Professional Documents

Culture Documents

Hazards & Risk Assessment Guide

Uploaded by

gad480Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hazards & Risk Assessment Guide

Uploaded by

gad480Copyright:

Available Formats

Hazards Identifcation & Risk Assessment

Hazards

Identifcation

&

Risk

Assessment

Procedures

Guide

KHALDA Petroleum Company Page 1

Re !"# $!!%

Hazards Identifcation & Risk Assessment

Document No.

KPC/HSE/S/!."#/$""%

August 2009

Distri&ution 'ist

Co() * Ho+der

1 C&airman & 'D

$ (eneral 'anager & 'D

" )peration (eneral 'anager

* Deputy )peration (eneral 'anager

+ ,inance (eneral 'anager

- Deputy ,inance (eneral 'anager

. /0ploration (eneral 'anager

% Deputy /0ploration (eneral 'anager

1 Pro2ect (eneral 'anager

1! Deputy Pro2ect (eneral 'anager

11 Administration (eneral 'anager

1$ (as )peration (eneral 'anager

1" H3/ (eneral 'anager

1* Deputy (as )peration (eneral 'anager

1+ ,ield (eneral 'anager

1- (as Plant (eneral 'anager

1. (as Plant Deputy (eneral 'anager

1% Deputy ,ield (eneral 'anager

11 4'5ARKA ,ield (eneral 'anager

$! 6arek ,ield 'anager

$1 Production (eneral 'anager

$$ Deputy Production (eneral 'anager

$" 'aintenance (eneral 'anager

KHALDA Petroleum Company Page $

Re !"# $!!%

Hazards Identifcation & Risk Assessment

$* Drilling (eneral 'anager

$+ Deputy Drilling (eneral 'anager

$- Contracts (eneral 'anager

$. Deputy Contracts (eneral 'anager

$% ,ield H3/ A('

$1 Internal Audit (eneral 'anager

Re,ision Records

Re,ision No. Date Descri(tion o-

C.an/e

A April $!!. Dra7t 7or reie8

1 9uly $!!. Issue 7or use

$ :oem;er $!!% 3econd issue

6&e custodian o7 t&is procedure is t&e H3/

(eneral 'anager and any suggested c&anges to

t&is procedure or <ueries a;out t&e applica;ility

o7 it s&ould ;e addressed to &im=

KHALDA Petroleum Company Page "

Re !"# $!!%

Hazards Identifcation & Risk Assessment

He is also responsi;le 7or co>coordinating

periodic reie8s o7 t&is procedure? 8&ic& 8ill

take place eery t8o years=

Contents

#." P0RP1SE AND 123EC4I5ES !

$." DE6INI4I1NS 7

$.# Genera+ -

$.$ Res(onsi&+e 3o& 4it+es .

8." R1'ES AND RESP1NSI2I'I4IES %

8.# C.airman & D and Genera+ ana/er & D %

8.$ Genera+ ana/ers 1

8.8 'ine ana/ers 1

8.9 'ine Su(er,isors 1!

8.! Ro+e o- t.e HSE Genera+ De(artment 1!

9." 61R0'A4ING 4HE 4EA #"

!." RISK SCREENING AND ASSESSEN4 PR1CESS #$

!.# Identi-) t.e Hazards 1"

KHALDA Petroleum Company Page *

Re !"# $!!%

Hazards Identifcation & Risk Assessment

!.$ E,a+uate t.e Risks 1*

!.8 Ana+)se t.e Risks 1*

!.9 Reduce / Contro+ Risk 1-

!.! Record t.e 6indin/s 1.

!.7 onitor and Re,ie: 1.

7." APPENDI; /RR)R@ 5))K'ARK :)6 D/,I:/D=

#." P0RP1SE AND 123EC4I5ES

6&is procedure coers all actiities o7 KHALDA? including

contractorAs personnel 8orking 7or KHALDA= Contractors 8it&

t&eir o8n H3/ arrangements must also comply 8it& t&is procedure

as a minimum=

It &as ;een deeloped to ac&iee compliance 8it& t&e H3/

'anagement 3ystem o7 Apac&e Corporation and /(PC

Regulations=

6&e purpose o7 t&is procedure is to ensure t&at all staB in KHALDA

operations or oCces are a8are o7? and understand? t&e importance

o7 t&eir responsi;ilities 7or &azard identifcation? risk assessment

and risk control 8it& respect to &ealt&? sa7ety and enironmental

management=

/Bectie risk control 8ill ena;le KHALDA to minimize t&e 7re<uency

and seerity o7 accidents#incidents and ill &ealt&? and minimize t&e

enironmental impact o7 its actiities=

6&e o;2ecties o7 t&is procedure areD

1. to proide a consistent approac& to H3/ &azard and

risk management

t&roug&out all actiities o7 t&e Company in order to

minimize H3/ risksE

KHALDA Petroleum Company Page +

Re !"# $!!%

Hazards Identifcation & Risk Assessment

2. to proide a structured process 7or H3/ risk

screening? assessment and

control=

$." DE6INI4I1NS

$.# Genera+

Hazard 3omet&ing 8it& t&e potential to

cause &arm? loss or enironmental

impact? 8&et&er ;y in2ury? illness or

damage=

Pro&a&i+it) 6&e +ike+i.ood o7 a &azard ;eing

realized=

Hazard E<ect 6&e e0tent o7 t&e conse=uences

FseerityG? 8&ic& could result 7rom

t&e &azard ;eing realized=

Risk Risk is t&e product o7 t&e pro;a;ility

and t&e &azard eBect=

Si/nifcant Indicates t&at a &azard or risk is

anyt&ing ot&er t&an triial=

KHALDA Petroleum Company Page -

Re !"# $!!%

Hazards Identifcation & Risk Assessment

Si/nifcant Risk )ne 8&ic& re<uires some 7orm o7

positie sa7eguard or control

measure to eliminate? or reduce it

to an accepta;le leelE

Contro+ easure A precautionary measure? 8&ic&

preents or reduces a risk= Control

'easures can include p&ysical?

procedural? and &uman systems=

$.$ Res(onsi&+e 3o& 4it+es

6&is procedure coers all KHALDA operations? including actiities in

oCces? 8are&ouse premises and in t&e feld= As t&ese operations

8ill &ae diBering organizational structures? it is necessary to use

generic terms 7or t&e personnel &aing responsi;ilities 7or risk

screening and assessment=

In order to proide clarity? t&ese generic terms are defned ;elo8

8it& e0amples= ,urt&er guidance may ;e o;tained 7rom t&e H3/

(eneral Department i7 re<uired= In certain locations? all o7 t&e

leels o7 superision descri;ed in t&is procedure may not ;e in

place and t&e same person may? t&ere7ore? &ae more t&an one

set o7 responsi;ilities=

All personnel are responsi;le 7or 8orking 8it& due regard to

&ealt&? sa7ety and t&e enironment? especially t&ose 8it&

responsi;ility 7or ot&ers? e=g=

KHALDA Petroleum Company Page .

Re !"# $!!%

Hazards Identifcation & Risk Assessment

'ine Su(er,isor> 6&e immediate superisor o7 t&e

personFsG 8&o 8ill per7orm t&e

actiities 7or 8&ic& t&e risk screening

and assessment is ;eing conducted=

'ine ana/er> 6&e manager o7 t&e site # department

8&ere t&e risks o7 t&e actiity are ;eing

screened and assessed e0ample? drilling

manger? maintenance manger?

transportation? general serices and

medical=

Genera+ ana/er> 6&e manager o7 t&e releant Diision 7or

t&e actiities ;eing considered e0ample?

operations? pro2ects? e0ploration?

contracts and administration=

8." R1'ES AND

RESP1NSI2I'I4IES

8.# C.airman & D/ Genera+ ana/er &

D

6&e C&airman and 'D and (eneral 'anager & 'D s&all ensure

t&at H3/ risk screening and assessments are carried out 7or all

actiities conducted ;y t&e (eograp&ical 4nit=

6&ey s&all ensure t&at actions and controls arising 7rom t&e

assessments are implemented=

6&ey s&all also ensure t&at suita;le and ade<uate resources o7

7unding and personnel are made aaila;le to conduct t&e H3/

KHALDA Petroleum Company Page %

Re !"# $!!%

Hazards Identifcation & Risk Assessment

risk assessments? to implement actions and controls arising 7rom

t&e assessments and 7or training o7 personnel=

8.$ Genera+ ana/er?s

/ac& (eneral 'anager s&ould initiate and lead a Hig& Leel Risk

3creening e0ercise 7or all ongoing Departmental actiities on an annual

;asis= Additionally? &e s&ould ensure t&atD

H3/ risk screening and assessments are conducted 7or all intended

actiities 8it&in

t&eir remit prior to per7orming t&e actiity=

All controls and actions arising 7rom suc& H3/ risk screenings and

assessments?

including procedures? are deeloped and implemented? and

monitor t&e progress

o7 implementation=

H3/ risk screening and assessment o;2ecties and targets are

set annually 7or all

personnel in t&eir Diision=

Line managers#superisors are 7ulflling t&eir responsi;ilities in

accordance 8it& t&e

procedure in &and=

All appropriate company and contractor personnel understand all

controls?

procedures and precautions 8&ic& apply to t&e actiities to ;e

carried out and are

trained as necessary=

8.8 'ine ana/er?s

KHALDA Petroleum Company Page 1

Re !"# $!!%

Hazards Identifcation & Risk Assessment

'ine ana/ers s&allD

Initiate and ensure t&e Risk screening#assessment is conducted

prior to any actiity under t&eir responsi;ilityE

,ormulate a team? including a mem;er 7rom H3/? to conduct t&e

re<uired Risk screening# assessment e0ercise 7or all actiitiesE

Participate in t&e e0ercise conducted 7or all ongoing departmental

actiities on annual ;asis=

,ollo8 up t&e deelopment and implementation o7 re<uired

controls=

8.9 'ine Su(er,isors

'ine Su(er,isors are re<uired toD

Lead task specifc risk assessment

Deelop and implement controls

Participate in risk screening teams

Report any impediments to Line 'anagerAs

8.! Ro+e o- t.e HSE Genera+ De(artment

In addition to t&e responsi;ilities descri;ed a;oe? t&e HSE

Genera+ De(artment 8ill also ;e responsi;le 7or proiding

assistance and#or adice in t&e 7ollo8ing areasD

Deeloping t&e scope o7 H3/ risk screening and assessmentsE

Incorporating releant risk screening and assessments into

Department annual 8ork plansE

Participating as re<uired in H3/ risk screening and assessments and

adising on t&e suita;ility o7 control measures and t&eir

implementationE

KHALDA Petroleum Company Page 1!

Re !"# $!!%

Hazards Identifcation & Risk Assessment

Reie8ing any 8ork produced ;y e0ternal consultants on ;e&al7 o7

t&e commissioning DepartmentE and

Assisting 8it& t&e preparation or reie8 o7 specifc procedures? H3/

plans or ;riefng documentation=

9." 61R0'A4ING 4HE 4EA

9.# Hi/. 'e,e+ Risk Assessment

Hig& Leel Risk Assessment s&ould ;e conducted 7or

all departmental actiities= A risk screening e0ercise o7

all departmental actiities is to ;e conducted on an

annual ;asis=

:eert&eless? ma2or actiities e=g=? pro2ect

modifcationsE seismic sureys? construction? drilling?

etc=? re<uire separate risk screening e0ercise prior to

t&e initiation=

6&e line manager s&ould plan t&e e0ercise ;y splitting

t&e 2o; into discrete su;>actiities and identi7ying t&e

re<uired e0pertise in t&e team? 8&ic& 8ill ;e doing t&e

assessment=

In general? t&ese &ig& leel risk assessment teams

s&ould ;e led ;y t&e department general manager and

include line manager and line superisor o7 t&e

proposed actiity along 8it& a mem;er o7 t&e H3/

(eneral Department and any ot&er e0pertise t&at is

t&oug&t necessary=

9.$ 4ask Re+ated Risk Assessment

6ask related risk assessments include specifc actiities

e=g= scaBold erection? material &andling?

loading#oHoading? transportation etc?==

6&e line manager in t&is case s&ould 7ormulate a team

led ;y t&e superisor o7 t&e specifc actiity and

including a mem;er o7 t&e H3/ (eneral Department

along 8it& any;ody specifc to t&e task i7 deemed

necessary=

KHALDA Petroleum Company Page 11

Re !"# $!!%

Hazards Identifcation & Risk Assessment

!." RISK SCREENING AND ASSESSEN4

PR1CESS

Risks arise 7rom t&e interaction o7 people? e<uipment?

materials and t&e 8ork enironment= 6&e intent o7 t&e

risk screening and assessment process is to

systematically identi7y t&e &azards? t&eir pro;a;ility o7

occurrence and t&eir potential conse<uences? screen

and assess t&e risks? deelop and implement control

measures 8&ic& minimize t&e risk? and record t&e

fndings o7 t&e process=

6&e process addresses t&ree 7undamental <uestionsD

FaG I&at can go 8rong and &o8 o7ten J

i.e. identi7y t&e .azards and t&e +ike+i.ood o7

occurrence=

F;G I&at 8ould &appen i7 somet&ing did go 8rong J

i.e. identi7y t&e conse=uences=

6&e product o7 t&e ans8er to t&ese frst t8o <uestions

esta;lis&es t&e initial potential risk 7rom t&e actiity=

FcG I&at can ;e done to preent or minimize t&is

risk J

i.e. identi7y and implement t&e contro+

measures needed=

6&e Risk 3creening and Assessment process consists o7

fe essential

stepsD

- Identi7y t&e Hazards

- /aluate t&e Risk

- Analyze t&e Risk

- Reduce#Control t&e Risk

KHALDA Petroleum Company Page 1$

Re !"# $!!%

Hazards Identifcation & Risk Assessment

- Record and Reie8

/ac& step o7 t&e assessment process s&ould ;e

completed ;e7ore

going onto t&e ne0t=

!.# Identi-) t.e Hazards

6&is is t&e starting point 7or t&e risk assessment and re<uires

consideration o7 all t&e tasks t&at are likely to ;e carried out=

In order to assess t&e risks associated 8it& t&e tasks? a

managea;le leel o7 detail is re<uired and t&is may re<uire t&e

task to ;e ;roken do8n into discrete steps=

5.1.1 Defnition o- 4asks

/ac& task s&ould ;e identifed in terms o7D

- Actiities

- 4se o7 plant and e<uipment

- 4se o7 materials#su;stances

- Iorkplace

- Procedures used

6&is s&ould &elp to ;uild up? in time? an inentory o7 tasks t&at

Departments conduct and t&e type o7 8ork carried out in t&e

diBerent 8orkplace areas=

!.#.$ Record t.e Hazards

)nce all t&e tasks &ae ;een identifed? an inentory s&ould ;e

dra8n up? 8&ic& lists all t&e tasks carried out in eac& 8orkplace

area= 6&ese tasks may ;e considered as routine? non>routine or

generic? and s&ould ;e 7ed 7or8ard 7or risk assessment=

6o ensure t&at all &azards are identifed at t&is stage? typical risk

screening key 8ords are descri;ed in Appendi0 1 and typical

&azard identifcation c&ecklist ta;les are proided 7or guidance in

KHALDA Petroleum Company Page 1"

Re !"# $!!%

Hazards Identifcation & Risk Assessment

Appendi0 $= 6&e c&ecklists gien are not e0&austie and s&ould

;e updated eac& time a ne8 &azard is identifed=

Look 7or 8&at could reasona;ly ;e e0pected to cause &arm=

Ignore t&e triial and concentrate on signifcant &azards? 8&ic&

could result in serious &arm or aBect seeral people=

'anu7acturer instructions and material data s&eets can &elp put

risks in perspectie=

!.$ E,a+uate t.e Risks

Decide 8&o may ;e &armed and &o8= 6&ink also a;out people

8&o may not ;e at t&e 8ork place at t&e time? e=g= cleaners?

isitors? contractors? and mem;ers o7 t&e pu;lic? etc= Is t&ere any

c&ance t&at t&ey mig&t ;e &armed ;y t&e actiitiesJ

Consider t&e pro;a;ility o7 realization o7 t&e &azards= 6ypical

7actors 8&ic& may aBect t&e analysis o7 pro;a;ility includeD

- 6&e num;er o7 times t&e situation occursE

- Duration o7 e0posureE

- Kuantities o7 materials inoledE

- /nironmental conditions? e=g= lig&ting? temperatureE

- Competence o7 people inoledE

- Condition o7 e<uipment=

/stimate t&e &azard eBects? i=e= t&e conse<uence o7 t&e risks

arising 7rom t&e &azards= 6&e assessed seerity rating o7 t&e

&azard eBects? 8it& or 8it&out any control measures in place?

s&ould ;e entered on t&e Risk Assessment 7orm as a num;er

using t&e Conse<uence F3eerityG Rating (uidance s&o8n in 6a;le

1= 3eerity ratings 7or enironment and asset damage are also

s&o8n 7or completeness=

Consider 8&et&er e0isting precautions are ade<uate or more

s&ould ;e done=

!.8 Ana+)ze t.e Risks

Analyze t&e initial Risk Rating FRisk Rating Iit& /0isting Control

'easuresG ;y multiplying t&e conse<uence num;er ;y t&e

KHALDA Petroleum Company Page 1*

Re !"# $!!%

Hazards Identifcation & Risk Assessment

likeli&ood num;er? to proide a risk rating For rankingG 7or eac&

&azard= 6&is num;er? on a scale o7 * to 1!!? s&ould ;e entered

in t&e Risk column on t&e Risk Assessment ,orm FAppendi0 +G=

6&e num;ers in t&e Risk column proide an indication o7 priority

and o7 t&e e0tent o7 t&e risk 8it&out any specifc control

measures=

6&e o;2ectie o7 t&is process is not to arrie at a certain num;er

;ut to proide a systematic met&od o7 ensuring t&at

conse<uence and likeli&ood ratings are analyzed care7ully and a

record made o7 t&e analysis 7or 7uture re7erence and reie8=

6&e ne0t step is to consider t&e e0isting control measures and

additional control measures needed to control? reduce and

minimize t&e risk 7or eac& identifed &azard=

6&e pre7erred &ierarc&y 7or t&e control measures is descri;ed in

3ection +=* ;elo8=

6&e control measures may address t&e conse<uence? t&e likeli&ood

or ;ot&= 6&e re<uired control measures 7or eac& &azard s&ould ;e

recorded alongside eac& &azard on t&e Risk Assessment ,orm

FAppendi0 -G= Appendi0 " proides guidance on t&e type o7

control measures t&at can ;e employed 7or t&e arious &azards=

Residual Risk L to assess t&e residual risk t&at remains 8it& t&e

control measures in place? ne8 &azard eBect Fconse<uenceG and

likeli&ood ratings are selected 7rom t&e scales s&o8n in 6a;les $

and "? respectiely? 8it& t&e inclusion o7 t&e control measures=

6&e product o7 t&ese t8o ratings proides a measure o7 t&e

Residual Risk and completes t&e risk analysis stage= 6&e

in7ormation proided in t&e Residual Risk ;o0 is used in t&e ne0t

stage o7 t&e risk assessment to ealuate 8&et&er t&e risk is

ade<uately controlled or not.

Risk /aluation > t&is is t&e fnal step in t&e risk assessment

process and 8ill re<uire t&e assessor to decide i7 t&e &azards

identifed &ae ;een controlled to a suita;le leel= 6&e risk

analysis stage took into account t&e control measures currently

applied to t&e &azard and? t&ere7ore? t&e result o7 t&e analysis

indicates t&e amount o7 risk t&at remains? or t&e residual risk=

,rom t&is analysis? t&e risk matri0 s&o8n ;elo8 in 6a;le "

indicates 8&et&er t&e residual risk o7 eac& &azard isD

KHALDA Petroleum Company Page 1+

Re !"# $!!%

Hazards Identifcation & Risk Assessment

- 6riial > F6G

- Ade<uately controlled > FAG

- 'oderately controlled > F'G

- Intolera;le L FIG

Record t&e results in t&e fnal Frig&t &andG column o7 t&e Risk

Assessment ,orm=

6&is risk rating assessment 8ill assist in deciding priorities 7or

action and in deciding t&e aut&orization leels 7or t&e 8ork

commensurate 8it& t&e risk=

In general? &ig& risks may re<uire t&e proision o7 considera;le

additional resources inoling special e<uipment? training? &ig&

leels o7 superision? and consideration o7 t&e most eBectie

met&ods o7 eliminating or controlling &azards=

3ome situations may re<uire special consideration? includingD

- i7 t&e task is ne8? comple0 or un7amiliar

- i7 t&e task is unusual or occasional

- i7 it is impractical to comply 8it& normal industry standards

- i7 preiously used sa7eguards are not appropriate 7or t&is

actiity

Lo8er leel risks may ;e considered as accepta;le ;ut actions

s&ould still ;e taken to try to reduce t&ese risks 7urt&er i7 possi;le

8it&in reasona;le limits=

!.9 Reduce / Contro+ Risk

4se t&e 7ollo8ing &ierarc&y to reduce risks to accepta;le leelsD

/limination or 3u;stitution

/liminate t&e &azardE e=g= use o7 sodium &ypoc&lorite solution

instead o7 7ree c&lorine gas 7or disin7ectant purposes=

KHALDA Petroleum Company Page 1-

Re !"# $!!%

Hazards Identifcation & Risk Assessment

Hazard Reduction

Reduce t&e &azard 8it& an alternatieE e=g= use Mame retardant

scaBold ;oards 8&ere &ot 8ork may ;e taking place=

Se/re/ation

Isolate t&e &azard 7rom peopleE e=g= 7encing o7 e0caations?

mac&ine guards=

Contro+

Control t&e &azard ;y introducing suita;le measures? 8&ic& may

;e in eit&er or ;ot& o7 t&e 7ollo8ing t8o categoriesE

Personal controls > competence ;ased Fe=g= 8ell trained staBG

)rganizational controls > rule ;ased Fe=g= ad&erence to 8ork

proceduresG

Controls s&ould ;e introduced using t&e 7ollo8ing pre7erred

se<uenceD

FaG procedures? suc& as permit to 8ork? emergency response?

etc=

F;G training and instruction

FcG superision

FdG maintenance

iti/ation

Proide personal protectie e<uipment FPP/G as necessary? e=g=

&ard &ats? ;oots? gloes? &arnesses to preent 7alls 7rom &eig&t?

etc=

6ypical control measures are proided in Appendi0 $=

I&en considering 8&at control measures are already proided or

need to ;e proided? to control or reduce t&e risk? t&e risk

assessor must take into account t&e possi;ility o7 control

measures not ;eing implemented ;ecause o7 &uman error? lack o7

maintenance? diCculty in compliance? comple0ity o7 instructions?

etc=

It is essential to discoer &o8 t&e task is actually carried out and

;ase t&e assessment on t&is? rat&er t&an assessing t&e likeli&ood

on &o8 t&e task is supposed to ;e carried out=

KHALDA Petroleum Company Page 1.

Re !"# $!!%

Hazards Identifcation & Risk Assessment

!.! Record t.e 6indin/s

,or eac& o7 t&e more signifcant &azards identifed? e=g= fre?

electric s&ock? etc? 8rite do8n t&e control measures to ;e used to

manage t&e risk 7rom t&e &azard? e=g= 7or fre? controls including

eacuation and emergency response procedures? fre

e0tinguis&ers? etc=

)nce t&e risk assessments &ae ;een completed? a Iork Plan

s&ould ;e prepared 7or t&e more comple0 actiities= A sample

plan is indicated in Appendi0 *=

!.7 onitor and Re,ie:

I7 t&ere is any signifcant c&ange to t&e &azards or conse<uences?

t&e risk assessments s&ould ;e reised and t&e data ;ase

updated= Risk assessments s&ould ;e reie8ed annually=

4a&+e No. # @ Hazard /Bect FConse<uenceG Rating

(uidance

Hazard )utcome

R

A

4

I

N

G

Conse=uence

AInBur)C

Conse=uence

AAsset Dama/eC

Conse=uence

AEn,ironmenta+

Dama/eC

A'oss o- Re(utationC

/0tensie damage= 'assie leak#spill=

KHALDA Petroleum Company Page 1%

Re !"# $!!%

Hazards Identifcation & Risk Assessment

'ultiple 7atalities 3&utdo8n=

3u;stantial or total

loss o7 plant=

'a2or pu;lic concern=

Reputation destroyed=

'a2or clean up= e=g= 8ell

;lo8out=

10

3ingle 7atality or

permanent

disa;ility? e=g=

cancer caused ;y

release o7

carcinogenic

su;stance? or

ast&ma=

'a2or damage=

Partial s&utdo8n o7

part o7 plant or

7acility=

'assie leak#spill=

Reputation ;adly

damaged=

:on>con7ormance 8it&

regulations=

8

'a2or in2ury? lost

time accident N"

days? e=g= 7alling

7rom &eig&t? ;roken

;ones? temporary

&ealt& eBect=

Localized damage=

Partial s&utdo8n o7

part o7 plant or

7acility=

Localized leak#spill=

Reputation in media

spotlig&t=

:on>con7ormance 8it&

regulations=

6

'inor in2ury? e=g=

sprains? ;urn 8it&

caustic c&emical?

;ack or lim; strain=

'inor damage=

Parts replacement?

e=g= pump or

compressor 7ailure=

'inor leak#spill= Pu;lic

concern= 3mall loss o7

reputation= :o lasting

eBect=

4

3lig&t in2ury # ,irst

Aid Case? e=g=

fnger cut=

3lig&t damage to

e<uipment= 'inimal

cost= 'inimal or no

do8ntime? e=g= minor

e&icle damage=

3lig&t leak= 3pill

minimal= :o loss o7

reputation= /Bect

contained locally= /=g=

leak 7rom a c&emical

drum=

2

Note t&at t&e use o7 num;ers 7or conse<uence rating 7rom t&e a;oe

scale does not make t&e risk assessment <uantitatie= It merely

proides a s&ort&and 8ay o7 recording t&e 2udgment o7 conse<uence

FseerityG and t&e priority 7or control measures= 6&e person carrying

out t&e risk assessment s&ould not ;ecome too o;sessed 8it& t&e

fguresE part o7 t&e purpose o7 t&e risk assessment is to identi7y t&e

control measures t&at need to ;e implemented= 6&ese fgures are

designed to assist 8it& t&e prioritization o7 suc& measures=

4a&+e No. $ D Likeli&ood Rating (uidance

'ike+i.ood Ratin/ Guidance 'ike+i.oo

KHALDA Petroleum Company Page 11

Re !"# $!!%

Hazards Identifcation & Risk Assessment

d Ratin/

Imminent or Acute

Harm 7rom a &azard is imminent or acute i7 no control

measures are proided at all and#or i7 one or more o7 t&e

7ollo8ing 7actors also applyD>

6&e &azard is a cause o7 large num;ers o7 in2uries or

ill &ealt& in

national or location statisticsE

People are e0posed to t&e &azard continuouslyE

6&e &azard is diCcult to see e=g= H$3 gasE

Healt&? 3a7ety and /nironment is not considered

&ig& priority ;y

t&ose inoled? including manager and superisors?

e=g= non>

ad&erence to P6I=

1!

5er) 'ike+)

Harm is ery likely i7 t&e control measures proided

depend on an indiidual using t&em on eery occasion

Fe=g= personal protectie e<uipment? P6I systemG or i7

training and superision are minimal? and#or i7 one or more

o7 t&e a;oe 7actors are present=

%

'ike+)

Harm is likely i7 t&e control measures proided depend on

an indiidual using t&em or ad2usting t&em on eery

occasion Fe=g= porta;le gas detectors? sa7e 8orking

proceduresG? or i7 training is proided and 8ork superised?

and#or i7 any o7 t&e 7actors gien 7or certain or imminent

&arm also apply=

-

Possi&+e

Harm may &appen i7 control measures include measures

t&at do not depend on t&e operator ;ut can ;reak do8n or

;e remoed or de7eated Fe=g= pressure sa7ety aleG? or i7

t&ere is no defned system o7 maintenance or superision

o7 t&e control measures= 6&e &azard is a potentially

signifcant cause o7 in2ury or ill &ealt&? or 7or 8&ic& a

num;er o7 people are o7ten e0posed=

*

0n+ike+)

6&e circumstances under 8&ic& &arm may &appen 8ill

reduce to &arm ;eing unlikely i7 t&ere is a defned system

o7 superision and maintenance? and#or i7 training is

proided and repeated regularly= )t&er 7actors making

&arm unlikely include &azards? 8&ic& are a cause o7 7e8

in2uries or cases o7 ill &ealt&? or 7or 8&ic& a 7e8 people are

$

KHALDA Petroleum Company Page $!

Re !"# $!!%

Hazards Identifcation & Risk Assessment

occasionally e0posed=

4a&+e No. 8 D Risk 'atri0

Conse=ue

nce

3lig&t

In2ury

,irst Aid

3&ort 6erm

Healt&

/Bect

3lig&t

Leak

'inor

In2ury

'inor

Healt&

/Bect

'inor Leak

'a2or In2ury

Lost 6ime

N " days

6emporary

Healt& /Bect

Local Leak

3ingle

,atality

Permanen

t

Disa;ility

'assie

Leak

'ultiple

,atalities

'assie

Leak

'ike+i.ood $ 9 7 % #"

Imminen

t

#

"

$! *! -! %! 1!!

Oery

Likely

% 1- "$ *% -* %!

Likely 7 1$ $* "- *% -!

Possi;le 9 % 1- $* "$ *!

4nlikely $ * % 1$ 1- $!

0 8 (T)

4ri,ia+ / 4o+era&+e Risk

:o action necessary proided control measures are

maintained=

12 24 (A) Ade=uate+) Contro++ed Risk

Risk is tolera;le 8&en control measures identifed are

implemented and maintained=

32 48 (M) oderate+) Contro++ed Risk

KHALDA Petroleum Company Page $1

Re !"# $!!%

Hazards Identifcation & Risk Assessment

,urt&er Risk Reduction 'easures must ;e considered=

60 100 (I)

Into+era&+e Risk

Risk unaccepta;le= 3eek specialist adice#support=

6&e results o7 t&e risk analyses indicate t&e e0tent o7 t&e risks= 6&e num;er

in eac& ;o0 is t&e risk rating num;er entered on t&e risk assessment 7orm?

arried at ;y multiplying toget&er t&e &azard eBect F3eerityG and likeli&ood

num;ers= 6&e &ig&er t&e num;er? t&e &ig&er is t&e risk rating=

7." APPENDI;

#. Risk Screenin/ Ke) Eords

'eaders.i( Personne+ Hea+t.

Sa-et)

Policy Drugs#Alco&ol 3u;stances ,ire

Commitment 3election As;estos

/0plosies

Communications 6raining :oise Road trael

6op>do8n 'otiation Poisons

Air trael

/litism Competence Carcinogens 3ea trael

3tandards Culture 3tress

Dro8ning

(uidance 6emporary 5iological

/lectricity

6argets /0perience Iild animals Hot

8ork

In7ormation Language 3e8age

Confned 3paces

Lessons Literacy ,ood#Iater Heig&ts

Planning Kuality /rgonomics

/0caation

)rganization Kuantity Lig&ting Diing

Control Certifcation Oi;ration

Rigging

Responsi;ility 3ize#3trengt& OD4s Hoisting

,eed;ack 3uperision Radiation

3caBolding

)penness 3tand>ins Hot#Cold

Po8er tools

Environment Engineering/Change Contrators !urhasing

Ieat&er C&ange Contract type KA#KC

3easons 'odifcations Contractor <uality Purc&ase

orders

Iaste Corrosion /0perience

3pecifcations

Disposal /rosion KA#KC

Receipt

/nergy#Resource 3tress Planning

Inspection

/missions 'etal 7atigue Kualifcation 3torage

KHALDA Petroleum Company Page $$

Re !"# $!!%

Hazards Identifcation & Risk Assessment

Disc&arges 3tructure 3c&edule

Handling

Iater Kuality Personnel

3egregation

/IA#Regulations Design Communications

Inentory

3pills Construction 6ec&nical

Critical parts

Permits 'aintenance :um;er 3pares

(eograp&y 3pecifcations 3u;>contractor Hazard

su;stances

Local sensitiities 3tandards 6emporary#Casual

H3/ e<uipment

Iater intake Inspection Discipline

3crap

Conseration Documentation /n7orcement 6ransportation

Leisure 6ec&nical aut&ority 'onitoring

Insurance

History Audit Local purc&asing

,lora#,auna

"#erating/$ehnia% Emergen& Monitoring 'eurit&

3imultaneous ,ire#/0plosion Audit 6errorism

3tart up 3pill#Leak Auditor

5om;

3&ut do8n Dispersion 6ec&nical

6&reat

Isolations 3tructural Limits

6&e7t

)ne>oB Iell control Permit ,raud

4nusual Po8er Reie8 Lig&ting

Assem;le Collision Inspection

Camera

Dismantle Ieat&er (eneral

Hi>2ack

3pecialist /art&<uake Critical

Politics

/0pert ,lood Hygiene Religion

3&i7t c&anges Landslide /nironment Reenge

$. Hazard C.eck+ist

HAFARD CHECK'IS4 D #

Hazards Associated 8it& Plant and /<uipment Fincluding no po8ered

plant and &and toolsG

Categor& $&#e o( )arm E*am#%es o( )a+ar,s

6&ermal 5urns

,ires

3calds

,rost;ite

Hot # cold sur7aceD

5lo8 torc&

Ielding Mame#arc

Re7rigerant

3team

Radiation IonizingD

> 5urns

P Rays

Alp&a or 5eta Rays

KHALDA Petroleum Company Page $"

Re !"# $!!%

Hazards Identifcation & Risk Assessment

> Cancers

> 5lood disorders

> 3ickness

:on> ionizingD

> 5urns

> 'elanomas

> Cataracts

> 3tatic s&ock

> Induced ;ody currents

:)R'

Lo8 3cale Actiity

:eutrons

'icro 8ae

Radio 7re<uency

Laser

4ltra iolet

In7ra red

/lectromagnetic

Ftrans7ormers? po8er

ca;lesG

:oise Hearing loss

Dea7ness

6innitus

'ac&ine

tools#e<uipment

Hand tools

Compressors

Pneumatic

tools#e<uipment

Oi;ration Oi;ration 8&ite fnger

I&ole ;ody eBects

Circulatory disorders

Pneumatic drill

)peration o7 mac&inery

)erload#de7ec

tie

due to

mec&anical

7ailure

Crus&ing Crane oerload

C&ain sling

/ye ;olt oerload

3caBold oerload

Display screen

e<uipment

/yestrain

Headac&es

'uscular discom7ort

Iork related upper lim;

Disorders

Poor layout o7 8ork

station

Poor 7urniture

Poorly sited screens

Illegi;le te0t

HAFARD CHECK'IS4 D $

Hazards Associated 8it& 'aterials and 3u;stances

Categor& $&#e o( )arm E*am#%es o( )a+ar,s

6ire/EG(+osion

Com;ustion

5urns

De&ydration

Hydrocar;ons

6im;er stack

Fe=g= scaBold ;oard storeG

Paper store

(rease

)ily rags

Plastic 7oam

,lamma;le

su;stances

5urns

De&ydration

Hydrocar;on gases?

condensate? oils

5ottled &ydrocar;on gases

KHALDA Petroleum Company Page $*

Re !"# $!!%

Hazards Identifcation & Risk Assessment

Fe=g= acetyleneG

Lu;ricants

Diesel

'et&anol

Paint#t&inners#solents

)0idizing

3u;stances

5urns /0plosie material

Pyrotec&nics Fe=g= MaresG

Detonators

Hea+t. Hazards

6o0ic 'aterial

AcuteD

- Respiratory irritation

- C&emical asp&y0iation

- :erous system eBects

- :arcotic eBects

- Damage to eye

C&ronic D

- > Anemia

- > Leukemia

Hydrogen 3ulp&ide

5enzene

'et&anol

Isocyanides

Corrosion In&i;itors

Dust

Paints

Degreasing 3olents

Anaero;ic sealant

Primers

Corrosie

'aterial

AcuteD

- 3kin? eye?

- Respiratory irritation

> ;urns

3ulp&uric acid

Caustic soda

Hydroc&loric acid

5leac&es

Irritant 'aterial AcuteD

- 3kin? eye and respiratory irritantD

> dermatitis

'anmade>

mineral f;er

Cement Dust

3odium &ypoc&lorite

3ensitizing

'aterials

AcuteD

> respiratory and skin allergic

reactions a7ter sensitization

Isocyanides

(luteralde&yde F;iocideG

6erpene

Ielding#soldering 7umes

Possi;le

Carcinogens

C&ronicD

> skin? lung cancers

> as;estosis? mesot&elioma

> dermatitis

As;estos

Polyaromatic &ydrocar;ons

4sed engine oil

Asp&y0iates Acute FsuBocationG and c&ronic

eBects on &ealt&

:itrogen

Car;on dio0ide

Argon

5iological AcuteD

> Legionnaires disease

> gastro>intestinal disorders

> 7ood poisoning

C&ronicD

> ast&ma

5acterial

Oiral

,ungal

5iological dusts FMour?

&ard8oodG

Contact Cuts? a;rasions

5urns? 7rost;ite

Roug& tim;er

Concrete ;locks

'olten metal

HAFARD CHECK'IS4 D 8

Hazards Associated 8it& Place o7 Iork

KHALDA Petroleum Company Page $+

Re !"# $!!%

Hazards Identifcation & Risk Assessment

Categor& $&#e o( )arm E*am#%es o( )a+ar,s

Access/Egress

Tripping

Slipping

Falls

Damaged flrs

Trailing ca!les

"il spills

#a$er n flrs

%ce

De!ris

Slping s&rface

'ne(en s$eps

)*anges in flr le(el

#r+ a$ *eig*$ Falls

Fragile rf

Edge f rf

Edge f me,,anine flr

#r+ n ladder

Erec$ing scaffld

-le in flr

"!s$r&c$ins S$ri+ing agains$

./ *eadrm

S*arp pr0ec$ins

#r+ (er/near

li1&ids

Fall in$ s&!s$ances2

- Dr/ning

- pisning

- s&ffca$in

Tan+

S&mp

#r+ (er sea

Emergencies En$rapmen$ d&ring escape3 e4g4 frm fire

.c+ed e5i$s

"!s$r&c$ed egresses

.ng e5i$ r&$e

Transpr$ Fa$ali$63 in0&r6

7$r (e*icle

Air

7arine

8ail

9edes$rian

:a$&ral -a,ards

%n0&r6

%llness

.ig*$ning

Flas* fld

Ear$*1&a+e

HAFARD CHECK'IS4 D 9

Hazards Associated 8it& t&e Iorking /nironment

Categor& $&#e o( )arm E*am#%es o( )a+ar,s

.ig*$

(:; 2 als increases ris+

f cn$ac$ /i$* $*er

*a,ards)

E6e s$rain

Arc e6e

)a$arac$s

<lare

9r lig*$ing

S$r!scpic effec$

Arc /elding

7l$en me$al

Tempera$&re

-ea$ s$ress

-6p$*ermia

S&n!&rn

7elanma

-6p$*ermia

)ld rm

"&$dr /r+

-$ /ea$*er

)ld /ea$*er

#ind c*ill fac$r

#r+ in rain3 sn/3 e$c4

:ise

-earing lss

Deafness

Tinni$&s

Am!ien$ :ise = 8> d;(A)

7ac*iner6 nise

8elief (al(e nise

KHALDA Petroleum Company Page $-

Re !"# $!!%

Hazards Identifcation & Risk Assessment

)nfined space

Asp*65ia$in #r+ in $an+

)*imne6

'n(en$ila$ed rm

?essel

Sil

?en$ila$in

@Sic+ ;&ilding S6ndrme@

:a&sea

Tiredness

F&mes

"drs

T!acc sm+e

E5$reme (*ig*/l/) *&midi$6

)A-A./ C)EC01I'$ 2 3

-a,ards Asscia$ed /i$* $*e 7e$*d f #r+

)a$egr6 T6pe f -arm E5amples f -a,ards

7an&al -andling

;ac+ in0&r6

-ernia

.if$ing

./ering

)arr6ing

9&s*ing

9&lling

-$ / )ld .ads

8&g* .ads

.i(e .ads - Animal / 9ersn

8epe$i$i(e 7(emen$

#r+ rela$ed &pper

lim! disrders

Ae6!ard /r+

'sing scre/dri(er

'sing *ammer and c*isel

9rd&c$in line $as+s

9s$&re

7&scle s$rains/ sprains

;ac+ pains

#r+ rela$ed &pper

lim! disrders

S$ress

Sea$ed /r+

#r+ a!(e *ead *eig*$

#r+ /i$* displa6 screen e1&ipmen$

#r+ a$ flr le(el

HAFARD CHECK'IS4 D 7

Hazards Associated 8it& Iork )rganization

Categor& $&#e o( )arm E*am#%es o( )a+ar,s

)n$rac$rs

%n0&ries and ill *eal$* $ empl6ees !6 cn$rac$rs4

#r+ %n0&ries and ill *eal$* $ cn$rac$rsB

empl6ees !6 /r+ in premises

#r+ a!(e empl6ees

'se f *armf&l s&!s$ances

)n$rac$rs /elding

9rcess f&mes

Ser(ices (e4g4 &ndergr&nd elec$rici$6

ca!les)

S$red *a,ard&s ma$erials

"rgani,a$in f /r+ %n0&ries $ empl6ees 7n$n&s /r+

S$ress

T m&c* /r+

.ac+ f cn$rl f 0!2

- lac+ f s&per(isin

- lac+ f infrma$in

- lac+ f ins$r&c$in

KHALDA Petroleum Company Page $.

Re !"# $!!%

Hazards Identifcation & Risk Assessment

- lac+ f $raining

- inade1&a$e mni$ring

#r+ $ demanding/*ig* /r+ ra$e

)mm&nica$in

9r(isin f &ns&i$a!le e1&ipmen$

#r+ in p&!lic areas %n0&ries and ill *eal$* f p&!lic Trailing ca!les

Traffic/plan$ m(emen$

"!s$r&c$ins $ pedes$rians

#r+ a!(e p&!lic

HAFARD CHECK'IS4 D H

Hazards > )t&er 6ypes

Categor& $&#e o( )arm E*am#%es o( )a+ar,s

A$$ac+ !6 animal r

insec$

;i$e

S$ing

)r&s*ing

Aic+

%ll *eal$*

;ees

Dg

-rse

)amel

Scrpin

Fleas

7s1&i$

Sna+e

A$$ac+ !6 peple

%n0&r6

%llness

9s$ $ra&ma s$ress

Disrder

)riminal a$$ac+

Angr6 c&s$mer

Dr&n+en persn

Dr&g a!&ser

7en$all6 ill persn

8. Contro+ easures Guidance

Control measures s&ould ;e applied as descri;ed ? using t&e

&ierarc&yD

E+imination or Su&stitution

/liminate t&e &azardE e=g= use o7 sodium &ypoc&lorite

solution instead o7 7ree c&lorine gas 7or disin7ectant

purposes=

Hazard Reduction

Reduce t&e &azard 8it& an alternatieE e=g= use Mame

retardant scaBold ;oards 8&ere &ot 8ork may ;e taking

place.

KHALDA Petroleum Company Page $%

Re !"# $!!%

Hazards Identifcation & Risk Assessment

Se/re/ation

Isolate t&e &azard 7rom peopleE e=g= 7encing o7

e0caations? mac&ine guards=

Contro+

Control t&e &azard ;y introducing suita;le measures?

8&ic& may ;e in eit&er or ;ot& o7 t&e 7ollo8ing t8o

categoriesE

Personal controls > competence ;ased Fe=g= 8ell trained

staBG

)rganizational controls > rule ;ased Fe=g= ad&erence to

8ork proceduresG

Contro+s s&ould ;e introduced using t&e 7ollo8ing

pre7erred se<uenceD

o procedures? suc& as permit to 8ork? emergency

response? etc=

o training and instruction

o superision

o maintenance

iti/ation

o Proide personal protectie e<uipment FPP/G as

necessary? e=g=

&ard &ats? ;oots? gloes? &arnesses to preent

7alls 7rom &eig&t?

etc=

o 6&e 7ollo8ing ta;les descri;e typical control

measures and are

not e0&austieD

"=1 Control 'easures 7or Healt& Hazards

o Atmosp&eric 'onitoring

o 5arrier Cream

o 5reat&ing Apparatus

o Detailed C)3HH Assessment

KHALDA Petroleum Company Page $1

Re !"# $!!%

Hazards Identifcation & Risk Assessment

o /nclosure#3egregation o7 Contaminant

o /rgonomic Assessment

o ,orced /0tract Oentilation

o In7ormation

o Instruction

o Local /0&aust Oentilation

o 'anual Handling Assessment

o 'edical 3ureillance#3creening

o 'inimized ,ume#Dust#Oapor Production

o :atural Oentilation

o Protectie Clot&ing

o Regular Cleaning#Decontamination

o Respiratory Protectie /<uipment

o Restricted Iorkplace /ating # Drinking # 3moking

o Restricted#Controlled Access to Iorkplace

o 3u;stituted 3a7er 'aterial

o 3uperision

o 6raining

"=$ Control 'easures 7or

,alling#38inging#Dropping Loads

o Additional 3uspension#3upport Deices

o Ade<uate Lig&ting

o 5anks man

o 5umper Protection

o Competent Li7ting )peration

o Competent Rigging

o ,ailure 'ode /Bect Analysis F,'/AG

o ,all Restraint Deice

o Load 'onitoring

o 'aintenance Program

o 'oement Restraint Deice

o )er&ead Protection

o )erload Iarning 3ystem

o Periodic /0amination#6esting#Inspection

o (eneral Issue Personal Protectie /<uipment

o Relocation o7 Oulnera;le /<uipment # Depressurization

o Restricted Access to 3a7e Distances

o 3a7ety Iatc&

o Iarning :otices

"=" Control 'easures 7or /lectricity

o Anti>static

o Classifcation o7 Hazardous Areas F,lamma;le (ases and OaporsG

FRe7 53+"*+G

KHALDA Petroleum Company Page "!

Re !"# $!!%

Hazards Identifcation & Risk Assessment

o /art& 'onitoring

o /<uipment & ,ittings Constructed? Installed & 'aintained 7or use

in Potentially /0plosie Atmosp&eres

o ,using

o Insulation

o Isolating 6rans7ormer

o Isolation

o P&ase 3eparation

o Residual Current Deice

o Permit to Iork#Limitation o7 Access

o 3&ielding

o Ooltage Reduction

o Iork Carried )ut ;y Competent Person#s

"=* Control 'easures 7or :oise#Oi;ration

o Audiometric

o Design )ut :oise#Oi;ration 7rom /<uipment

o Design )ut :oise#Oi;ration 7rom 6ask

o Detailed :oise#Oi;ration Assessment

o /nclose :oisy#Oi;rating /<uipment

o /ngineering Controls

o Hearing Protection Qone

o :oise#Oi;ration /0posure 'onitoring

o :oise#Oi;ration 3urey

o Restricted Access to :oisy#Oi;rating Areas

o 3election and use o7 Appropriate Hearing Protectors

o Iarning 3igns

o Iork Patterns e=g=D Defned 3pells o7 /0posure

"=+ Control 'easures 7or /mergency

o Ade<uate Planning

o Competent Person#s in C&arge

o Plat7orm PA and Alarm 3ystem

o /mergency Response Procedures

o Drills#/0ercises#6raining

o Proision o7 Ade<uate //R ,acilities

"=- Control 'easures 7or /<uipment ,ailure

o Appropriate 'aterials F,it 7or PurposeG

o Certifed /<uipment#'aterials

o Design Diersity

o Design Redundancy

KHALDA Petroleum Company Page "1

Re !"# $!!%

Hazards Identifcation & Risk Assessment

o ,ailure 'ode /Bects Analysis

o ,ault 6ree Analysis

o HAQ)P

o Planned Preentatie 'aintenance Program

o )perational 'onitoring

o Regular Inspection#6esting

"=. Control 'easures 7or

'ac&inery#/<uipment

o Control 3ystem Interlocked (uarding

o /mergency 3top Deice

o ,i0ed (uarding

o Planned Preentatie 'aintenance Program

o 'ec&anical and /lectrical Isolation

o Permit to Iork 3ystem

o (eneral Issue Protectie /<uipment

o Iarning 3igns#:otices

"=% Control 'easures 7or /0plosion

o /lectrical /<uipment and ,ittings Constructed? Installed and

'aintained in Accordance 8it& 53+"*+

o 5last Iall#/nclosure

o Deluge on Confrmed (as Detection

o /art& 'onitoring

o /0clusion o7 Ignition 3ources

o /0plosion Oenting#Relie7

o Inert (as 5lanketing

o Leak#3pillage Detection > Porta;le (as 'onitor

o Leak#3pillage Detection > (as Detection 3ystem

o Purging

o 3ecurity o7 Access to /0plosie 'aterials

o Permit to Iork 3ystem

o 4se o7 :on>3parking 6ools

o 3a7ety#,ire Iatc&

o Pressure Relie7 Panels

"=1 Control 'easures 7or ,ire

o Automatic ,ire Doors

o Classifcation o7 Hazardous Areas Re7= 53+"*+

o Containment#3egregation o7 ,lamma;le 'aterials

o /mergency 3&ut Do8n 3ystem

o /0clusion o7 Ignition 3ources

KHALDA Petroleum Company Page "$

Re !"# $!!%

Hazards Identifcation & Risk Assessment

o /0clusion o7 )0ygen 3ources

o ,ire /0tinguis&ing Protection 3ystems > ,ire? Iater? C)$? Halon

o Passie ,ire Protection

o ,ire Iatc&

o ,ire and (as Detection 3ystem

o Depressurization#5lo8 do8n 3ystem

o Inspection#Certifcation o7 Premises

o 3el7>Closing ,ire Doors

o Porta;le ,ire /0tinguis&ers

o Porta;le (as 'onitors

o 4se o7 ,ire 5lankets

o Permit to Iork 3ystem

3.10 Control 'easures 7or Human /rror

o Ade<uate Rest Periods

o Audit Per7ormance

o Defned Competence Leel

o Defned Per7ormance 3tandard

o Defned Responsi;ilities

o Ade<uate In7ormation

o Ade<uate Instruction

o Ade<uate 3uperision

o Ade<uate 6raining

3.11 Control 'easures 7or /ntry into Confned

3pace

o Atmosp&eric 'onitoring o7 Confned 3pace

o 5reat&ing Apparatus

o Li7eline

o 3a7ety Iatc&

o ,orced Oentilation

o :atural Oentilation

o /<uipment Positiely Isolated F'ec&anical#/lectricalG

o Ade<uate Lig&ting

o 3a7e Access#/gress

o Permit>6o>Iork 3ystem

3.12 Control 'easures 7or Pressure

o Appropriate Design#Construction 'aterials

o 5arriers at 3a7e Distance

o Certifed /<uipment#'aterials

KHALDA Petroleum Company Page ""

Re !"# $!!%

Hazards Identifcation & Risk Assessment

o Periodic Inspection#6esting /0amination

o Pressure 'onitoring

o )erpressure Protection e=g=D P3O? 5ursting Disc? Pressure Relie7

Panels

o 3a7e Iorking Pressure 3pecifcation

3.13 Control 'easures 7or Ionizing Radiation

o Competent Personnel

o Dose 'onitoring

o Healt& 3ureillance

o Local Rules

o Personal Protectie /<uipment

o Ade<uate 6raining

o Appointed Radiation Protection 3uperisor

o Permit to Iork 3ystem

o Iarning 3igns

o Area Cordoned )B F6&ree DimensionallyG

o :on>essential Personnel Cleared

o PA Announcements

3.14 Control 'easures 7or 3lip#6rip#,all

o Ade<uate Lig&ting

o Appropriate ,oot8ear

o )penings Coered

o /dge Protection#Rails#5arriers

o ,i0ed Plat7orm#Ladder

o (ood Housekeeping

o Harness? Line and Attac&ment

o :on>slip 3ur7ace

o Periodic Cleaning

o Periodic Inspection

o (eneral Issue Personal Protectie /<uipment

o Iarning :otices=

9 Risk Assessment EGam(+e

KHALDA Petroleum Company Page "*

Re !"# $!!%

Hazards Identifcation & Risk Assessment

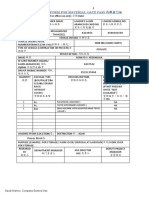

N1. HAFARD C1NSEI0ENCE E;IS4ING

C1N4R1'

RISK ANA'JSIS

AE;IS4ING

C1N4R1'SC

REI0IRED

ADDI4I1NA'

C1N4R1'

EAS0RES

RISK ANA'JSIS

AEI4H E;4RA

C1N4R1'SC

E5A'0A4I1N

SE5E

RI4J

'IKE'IH

11D

RISK SE5ERI4J'IKE'I

H11D

RISK

1

,ire o7 oil

producing

8ell

'a2or damage to assets?

potential 7or multiple

7atalities and serious

in2uries

Relia;le /3D

system?

Relia;le fre

detection system

Relia;le ,,

system

)perating

procedure in

place as Permit to

Iork 3ystem

1! * *! Conduct more

7re<uent fre8ater

tests

/nsure /3D

systems regularly

tested in

accordance 8it&

specifcation

1! $ $! 6&e control measures

must ;e 7ully

maintained to keep

t&em as relia;le as

possi;le and reduce

&uman error

$

,ire o7

producing or

test

separator

/0tensie damage Ft&e

separator can ;lo8G and

possi;ility o7 multiple

7atalities Ft&e separators

are located on t&e

plat7orm D1! manned

all t&e timeG

Preentie

'aintenance

3ystem

and inspections o7

separators and

e<uipment FP3O?

/3D? instruments

etc=G

Relia;le /3D

system?

Relia;le fre

detection system

Relia;le ,,

system

)perating

procedure

In place as Permit

to

Iork 3ystem

1! * *!

Increase 7re<uency

o7 inspections o7

e<uipment

Conduct more

7re<uent fre8ater

tests

/n&ance training o7

frefg&ting

personnel

1! $ $!

,ull implementation

o7 /0isting and

Additional Control

'easures

Re<uired

8

,ire

propagate

7rom 'IP*

to 'IP+ or

ice ersa

'a2or damage to assets?

potential 7or multiple

7atalities and serious

in2uries

6&ese 9ackets are close

to eac& ot&er

Relia;le /3D

system? relia;le

fre detection

system and

relia;le

,,#Cooling

system to reduce

t&e t&ermal

radiation in case

o7 fre

)perating

procedure

in place as Permit

to

Iork 3ystem

1! * *!

/n&ance

communications

;et8een plat7orms

/0c&ange

in7ormation on

Permits to Iork

prior to

aut&orization

Deelop 2oint

/mergency

Response Process

1! $ $! ,ull implementation

o7 /0isting and

Additional Control

'easures Re<uired

9

Pool fre on

t&e sea

'a2or damage to assets?

potentiality o7 multiple

7atalities and serious

in2uries

Relia;le /3D

system?

Relia;le fre

detection system

Relia;le ,,

system

1! * *!

Reie8 e0tent o7

implementation o7

Permit 6o Iork

3ystem

1! $ $! ,ull implementation

o7 /0isting and

Additional Control

'easures Re<uired

KHALDA Petroleum Company Page "+

Re !"# $!!%

Hazards Identifcation & Risk Assessment

! HSE Eork P+an EGam(+es

# Descri(tion o- Acti,it)

6&is generic risk assessment and control arrangements coers t&e erection and

dismantling o7

scaBolding on a construction site 7or 8ork at &eig&ts carried out ;y employees

and contractors=

$ Persons at Risk

Personnel erecting and#or dismantling t&e scaBolding 8ill ;e especially at risk

7rom t&e 7ollo8ing

&azards= Any ot&er person in t&e area could also ;e at risk 7rom 7alling o;2ects or

scaBolding collapse=

8 Hazards

6&e signifcant &azards associated 8it& t&e erection#dismantling o7 scaBolding are

D

o 3caBolding Collapse

o Aderse Ieat&er FHig& Iind? Rain? 3no8G

o ,alling );2ects

o PersonFsG ,alling 7rom 3caBolding

o Inade<uate Lig&ting

o )pen (rating Fi7 applica;leG

o Access#/gress

o 6rapping o7 5ody Parts 5et8een 3caBolding Components or 5et8een

Components and 3ur7aces

o 3triking People or /<uipment 8it& 3caBolding Components

o 3triking#);structions

o Contact 8it& Hot#Cold 3ur7aces

)t&ers &azards include? ;ut are not restricted to D

o Particles FDust 7rom 5oard Cutting? De;ris in 6u;ingG

o Cuts#a;rasions 7rom 3&arp /dges? Contact 8it& Hand 3a8s

o /0treme Am;ient 6emperature

o 3tacking#3toring o7 3caBolding Components

9 Risk Ana+)sis and E,a+uation

6&e 7ollo8ing arrangements s&ould eliminate or reduce t&e risk 7rom t&e a;oe

&azards to a tolera;le

leel= 6&e risk assessment on 8&ic& t&ese are ;ased Fidentifcation o7 t&e

&azards? analysis o7 seerity

and likeli&ood o7 t&e &azards and identifcation and ealuation o7 control

measuresG is fled in t&e Site

Ofce. Additional risk assessments must ;e conducted and appended to t&is

assessment 8it& details

o7 t&e appropriate arrangements? i7 any ot&er &azards are identifed not included

a;oe=

! Arran/ements

KHALDA Petroleum Company Page "-

Re !"# $!!%

Hazards Identifcation & Risk Assessment

!.# P+annin/ and 1r/anizin/

6&e (responsible person) s&all ensure t&at scaBolding can ;e

erected and dismantled

sa7ely and eCciently at t&e 8ork site taking into account specifc

area &azards? ot&er

persons and actiities 8it&in t&e area= I&ere t&ere is any dou;t?

t&e HSE Engineer

s&all ;e consulted 7or adice=

Competent superisors s&all ;e employed to carry out inspections=

All scaBolding

s&all ;e erected? altered or dismantled ;y competent 3caBold or

under t&e direct

superision o7 a competent person=

6&e Site Supervisor s&all ensure t&at t&e 7ollo8ing e<uipment is proided and

maintained D>

o sa7ety &arness 7or use 8&en 8orking a;oe $m=

o protectie clot&ing Fincluding sa7ety &elmet? sa7ety 7oot8ear? gloes? 8arm

8eat&er during

e0treme cold 8eat&erG=

o eye protection=

o &earing protection Fi7 re<uired ;y t&e Iorkplace :oise AssessmentG=

o communication Fsa7ety 8atc& to control roomG? i7 &ot 8ork is inoled=

6&e 8ork plan s&all allo8 7or suCcient rest periods during periods o7 e0treme &ot#cold

8eat&er=

!.$ ana/ement Contro+

:o person s&all erect? alter or dismantle any scaBolding unless

aut&orized ;y t&e

(appropriate senior person as above) or appointed representatie= 6&e

superisor must

ensure t&e 7ollo8ing 8&en scaBolding is to ;e erected? altered or

dismantledD>

con7ormance 8it& 53 +1." D 111" Code o7 Practice 7or Access and Iorking

3caBolds and

3pecial 3caBold 3tructures in 3teel=

inspection and su;se<uent tagging o7 approed scaBolding=

compliance 8it& load ;earing capacity=

8ork is suspended and t&e site made sa7e during e0treme 8eat&er

conditions=

inspection o7 scaBolding prior to continuing 8ork 7ollo8ing e0treme 8eat&er

conditions=

stand;y essel is on location? sa7ety 8atc& posted and oer;oard disc&arges

noted? i7 8ork

oer t&e sea=

compliance 8it& manual &andling assessment=

guard rails and toe # kicker ;oards are ftted=

scaBolding area is ;arrier oB? 8arning tape#notices are posted and restricted

access

imposed=

ulnera;le#7ragile e<uipment 8it&in t&e area are noted=

KHALDA Petroleum Company Page ".

Re !"# $!!%

Hazards Identifcation & Risk Assessment

secure means 7or li7ting#&andling#storing o7 scaBold components are

employed=

&ig& standard o7 &ousekeeping=

materials and tools are remoed 7rom or secured to t&e scaBolding 8&en not

in use=

suita;le 7all arrestors to ;e 8orn 8&en 8orking a;oe $m=

ladders are secured=

ade<uate lig&ting is proided=

open areas in Moors to ;e ;arrier oB#&and railed=

access#egress routes are uno;structed and alternatie escape routes are

aaila;le=

o;structions? protrusions? &ot#cold sur7aces are noted=

;oards are protected 7rom &ot sur7aces=

protection is proided on cut sur7aces=

compliance 8it& 8orkplace noise assessment and confned space risk

assessment? 8&ere

appropriate=

!.8 Procedures -or Serious or Imminent Dan/er

Any de7ect noted in t&e scaBolding e<uipment must ;e reported and

attended to

immediately=

7 onitorin/ and Re,ie:

7.# Ins(ections

6&e Site Supervisor s&all ensure t&at t&e e<uipment? 7acilities

and 8orking practices are maintained to t&ese standards ;y

arranging regular inspections ;y a competent personFsG=

All ne8 or &ired scaBolding components 8ill ;e inspected and

approed 7or use ;y a competent person prior to use= A record o7

t&e inspection s&all ;e made and fled in t&e Site Construction

Ofce.

All scaBolding s&all ;e inspected at 7 day interals ;y t&e

supervisor and a record o7 inspections made and fled in t&e Site

Construction Ofce.

7.$ Risk Assessment Re,ie:

6&is risk assessment and arrangements s&all ;e reie8ed at

interals o7 " mont&s

or a7ter any reported complaint? incident or accident? or

8&eneer t&e actiity

c&anges=

KHALDA Petroleum Company Page "%

Re !"# $!!%

Hazards Identifcation & Risk Assessment

7 Risk Assessment 6orm

KHALDA Petroleum Company Page "1

Re !"# $!!%

Hazards Identifcation & Risk Assessment

KHALDA Petroleum Company Page *!

Re !"# $!!%

Hazards Identifcation & Risk Assessment

'ocation> 3&ams 6arek 1%R P#L=

SSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSS

SSSSSSSSSSSSSSS

4ask/Acti,it)> Hot tapping actiity=

SSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSSS

SSSSSSSSSSSS=

Pre(ared &) AA((+icantC> SSSSSSSSSSSSSSSSSSSSSSSS== Date>

11#!$#$!1! SSSSSSSSSSSSSSS==

Area Aut.orit)> SSSSSSSSSSSSSSSSSSSSSSS=== Date>

11#!$#$!1! SSSSSSSSSSSSSSS==

Item

N1.

HAFARD RISK E;IS4ING C1N4R1'

RISK ANA'JSIS

AE;IS4ING C1N4R1'SC

REI0IRED ADDI4I1NA'

C1N4R1' EAS0RES

RISK ANA'JSIS

AEI4H C1N4R1'SC E5A'0A4I1N

SE5ERI4J 'IKE'IH11D RISK SE5ERI4J 'IKE'IH11D RISK

1

Erec$ing scafflding4

7inr in0&r6

-All scafflding s$r&c$&res

s*all !e erec$ed /i$* me$al

cmpnen$4

-All fi$$ings s*all !e f a me$al

$6pe appr(ed $ A:S%4

-All lse r &ns&i$a!le

ma$erial s*all n$ !e &sed fr

$*e cns$r&c$in r s&ppr$ing

f scafflding4

-scafflding erec$in cre/

s*&ld !e 1&alified4

-Appl6 scaff $ag s6s$em and

scaffld inspec$r s*&ld !e

1&alified en&g*4

-7ain$ain *&se+eeping a$

scaffld pla$ frm4

4 2 8

: ac$in necessar6

pr(ided cn$rl

meas&res are

main$ained4

KHALDA Petroleum Company Page *1

Re !"# $!!%

Hazards Identifcation & Risk Assessment

2

.ading $*e $apping

mac*ine fall d/n n

e5is$ing pipes4

-9rper$6

damage4

-Fire /

E5plsin4

-Fll/ing all lif$ing

prced&re4

-'sing s&i$a!le and cer$ified

crane4

-'sing s&i$a!le and

cer$ified rigging e1&ipmen$4

10 4 40

-8e(ie/ $*e emergenc6 plan

frm )mm&nica$in

and si,e $ &se

re1&ired e1&ipmen$4

10 2 20

,ull implementation o7

/0isting and Additional

Control 'easures Re<uired

3 'sing grinder fr

8em(e $*e ca$ing4

Slig*$ in0&r6

-99E fr *$ /r+4

-7ni$ring4

4 2 8

: ac$in necessar6

pr(ided cn$rl

meas&res are

main$ained

4

#elding / sldering

f&mes4

-7&l$iple

fa$ali$ies

-prper$6

damage4

-)rrsin $es$4

-99E fr *$ /r+4

-mni$ring

10 4 40

-8e1&ired gas fl/ fr *ea$

dissipa$in4

10 2 20

,ull implementation o7

/0isting and Additional

Control 'easures Re<uired

3

%mprper $ls fr /r+

!eing perfrmed4

-9ersnal

in0&r64

-All persnnel m&s$ !e /ear

/i$* re1&ired 99E4

-)er$ified $ls4

--and $ls are reg&lar

cleaned and inspec$ed4

4 2 8

: ac$in necessar6

pr(ided cn$rl

meas&res are

main$ained

6

-.se f ni$rgen

*ses4

-Fall d/n ni$rgen

c6linder

-9ersnnel

in0&ries4

-9rper$6

damage4

-All *ses s*&ld !e c*ec+ed

and fi$ /i$* $es$ed press&re f

mac*ine4

-)*ec+ all $ig*$en par$s4

-)6linders s*&ld !e s$red3

*andled3 and &sed in (er$ical

psi$in4

4 2 8

: ac$in necessar6

pr(ided cn$rl

meas&res are

main$ained4

4

-7iss-pera$in d&e $

(al(e par$iall6 pening4

-7iss-

pera$in4

-?al(e $ !e cmple$el6

pened and pa$*s f !ring

$ !e c*ec+ed4

4 2 8

: ac$in necessar6

pr(ided cn$rl

meas&res are

main$ained4

KHALDA Petroleum Company Page *$

Re !"# $!!%

Hazards Identifcation & Risk Assessment

8

-)&$$ing $*e !$$m

side f $*e pipe d&e $

c&$$er pil$4

-Fire C

e5plsin

-prper$6

damage4

)&$$ers / pil$ dis$ance $ !e

c*ec+ed and ad0&s$ !efre

s$ar$ $*e pera$in4

4 2 8

: ac$in necessar6

pr(ided cn$rl

meas&res are

main$ained4

9

8eleasing press&re

frm $*e mac*ine frm

$*e mac*ine (en$4

-Fire C

e5plsin

-%ns&re $*a$ n ne e5cep$

a&$*ri,ed persns inside $*e

*$ $apping area4

-S*&$ ff all mac*ine and

e1&ipmen$ inside $*e *$ $ap

area4

4 2 8

: ac$in necessar6

pr(ided cn$rl

meas&res are

main$ained4

KHALDA Petroleum Company Page *"

Re !"# $!!%

You might also like

- The Control of Hazardous Energy (Lockout/Tagou T)Document27 pagesThe Control of Hazardous Energy (Lockout/Tagou T)talhabctianNo ratings yet

- Safety Tier-1 Audit ChecklistDocument11 pagesSafety Tier-1 Audit ChecklistnursharunNo ratings yet

- Safety Alert: Pipe Fall From Skids Resulting in 2 Fatalities - Investigation LessonsDocument4 pagesSafety Alert: Pipe Fall From Skids Resulting in 2 Fatalities - Investigation LessonskhaledNo ratings yet

- Saudi Aramco Telecom Equipment InstallationDocument5 pagesSaudi Aramco Telecom Equipment InstallationaymenmoatazNo ratings yet

- Hse MS SlidesDocument32 pagesHse MS SlidesEneyo Victor100% (1)

- GN-Permit To Work SystemDocument13 pagesGN-Permit To Work SystemchachaNo ratings yet

- Confined Space TrainingDocument45 pagesConfined Space TrainingShogan05100% (1)

- Dropped Object PreventionDocument118 pagesDropped Object PreventionRazvan-Teodor PuscasuNo ratings yet

- Critical Lift ChecklistDocument4 pagesCritical Lift ChecklistUdha Pengen SuksesNo ratings yet

- Explosive Safety PR89POGC001Document10 pagesExplosive Safety PR89POGC001Nizar KhalidNo ratings yet

- BP Code of Conduct EnglishDocument28 pagesBP Code of Conduct EnglishAhmed El batalNo ratings yet

- Safety 2Document15 pagesSafety 2hyde2520015754No ratings yet

- 500 Ton 24 in Service ManualDocument23 pages500 Ton 24 in Service ManualImed HammoudaNo ratings yet

- LOLER Inspection Checklist GuideDocument25 pagesLOLER Inspection Checklist GuideTatak Bay AhmedNo ratings yet

- Rig Specific Emergency Response Plan Rev1Document33 pagesRig Specific Emergency Response Plan Rev1bilou100% (1)

- REGDOC2 1 2 Safety Culture Final EngDocument31 pagesREGDOC2 1 2 Safety Culture Final Engnagatopein6No ratings yet

- KPI Presentation PDFDocument31 pagesKPI Presentation PDFgilbertotiburcioNo ratings yet

- Gotcha BrochureDocument6 pagesGotcha BrochureNurfirman HNo ratings yet

- Motor Vehicle Safety ProcedureDocument6 pagesMotor Vehicle Safety ProcedureRonny FitriadiNo ratings yet

- HAZOP Analysis of Well Test OperationsDocument4 pagesHAZOP Analysis of Well Test OperationsMohamed SamirNo ratings yet

- Npe Project Ikpt Hsse Programs 2018: NO. Programmed & CoursesDocument1 pageNpe Project Ikpt Hsse Programs 2018: NO. Programmed & CoursesilhamNo ratings yet

- Guidelines For Hse AuditingDocument15 pagesGuidelines For Hse AuditingSteppesonNo ratings yet

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex IDocument3 pagesPro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex IMohammed Hamza100% (1)

- Lifting Plan V - 409 18ins Con ValDocument9 pagesLifting Plan V - 409 18ins Con ValAhmed Butt100% (1)

- Wellhead Safety GE Oil Gas Pressure ControlDocument20 pagesWellhead Safety GE Oil Gas Pressure ControlCarlos A.No ratings yet

- Schlumberger Management System OverviewDocument20 pagesSchlumberger Management System OverviewsudharsanNo ratings yet

- Safety Moment There Is No Shortcut To Safety 448cuoDocument6 pagesSafety Moment There Is No Shortcut To Safety 448cuoInnocent BhaikwaNo ratings yet

- Qa Imco Hse Ms QT 001 Hse Management SystemDocument21 pagesQa Imco Hse Ms QT 001 Hse Management SystemFrancis Enriquez TanNo ratings yet

- Manual Handling in The WorkplaceDocument2 pagesManual Handling in The WorkplaceDavid Pask-HughesNo ratings yet

- ISO 14001 Environmental Management System RequirementsDocument5 pagesISO 14001 Environmental Management System RequirementskemalNo ratings yet

- Vacuum Truck Plant Pre-Acceptance ChecklistDocument3 pagesVacuum Truck Plant Pre-Acceptance Checklistحماية منتجNo ratings yet

- SWP-12 Pressure TestDocument3 pagesSWP-12 Pressure TestLumin HanNo ratings yet

- 51 Confined SpaceDocument1 page51 Confined SpaceAnonymous ANmMebffKRNo ratings yet

- Ocm1 Confined SpaceDocument2 pagesOcm1 Confined SpacerapidsicuminteNo ratings yet

- Emediong U. - Risk Assessment Matrix 1 WorkingDocument20 pagesEmediong U. - Risk Assessment Matrix 1 WorkingsterlingNo ratings yet

- Cold Work PermitDocument11 pagesCold Work PermitMuneeb Ur Rehman100% (1)

- Wire LineDocument9 pagesWire LineAchmad Arief SolichinNo ratings yet

- Contractor Job Safety Plan: Project NameDocument15 pagesContractor Job Safety Plan: Project Namedroffilcz27No ratings yet

- How To Conduct Workplace Inspections: A Health and Safety Guideline For Your WorkplaceDocument6 pagesHow To Conduct Workplace Inspections: A Health and Safety Guideline For Your WorkplacemashanghNo ratings yet

- Frequently Asked Questions About The Life-Saving RulesDocument6 pagesFrequently Asked Questions About The Life-Saving RulesTFattahNo ratings yet

- Monthly Hse Rig InspectionDocument7 pagesMonthly Hse Rig InspectionHidacio Da LimiaNo ratings yet

- HSAC RP NBR 191 - Offshore Helideck Incident Bowtie - 1st Edition - Amendment 1Document78 pagesHSAC RP NBR 191 - Offshore Helideck Incident Bowtie - 1st Edition - Amendment 1Pat BNo ratings yet

- SIPP Training - 064413Document11 pagesSIPP Training - 064413Ndi FlavourNo ratings yet

- Applying Modified HAZOPs to Well TestingDocument1 pageApplying Modified HAZOPs to Well TestingHakim YahiaouiNo ratings yet

- Confind SpaceDocument11 pagesConfind Spacesolomonbeg100% (1)

- Coiled Tubing UnitDocument2 pagesCoiled Tubing UnitHao XuNo ratings yet

- HSSE Pack - Site Training PackDocument36 pagesHSSE Pack - Site Training Packfarhan Ali100% (1)

- 4 PSM Standard Operating Procedures2Document51 pages4 PSM Standard Operating Procedures2Ahmed AmerNo ratings yet

- Manual: Procedure Titel: HSE-ManualDocument11 pagesManual: Procedure Titel: HSE-ManualGeetha_jagadish30No ratings yet

- Safe Systems of Work 2Document23 pagesSafe Systems of Work 2Hossam AbdelmoneimNo ratings yet

- Health, Safety, Security, Environment, and Quality PolicyDocument1 pageHealth, Safety, Security, Environment, and Quality PolicyVăn PhúcNo ratings yet

- GP Handling The WeaponDocument2 pagesGP Handling The WeaponBeder MirjanNo ratings yet

- OIl Rig Safety ChecklistDocument10 pagesOIl Rig Safety ChecklistTom TaoNo ratings yet

- Safety Management - Module2Document27 pagesSafety Management - Module2Atienza ArjayNo ratings yet

- Calibrate Provers ConfidentlyDocument2 pagesCalibrate Provers Confidentlyjohnloops100% (1)

- Quality Expert with 17+ Years ExperienceDocument3 pagesQuality Expert with 17+ Years ExperiencevaibhavshankersharmaNo ratings yet

- CS 564 Software Requirements Engineering – Lecture 11 Risk AnalysisDocument50 pagesCS 564 Software Requirements Engineering – Lecture 11 Risk AnalysisJohn ArthurNo ratings yet

- Sample HEALTHDocument8 pagesSample HEALTHRobin RubinaNo ratings yet

- Simulation TextDocument79 pagesSimulation TextKristin MackNo ratings yet

- Solar Cells: Yogesh WakchaureDocument23 pagesSolar Cells: Yogesh Wakchauregad480No ratings yet

- Two Phase Flow RegimeDocument4 pagesTwo Phase Flow RegimeRafael ReyesNo ratings yet

- Free Convection: Its Free, No Operating Cost! .. Its Natural .Document34 pagesFree Convection: Its Free, No Operating Cost! .. Its Natural .gad480No ratings yet

- Take A Quicker Approach To Staggered BlowdownDocument3 pagesTake A Quicker Approach To Staggered Blowdowngad480No ratings yet

- Keyword:: - Thermal, - Heat, - Radiation, - Infra-Red, - EmitDocument24 pagesKeyword:: - Thermal, - Heat, - Radiation, - Infra-Red, - EmitPowthiran PushparajNo ratings yet

- Section 5 Equipment Selection, Sizing & DesignDocument43 pagesSection 5 Equipment Selection, Sizing & Designgad480No ratings yet

- Common Mistakes With Process EngineeringDocument3 pagesCommon Mistakes With Process Engineeringgad480No ratings yet

- Practical Process ControlDocument277 pagesPractical Process Controlgad480No ratings yet

- Vapor Depressurization - Concept and Implementation PDFDocument3 pagesVapor Depressurization - Concept and Implementation PDFgad480100% (1)

- OGP 444 Guide To Health & Safety ReportingDocument54 pagesOGP 444 Guide To Health & Safety Reportingmseymour91No ratings yet

- Know Your Engineering PhasesDocument7 pagesKnow Your Engineering Phasesgad480No ratings yet

- DEWA CoursesDocument4 pagesDEWA Coursesgad480No ratings yet

- OGP 444 Guide To Health & Safety ReportingDocument54 pagesOGP 444 Guide To Health & Safety Reportingmseymour91No ratings yet

- Advanced Gas Processing: A. Shahsavand A. Shahsavand A. Shahsavand A. ShahsavandDocument47 pagesAdvanced Gas Processing: A. Shahsavand A. Shahsavand A. Shahsavand A. Shahsavandgad480No ratings yet

- Wolverine-Engineering Data BookDocument454 pagesWolverine-Engineering Data Bookgad480100% (1)

- Does an F-Shell Heat Exchanger Suit Your ProcessDocument6 pagesDoes an F-Shell Heat Exchanger Suit Your Processishu vohraNo ratings yet

- Pressure Relief Systems 2014 Rev A PDFDocument118 pagesPressure Relief Systems 2014 Rev A PDFgad480100% (1)

- Flare Measurement ChallengesDocument4 pagesFlare Measurement ChallengesCarlos Alberto BalderramaNo ratings yet

- Design Requirements For Pressure Safety Relief Valves: Codes: Structure & ComparisonDocument5 pagesDesign Requirements For Pressure Safety Relief Valves: Codes: Structure & Comparisontss1372350% (2)

- Calculation of Relief Rate Due To External Heat Input For Dense Phase FluidsDocument3 pagesCalculation of Relief Rate Due To External Heat Input For Dense Phase FluidsphantanthanhNo ratings yet

- Fine-Tune Relief CalculationsDocument6 pagesFine-Tune Relief Calculationsgad480No ratings yet

- Super Sonic Solution PDFDocument2 pagesSuper Sonic Solution PDFgad480No ratings yet

- Flare Radiation PredictionDocument30 pagesFlare Radiation PredictionSmith ChhatrabhutiNo ratings yet

- Refrigeration CyclesDocument17 pagesRefrigeration CyclesKhairatun NisaNo ratings yet

- Chemical Engineering - Size Safety-Relief Valves For Any ConditionsDocument9 pagesChemical Engineering - Size Safety-Relief Valves For Any Conditionshajar_athirah75% (4)

- Design Requirements For Pressure Safety Relief Valves: Codes: Structure & ComparisonDocument5 pagesDesign Requirements For Pressure Safety Relief Valves: Codes: Structure & Comparisontss1372350% (2)

- Student SupDocument128 pagesStudent SupBhanupriya VaishnawNo ratings yet

- Engineering Design Guideline Separator Vessel Rev01Document28 pagesEngineering Design Guideline Separator Vessel Rev01Yan Laksana50% (4)

- Industrial Flare Testing PDFDocument5 pagesIndustrial Flare Testing PDFgad480No ratings yet

- Fundamentals of PSV Sizing (Part 1Document45 pagesFundamentals of PSV Sizing (Part 1gad480No ratings yet

- Approval Form For Material Gate Pass 内部出门证: COD Muhammed Thanzeel 8424503 0580281560Document1 pageApproval Form For Material Gate Pass 内部出门证: COD Muhammed Thanzeel 8424503 0580281560Muhammed ThanzeelNo ratings yet

- Underpinning: TypesDocument5 pagesUnderpinning: TypesEnggUsmanZafarNo ratings yet

- Book To PrintDocument291 pagesBook To PrintIan Untalan67% (6)

- SQL Narayana ReddyDocument124 pagesSQL Narayana ReddyTarikh Khan100% (1)

- Hyperion AumDocument24 pagesHyperion AumIssam HejazinNo ratings yet

- Kitting Project Streamlines Tractor Component AssemblyDocument44 pagesKitting Project Streamlines Tractor Component AssemblyRohit NagarNo ratings yet

- The 62443 Series OverviewDocument4 pagesThe 62443 Series OverviewJuan RiveraNo ratings yet

- Jules Pace 2023 Updated ResumeDocument3 pagesJules Pace 2023 Updated Resumeapi-651678757No ratings yet

- NRMCA ACPA StreetPaveDocument67 pagesNRMCA ACPA StreetPaveJairo MijangosNo ratings yet

- 2018-05 Greengauge21 Beyond - HS2WEBDocument220 pages2018-05 Greengauge21 Beyond - HS2WEBscribdstorageNo ratings yet

- Apple Macintosh 12-83Document18 pagesApple Macintosh 12-83heliosnineNo ratings yet

- GCC Automotive Salary GuideDocument19 pagesGCC Automotive Salary GuidemfakhrulNo ratings yet

- Heyer SagaDocument575 pagesHeyer SagaTawanannaNo ratings yet

- RCC FOOTING DETAILSDocument20 pagesRCC FOOTING DETAILSBijoy AVNo ratings yet

- JD TM-DC BSG-MT 1Document2 pagesJD TM-DC BSG-MT 1Anshuman Tiwari 4-Year B.Tech. Mining EngineeringNo ratings yet

- Development of Transportation in India 1976Document6 pagesDevelopment of Transportation in India 1976VijayuduGnanamkondaNo ratings yet

- Vocational Training ProgramDocument6 pagesVocational Training ProgramolabodeogunNo ratings yet

- Advanced Excel Data Management & AnalysisDocument3 pagesAdvanced Excel Data Management & AnalysisGaurav Shankar MullickNo ratings yet

- VSSC SummaryDocument6 pagesVSSC SummaryViji VijithaNo ratings yet

- DB KAF 4.3 en WebDocument14 pagesDB KAF 4.3 en WebnawajhaNo ratings yet

- Software Testing Uharc LicenseDocument1 pageSoftware Testing Uharc Licenseaanur1gNo ratings yet

- 0 EDEM Applications MeDocument16 pages0 EDEM Applications MeRuben PurcaNo ratings yet

- Kansai Group Corporation Invoice for Vehicle Export to MaldivesDocument1 pageKansai Group Corporation Invoice for Vehicle Export to MaldivesIbrahim JaleelNo ratings yet

- Inventory Management Practices of The Selected Meatshops inDocument24 pagesInventory Management Practices of The Selected Meatshops inZarah H. Leong0% (1)

- Fishinger Road Transportation PlanDocument89 pagesFishinger Road Transportation Planapi-267404258No ratings yet

- Jawaban Sertifikasi SAPDocument4 pagesJawaban Sertifikasi SAPanggie100% (2)

- C.Abdul Hakeem College of Engineering and Technology, Melvisharam Department of Aeronautical Engineering Academic Year 2020-2021 (ODD)Document1 pageC.Abdul Hakeem College of Engineering and Technology, Melvisharam Department of Aeronautical Engineering Academic Year 2020-2021 (ODD)shabeerNo ratings yet

- 2.2 Force, Power in Metal Cutting Q&A For StudentDocument7 pages2.2 Force, Power in Metal Cutting Q&A For StudentnikhilbathamNo ratings yet

- ATOS Compact Scan en RevADocument11 pagesATOS Compact Scan en RevAkoalaboiNo ratings yet

- Unitech Metro - SAFE WORK METHOD STATEMENT - CARPENTRYDocument3 pagesUnitech Metro - SAFE WORK METHOD STATEMENT - CARPENTRY'David Tee100% (2)