Professional Documents

Culture Documents

BT Road Estimate Model

Uploaded by

sasidharkatari91572Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BT Road Estimate Model

Uploaded by

sasidharkatari91572Copyright:

Available Formats

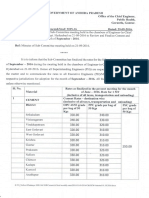

Sl. No.

Description

Source (name of

quarry)

Unit Cost at source

Lead in

K.M.

Conveyanc

e Charges

Deduct 14 %

contractor

profit

Seign-

charges

Total Rate.

1 Cost of Cement OPC Local 4000.00 4000.00

2 Cost of Sand for Mortor Concrete Items Jalleru 1 Cum 462.00 7.00 109.30 13.42 40.00 597.88

3 Cost of Sand for Motor Jalleru 1 Cum 606.00 7.00 109.30 13.42 40.00 741.88

4 Cost of Sand for filling Jalleru 1 Cum 342.00 7.00 109.30 13.42 40.00 477.88

5 Aggregates 6 mm Nominal size EGK Road 1 Cum 735.00 45.00 556.60 68.35 50.00 1273.25

6 Aggregates 10 mm Nominal size EGK Road 1 Cum 935.00 45.00 556.60 68.35 50.00 1473.25

7 Aggregates 13.2/12.5 mm Nominal size EGK Road 1 Cum 1097.00 45.00 556.60 68.35 50.00 1635.25

8 Aggregates 20 mm Nominal size EGK Road 1 Cum 1365.00 45.00 556.60 68.35 50.00 1903.25

9 Aggregates 25 mm Nominal size EGK Road 1 Cum 1313.00 45.00 556.60 68.35 50.00 1851.25

10 Aggregates 40 mm Nominal size EGK Road 1 Cum 845.00 45.00 556.60 68.35 50.00 1383.25

11 Aggregates below 5.6mm EGK Road 1 Cum 557.00 45.00 556.60 68.35 50.00 1095.25

12 Aggregates 22.4 mm to 2.36mm EGK Road 1 Cum 914.00 45.00 556.60 68.35 50.00 1452.25

13 Aggregates 22.4 mm to 5.60 mm EGK Road 1 Cum 1040.00 45.00 556.60 68.35 50.00 1578.25

14 Aggregates 45 mm to 22.4 mm EGK Road 1 Cum 1145.00 45.00 556.60 68.35 50.00 1683.25

15 Aggregates 63 mm to 45 mm EGK Road 1 Cum 662.00 45.00 556.60 68.35 50.00 1200.25

16 Aggregates 11.2 mm to 0.09 mm EGK Road 1 Cum 704.00 45.00 556.60 68.35 50.00 1242.25

17 Aggregates 13.2 mm to 0.09 mm EGK Road 1 Cum 798.00 45.00 556.60 68.35 50.00 1336.25

18 Aggregates 13.2 mm to 5.6 mm EGK Road 1 Cum 919.00 45.00 556.60 68.35 50.00 1457.25

19 Aggregates 53 mm to 22.4 mm EGK Road 1 Cum 872.00 45.00 556.60 68.35 50.00 1410.25

20 Aggregates10 mm to 5 mm EGK Road 1 Cum 875.00 45.00 556.60 68.35 50.00 1413.25

21 Aggregates 25 mm to 10 mm EGK Road 1 Cum 1129.00 45.00 556.60 68.35 50.00 1667.25

22 Aggregates Below 5.6 mm EGK Road 1 Cum 557.00 45.00 556.60 68.35 50.00 1095.25

23 Cost of Gravel janampeta 1 Cum 103.00 5 84.10 10.33 22.00 198.77

24 Cost of Stone Dust/ EGK Road 1 Cum. 357.00 45.00 556.60 68.35 50.00 895.25

Quarry rubbish 1 Cum. 81.00 45.00 556.60 68.35 50.00 619.25

25 Cost of Steel Local 1 MT 44000 44.00

28 Cost of Bricks

29 20 MM HBG Metal (Graded) 0.70 cm 1903.25 1332.27

0.10 cm 1635.25 163.52

0.10 cm 1473.25 147.32

0.10 cm 1273.25 127.32

1770.45

20 MM HBG Metal (Graded)

6 mm HBG Metal

JANGAREDDYGUDEM NAGARPANCHAYAT

Material Lead Statement for 2014-15

20mmHBG Metal

12mmHBG Metal

10 mm HBG Metal

Ordinary soil

Manual Means Upto 3m depth unit -

1.00 Cum

Taking out put 10 Cum

Labour

Mate

Mazdoor (Unskiled) day 3.64 295.00 1073.80

20% labour 214.76

Total 1288.56

14% over heads and contractor profit 180.40

1468.96 10 Cum

146.90 1 Cum

ii

Unit = cum

Taking output = 300 cum

a)Labour

Mate day -

Mazdoor (Skilled) day 2.48 385.00 954.80

Mazdoor (Unskilled) day 10.00 295.00 2950.00

M.A 20% on Labour 780.96

b) Machinery

Motor grader 110 HP 50 cum per

hour

hour 6.00 0.00 0.00

Three wheel 80-100 kN static roller

@10 cum per hour P.No.43

hour 30.00 1718.70 51561.00

Water tanker 6 kl capacity hour 5.00 80.48 402.38

Tractor with Rotavator 25 cum per

hour

hour 12.00 0.00 0.00

c) Material 0.00

Naturally Occuring Stone Dust (local

materials as per Table 400.13) cum 300.00 895.25 268573.68

Seigniorage 300.00 0.00 0.00

Water - P-34 KL 30.00 103.00 3090.00

328312.82

d&e) Overheads & Contractors

Profit @ 14%

45963.79

JANGAREDDYGUDEM NAGARPANCHAYAT

DATA - 2014-15

Granular Sub Base with Stone Dust

Granular sub-base/base/surface course with local materials (Table 400.13) by mix in

place method normal Construction of granular sub-base by providing local material

spreading in uniform layers with motor grader on prepared surface, mixing by mix in

place method with rotavator at once and compacting with smooth wheel roller to

achieve the desired density complete as per Clause 401.4 as per Technical Specification

Clause 408 MORD - RBR-SBBS-12 P.338

Earthwork in excavation for structures as per drawing and technical specifications Clause

305.1 including setting out, construction of shoring and bracing, removal of stumps and other

deleterious material and disposal upto a lead of 50 m, dressing of sides and bottom and

backfilling in trenches with excavated suitable material as per Technical Specification 305

MORD / 304 MORTH (Page No.484) RBR FN-DN1 and as directed by the departmental officer in-

charge of work as per s.s

2

Cost for 300 cum = a+b+c+d+e 374276.61

Rate per cum = (a+b+c+d+e)/300 1247.59 /1 Cum

ii

Unit = cum

Taking output = 300 cum

a)Labour

Mate day -

Mazdoor (Skilled) day 2.40 385.00 924.00

Mazdoor (Unskilled) day 8.00 295.00 2360.00

Add 20% 3284.00

b) Machinery

Motor grader 110 HP 50 cum per

hour

hour 6.00

- -

Three wheel 80-100 kN static roller

@10 cum per hour

hour 30.00 1718.70 51561.00

Water tanker 6 kl capacity hour 5.00 80.48 402.38

Tractor with Rotavator 25 cum per

hour

hour 12.00

- -

c) Material

Soil gravel mixture/quarry waste

(Local material as per Table400.13)

(Gravel)

cum 300.00 198.77 59631.58

Gravel 75% 0.00 0.00 0.00

Seigniorage Gravel 0.00 0.00 0.00

Water kl 30.00 103.00 3090.00

121252.95

d&e) Overheads & Contractors

Profit @ 14%

16975.41

Cost for 300 cum = a+b+c+d+e 138228.37

Rate per cum = (a+b+c+d+e)/300

460.76 /1 Cum

Granular sub-base/base/surface course with local materials (Table 400.13) by mix in

place method normal Construction of granular sub-base by providing local material

spreading in uniform layers with motor grader on prepared surface, mixing by mix in

place method with rotavator at once and compacting with smooth hand roller to achieve

the desired density complete as per Clause 401.4 as per Technical Specification Clause

408 MORD.

Granular Sub Base Gravel for side berms

3

L B D

1 x 1 1010.00 4.50 0.10 454.50

or Say 460.00 cum 1247.59 cum 573890.808

1 x 1 1010.00 4.50 0.10 454.50

or Say 460.00 cum 857.752 cum 394565.962

1

1 X 1 1010.00 4.30 0.20 868.60 cum 2,373.03 1cum 2061211

2

1 X 1 1010.00 4.00

4040.00 sqm

8.83

1sqm 35664

3

1 X 1 1010.00 4.00 0.025 101.00 cum 7236.92 1cum 730929

4

JANGAREDDYGUDEM NAGARPANCHAYAT

Detailed cum Abstract Estimate

Name of Work: Providing B.T. road from Akshitha Hospital (Srinivasapuram Road) to By-Pass Road via Saibaba

Temple, in 18th Ward of Jangareddygudem Nagarpanchayat

Estimate Amt: Rs. 34,60,000.00

Sl.

No

Description of Item Nos

Measurments

Quantity Rate

Supply and Delivery of Quary Dust from approved Quary including cost and

conveyance senries of materials from approved Quary including spreading of Quary

Dust and rolling with road roller for low lying road portion

Granular sub-base/base/surface course with local materials (Table 400.13) by mix

in place method normal Construction of granular sub-base by providing local

material spreading in uniform layers with motor grader on prepared surface,

mixing by mix in place method with rotavator at once and compacting with smooth

hand roller to achieve the desired density complete as per Clause 401.4 as per

Technical Specification Clause 408 MORD.

per Amount

Providing laying, spreading and compacting graded HBG crushed stone aggregate to Wet

Mix macadem specifictation including cost, seigniorage of all materials and including

premixing the material with water at OMC in Mechanical mix plant carriage of mixed

material by tripper to site, laying in uniform layers with paver in base coursed on well

prepared surface and compacting with Vibratory rooler to acheive the desired density

etc., complete as per SS and as directed by the departmental officer in charge of the

work. (in Two layers)

Providing and applying tack coat with bitumen emulsion using emulsion pressure

distributor at the rate of 0.20 kg per sqm on the prepared bituminous/granular surface

cleaned with mechanical broom as per Tech. specification No 503 MORTH

Providing 25 mm thick compacted Semi-Dense Bituminous Concrete by hot mix plant

using hard blasted granite crushed aggregates of Grading -2 as per table 500-15 of

specification 508 of MoRT&H (4th Revision), premixed with bituminous binder 60/70

grade @ 5% of mix and filler, transporting the hot mix to work site, laying with

mechanical paver finisher to the required grade, level and alignment, rolling with smooth

wheeled,vibratory and tandem rollers to achieve the desired compaction as per

MoRT&H Specification 508 (4th Revision) complete for finished item of work in all

respects as directed by Engineer-in-charge.

Providing and laying surface dressing in single coat using 6 mm nominal size IRC HBG

machine crushed stone aggregates @ 0.004 cum / sqm on a layer of bitumen binder of

80/100 grade @ 0.75 kg / sqm laid on prepared surface and rolling with 8-10 T Power

1 X 1 1010.00 4.00 4040.00 sqm 38.54 1 sqm 155697

5

1 x 2 1010.00 1.00 0.20 404.00 cum 460.76 1cum 186147

3169648

6 Provision for VAT at 5.00% 158482

7 Provision for labour cess @ 1% 31696

8 Provision for TC & SC CHarges @ 3 % 95089

9 provision for unforeseen items 5000

Total 3459916

Say 3460000

Granular sub-base/base/surface course with local materials (Table 400.13) by mix in

place method normal Construction of granular sub-base by providing local material

spreading in uniform layers with motor grader on prepared surface, mixing by mix in

place method with hand roller and ramming to achieve the desired density complete as

per Clause 401.4 as per Technical Specification Clause 408 MORD. - for side berms

You might also like

- Data preparation rates excavation concrete works 2015Document14 pagesData preparation rates excavation concrete works 2015Ravi RajaNo ratings yet

- Rate Analysis For Shuttering of Floor Beam /slabDocument1 pageRate Analysis For Shuttering of Floor Beam /slabEngr. MahmudNo ratings yet

- Interagency Helicopter Operations GuideDocument548 pagesInteragency Helicopter Operations GuideJeffTabor100% (1)

- Tile Rate Analysis PDFDocument3 pagesTile Rate Analysis PDFSangam Suresh100% (1)

- Rate Analsis Chapter No 25 Iron WorkDocument76 pagesRate Analsis Chapter No 25 Iron WorkSarin100% (1)

- APRILIA Caponord 1200 ManualDocument168 pagesAPRILIA Caponord 1200 ManualNur Ain Nusrah50% (2)

- Analysis of Boundary WallDocument7 pagesAnalysis of Boundary WallsamirNo ratings yet

- Providing and laying bituminous concreteDocument2 pagesProviding and laying bituminous concreteHPSIDC MehatpurNo ratings yet

- Rate Analysis 2 50m Test Pile R1Document15 pagesRate Analysis 2 50m Test Pile R1arif hossain labuNo ratings yet

- Rate Analysis For Concrete PavementDocument1 pageRate Analysis For Concrete PavementSuraj Shenoy Nagar100% (1)

- Total Price Adjustment SheetDocument1 pageTotal Price Adjustment SheetpraveshNo ratings yet

- Rate Analysis - P$CDocument557 pagesRate Analysis - P$CHemant Dhaked0% (1)

- BOQ OF EXTENSION WORK FOR FACTORY SHEDDocument72 pagesBOQ OF EXTENSION WORK FOR FACTORY SHEDHarsh BhavsarNo ratings yet

- Analysis of Rates For Building Construction WorksDocument5 pagesAnalysis of Rates For Building Construction WorksRajarathinam ThangaveluNo ratings yet

- Mfar Constructions Limited: SL - No Description of Item UnitDocument12 pagesMfar Constructions Limited: SL - No Description of Item UnitNaveen TibbaNo ratings yet

- Rate Analsis Chapter No. 15 (Sheet Pilling)Document16 pagesRate Analsis Chapter No. 15 (Sheet Pilling)M HAFEEZ RAJANo ratings yet

- MainReport PDFDocument306 pagesMainReport PDFSusheel BhardwajNo ratings yet

- Analysis of Rate S. No. Code Description Unit Quantity Rate Amount 1Document3 pagesAnalysis of Rate S. No. Code Description Unit Quantity Rate Amount 1Shashank Shekhar MishraNo ratings yet

- Construction of Generator & Store Room Rate AnalysisDocument5 pagesConstruction of Generator & Store Room Rate Analysiskishan sojitra100% (1)

- Rule Book - Sleeping Gods - Ver 3.1 (Post Release)Document40 pagesRule Book - Sleeping Gods - Ver 3.1 (Post Release)pl4yerr1No ratings yet

- Rate Analysis Civil Engg..FormatDocument63 pagesRate Analysis Civil Engg..FormatLuojisi Cil100% (1)

- Item No. Description Unit Rate Code Rate (RS) Quantity Labour Cost (RS) Material Cost (RS)Document1 pageItem No. Description Unit Rate Code Rate (RS) Quantity Labour Cost (RS) Material Cost (RS)RANADIP100% (1)

- Civil Rate AnalysisDocument72 pagesCivil Rate AnalysissameershedgeNo ratings yet

- DETAILED ESTIMATEDocument12 pagesDETAILED ESTIMATEsasidharkatari91572No ratings yet

- Box Type Waterproofing TreatmentDocument268 pagesBox Type Waterproofing TreatmentraviNo ratings yet

- RateAnalysisVol 2Document1,341 pagesRateAnalysisVol 2babarNo ratings yet

- Rate Analysis For Shuttering Using Plywood - Roof SlabDocument23 pagesRate Analysis For Shuttering Using Plywood - Roof SlabTharan RaiNo ratings yet

- Cold mix vs hot mix cost comparisonDocument8 pagesCold mix vs hot mix cost comparisonChManikumarNo ratings yet

- Rate AnalysisDocument7 pagesRate AnalysisPradeep MaratheNo ratings yet

- RCC concrete slab construction cost per sq ft in IndiaDocument18 pagesRCC concrete slab construction cost per sq ft in IndiaRavinderNo ratings yet

- Comparing Costs of Conventional and Mivan Shuttering FormworkDocument9 pagesComparing Costs of Conventional and Mivan Shuttering Formworkmanish100% (1)

- Arunachal Pradesh Analysis of Rates For Road and Bridge Works 2010Document232 pagesArunachal Pradesh Analysis of Rates For Road and Bridge Works 2010Harish Kumar MahavarNo ratings yet

- Manpower & Material Requirements of Civil Works.Document20 pagesManpower & Material Requirements of Civil Works.Bhavanishankar ShettyNo ratings yet

- SEED STORAGE, Kiwool, Sindhupalchowk Rate Analysis, Sindupalchowk, (2072-2073)Document21 pagesSEED STORAGE, Kiwool, Sindhupalchowk Rate Analysis, Sindupalchowk, (2072-2073)Dipesh Dahal100% (1)

- Rate Analysis HUme PipesDocument14 pagesRate Analysis HUme PipesSarin67% (3)

- Slipform Rate AnalysisDocument5 pagesSlipform Rate Analysischaithra_140% (1)

- Irussor - 2021 (Sor) 28 - 07 - 2022Document131 pagesIrussor - 2021 (Sor) 28 - 07 - 2022raja shekarNo ratings yet

- 2.rate Analysis 22.1.15 Brick & Stone MasonryDocument11 pages2.rate Analysis 22.1.15 Brick & Stone MasonryAbhishek Agrawal100% (1)

- Analysis of False CeilingDocument3 pagesAnalysis of False CeilingMuhammad Shahid HussainNo ratings yet

- Bathing GhatDocument56 pagesBathing Ghatsasidharkatari9157233% (3)

- Rate Analysis r4Document60 pagesRate Analysis r4Akshay dareNo ratings yet

- Rate Analysis For ShutteringDocument2 pagesRate Analysis For ShutteringJames JohnsonNo ratings yet

- Quotation For Groove CuttingDocument2 pagesQuotation For Groove Cuttingsasidharkatari91572100% (1)

- S.W. Gully TrapDocument16 pagesS.W. Gully TrapAnonymous 9b8vCz1W100% (1)

- Rate Analysis and Estimate: Brick Work With 1:6 Cement Sand MortarDocument6 pagesRate Analysis and Estimate: Brick Work With 1:6 Cement Sand MortarBaskaran SeetharamanNo ratings yet

- Rate Analysis Morang - FinalDocument27 pagesRate Analysis Morang - Finalnitish JhaNo ratings yet

- Civil Work Rate AnalysisDocument5 pagesCivil Work Rate AnalysisLove Rain Walk100% (2)

- 32mm Thick Flush Doors Rs 140Document9 pages32mm Thick Flush Doors Rs 140lkovijayNo ratings yet

- Bitumen Macadam Rate Analysis for MIHAN Warehouse ProjectDocument6 pagesBitumen Macadam Rate Analysis for MIHAN Warehouse Projectparth088No ratings yet

- 22 02 2016 Shuttering Work Rate AnalysisDocument22 pages22 02 2016 Shuttering Work Rate Analysissplashierprince50% (2)

- CD.14 Vessel Structural ConditionsDocument3 pagesCD.14 Vessel Structural ConditionsJarosławWierzganowski100% (1)

- MN S 41604 Alstom ETCS Trackside Maintenance Manual 0Document170 pagesMN S 41604 Alstom ETCS Trackside Maintenance Manual 0paulaNo ratings yet

- Maharashtra Jeevan Pradhikaran Rate Analysis 2012 2013Document177 pagesMaharashtra Jeevan Pradhikaran Rate Analysis 2012 2013ulhas_nakasheNo ratings yet

- Dado Rate Analysis and Approximate Estimation of BridgeDocument14 pagesDado Rate Analysis and Approximate Estimation of BridgeNikhil RathiNo ratings yet

- Brick Masonry RateDocument3 pagesBrick Masonry RateSam Roger100% (1)

- Analysis of RatesDocument33 pagesAnalysis of RatesVnb Reddy100% (2)

- Measurement Sheet for Excavation, PCC, Kerbstone and Joint Filling WorksDocument2 pagesMeasurement Sheet for Excavation, PCC, Kerbstone and Joint Filling WorksYashashree Group100% (1)

- Labour supply quotation for retaining wall workDocument4 pagesLabour supply quotation for retaining wall worknandiniNo ratings yet

- Factual Civil Engineering: Cement ReconcilationDocument5 pagesFactual Civil Engineering: Cement ReconcilationDeepak Kaushik100% (1)

- Rate Analysis For CenteringDocument1 pageRate Analysis For Centeringbd_gupta_3No ratings yet

- Code Description Unit Quantity Rate Amount: Sub Head: 16-Road WorkDocument2 pagesCode Description Unit Quantity Rate Amount: Sub Head: 16-Road WorkSanjan Sameer100% (1)

- Rate Analysis of OBD PaintDocument2 pagesRate Analysis of OBD PaintDarshan Raghunath100% (2)

- MP PWD Schedule of Rates for Road and Bridge WorksDocument96 pagesMP PWD Schedule of Rates for Road and Bridge WorksPranjal Agrawal40% (5)

- Rate Analysis-NormsDocument7 pagesRate Analysis-NormsGajendra Joshi0% (1)

- PU Injection Foam Rate AnalysisDocument1 pagePU Injection Foam Rate AnalysishsclNo ratings yet

- RateAnalysis 22ndjanDocument412 pagesRateAnalysis 22ndjanYusuf You Can0% (1)

- SNM RoadDocument18 pagesSNM RoadKiran KumarNo ratings yet

- CC Road Estimate RedlawadaDocument15 pagesCC Road Estimate RedlawadaManiteja Reddy TatipallyNo ratings yet

- SFC RjyDocument3 pagesSFC Rjysasidharkatari91572No ratings yet

- Detailed Cum Abstract Estimate: Municipal Corporation, Eluru Name of Work: Construction of CC DrainDocument1 pageDetailed Cum Abstract Estimate: Municipal Corporation, Eluru Name of Work: Construction of CC Drainmurali100% (1)

- Repairs To Motors 30-07-2017Document32 pagesRepairs To Motors 30-07-2017sasidharkatari91572No ratings yet

- Bore EstimateDocument11 pagesBore Estimatesasidharkatari91572No ratings yet

- TPG EOT Request Letter by The Agency 13-04-2016Document5 pagesTPG EOT Request Letter by The Agency 13-04-2016sasidharkatari91572No ratings yet

- Sivaji ProbationDocument2 pagesSivaji Probationsasidharkatari91572No ratings yet

- TPG MPLADS Estimate To Print - Xls 05-12-2015Document12 pagesTPG MPLADS Estimate To Print - Xls 05-12-2015sasidharkatari91572No ratings yet

- TPG MPLADS Estimate On Bhimavaram Bypass RoadDocument15 pagesTPG MPLADS Estimate On Bhimavaram Bypass Roadsasidharkatari91572No ratings yet

- Details of Bill StatusDocument2 pagesDetails of Bill Statussasidharkatari91572No ratings yet

- Comparative Statement 03122016Document4 pagesComparative Statement 03122016sasidharkatari91572No ratings yet

- Quotation: S.N o Particulars Qty Rate Rs. Amount RsDocument2 pagesQuotation: S.N o Particulars Qty Rate Rs. Amount Rssasidharkatari91572No ratings yet

- 6 - Annual Account Slip - 2015 - 2016Document1 page6 - Annual Account Slip - 2015 - 2016vasheekarNo ratings yet

- Comparative Statement 03122016Document4 pagesComparative Statement 03122016sasidharkatari91572No ratings yet

- 6 - Annual Account Slip - 2015 - 2016Document1 page6 - Annual Account Slip - 2015 - 2016vasheekarNo ratings yet

- Quotation: S.N o Particulars Qty Rate Rs. Amount RsDocument2 pagesQuotation: S.N o Particulars Qty Rate Rs. Amount Rssasidharkatari91572No ratings yet

- VMC Drains West Assembly LengthsDocument6 pagesVMC Drains West Assembly Lengthssasidharkatari91572No ratings yet

- 6 - Annual Account Slip - 2015 - 2016Document1 page6 - Annual Account Slip - 2015 - 2016vasheekarNo ratings yet

- 42 ND Div - Yoga School BillDocument123 pages42 ND Div - Yoga School Billsasidharkatari91572No ratings yet

- IndexDocument4 pagesIndexsasidharkatari91572No ratings yet

- Smart Pulse Survey Report On 23-11-2016 On 11.59 A.MDocument4 pagesSmart Pulse Survey Report On 23-11-2016 On 11.59 A.Msasidharkatari91572No ratings yet

- Andhra Bank Street GNT Road to 1st LT dismantling estimatesDocument42 pagesAndhra Bank Street GNT Road to 1st LT dismantling estimatessasidharkatari91572No ratings yet

- JR Gudem Est Revisedwith Electrical EstimateDocument201 pagesJR Gudem Est Revisedwith Electrical Estimatesasidharkatari91572No ratings yet

- Smart Pulse Survey Report On 26-11-2016 On 19-42 HoursDocument4 pagesSmart Pulse Survey Report On 26-11-2016 On 19-42 Hourssasidharkatari91572No ratings yet

- Bill All Forms - JRG 11th Ward RoadDocument60 pagesBill All Forms - JRG 11th Ward Roadsasidharkatari91572No ratings yet

- Drilling of Bores (ASC Grant) 2015Document12 pagesDrilling of Bores (ASC Grant) 2015sasidharkatari91572No ratings yet

- Approved Monthly Rates - September - 2016Document2 pagesApproved Monthly Rates - September - 2016sasidharkatari91572No ratings yet

- TNK - Work Slip On 30.10.2013.Document7 pagesTNK - Work Slip On 30.10.2013.sasidharkatari91572No ratings yet

- TPG MPLADS Work Slip For 20.00 Lakhs - 23!06!2016Document20 pagesTPG MPLADS Work Slip For 20.00 Lakhs - 23!06!2016sasidharkatari91572No ratings yet

- Wartsila O Pumps Svanehoj Variable Speed ControlDocument8 pagesWartsila O Pumps Svanehoj Variable Speed ControlDavid MooreNo ratings yet

- HS 855 HD: Technical Data Hydraulic Crawler CraneDocument17 pagesHS 855 HD: Technical Data Hydraulic Crawler CranePol Peña QuispeNo ratings yet

- Epic OrkDocument5 pagesEpic Orkal mailNo ratings yet

- California High-Speed Rail Authority Seeks Expressions of Interest for Tier III TrainsetsDocument4 pagesCalifornia High-Speed Rail Authority Seeks Expressions of Interest for Tier III Trainsetsjackson michaelNo ratings yet

- Light Auto Turn Off 40Document2 pagesLight Auto Turn Off 40Sherman KillerNo ratings yet

- APSRTC-UTS - Advance Ticket BookingDocument1 pageAPSRTC-UTS - Advance Ticket Booking9492426068No ratings yet

- Guidance for Controllers on Communication FailuresDocument6 pagesGuidance for Controllers on Communication Failureseak_ya5875No ratings yet

- Coreg 72Document25 pagesCoreg 72Brandy HimawanNo ratings yet

- Research Article: Algorithms For Pallet Building and Truck Loading in An Interdepot Transportation ProblemDocument12 pagesResearch Article: Algorithms For Pallet Building and Truck Loading in An Interdepot Transportation ProblemHữu BìnhNo ratings yet

- Hyundai-Cat 4390037 PDFDocument24 pagesHyundai-Cat 4390037 PDFbagus fauziNo ratings yet

- Report - 2022-06-09T183004.847Document1 pageReport - 2022-06-09T183004.847Pallavi PadariaNo ratings yet

- Sabrina Azzahra J3J218481Document40 pagesSabrina Azzahra J3J218481Sabrina AzzahraNo ratings yet

- Position Paper About Cebu PacificDocument1 pagePosition Paper About Cebu PacificPeter Paul ParasNo ratings yet

- 1500 Series Simplified Front End Accessory Drive - 03022016Document3 pages1500 Series Simplified Front End Accessory Drive - 03022016M. ShaatNo ratings yet

- Piracy & ArmedDocument15 pagesPiracy & ArmedMehedi Hossain MithilNo ratings yet

- Paper SlotervaartDocument10 pagesPaper SlotervaartWieger BuijsNo ratings yet

- TRAFFICDocument4 pagesTRAFFICJuan, Daniella MarieNo ratings yet

- BD Railway e-ticket booking confirmationDocument1 pageBD Railway e-ticket booking confirmationTahid RazibNo ratings yet

- L85Document10 pagesL85tdfsksNo ratings yet

- International Airports MCQs (Solved) - World General KnowledgeDocument8 pagesInternational Airports MCQs (Solved) - World General KnowledgeshahzaibNo ratings yet

- GUS Trash Feasibility StudyDocument504 pagesGUS Trash Feasibility StudyDaily FreemanNo ratings yet

- Boeing 727-200: Microsoft Flight Simulator 2004Document4 pagesBoeing 727-200: Microsoft Flight Simulator 2004Raph 1123No ratings yet

- PM Col VII Short NotesDocument30 pagesPM Col VII Short Notesajaypradhan140490No ratings yet

- State of The Art Asphalt For Airport Pavement SurfacingDocument22 pagesState of The Art Asphalt For Airport Pavement SurfacingRita Moura FortesNo ratings yet