Professional Documents

Culture Documents

IEC

Uploaded by

Jay JayCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IEC

Uploaded by

Jay JayCopyright:

Available Formats

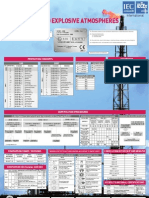

Temperature Class

Maximum

Surface

Temperature

NEC 500

NEC 505 /

CENELEC

450C T1 T1

300C T2 T2

280C T2A

260C T2B

230C T2C

215C T2D

200C T3 T3

180C T3A

165C T3B

160C T3C

135C T4 T4

120C T4A

100C T5 T5

85C T6 T6

Group, Area Classifcation

CENELEC / IEC / ATEX

Equipment

Group

Equipment Protection Level

Area Classification ATEX

94/9/EC

Explosive atmosphere present

ATEX

CENELEC/

IEC

Gas / Vapor Dust

II

1G/1D* Ga/Da* Zone 0 Zone 20 Continuously or for long periods of time

2G/2D* Gb/Db* Zone 1 Zone 21 Occasionally in normal operation

3G/3D* Gc/Dc* Zone 2 Zone 22 Infrequently or for short periods of time

Explosion Substance Group

NEC / IECEX / ATEX

Substance

Equipment

Classification

Substance

Group

IECEx / ATEX

Group

NEC

Acetylene

Class I

A

IIC

500

Hydrogen B

Ethylene C

IIB

Propane D IIA

Methane Mining I

Combustible Metal Dusts

Class II

E

IIIC

505 Conductive Dusts F

Non-conductive Dusts G IIIB

Combustible Fibers and

Flyings

Class III IIIA 500

Class, Area Classifcation

NEC 500/ 505 /506

Area Classifcation

Explosive atmosphere present

NEC500

NEC 505 /

CENELEC

NEC 506/

CENELEC

Division 1

Zone 0 Zone 20

Continuously or

for long periods of time

Zone 1 Zone 21 Occasionally in normal operation

Division 2 Zone 2 Zone 22

Infrequently or for short periods of time

or do not likely to occur in normal

operation

Typical Marking Example

Explosion Protection

Marking

Group / Class,

Area Classification

Protection

Method

Explosion

Group

Temperature

Class

EPL* Directive Legislation

II 2 G/D Ex ib IIB T4 ATEX

IEC / CENELEC

(Europe)

Ex ib IIB T4 Da IECEx

Class I Zone 1 AEx ib IIB T4 FM

NEC 505

(USA)

Class I, II, III Division 1

Group

A, B, C, D, E, F

T4 FM / UL

NEC 500

(USA)

Application Terminal

Power Supply

Communication Interface Module

RS232

RS232

Ethernet

Printer

PC connection

I/O Control

Remote Weighing Display

Tank on

Weigh Modules

Junction Box

AC Source

*Equipment Protection Level

*G = Gas / D = Dust

Marking of Weighing Equipment

for Hazardous Areas

Safe Area Hazardous Area

Protection Method

Type of

Protection

Symbol Design Principle

Classified Area

Standard

Category Division

Increased

Safety

Ex e

Dust / water

tight enclosure

II 2 G

II 3 G

1

2

IEC EN 60079-7

ISA/UL 60079-7

Intrinsic

Safety

Ex ia

Limit energy; no sparks or

surface temperature

II 1 G 1

IEC EN 60079-11

UL 60079-11

FM 3610

Ex ib II 2 G 1

Ex ic II 3 G 2

Pressurized Ex p

Purge enclosure with the

inert pressurized air

II 2 G

II 3 G

1, 2

IEC EN 60079-2

UL 60079-2

FM 3620

Encapsulation

Ex ma

Keep the explosive atmo-

sphere away from any

source of ignition

II 1 G 1

IEC EN 60079-18

ISA/UL 60079-18

Ex mb II 2 G 1

Ex mc II 3 G 2

Oil

Immersion

Ex o

Keep the explosive

atmosphere away from the

ignition source

II 2 G

II 3 G

1

2

IEC EN 60079-6

ISA/UL 60079-6

FM 3600

Protection n

Ex nA non-sparking device II 3 G 2

IEC EN 60079-15

ISA/UL 60079-15

FM 3600

Ex nC

sparking devices and

components

II 3 G 2

Ex nR restricted II 3 G 2

Ex nL limited Energy II 3 G 2

Flame

Proof

Ex d

Contain the explosion,

quench the flame

II 1 G

II 2 G

1

2

IEC EN 60079-1

ISA/UL 60079-1

Protection by

enclosure

tD

Special enclosure design,

measuring equipment

II 1 D

II 2 D

1

2

IEC EN 61241-1

IEC EN 60079-31

Ex d

Ex m

Ex o

Analog Platform

Application Terminal

Power Supply

Communication Interface Module

RS232

RS232

Crossed Ethernet cable

Printer

PC connection

Remote Terminal

Safe Area Hazardous Area

Ex tD

Ex n

Hazardous Solutions Zone 1/21, Division 1 Hazardous Solutions Zone 1/21, Division 1

www.mt.com/ind-wp-intrinsic-safe

You might also like

- iUPS101: XXXX Ii 2 G Ex D (E) Iib T6 GBDocument1 pageiUPS101: XXXX Ii 2 G Ex D (E) Iib T6 GBAdemola Olajide TejumolaNo ratings yet

- Intertek Poster A1 (HazLoc - Guide) - 0Document1 pageIntertek Poster A1 (HazLoc - Guide) - 0Antonio FilipeNo ratings yet

- ExtronicsWallchart 160708Document1 pageExtronicsWallchart 160708Shyam VarunNo ratings yet

- Hazardous Area ClassificationsDocument1 pageHazardous Area ClassificationsAndrew Bull100% (2)

- Hazardous Area Table IEC & NEC (NEMA) Cooper Crouse Hinds PDFDocument1 pageHazardous Area Table IEC & NEC (NEMA) Cooper Crouse Hinds PDFAgustinus Made Theo Dwijaya100% (3)

- Marking Electrical Equipment for Explosive AtmospheresDocument1 pageMarking Electrical Equipment for Explosive AtmospheressaiyedasadNo ratings yet

- Poster Explosive CEDocument1 pagePoster Explosive CENico ArdeleanNo ratings yet

- Intrinsic SafetyDocument85 pagesIntrinsic Safetycaigithe852456100% (2)

- Atex ChartDocument1 pageAtex ChartShinoj B.c.100% (2)

- DS59 IEC 60079 0 2011 The Differences and The ConsequencesDocument3 pagesDS59 IEC 60079 0 2011 The Differences and The ConsequencesGlen AshwellNo ratings yet

- ATEX Rating ChartDocument1 pageATEX Rating ChartAshish Joshi67% (3)

- Cable Glands in Hazardous Areas CCG PresentationDocument59 pagesCable Glands in Hazardous Areas CCG PresentationAwotiku Abimbola100% (2)

- 10-1 2018 3Document9 pages10-1 2018 3Efari BahcevanNo ratings yet

- IEC 61439 Parts 1 & 2 Low-Voltage Switchgear and Controlgear AssembliesDocument35 pagesIEC 61439 Parts 1 & 2 Low-Voltage Switchgear and Controlgear AssembliesAlejandro Maturano100% (1)

- Hazardous Area ClassificationDocument63 pagesHazardous Area Classificationhtetwin100% (3)

- Conference IEC 60079-14Document79 pagesConference IEC 60079-14arturoncNo ratings yet

- Rockwell Machine Safety ISO 13849-1Document17 pagesRockwell Machine Safety ISO 13849-1Arun BabuNo ratings yet

- Explosion Protection Wall Chart BASEEFADocument1 pageExplosion Protection Wall Chart BASEEFAweby98No ratings yet

- Iec 60079-25 Intrinsically Safe SystemsDocument65 pagesIec 60079-25 Intrinsically Safe SystemsDalamagas KwnstantinosNo ratings yet

- Ex Essential Explosion Protection Rstahl B enDocument56 pagesEx Essential Explosion Protection Rstahl B encruzleeno100% (1)

- New Atex Directive: Lars EkströmDocument23 pagesNew Atex Directive: Lars EkströmvalimironescuNo ratings yet

- IEC 60079-18 - 2009 - Encapsulated Protection - Ex M PDFDocument35 pagesIEC 60079-18 - 2009 - Encapsulated Protection - Ex M PDFRadu Babau100% (1)

- Procom Ex certified antennas for hazardous environmentsDocument8 pagesProcom Ex certified antennas for hazardous environmentsBao Quoc Mai100% (1)

- ISA-61241 Electrical Aparatus To Use in Zone21y22Document26 pagesISA-61241 Electrical Aparatus To Use in Zone21y22nicolascsNo ratings yet

- Explosionprotection enDocument52 pagesExplosionprotection enfuvl01No ratings yet

- How To Calculate An Intrinsically Safe Loop ApprovalDocument7 pagesHow To Calculate An Intrinsically Safe Loop ApprovalAlexander Ariza Nadjar100% (1)

- IEC 60079-11 equipment intrinsic safety updatesDocument6 pagesIEC 60079-11 equipment intrinsic safety updatesQuynh ElectricalNo ratings yet

- IEC Standards for Explosive AtmospheresDocument1 pageIEC Standards for Explosive AtmospheresMaahiNo ratings yet

- Atex GuideDocument6 pagesAtex GuideValiNo ratings yet

- Is-IEC 60079-31 (2008) - Explosive Atmospheres, Part 31 - Equipment Dust Ignition Protection by Enclosure TDocument15 pagesIs-IEC 60079-31 (2008) - Explosive Atmospheres, Part 31 - Equipment Dust Ignition Protection by Enclosure TparathasiNo ratings yet

- IEEE Seminar Hazardous ClassificationDocument39 pagesIEEE Seminar Hazardous ClassificationMochamad Aziz100% (1)

- ATEX Guide to Explosive Atmosphere ProtectionDocument44 pagesATEX Guide to Explosive Atmosphere Protectionminah22100% (4)

- Hazardous Area ClassificationDocument23 pagesHazardous Area ClassificationDattatray Nikam100% (11)

- IEC61285 Analyser HouseDocument34 pagesIEC61285 Analyser HouseLuigi SergiNo ratings yet

- ISO 12100 The Ultimate Step-By-Step GuideFrom EverandISO 12100 The Ultimate Step-By-Step GuideRating: 1 out of 5 stars1/5 (1)

- Ingress SafetyDocument1 pageIngress Safetyjohn_tigerNo ratings yet

- Types of Protection for Electrical and Non-Electrical Equipment in Explosive AtmospheresDocument1 pageTypes of Protection for Electrical and Non-Electrical Equipment in Explosive AtmospheresHimanshu ChichraNo ratings yet

- Classification of Hazardous AreasDocument1 pageClassification of Hazardous Areasadhi2001No ratings yet

- ATEX-affisch MaluxDocument1 pageATEX-affisch MaluxHomer SilvaNo ratings yet

- Atex eDocument1 pageAtex egtomyNo ratings yet

- Equipment Certification Guide For Hazardous Areas: North America Atex and Iec Ex ComparisonDocument1 pageEquipment Certification Guide For Hazardous Areas: North America Atex and Iec Ex ComparisonBalan PalaniappanNo ratings yet

- Safety. Everywhere.: Electrical Equipment Non-Electrical EquipmentDocument1 pageSafety. Everywhere.: Electrical Equipment Non-Electrical EquipmentNavin KeralaNo ratings yet

- Your Safety - Our Reality: Class I, Zone 1, A Ex de IIC T6 Ex de Iic T6 Ex de Iic T6Document1 pageYour Safety - Our Reality: Class I, Zone 1, A Ex de IIC T6 Ex de Iic T6 Ex de Iic T6And WebNo ratings yet

- IECEx Certification Bodies for Explosive Atmospheres EquipmentDocument1 pageIECEx Certification Bodies for Explosive Atmospheres EquipmentMrudang MehtaNo ratings yet

- DS51 Non Electrical Wallchart Iss5 0813Document1 pageDS51 Non Electrical Wallchart Iss5 0813perumal1312No ratings yet

- At ExDocument2 pagesAt ExMoustafa Ibrahim YehyaNo ratings yet

- CSA Group WallchartDocument1 pageCSA Group WallchartMohd Lutfi MahaliNo ratings yet

- EX Plakat GBDocument1 pageEX Plakat GBBohumil NáplavaNo ratings yet

- Bartec Hazardous Class PosterDocument1 pageBartec Hazardous Class PosterDen Andri Nchu100% (2)

- Lcie Bureau Veritas Atex Poster PDFDocument1 pageLcie Bureau Veritas Atex Poster PDFAncaOniscuNo ratings yet

- 207-x Marking UkDocument4 pages207-x Marking UkgueridiNo ratings yet

- Basics of Explosion Protection - IecDocument4 pagesBasics of Explosion Protection - IecbenounaomarNo ratings yet

- ATEX Reference GuideDocument2 pagesATEX Reference Guidebabis1980No ratings yet

- North America: Hazardous Areas, Explosive Atmospheres and Equipment GroupDocument1 pageNorth America: Hazardous Areas, Explosive Atmospheres and Equipment GroupkazdanoNo ratings yet

- Hazardous AREA ClassificationDocument10 pagesHazardous AREA Classificationfarzam100% (1)

- WEG Guide To Explosive Atmospheres Wallchart 50042119 Quick Guide EnglishDocument1 pageWEG Guide To Explosive Atmospheres Wallchart 50042119 Quick Guide EnglishJohnNo ratings yet

- Clasificacion de Enclosures Nema Ip AtexDocument5 pagesClasificacion de Enclosures Nema Ip AtexJORGE ALBERTO PEREZ RAMIREZNo ratings yet

- Shared Research Flammable Mist PDFDocument2 pagesShared Research Flammable Mist PDFJay JayNo ratings yet

- Scaled Wind Farm FMEA Reveals Hydraulic System SafetyDocument96 pagesScaled Wind Farm FMEA Reveals Hydraulic System SafetyJay JayNo ratings yet

- TSDocument54 pagesTSnosula87No ratings yet

- Offshore Platform SmallerDocument1 pageOffshore Platform SmallerBaba JohnehNo ratings yet

- Offshore Platform SmallerDocument1 pageOffshore Platform SmallerBaba JohnehNo ratings yet

- Shared Research Flammable Mist PDFDocument2 pagesShared Research Flammable Mist PDFJay JayNo ratings yet

- Gas Detector Brochure POG WebDocument11 pagesGas Detector Brochure POG WebBaba JohnehNo ratings yet

- Accident Analysis PDFDocument25 pagesAccident Analysis PDFJay JayNo ratings yet

- Helicopter Operations: Oil & Gas Consultancy ServicesDocument4 pagesHelicopter Operations: Oil & Gas Consultancy ServicesJay JayNo ratings yet

- Pumps and System CurvesDocument22 pagesPumps and System CurvesgusgifNo ratings yet

- Offshore Platform SmallerDocument1 pageOffshore Platform SmallerBaba JohnehNo ratings yet

- Helicopter Operations: Oil & Gas Consultancy ServicesDocument4 pagesHelicopter Operations: Oil & Gas Consultancy ServicesJay JayNo ratings yet

- Offshore Platform SmallerDocument1 pageOffshore Platform SmallerBaba JohnehNo ratings yet

- Process Safety in Chevron PDFDocument40 pagesProcess Safety in Chevron PDFAndika Dimas Prinanda100% (1)

- TSDocument54 pagesTSnosula87No ratings yet

- RockWell Automation (2013) - Process Safebook 1 - Functional Safety in The Prcess Industry (Principles, Standards and Implementation)Document170 pagesRockWell Automation (2013) - Process Safebook 1 - Functional Safety in The Prcess Industry (Principles, Standards and Implementation)Georges Kouroussis100% (1)

- Shell Hazardous Area Classification FundamentalsDocument30 pagesShell Hazardous Area Classification Fundamentalsthekevindesai100% (16)

- Lines of Defence/Layers of Protection Analysis in The COMAH ContextDocument56 pagesLines of Defence/Layers of Protection Analysis in The COMAH ContextJay JayNo ratings yet

- BETE FireProtectionDocument8 pagesBETE FireProtectionmax_powerNo ratings yet

- Det Tronics High Hazard Best Practices White Paper 74 1020Document6 pagesDet Tronics High Hazard Best Practices White Paper 74 1020Jay JayNo ratings yet

- Product Information SWEDAC Damping CassettesDocument8 pagesProduct Information SWEDAC Damping CassettesJay JayNo ratings yet

- Safety in Design PDFDocument11 pagesSafety in Design PDFharryNo ratings yet

- BETE FireProtectionDocument8 pagesBETE FireProtectionmax_powerNo ratings yet

- Fire Pump Design & Testing TS 300 1 1 Friday 9:00am 12:00pm Greg TromboldDocument74 pagesFire Pump Design & Testing TS 300 1 1 Friday 9:00am 12:00pm Greg TromboldDonbabajayNo ratings yet

- Ageing Plant Core PDFDocument16 pagesAgeing Plant Core PDFMohamed FaroukNo ratings yet

- Management of Functional Safety Guideline Process PDFDocument13 pagesManagement of Functional Safety Guideline Process PDFJay JayNo ratings yet

- Safety in Design PDFDocument11 pagesSafety in Design PDFharryNo ratings yet

- Water Deluge Protection of LPGDocument20 pagesWater Deluge Protection of LPGVivi OktaviantiNo ratings yet

- Safety in Design PDFDocument11 pagesSafety in Design PDFharryNo ratings yet

- SAFETY IN DESIGN: KEY PRINCIPLES AND BENEFITSDocument14 pagesSAFETY IN DESIGN: KEY PRINCIPLES AND BENEFITSJay JayNo ratings yet

- 1757 In092b en PDocument20 pages1757 In092b en PnmnicolauNo ratings yet

- Iranian Petroleum Standard for Gas HandlingDocument32 pagesIranian Petroleum Standard for Gas HandlingTalebNo ratings yet

- Sealconex1 60 PDFDocument64 pagesSealconex1 60 PDFseanll2563No ratings yet

- Agv10 Manual PDFDocument60 pagesAgv10 Manual PDFEd OviedoNo ratings yet

- Hazardous Area ClassificationDocument100 pagesHazardous Area ClassificationVishal NarkhedeNo ratings yet

- Product Data Sheet Rosemount 2240s Multi Input Temperature Transmitter en 104518Document24 pagesProduct Data Sheet Rosemount 2240s Multi Input Temperature Transmitter en 104518matthew kagurabadzaNo ratings yet

- Wastewater Technical ManualDocument32 pagesWastewater Technical ManualagonzalezcordovaNo ratings yet

- Bowex-Elastic: KTR-N Sheet: Edition: 40113 EN 1 of 21 6Document21 pagesBowex-Elastic: KTR-N Sheet: Edition: 40113 EN 1 of 21 6влад камрNo ratings yet

- Transmisores de Nivel FisherDocument16 pagesTransmisores de Nivel Fishercolh_10052789No ratings yet

- SCADAPack RTUs Controllers IO DatasheetDocument54 pagesSCADAPack RTUs Controllers IO DatasheetAqua Technology GroupNo ratings yet

- MANUAL de INSTALC. FUNC. y MANTENIMIENTO Flygt 2201Document54 pagesMANUAL de INSTALC. FUNC. y MANTENIMIENTO Flygt 2201José SNo ratings yet

- An Introduction To Boiler Control Systems R1Document35 pagesAn Introduction To Boiler Control Systems R1Smiss KarlNo ratings yet

- Abs Rules Part4 2001Document232 pagesAbs Rules Part4 2001Denny Angriawan NurcahyaNo ratings yet

- Fisher D4 Control Valve Assembly: FeaturesDocument12 pagesFisher D4 Control Valve Assembly: FeaturesAlberto GuillenNo ratings yet

- Abtech Junction Boxes and Enclosures - Industrial Hazardous Area High Voltage Catalogue 2012Document242 pagesAbtech Junction Boxes and Enclosures - Industrial Hazardous Area High Voltage Catalogue 2012rocketvtNo ratings yet

- OSH Safety Health DisciplinesDocument16 pagesOSH Safety Health DisciplinesEDRICK PARASNo ratings yet

- Hydrogen SafetyDocument6 pagesHydrogen SafetyjoseritoNo ratings yet

- 32M 06004 01.metric PDFDocument66 pages32M 06004 01.metric PDFErdian FakirNo ratings yet

- D06-4001-000 RAEGuard 3 - MANUAL - EN - RevADocument82 pagesD06-4001-000 RAEGuard 3 - MANUAL - EN - RevAalNo ratings yet

- Hazardous Areas ClassificationsDocument6 pagesHazardous Areas ClassificationsAV ShrinivasNo ratings yet

- E C S PDFDocument412 pagesE C S PDFRájDèép TrìpâţhíNo ratings yet

- ESI Tuning MixDocument14 pagesESI Tuning MixMauricio CruzNo ratings yet

- Manual RM140W Overfill Protection Rack Monitor PDFDocument41 pagesManual RM140W Overfill Protection Rack Monitor PDFJambu AlasNo ratings yet

- Brochure Ex-P Pressurized Enclosure System Zone1 f850sDocument6 pagesBrochure Ex-P Pressurized Enclosure System Zone1 f850ssaman749No ratings yet

- Eddy Probes SystemsDocument55 pagesEddy Probes SystemsRoberto Galina OrtizNo ratings yet

- Actuated Quarter Turn IPF Valves SpecificationDocument117 pagesActuated Quarter Turn IPF Valves Specificationviperjet67% (3)

- Heat Trace InstallDocument24 pagesHeat Trace InstallpfpuimNo ratings yet

- AADvance Especificacines TecnicasDocument146 pagesAADvance Especificacines TecnicasIsaac MendibleNo ratings yet

- Catalogo GeneralDocument20 pagesCatalogo Generalmiyagui77No ratings yet

- Umc22 FBPDocument104 pagesUmc22 FBPWil Bruno Berrocal CárdenasNo ratings yet