1:200 scale

elevations provided are not detailed enough to allow for an accurate assessment

of compliance to be undertaken.

Cl. F4.4 Artificial lighting must be AS 1680.01998 compliant.

Cl. F4.5 Ventilation to rooms and spaces must be either natural or AS 1668.21991

compliant mechanical ventilation.

Cl. F4.6 Where natural ventilation is to be provided to rooms the openable size of the

window or opening need be not less than 5% of the floor area of the room being

ventilated. This will be assessed once the window and door schedule is provided.

Please also clarify whether 50% of the window area provided is openable.

Cl. F4.11 The carpark must be provided with either natural ventilation or mechanical

ventilation as per AS 1668-2 1991.

Cl. F4.12 Where the caf and kitchen contains either:

A cooking apparatus with a total electrical input exceeding 8 kW, or a total

gas input exceeding 29 MJ /hr; or

A total electrical input exceeding 0.5 kW/m

2

, or a total gas input exceeding

1.8 MJ /m

2

;

an AS/NZS 1668.1 1998 and AS 1668.2 1991 compliant kitchen exhaust

hood must be provided.

Cl. F5.3 Please provide certification from an acoustic engineer that the floor of the

building required to have an impact sound insulation rating will:

1. have the required value for weighted normalised impact sound pressure

level with spectrum adaptation term (L

n,w

+C

1

) determined in

accordance with AS/IOSO 717.2 using results from laboratory

measurements; or

2. comply with Specification F5.2.

Please provide certification from an acoustic engineer that the walls of the

building required to have an impact sound insulation rating will be of

discontinuous construction as defined in this clause.

Trevor R Howse & Associates Pty Ltd

- 24 -

Cl. F5.4 The floor of the suites need have an R

w

+C

r

(airborne) of not less than 50 and an

L

n,w

+C

1

(impact) not more than 62 if it separates sole-occupancy units or a sole-

occupancy into from a plant room, lift shaft, stairway, public corridor, public

lobby or the like or different classifications.

Cl. F5.5 The wall between units need to have an R

w

+C

r

(airborne) of not less than 50 and

an R

w

(airborne) of not less than 50 if it separates sole-occupancy units or a sole-

occupancy into from a plant room, lift shaft, stairway, public corridor, public

lobby or the like or different classifications.

Where the wall separates bathrooms, sanitary compartments, laundries or

kitchens in one unit from a sleeping area in another the walls will need be

discontinuous construction as per clause F5.3(b).

The door assembly of the suites need have an R

w

not less than 30

Cl. F5.6 Please provide certification from an acoustic engineer that any services will be

sound insulated as per Clause F5.6 of BCA 2006.

Cl. F5.7 Flexible coupling need be used at the point of connection of service pipes and

circulating pumps.

4 4. .7 7 S SE EC CT TI IO ON N G G A AN NC CI IL LL LA AR RY Y P PR RO OV VI IS SI IO ON NS S

Cl. G1.01 Provision for cleaning of external windows must be provided either by

complying with a method within the Occupational Health and Safety Act 2000

and its Regulation or the windows must be able to be cleaned from the inside.

4 4. .8 8 S SE EC CT TI IO ON N J J E EN NE ER RG GY Y E EF FF FI IC CI IE EN NC CY Y

Cl. J1.2

(A)

Please provide certification that insulation (if required to achieve compliance

with the Part J 1 of the BCA) will comply with AS/NZS 4859.1 2002, and be

installed so that it

1. abuts or overlaps adjoining insulation (other than at supporting members,

e.g. studs, noggings, joists, furring channels, etc where the insulation must

abut against the members) and

2. forms a continuous barrier with ceilings, walls, bulkheads, floors or the

like that inherently contribute to the thermal barrier; and

3. will not affect the safe or effective operation of a service or fitting.

Cl.

J1.2(B)

Please provide certification that reflective insulation (if required to achieve

compliance with the Part J 1 of the BCA) will be installed within

1. the necessary air space to achieve the required R-Value between a reflective

side of the reflective insulation and a building lining or cladding; and

2. the reflective insulation closely fitted against any penetration, door, or

window opening; and

3. that the reflective insulation will be adequately supported by framing

members; and

4. that each adjoining sheet or roll membrane will be overlapped more than

50mm or taped together.

Cl.

J1.2(C)

Please provide certification that bulk insulation (if required to achieve

compliance with the Part J 1 of the BCA) will be installed so that

1. it maintains its position and thickness (other than where it crosses roof

battens, water pipes, electrical cabling or the like; and

2. that (in a ceiling where there is no bulk insulation or reflective insulation in

the wall beneath), that it will overlap the wall by more than 50mm.

Trevor R Howse & Associates Pty Ltd

- 25 -

Cl.

J1.2(D)

Note : roof, ceiling, wall and floor materials and associated surfaces are deemed

to have the thermal properties listed in Specification J 1.2.

Cl. J1.3

(A) (C)

Please provide certification that the roof or ceiling that is part of the

ENVELOPE of the new works will achieve the total R-Value specification in

table J1.3 for the direction of heat flow. Please note that this development is

within climate zone 5.

Cl.

J1.3(D)

Metal roofs only.

Please certify that the any metal roofs, due to being required to achieve a

minimum Total R-Value, and having metal sheet roofing fixed to metal purlins,

rafters or battens and not having a ceiling lining or having a ceiling lining fixed

directly to the metal purlins, rafters or battens will have:

a thermal break consisting an R-Value of not less than 0.2 installed between

the metal sheet roofing and its supporting member.

Cl.

J1.3(E)

Please note the thermal properties of various roof and ceiling construction for

use for calculation of R-Values.

Cl.

J1.5(A)

(A) Provide certification that each part of the external wall that is part of the

envelope will comply with one of the options in Table J 1.5a or table 1.5b.

Cl.

J1.5(E)

(E) Please provide certification that the metal framed wall (required to achieve a

Total R-Value)that has lightweight external cladding such as weatherboard,

fibre cement or metal sheeting (and does not have a wall lining or where the

wall lining is fixed directly to the frame) will have:

a thermal break installed between the metal frame and the external cladding

and consists of a material with an R-Value of not less than 0.2.

Note Specification J 1.5 which contains wall construction thermal properties.

Cl. J2.1 Please note the exemptions in the application of part for class 7,8,9b, atrium and

solariums.

Cl. J2.3

Class 3

An aggregate conductance and solar heat gain must be undertaken for the

glazing in each storey of a sole-occupancy unit, public space or other occupied

space and must not exceed specified allowances.

AGGREGATE CONDUCTANCE

To allow for an assessment to be undertaken please provide the following

information for conductance:

The area of each section of glazing within each storey of the building. This

should be in the form of a window schedule that indicates the area of the

glazing only as well as the location of each window.

The Total U-Value for each glazing element proposed. The Total U-value

for the glazing is the thermal resistance in units of W/m

2

K. This

information would be available from your glazing supplier.

The floor areas for each room within the units, as well as for each public

space or occupied space individually tabulated.

Trevor R Howse & Associates Pty Ltd

- 26 -

Cl. J2.3

contd

AGGREGATE SOLAR HEAT GAIN

To allow for an assessment to be undertaken please provide the following

information for solar heat gain:

The solar exposure factor for each glazing element. This is obtained from

table J 2.3(b). To calculate the solar exposure factor the P/H number will

also need to be calculated using figure J 2.4. Alternatively if you wish this

office to calculate the solar exposure factor please provide detailed

sectional views of the building through each side of the building as a

minimum so that eaves and balcony overhang dimensions may be

calculated. If shading devices are proposed please provide details of each

shade structure.

Provide the Solar Heat Gain Coefficients (SHGC) for each piece of glazing

proposed. This can only be obtained from the supplier of the glazing.

Alternatively if the above information is not available at this stage of the

development process compliance with this clause of the BCA may be

undertaken at the Construction Certificate stage when all information is

readily available.

Cl. J2.3

or Cl.

J2.4

Class 6

building

< 500m

2

.

See either J 2.3 of J 2.4

Cl. J2.4

Classes 6 and 9b

Note that this clause is only applicable to air-conditioned parts of the

building.

The glazing in each storey of the building and facing each orientation must be

assessed to determine the aggregate air-conditioning energy value to ensure that

it does not exceed the allowance obtained by multiplying the area of the faade

(orientation) by the energy index (see table J 2.4(a).

Please provide the following information for each window within the building:

The area of each section of glazing within each storey of the building. This

should be in the form of a window schedule that indicates the area of the

glazing only as well as the location of each window.

Provide the Solar Heat Gain Coefficients (SHGC) for each piece of glazing

proposed. This can only be obtained by the supplier of the glazing.

The Total U-Value for each glazing element proposed. This can only be

obtained by the supplier of the glazing.

The energy constants A, B and C. these are calculated using Table J 2.4(b). For

each window you first work out which way it is facing then note which climate

zone it is within. For this project the development is proposed within climate

zone 5.

Trevor R Howse & Associates Pty Ltd

- 27 -

Cl. J2.4

contd

The heating shade multiplier for each glazed element (taken from table

J 2.4(c). This is a calculated as follows:

First calculate G in the table. It is the height that the shading

element is located above the top of the window/door head.

P is the length the shade part of the building that extends horizontally

to protect each opening. H is the height of the specified window. Thus

P/H plus the orientation of the window (north south east west etc)

allows you to calculate the heating shade multiplier by using table

J 2.4(c).

The cooling shading multiplier for each glazed element (taken from table

J 2.4(d). This is calculated as follows:

Take figures G and P/H from the above calculations. Then review the

orientation within table 2.4(d) to determine the figure for the cooling

shading multiplier.

Alternatively the energy constants, heating shading multiplier and cooling

shading multiplier can be calculated by this office to determine if compliance is

achieved.

To determine if compliance is achieved the aggregate air-conditioning energy

value attributable to the glazing must not exceed the allowance obtained by

multiplying the faade area of the orientation by the energy index in table

J 2.4(a). Note that where the air-conditioning energy value of a glazed

element is less than zero the value must be taken as zero.

Alternatively if the above information is not available at this stage of the

development process compliance with this clause of the BCA may be

undertaken at the Construction Certificate stage when all information is

readily available.

Cl. J2.5 Where a non-compliance occurs with respect to clauses J 2.3 or J 2.4 additional

shading of the openings will be required to be provided to achieve compliance.

The requirement for any additional shading can only be confirmed once the

compliance status of clauses J 2.3 and J 2.4 are known.

Cl. NSW

J3.1

Note: this section is not applicable in any parts of the building that are provided

with evaporative cooler air-conditioning only. It is also not applicable to the e-

learning area of retail area if no air-conditioning is provided or to a part of a

building where the mechanical ventilation required by Part F4 of the BCA

provides sufficient pressurisation to prevent air infiltration.

Cl. J3.4 Please provide certification that a seal to restrict air infiltration will be fitted

to each edge of a door, openable window or the like . The seal must be

either a foam seal , rubber compressible strip seal or fibrous seal (to restrict

the air infiltration) where to an openings that serves

a conditioned space.

Note that the above requirements do not apply to:

a window complying with AS 2047; or

a louvre door, louvre window or other such opening; or

fire door; or

a roller shutter door, roller shutter grille or other security door or device.

Please provide certification that the main entrance to the building (if leading

to a conditioned space) will be fitted with a self-closing door.

Trevor R Howse & Associates Pty Ltd

- 28 -

Cl. J3.5 Please provide certification that a miscellaneous exhaust fan (such as a

bathroom or domestic kitchen exhaust fan) will be fitted with a sealing device

such as a self-closing damper of the like when serving:

a conditioned space.

Cl. J3.6 Please provide certification that roofs, walls, floors and any openings such as

windows and doors will be constructed to minimize air leakage as detailed

below:

construction must provide for enclosure by internal lining systems that are

close fitting at ceiling, wall and floor junctions; or

by the sealing using caulking, skirting, architraves, cornices or the like.

Cl. J3.7 Please provide certification that any evaporative cooler will be fitted with a self-

closing damper when serving a heated space.

Cl. J5.2 Please provide certification that the air-conditioning system/unit will be capable

of :

being inactivated when the sole-occupancy unit, building or part of building

is not occupied; and

where the air-conditioning unit/system has motorized outside air and return

dampers, that the dampers will close when the air-conditioning unit/system

is inactivated.

having any supply and return ductwork insulated and sealed as per

Specification J 5.2.

when serving more than one sole-occupancy unit, air-conditioning

zone or areas with different heating and cooling needs

thermostatically control the temperature of each sole-occupancy unit,

zone or area; and

not control the temperature by mixing actively heated air and actively

cooled air; and

limit reheating to not more than 7.5K rise in temperature at the supply

rate for the space served and may be increased or decreased at the

same rate that the supply air rate is respectively decreased or

increased.

in a class 3 building be capable of controlling the temperature of a sole-

occupancy unit at a different temperature during sleep periods than other

periods.

when the air flow exceeds 1000L/s, be designed so that the total motor shaft

power of the fans in the system does not exceed

12 W/m

2

for a building not more than 500m

2

; or

15W/m

2

for a building more than 500m

3

.

Note that the requirements of (6) above are not applicable to

fans in package A/C plant complying with clause J 5.4(c); and

the input power for an energy reclaiming system that pre conditions

outdoor air; and

the input power for process related components such as high

efficiency particulate air filters.

Trevor R Howse & Associates Pty Ltd

- 29 -

Cl. J5.2

(cont.)

Please certify that any mechanical ventilation system:

will be capable of being inactivated when the building is not

occupied; and

when serving a conditioned space not provide mechanical ventilation

in excess of the minimum quantity required by part F4 by more than

50% other than where there is :

additional unconditioned outside air supplied to provide free

cooling or to balance required exhaust ventilation such as

toilet exhaust or to balance process exhaust such as from as

health care building or laboratory.

Additional exhaust ventilation needed to balance the required

mechanical ventilation; or

An energy reclaiming system that pre-conditions outside air.

Provide certification that where a mechanical ventilation system has an

airflow rate of more than 1000m

2

:

will have a fan motor shaft power to air flow rate ratio or fan motor

input power to air flow rate ratio in accordance with Table J5.2; and

ilation system Please provide certification that the mechanical vent

(when serving more than 40 spaces in a carpark)

will be controlled by an atmospheric contaminant monitoring system

in accordance within AS 1668.2; and

maintain an average minimum air change rate of 0.5 air changes per

hour other than when the carpark is not occupied for a period of more

than 2 hours.

inhibit

Provide certification that the requirements of items 1 to 9 above will not

any smoke hazard management operation of air-conditioning and

mechanical ventilation systems; and

essential ventilation such as for a garbage room, lift motor room, gas

meter enclosure or gas regulator enclosure or the like.

Cl. J5.3 Please certify that a time switch in accordance with specification J 6 will be

provided to control each of the following:

an air-conditioned system of more than 10kWr; and/or

a ventilation system with an air-flow rate of more than 1000L/s; and/or

heating systems of more than 10Kw

heating

.

Cl. J5.4

(A)

Please provide certification that systems providing heating or chilling for air-

conditioning systems will

have any piping, vessels, heat exchangers or tanks containing heated or

chilled fluid insulated in accordance with Specification J 5.4 (other than

those covered by Minimum Energy Performance Standards MEPS); and

where water is circulated by pumping at 2L/s

be designed so that the total of the motor shaft power to the air-

conditioning pump does not exceed:

2

3W/m for a building not more than 500m

4W/m

2