Professional Documents

Culture Documents

Sinac25 40

Uploaded by

Charly GomezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sinac25 40

Uploaded by

Charly GomezCopyright:

Available Formats

Sinac

25/40 SM

A

p

r

o

d

u

c

t

w

i

t

h

i

n

t

h

e

S

i

n

a

c

f

a

m

i

l

y

Incorporating the very latest advances in induction technology, the Sinac range offers unrivalled

reliability and application exibility.

Sinac increases throughput.

Fast, easy, accurate and repeatable heat delivery improves productivity.

Sinac improves quality.

Sinacs microcontroller feature lets you pre-set temperatures and ramp-up and dwell

times. Precise repeatability of heating cycles is assured.

Sinac is environment friendly.

No ames, no gas and virtually no radiant heat mean a more comfortable, more

productive working environment. Good news for the natural environment, too.

Sinac lets you do more.

Sinacs exibility and application versatility let you perform practically any heating

task.

Sinac reduces costs.

Precise heat delivery means you get things right the rst

time. Scrap, re-working and energy costs are minimized.

*

* The system shown is for illustrative purposes only. Coils and coil xtures are optional extras.

Sinac

25/40 SM

PRODUCT FEATURES

Stationary systems

Sinac is EFD Inductions range of complete stationary heating

systems. Sinacs compact design saves valuable oor space

and simplies in-line integration and retrotting.

Range of coils

Sinac systems can be tted with a practically limitless range of

coil designs. EFD Induction are specialists at designing, testing

and delivering customized, long-life coils.

Advanced MMI

Sinac features advanced Man/Machine Interface (MMI) control

panels. Sinacs clear, menu-based and multi-language control

panel maximize ease-of-use. Functionality is based on our

specially designed microcontroller. The coil can either be xed

in position, or operated manually when attached to a handheld

transformer (HHT).

Remote control

A remote control unit lets you control heating cycles via feed-

back to the microcontroller. Sinac is available with eld buses

and is compatible with Probus-DP, Devicenet, Ethernet. etc.

Robot compatible

Sinac can be adapted to any robot, allowing quick, no-fuss

intergration into automated production lines. The HHT can

easily be mounted on a robot arm.

Maximum output power

With Sinacs maximum power feature you can, for limited peri-

ods of time, operate with an output power far in excess of the

continuous output power.

TECHNICAL DATA

www.efd-induction.com

Model

Output

Continuous output power

Max. output power intermittent

Duty factor / cycle time

Output power regulation range

Frequency range

HHT 240 power cable length

Supply

Supply voltage range

Frequency

Nominal voltage

Nominal line current

Max. line current intermittent

Nominal apparent power

Maximum apparent power

Recommended fuse

Sinac 25/40 SM

25 kW

40 kW

50%/10 min

2-100 %

10 - 25 kHz

5 m (10 m)

3x 400-480 V + 10%

50/60 Hz

400 V

45A (RMS)

67A (RMS)

31 kVA

47 kVA

63 Amp

Cooling

Water consumption, min.

Water inlet temperature

Water pressure min./max.

Cooling water quality - ph

Enclosure

Ambient operating temp.

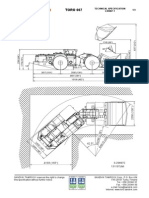

Outer dimensions cabinet (WxDxH)

Weight with HHT 240

Enclosure protection

Color

HHT 240 outer dimension (LxOD)

HHT 240 weight without handle

14 l/min*

max. 35

o

C

4/6 bar *

between 7.0 and 9.0

+5

o

C - +50

o

C

600x350x760 mm

95 kg

IP 54

RAL 7035 Grey

132 x 77 mm

3,5 kg

APPLICATIONS AREAS

Sinac is ideal for a wide range of applications: brazing, shrink tting, hardening, curing, straightening, heat treatment, etc. Sinac

is suitable for heating all kinds of electrical conductive materials like copper, aluminum, steel, stainless steel, brass, titanium, etc.

* Depends on coil

Subject to modication

EFD - 100301 - 002/12

You might also like

- Sinac 25 - 40Document2 pagesSinac 25 - 40Charly GomezNo ratings yet

- ENRX Sinac 100 160 SM EN LOWDocument2 pagesENRX Sinac 100 160 SM EN LOWShinrai ForuNo ratings yet

- ENRX Sinac 50 80 SM EN LOWDocument2 pagesENRX Sinac 50 80 SM EN LOWShinrai ForuNo ratings yet

- Plugin Minac70 110Document2 pagesPlugin Minac70 110skluxNo ratings yet

- Plugin Sinac200 320Document2 pagesPlugin Sinac200 320skluxNo ratings yet

- Plugin Minac50 80Document2 pagesPlugin Minac50 80skluxNo ratings yet

- Plugin Minac140 220Document2 pagesPlugin Minac140 220skluxNo ratings yet

- Plugin Minac12 18Document2 pagesPlugin Minac12 18skluxNo ratings yet

- Plugin Sinac300PMDocument2 pagesPlugin Sinac300PMskluxNo ratings yet

- ENRX Minac 6 10 SH EN LOWDocument2 pagesENRX Minac 6 10 SH EN LOWShinrai ForuNo ratings yet

- STP60 10 DEN1510 V11webDocument4 pagesSTP60 10 DEN1510 V11websalvgranNo ratings yet

- Unit5c Washing MachineDocument24 pagesUnit5c Washing MachineMukesh 2004No ratings yet

- Wall Mounted PDFDocument5 pagesWall Mounted PDFAhmed AzadNo ratings yet

- Colchester Tornado Brochure With Gripfast PDFDocument5 pagesColchester Tornado Brochure With Gripfast PDFMoustaffa100% (1)

- S7300Document240 pagesS7300Fernando PatroneNo ratings yet

- Low Voltage Switchgear PDFDocument12 pagesLow Voltage Switchgear PDFchidambaram kasiNo ratings yet

- iQA Series: Portable Passive Intermodulation AnalyzerDocument2 pagesiQA Series: Portable Passive Intermodulation AnalyzerMohamed JablounNo ratings yet

- Integrator Series AC DrivesDocument9 pagesIntegrator Series AC Drivesjohxav10No ratings yet

- Datasheet HSIx0020 V16 EngDocument2 pagesDatasheet HSIx0020 V16 EngChiana PetreNo ratings yet

- ENRX Minac 70 110 SM Twin EN LOWDocument2 pagesENRX Minac 70 110 SM Twin EN LOWShinrai ForuNo ratings yet

- Idi ProdSht Series 3000 2pg Jul11Document2 pagesIdi ProdSht Series 3000 2pg Jul11Mohammed FellaniNo ratings yet

- ABB Instrumentation: 600T Series TransmittersDocument10 pagesABB Instrumentation: 600T Series Transmittersalbert_ben13No ratings yet

- ABB Micro Drives: ACS150 0.37 To 4 kW/0.5 To 5 HP CatalogDocument12 pagesABB Micro Drives: ACS150 0.37 To 4 kW/0.5 To 5 HP CatalogCarlos RodriguesNo ratings yet

- 210kw Stype PG Us UlDocument4 pages210kw Stype PG Us UlronniedakingpouNo ratings yet

- TB9100 P25 Base Station SpecificationsDocument2 pagesTB9100 P25 Base Station Specificationsjunak72No ratings yet

- F4S Ramping Temperature ControllerDocument4 pagesF4S Ramping Temperature ControllervankarpNo ratings yet

- Acelerador MH 2000Document3 pagesAcelerador MH 2000jesus silvaNo ratings yet

- NI C Series Overview: DatasheetDocument10 pagesNI C Series Overview: DatasheetAriel GamarraNo ratings yet

- Sma SMC 9000tl-11000tl enDocument2 pagesSma SMC 9000tl-11000tl enTomuta StefanNo ratings yet

- Bosch BPT S String Inverters PDFDocument4 pagesBosch BPT S String Inverters PDFUsmanNo ratings yet

- Index ABC Siemens Fanuc enDocument16 pagesIndex ABC Siemens Fanuc enioancasian2015100% (1)

- Garantia - KacoDocument8 pagesGarantia - KacoMickael SoaresNo ratings yet

- Sharp NDDocument2 pagesSharp NDjgkigkelosNo ratings yet

- NI C Series Overview: DatasheetDocument11 pagesNI C Series Overview: DatasheetAntonio HerreraNo ratings yet

- Cps Sca50 60ktl Do Us 480 DatasheetDocument2 pagesCps Sca50 60ktl Do Us 480 Datasheetnelson_grandeNo ratings yet

- CPS SCA50 60KTL DO US 480 Datasheet PDFDocument2 pagesCPS SCA50 60KTL DO US 480 Datasheet PDFnelson_grandeNo ratings yet

- 9 PRO Alpha550 ENDocument12 pages9 PRO Alpha550 ENZayene KhmaisNo ratings yet

- Satcom Technologies Volume 1 v125Document68 pagesSatcom Technologies Volume 1 v125ธนวรรณ โภคาอนนต์No ratings yet

- Speed Sensors Line Guide: FeaturesDocument6 pagesSpeed Sensors Line Guide: FeaturesAbdoNo ratings yet

- 100KW 1MW InverterDocument6 pages100KW 1MW InverterJose MontillaNo ratings yet

- VRV 3 - SDocument20 pagesVRV 3 - SAeon SystemsNo ratings yet

- APG-Neuros Brochure EnglishDocument12 pagesAPG-Neuros Brochure EnglishkrustyboxNo ratings yet

- Up To Efficiency!: MBTU ModelsDocument8 pagesUp To Efficiency!: MBTU ModelslordsethdarknessNo ratings yet

- Sitrans F: Sitrans F M Magflo Electromagnetic Flowmeters Explore The Siemens SolutionDocument18 pagesSitrans F: Sitrans F M Magflo Electromagnetic Flowmeters Explore The Siemens SolutionAlonso CoradoNo ratings yet

- FC51Document8 pagesFC51Nguyễn Minh TríNo ratings yet

- Manual AutonicsDocument205 pagesManual Autonicsfey_tunerNo ratings yet

- HIH9000 SeriesDocument13 pagesHIH9000 SeriesDan LeNo ratings yet

- Panouri Solare SHARPDocument2 pagesPanouri Solare SHARPMoisi IonutNo ratings yet

- STULZ CyberAir Mini CW Brochure 2104 ENDocument2 pagesSTULZ CyberAir Mini CW Brochure 2104 ENAsadNo ratings yet

- FC360 Selection GuideDocument16 pagesFC360 Selection GuideMukund FarjandNo ratings yet

- Magnetic Particle Inspection EquipmentDocument16 pagesMagnetic Particle Inspection EquipmentSergio CalderonNo ratings yet

- Compact V/f & Sensorless InverterDocument12 pagesCompact V/f & Sensorless InverterAdrian DobrinNo ratings yet

- Robocut: α-C iB seriesDocument32 pagesRobocut: α-C iB seriesNcir TaherNo ratings yet

- Kanthal Ladle HeatingDocument4 pagesKanthal Ladle HeatingETA THERMALNo ratings yet

- Variador Yaskawa Pl.a1000.01Document76 pagesVariador Yaskawa Pl.a1000.01Tomas Enrique Ramirez GomezNo ratings yet

- Millimeter-Wave Receiver Concepts for 77 GHz Automotive Radar in Silicon-Germanium TechnologyFrom EverandMillimeter-Wave Receiver Concepts for 77 GHz Automotive Radar in Silicon-Germanium TechnologyNo ratings yet

- User Manual MinacDocument42 pagesUser Manual MinacCharly Gomez100% (1)

- KRC1 Start-Up PDFDocument29 pagesKRC1 Start-Up PDFRafael50% (2)

- Z197 E1 02A+ZX L N+UsersManualDocument186 pagesZ197 E1 02A+ZX L N+UsersManualCharly GomezNo ratings yet

- Ab SLM MDocument2 pagesAb SLM MAnnel Atenco GómezNo ratings yet

- IGBTDocument7 pagesIGBTCharly GomezNo ratings yet

- 17-06 McClelland Neil Screen Not Just Glass FinsDocument5 pages17-06 McClelland Neil Screen Not Just Glass FinsPaulNo ratings yet

- 6-General Miling InfoDocument5 pages6-General Miling InfoSakthi VelNo ratings yet

- Microsoft PowerPoint - Chiller Vs VRF PDFDocument23 pagesMicrosoft PowerPoint - Chiller Vs VRF PDFcalvin.bloodaxe44780% (2)

- Rewocare HV 100 - ApresentaçãoDocument12 pagesRewocare HV 100 - Apresentaçãohenriquefxs2926No ratings yet

- Wet BenchDocument29 pagesWet BenchAnurag KiroriwalNo ratings yet

- Degradation and Preservation Methods of Timber StructuresDocument24 pagesDegradation and Preservation Methods of Timber StructuresLórántBirtalanNo ratings yet

- MSEDCL Approved Vendor List (All Schemes) - VCB+CRP+IsolatorDocument11 pagesMSEDCL Approved Vendor List (All Schemes) - VCB+CRP+IsolatorSushil RautNo ratings yet

- Plaster ProfilesDocument16 pagesPlaster ProfilesSami LouisNo ratings yet

- TORO 007 Technical SpecificationDocument3 pagesTORO 007 Technical SpecificationArutnev EduardoNo ratings yet

- Bill of QuantityDocument20 pagesBill of QuantityBerry MarshalNo ratings yet

- Pulsed Laser Deposition (PLD)Document32 pagesPulsed Laser Deposition (PLD)Mohit YadavNo ratings yet

- Cálculo Consumo de Agua EstacionariasDocument2 pagesCálculo Consumo de Agua Estacionariasgabo_2612No ratings yet

- Disclosure To Promote The Right To InformationDocument25 pagesDisclosure To Promote The Right To InformationztmpNo ratings yet

- Bensultap 464Document6 pagesBensultap 464jessica montielNo ratings yet

- F1 CARS ChassisDocument27 pagesF1 CARS ChassisNikhil Goyal100% (1)

- TP16-2-Appearance of Embellishment & Trims After A Durability Wash TestDocument4 pagesTP16-2-Appearance of Embellishment & Trims After A Durability Wash TestSazzad Hossain Hossain100% (1)

- IM Protection Using PSCADDocument8 pagesIM Protection Using PSCADRavishankar KankaleNo ratings yet

- 1.canteen: TOTAL 15508 WDocument7 pages1.canteen: TOTAL 15508 WSanoj SebastianNo ratings yet

- HPB Series Photoelectric Controls Specifications and Features GuideDocument9 pagesHPB Series Photoelectric Controls Specifications and Features GuideRusdian Hasbi RidhoNo ratings yet

- Designguide Ankre 0408Document152 pagesDesignguide Ankre 0408Federico.IoriNo ratings yet

- Geosynthetic Reinforced Pile Supported Embankments PlaxisDocument121 pagesGeosynthetic Reinforced Pile Supported Embankments PlaxisAnonymous 5exSerNo ratings yet

- Carraro Transmission Parts CatalogDocument15 pagesCarraro Transmission Parts CatalogMichael Kubler67% (3)

- T/LL140 Series Fuel Level Sensor: Technical DataDocument1 pageT/LL140 Series Fuel Level Sensor: Technical Datacarlos andres mendezNo ratings yet

- 8 - Kaplan Turbines PDFDocument28 pages8 - Kaplan Turbines PDFMuhammad FirdausNo ratings yet

- Jaidah ElectricalDocument8 pagesJaidah Electricalahmed50alasal100% (1)

- Sustainable Performance in The Construction Industry: CEMEX STUDY 18/5/10 14:34 Page 1Document4 pagesSustainable Performance in The Construction Industry: CEMEX STUDY 18/5/10 14:34 Page 1Nikhil SatavNo ratings yet

- CAT Engine Driving TipsDocument2 pagesCAT Engine Driving Tipsjinxy5779No ratings yet

- Separation of Rayon Thread Thread Using Filter PaperDocument14 pagesSeparation of Rayon Thread Thread Using Filter PaperPandi Selvi ASNo ratings yet

- Bladder Tanks Data SheetDocument4 pagesBladder Tanks Data SheetIndra JumenaNo ratings yet

- Dando Mintec 9000 (Dando Drilling Indonesia)Document2 pagesDando Mintec 9000 (Dando Drilling Indonesia)Dando Drilling Indonesia100% (2)