Professional Documents

Culture Documents

INSULATED SHAFT TYPE

Uploaded by

shyhuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

INSULATED SHAFT TYPE

Uploaded by

shyhuCopyright:

Available Formats

174

Metal

Shaft

Insulated

Shaft

Hollow

Shaft

Ring

Type

Detector

Slide

Push

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

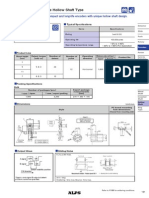

Refer to P.176 for product varieties.

Refer to P.193 for soldering conditions.

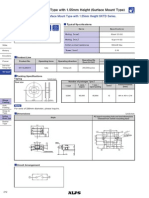

Product No.

Drawing

No.

Number of

detent

Number of

pulse

Length of the shaft

(LM

1

) (mm)

4 Vertical

24

12

20

25

25

20

30

25

30

Standard

3 to 20

Standard

25 15

Heavy 40 15

24

12

Without

EC12E2420802

EC12E1220813

EC12E2420801

EC12E2430804

EC12E2420803

EC12E2430803

EC12E2460802

Operating

direction

Detent torque

mNm

1,900 1,900

Minimum order unit pcs.

Japan Export

With Bushing Type

EC12

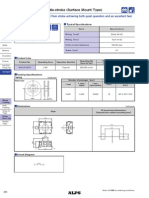

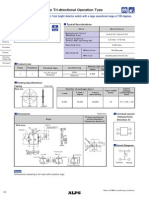

12mm Size Insulated Shaft Type

Insulated shaft type with a wide variety of applications.

Typical Specifications

Items Specifications

Rating 0.5mA 5V DC

Operating life

Without detent

15,000cycles

30,000cyclesLightest jog

With detent 30,000cycles

Operating temperature range

EC12E: 10 to 70

EC12D: 40 to 85

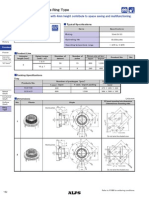

Product No.

Drawing

No.

Minimum order unitpcs.

Japan Export

Number of

pulse

Number of

detent

Operating

direction

Detent torque

mNm

Length of the shaft

(LM

1

) (mm)

Standard type

Product Line

2

2,400 2,400

3,000 3,000

2,400 2,400

3,000 3,000

2,400 2,400

3,000 3,000

2,400 2,400

3,000 3,000

2,400 2,400

1

3

1

3

1

2

3

1

3

1

Vertical

12

24

Without

Standard

3 to 20

15

20

25

15

17.5

20

25

8.5

Hollow shaft

20

25

8.5

Hollow shaft

25

20

25

Lightest jog

3 2

Standard

3 to 20

Lightest jog

3 2

Lightest jog

10 max.

Standard

25 15

EC12E1220407

EC12E1220406

EC12E1220405

EC12E1240405

EC12E1240406

EC12E1220301

EC12E1240301

EC12E24204A7

EC12E24204A2

EC12E24204A8

EC12E24204A9

EC12E2420301

EC12E24404A8

EC12E24404A6

EC12E2440301

EC12E2430404

20

EC12E24104A6

EC12E2430401

12

24

8.5

Hollow shaft

8.5

Hollow shaft

Nuts and washers are not included. If required, please contact us.

Note

175

Metal

Shaft

Insulated

Shaft

Hollow

Shaft

Ring

Type

Detector

Slide

Push

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

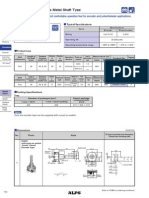

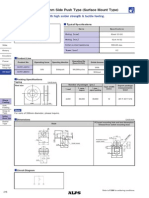

With Switch Type

5 Vertical 30

5 3

10 5

3

0.5 15 17.5

EC12D1564402

EC12D1524403

5 3

10 5

6

EC12D1564404

EC12D1524406

1,280 2,560

Minimum order unit pcs.

Export Japan

Product No.

Drawing

No.

Number

of detent

Number

of pulse

Length of the shaft

(LM

1

) (mm)

Operating

force of switch N

Travel of push-on

switchmm

Operating

direction

Detent torque

mNm

Refer to P.176 for product varieties.

Refer to P.193 for soldering conditions.

EC12D is suitable for automotive use.

Notes

Tray

Packing Specications

3,000 3,000 EC12E 03

Product No.

Number of packagespcs.

369 525 204 2,400 2,400 EC12E 04

1,900 1,900 EC12E 08

2,560 1,280 EC12D 360 540 290

Export package

measurements

mm 1 case / Japan 1 case / export packing

Dimensions

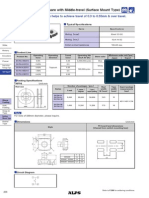

3.5 LM1

R1 5 (5)

(0.8)

2

3.5

6.8

6

4

.

5

Mounting surface

14

12.4

(8.2)

(

1

0

.

2

)

1

3

.

2

Photo Style

Short shaft

No.

1

2

Hollow shaft

3

PC board mounting hole

dimensions

Viewed from mounting side

Unit:mm

17.5 5

LM1 R1

20 7

25 12

High collar type

Product Line

12mm Size Insulated Shaft Type EC12

176

Metal

Shaft

Insulated

Shaft

Hollow

Shaft

Ring

Type

Detector

Slide

Push

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

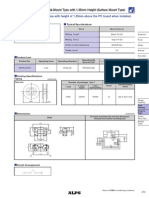

17.5 3

5

0.5

14.1

12.5

A

C

D

1

1

.

7

B

E

3.5

6.8

Mounting surface

5

.

9

7

5

4

.

4

7

5

5 (6)

2

Switch travel

Shaft Dimensions

Flat Type

Unit:mm

EC12E EC12D

With bushing type

LM

1

R

1

20

25

30

35

A

5

5

7

12

12

12

LM

1

R

1

17.5

20

22.5

25

5

7

7

12

12 30

Detailed dimensions

Excluding the 12 detent type

Not available for types without detents

Detailed dimensions

LM1

R1

4

.

5

0

.

5

6

Mounting surface

Locating lug detail

No thread area

1

3.5

8

LM1

7

5.5

3.5

2

4

.

5

6

M9x0.75

Mounting surface

R1

A

8

(

1

0

.

2

)

14

1

3

.

2

12.4

(8.2)

0

.

4

2.5

7

X X

Y

Y

Dimensions Unit:mm

No.

4

5

Photo Style

PC board mounting hole dimensions

Viewed from mounting side

Locating lug detail

No thread area

1

3.5

8

LM1

7

5.5

3.5

2

4

.

5

6

M9x0.75

Mounting surface

R1

A

8

(

1

0

.

2

)

14

1

3

.

2

12.4

(8.2)

0

.

4

2.5

7

X X

Y

Y

13.2

2

3-1

2

2

.

1

5

C A B

7

.

5

holes

With bushing

With push-on switch

type

13.3

11.1

2.05 2.05

5.95

6

.

8

5

8

.

3

3

.

4

5

2

.

1

5

A

C D

B

E

5-1.05 holes

A

-

-

LM1

20

25

R1

7

12

5 30 12

Output wave

A signal

B signal

OFF ON

ON OFF

CW direction

Detent stabillity position

When the switch is provided

Sliding noise

5V DC

R R

Terminal B Terminal A

Terminal C

Encoder

Test circuit

t t

V1

V2

5

V

ON ON OFF

Output waveform

Sliding direction

t : Masking time to avoid chattering Measurement conditionRotation speed 360/s

EC12E

EC12D

V

1

V

2

1.5V max.

At R = 10k

Chattering : 3ms max.

Bounce : 2ms max.

V

1

V

2

2.5V max.

At R = 5k

Chattering : 3ms max.

Bounce : 2ms max.

12mm Size Insulated Shaft TypeProduct Varieties

EC12 12mm Size Insulated Shaft Type

A signal

B signal

ON OFF

OFF ON

CW direction

Detent stabillity position

Detent position cannot be specified for B signal.

Encoders Encoders Encoders

157

Metal

Shaft

Insulated

Shaft

Hollow

Shaft

Ring

Type

Detector

Slide

Push

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

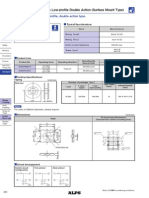

Type

Insulated Shaft Type Hollow Shaft Type

12mm size 18mm size 5mm size 10mm size

Series EC12E EC12D EC18A EC05E EC10E

Photo

Output IncrementalTwo phase A and B Absolute type IncrementalTwo phase A and B

Shaft types Single-shaft Hollow shaft

Operating direction Vertical Vertical Horizontal Horizontal

Number of pulse /

Number of detent

12 / 12

24 / 24

24 / Without

15 / 30

12 positions

16 positions

12 / 12

12 / 24

12 / 12

Features - With push-on switch

Water Resisting

Performance IPX7

Surface

Mount Type

-

Dimensions

mm

W 12.4 12.5 20 5.7 7.5 9.8

D 13.2 11.7 18 6 3.3 4.4

H 5 8.75 2.7 7.25 10.6 / 12.6 / 14.6

Operating temperature range 10 to 70 40 to 85 20 to 60 30 to + 85

5 to + 45

30 to + 85For Automotive

Operating life

15,000 cycles

30,000 cycles

30,000 cycles 100,000 cycles

Automotive use - - -

Life cycle (availability)

Electrical

performance

Rating 0.5mA 5V DC 1mA 5V DC 1mA 10V DC 0.55mA 5.5V DC 1mA 5V DC

Max./min. operating current

Resistive load

5mA / 0.5mA 10mA / 1mA - 0.55mA / -

Insulation

resistance

10M min.

50V DC

100M min. 250V DC 10M min. 250V DC 50M min. 50V DC

Voltage proof 50V AC for 1 minute

300V AC for 1 minute

or 360V AC for 1s

50V AC for 1 minute or

60V AC for 2s

50V AC for 1 minute

Mechanical

performance

Rotational torque

Without detent

10mNm max.

2515mNm

4015mNm

- - - -

Detent torque

3 2mNm

3 to 20mNm

5 3mNm

10 5mNm

60 20mNm 1.6 1.3mNm

5 3mNm

6 3mNm

Push-pull

strength

80N 100N

Push 100N /

pull 50N

-

Shaft configuration Flat, Hollow Shaft Flat Hollow shaft

Terminal type Insertion Reflow Insertion

Switch

Specications

Switch type - Push-on switch - - -

Contact

arrangement

-

Single pole and

single throwPush-on

- - -

Travel mm - 0.5 0.3 - - -

Operating

force N

-

3

1.5

1 6

2.5

2

- - -

Rating - 1mA 5V DC - - -

Contact

resistance

-

100m max. for initial period;

200m max. after operating life.

- - -

Operating life - 30,000times min. - - -

Page 174 177 179 181

Encoders Soldering Conditions 193

Encoders Cautions 194

Notes

1. The operating temperature range for automotive applications can be raised upon request. Please contact us for details.

2. indicates applicability to all products in the series, while indicates applicability to some products in the series.

List of Varieties

193

Metal

Shaft

Insulated

Shaft

Hollow

Shaft

Ring

Type

Detector

Slide

Push

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

Encoders Soldering Conditions

Soldering surfacetemperature Soldering temperature Heating time Soldering time

No. of solders

3 s EC11J

EC10E, EC12D, EC12E

EC45A, EC60A

EC40A

EM20B

EC05E, EC09E, EC10E, EC111, EC11B,

EC11E, EC11G, EC11K, EC12D, EC12E,

EC18A, EC20A, EC21A, EC28A, EC35A,

EC35AH, EC35B, EC40A, EC45A, EC50A,

EC60A, EM20B

EC09E, EC11B, EC111, EC11E, EC11G,

EC11K, EC18A, EC20A, EC21A, EC28A,

EC35A, EC35AH, EC35B, EC50A

Series

Series

350 max. 3s max. 1 time

100 max. 2605 2 min. max. 51s 2 time max.

35010 2 time

100 max.

100 max.

110 max.

80 max.

2605

260 max.

260 max.

260 max.

1 min. max.

2 min. max.

1 min. max.

1 min. max.

31s

5s max.

10s max.

3s max.

2 time max.

2 time max.

1 time

2 time max.

Tip temperature Soldering time No. of solders

Preheating Dip soldering

Reference for Dip Soldering

Condition for Refow

Reference for Hand Soldering

EC05E

EC11J

Series

260 230 180 150 2 min.max. 3s 40s 4 min. max 2 time max.

250 min. 230 min. 180 150 60s to 120s 30s to 40s 2 time max.

A B C D E F G H No. of reows

Temperature profle

1

0

1.When using an infrared reow oven, solder may sometimes not be applied. Be sure to use a hot air reow oven or a

type that uses infrared rays in combination with hot air.

2.The temperatures given above are the maximum temperatures at the terminals of the potentiometer when

employing a hot air reow method. The temperature of the PC board and the surface temperature of the

potentiometer may vary greatly depending on the PC board material, its size and thickness. Ensure that the surface

temperature of the potentiometer does not rise to 250C or greater.

3.Conditions vary to some extent depending on the type of reow bath used. Be sure to give due consideration to this

prior to use.

Notes

300

200

100

A

B

C

Time (s)

G max.

F max.

H max.

E max.

Room

temperature

T

e

m

p

e

r

a

t

u

r

e

(

C

)

Pre-heating

D

You might also like

- 10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignDocument3 pages10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignshyhuNo ratings yet

- EC18A 18mm Insulated Shaft EncoderDocument4 pagesEC18A 18mm Insulated Shaft EncodershyhuNo ratings yet

- SEO Rotary EncodersDocument4 pagesSEO Rotary EncodersshyhuNo ratings yet

- 35mm Ring Encoder GuideDocument3 pages35mm Ring Encoder GuideshyhuNo ratings yet

- Insulated Shaft Rotary EncodersDocument3 pagesInsulated Shaft Rotary EncodersshyhuNo ratings yet

- 21mm Ring Encoder Guide with Specs & Soldering TipsDocument4 pages21mm Ring Encoder Guide with Specs & Soldering TipsshyhuNo ratings yet

- List of Varieties: Detector Slide Push RotaryDocument5 pagesList of Varieties: Detector Slide Push RotaryshyhuNo ratings yet

- 1.2 (H) MM, Single-Side Recoil TypeDocument4 pages1.2 (H) MM, Single-Side Recoil TypeshyhuNo ratings yet

- 20mm Metal Shaft Encoder & Potentiometer GuideDocument4 pages20mm Metal Shaft Encoder & Potentiometer GuideshyhuNo ratings yet

- 45mm Size Ring Type: Large Ring, Heavy Torque Device Perfect For Large Ring Knob DesignDocument3 pages45mm Size Ring Type: Large Ring, Heavy Torque Device Perfect For Large Ring Knob DesignshyhuNo ratings yet

- EC35AH: 35mm Size ABC Switch TypeDocument4 pagesEC35AH: 35mm Size ABC Switch TypeshyhuNo ratings yet

- Rotary Encoder GuideDocument3 pagesRotary Encoder GuideshyhuNo ratings yet

- 20mm Size Metal Shaft Magnetic TypeDocument4 pages20mm Size Metal Shaft Magnetic TypeshyhuNo ratings yet

- Recoil Type For Single-Side and Both SidesDocument5 pagesRecoil Type For Single-Side and Both SidesshyhuNo ratings yet

- 12mm Square Long-Life (Snap-In Type) : Long-Life Type With Unique Dust-Proof Structure and Highly Reliable Metal ContactsDocument4 pages12mm Square Long-Life (Snap-In Type) : Long-Life Type With Unique Dust-Proof Structure and Highly Reliable Metal ContactsshyhuNo ratings yet

- TACT Switch GuideDocument3 pagesTACT Switch GuideshyhuNo ratings yet

- SSSS7Document5 pagesSSSS7shyhuNo ratings yet

- 60mm Size Ring Type: Large Ring Structure Contributes To MultifunctioningDocument3 pages60mm Size Ring Type: Large Ring Structure Contributes To MultifunctioningshyhuNo ratings yet

- 12mm Size Insulated Shaft TypeDocument4 pages12mm Size Insulated Shaft TypeZoltán Halász100% (2)

- 4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeDocument3 pages4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeshyhuNo ratings yet

- 6×3.5mm Compact (Snap-In Type) : Switch Contributing To High-Density Mounting, Available With Top or Side Push OperationDocument4 pages6×3.5mm Compact (Snap-In Type) : Switch Contributing To High-Density Mounting, Available With Top or Side Push OperationshyhuNo ratings yet

- 12mm Square (Snap-In Type) : Joint Stem & Flat Stem With Stable Operation FeelingDocument4 pages12mm Square (Snap-In Type) : Joint Stem & Flat Stem With Stable Operation FeelingshyhuNo ratings yet

- SKHH 6mm Square Tact Switch Product GuideDocument6 pagesSKHH 6mm Square Tact Switch Product GuideshyhuNo ratings yet

- 9mm Size Metal Shaft Type: A Compact 9.5mm Size and Round Shape Contribute To Save SpaceDocument3 pages9mm Size Metal Shaft Type: A Compact 9.5mm Size and Round Shape Contribute To Save SpaceshyhuNo ratings yet

- 3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)Document3 pages3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)shyhuNo ratings yet

- 10mm Square Water-proof Tact Switch SpecificationsDocument5 pages10mm Square Water-proof Tact Switch SpecificationsshyhuNo ratings yet

- Quiet Surface Mount Switch SpecificationsDocument3 pagesQuiet Surface Mount Switch SpecificationsshyhuNo ratings yet

- 5.2mm Square Low-Profile (Surface Mount Type)Document4 pages5.2mm Square Low-Profile (Surface Mount Type)shyhuNo ratings yet

- High Operation Force, Low Contact Resistance Type (Surface Mount Type)Document3 pagesHigh Operation Force, Low Contact Resistance Type (Surface Mount Type)shyhuNo ratings yet

- Snap-in Tact Switch Specs and Soldering GuideDocument3 pagesSnap-in Tact Switch Specs and Soldering GuideshyhuNo ratings yet

- 6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeDocument5 pages6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeshyhuNo ratings yet

- 35mm Size Composite Operation Type: Composite Operation Device That Integrates Both Ring Encoder and Self Return SwitchDocument3 pages35mm Size Composite Operation Type: Composite Operation Device That Integrates Both Ring Encoder and Self Return SwitchshyhuNo ratings yet

- SKEGDocument4 pagesSKEGshyhuNo ratings yet

- SKQM 6 × 3.5mm Compact (Surface Mount TypeDocument3 pagesSKQM 6 × 3.5mm Compact (Surface Mount TypeshyhuNo ratings yet

- 50mm Size Ring Type: Large Encoder With 31mm Inside Diameter Even Takes A Small LCDDocument3 pages50mm Size Ring Type: Large Encoder With 31mm Inside Diameter Even Takes A Small LCDshyhuNo ratings yet

- 1.25mm Height Low-Profile Side Push Surface Mount TypeDocument3 pages1.25mm Height Low-Profile Side Push Surface Mount TypeshyhuNo ratings yet

- 7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsDocument3 pages7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsshyhuNo ratings yet

- Side Push Surface Mount Type With 1.55mm Height SKTD SeriesDocument3 pagesSide Push Surface Mount Type With 1.55mm Height SKTD SeriesshyhuNo ratings yet

- 4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingDocument3 pages4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingshyhuNo ratings yet

- 265 6.1×3.7mm Compact Switch SpecsDocument3 pages265 6.1×3.7mm Compact Switch SpecsshyhuNo ratings yet

- AlpsDocument4 pagesAlpsciohaniNo ratings yet

- SPED2 Push Switch SpecsDocument3 pagesSPED2 Push Switch SpecsshyhuNo ratings yet

- 6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelDocument3 pages6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelshyhuNo ratings yet

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDocument4 pages6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuNo ratings yet

- Snap-in switch documentDocument3 pagesSnap-in switch documentshyhuNo ratings yet

- Quiet Type With 0.9mm Stroke (Surface Mount Type)Document3 pagesQuiet Type With 0.9mm Stroke (Surface Mount Type)shyhuNo ratings yet

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Document3 pagesSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNo ratings yet

- Total Hight of 3.1mm. Surface Mount Package With Ground TerminalDocument3 pagesTotal Hight of 3.1mm. Surface Mount Package With Ground TerminalshyhuNo ratings yet

- Side Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)Document3 pagesSide Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)shyhuNo ratings yet

- List of Varieties: Top Push Side PushDocument5 pagesList of Varieties: Top Push Side PushshyhuNo ratings yet

- G8ND Automotive PCB Relay Controls DC Motor DirectionDocument3 pagesG8ND Automotive PCB Relay Controls DC Motor Directionbalescu_florentinaNo ratings yet

- Ordering Information: Sealed Snap Action SwitchDocument6 pagesOrdering Information: Sealed Snap Action SwitchG Sandeep KumarNo ratings yet

- Model Number Structure: Enclosed SwitchDocument10 pagesModel Number Structure: Enclosed SwitchJavierNo ratings yet

- Spvqa: Water-Proof TypeDocument4 pagesSpvqa: Water-Proof Typeshyhu100% (1)

- CC936ADocument4 pagesCC936AKen Lau Boun KongNo ratings yet

- Automotive Relays: Twin Relays EN2/EP2 Series Single Relays EP1/MR301 SeriesDocument13 pagesAutomotive Relays: Twin Relays EN2/EP2 Series Single Relays EP1/MR301 SeriesdziboNo ratings yet

- 3.7mm Square Low-Profile (Surface Mount Type)Document3 pages3.7mm Square Low-Profile (Surface Mount Type)Hung KeeNo ratings yet

- Low-Profile Tri-Directional Operation TypeDocument3 pagesLow-Profile Tri-Directional Operation TypeshyhuNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Medijski linč Gorana JevtićaDocument64 pagesMedijski linč Gorana JevtićashyhuNo ratings yet

- WM 00013Document127 pagesWM 00013shyhuNo ratings yet

- List of Varieties: Resistive Position SensorsDocument1 pageList of Varieties: Resistive Position SensorsshyhuNo ratings yet

- List of Varieties: Detector Slide Push RotaryDocument5 pagesList of Varieties: Detector Slide Push RotaryshyhuNo ratings yet

- 4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeDocument3 pages4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeshyhuNo ratings yet

- RDC40 RDC50 RDC90: Rotary TypeDocument6 pagesRDC40 RDC50 RDC90: Rotary TypeshyhuNo ratings yet

- Hollow-Shaft Type That Enables Output Covering The Whole 360-Degree Angle Due To Adoption of 2-Phase OutputDocument4 pagesHollow-Shaft Type That Enables Output Covering The Whole 360-Degree Angle Due To Adoption of 2-Phase OutputshyhuNo ratings yet

- List of Varieties: Detector Slide Push RotaryDocument5 pagesList of Varieties: Detector Slide Push RotaryshyhuNo ratings yet

- Resistive Position Sensors Specifications and Testing MethodsDocument4 pagesResistive Position Sensors Specifications and Testing MethodsshyhuNo ratings yet

- Resistive Position Sensors Linear Type Specifications and VarietiesDocument5 pagesResistive Position Sensors Linear Type Specifications and VarietiesshyhuNo ratings yet

- Linear Type Exclusively Used To Detect The Angle of Vehicle Head LightsDocument5 pagesLinear Type Exclusively Used To Detect The Angle of Vehicle Head LightsshyhuNo ratings yet

- TACT Switch GuideDocument3 pagesTACT Switch GuideshyhuNo ratings yet

- 6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelDocument3 pages6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelshyhuNo ratings yet

- SKQM 6 × 3.5mm Compact (Surface Mount TypeDocument3 pagesSKQM 6 × 3.5mm Compact (Surface Mount TypeshyhuNo ratings yet

- 3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)Document3 pages3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)shyhuNo ratings yet

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Document3 pagesSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNo ratings yet

- 5.2mm Square Low-Profile (Surface Mount Type)Document4 pages5.2mm Square Low-Profile (Surface Mount Type)shyhuNo ratings yet

- 265 6.1×3.7mm Compact Switch SpecsDocument3 pages265 6.1×3.7mm Compact Switch SpecsshyhuNo ratings yet

- Side Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)Document3 pagesSide Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)shyhuNo ratings yet

- Quiet Type With 0.9mm Stroke (Surface Mount Type)Document3 pagesQuiet Type With 0.9mm Stroke (Surface Mount Type)shyhuNo ratings yet

- Total Hight of 3.1mm. Surface Mount Package With Ground TerminalDocument3 pagesTotal Hight of 3.1mm. Surface Mount Package With Ground TerminalshyhuNo ratings yet

- Quiet Surface Mount Switch SpecificationsDocument3 pagesQuiet Surface Mount Switch SpecificationsshyhuNo ratings yet

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDocument4 pages6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuNo ratings yet

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Document3 pagesSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNo ratings yet

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDocument4 pages6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuNo ratings yet

- 4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingDocument3 pages4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingshyhuNo ratings yet

- Side Push Surface Mount Type With 1.55mm Height SKTD SeriesDocument3 pagesSide Push Surface Mount Type With 1.55mm Height SKTD SeriesshyhuNo ratings yet

- List of Varieties: Top Push Side PushDocument5 pagesList of Varieties: Top Push Side PushshyhuNo ratings yet

- 1.25mm Height Low-Profile Side Push Surface Mount TypeDocument3 pages1.25mm Height Low-Profile Side Push Surface Mount TypeshyhuNo ratings yet

- Measuring Torque, Wobble, Voltage Withstand and Insulation of Rotating ShaftsDocument1 pageMeasuring Torque, Wobble, Voltage Withstand and Insulation of Rotating ShaftsshyhuNo ratings yet

- Calculus HandbookDocument198 pagesCalculus HandbookMuneeb Sami100% (1)

- ODWEK BasicsAndBeyondDocument314 pagesODWEK BasicsAndBeyondcursocmodNo ratings yet

- Edit Spatial Data Topologically & Non-TopologicallyDocument53 pagesEdit Spatial Data Topologically & Non-TopologicallyridhuanNo ratings yet

- BME-04 Calibration of Biomedical EquipmentDocument2 pagesBME-04 Calibration of Biomedical EquipmentPAPPU RANJITH KUMARNo ratings yet

- Skyscanner Tone of VoiceDocument32 pagesSkyscanner Tone of VoiceJefferson Bobby OrtegaNo ratings yet

- It Lecture 2Document23 pagesIt Lecture 2Muhammad Ali MasoodNo ratings yet

- Subnetting Class C IP AddDocument1 pageSubnetting Class C IP AddKeenly PasionNo ratings yet

- VeriFinger SDK Brochure 2012-12-03Document21 pagesVeriFinger SDK Brochure 2012-12-03Manish NarkhedeNo ratings yet

- Playstation 4 Basic Repair GuideDocument4 pagesPlaystation 4 Basic Repair GuideMauricio Trujillo PazNo ratings yet

- Graph Theory Modeling ErrataDocument6 pagesGraph Theory Modeling ErrataAnonymous IHf491dNo ratings yet

- 8251 PciDocument14 pages8251 PciSoham ChatterjeeNo ratings yet

- A Review of 2D &3D Image Steganography TechniquesDocument5 pagesA Review of 2D &3D Image Steganography TechniquesEditor IJRITCCNo ratings yet

- Watson Studio-Student Guide PDFDocument62 pagesWatson Studio-Student Guide PDFghadaNo ratings yet

- Hack-A-Thon: 29th March 2020 - 24th May 2020Document6 pagesHack-A-Thon: 29th March 2020 - 24th May 2020Rohit KumarNo ratings yet

- Manual Struts 2 Tutorial For BeginnersDocument302 pagesManual Struts 2 Tutorial For BeginnersCarlos M Gomez BNo ratings yet

- Applications Highlights: - Manufacturing, Electronics and Automotive: - Medical - Clinical Lab AutomationDocument2 pagesApplications Highlights: - Manufacturing, Electronics and Automotive: - Medical - Clinical Lab AutomationWarkaNo ratings yet

- Serial Port Communication LabviewDocument5 pagesSerial Port Communication Labviewpj_bank100% (2)

- SVC Training Document VKSDocument51 pagesSVC Training Document VKSTien Dat TranNo ratings yet

- The Ultimate Scalper Course ManualDocument248 pagesThe Ultimate Scalper Course ManualAspirant100% (5)

- FortiManager-7 4 0-Administration - GuideDocument937 pagesFortiManager-7 4 0-Administration - GuideJosé PabloNo ratings yet

- Open Source Real-Time Temperature MonitoringDocument39 pagesOpen Source Real-Time Temperature MonitoringdhaNo ratings yet

- Universiti Malaysia Sarawak Pre-TranscriptDocument2 pagesUniversiti Malaysia Sarawak Pre-Transcriptsalhin bin bolkeriNo ratings yet

- l1 Sep IntroductionDocument6 pagesl1 Sep IntroductionFact HubNo ratings yet

- Quadruped Walking Running SimulationDocument49 pagesQuadruped Walking Running SimulationbilynbkNo ratings yet

- Boq ElcDocument12 pagesBoq ElcRicardo JuliusNo ratings yet

- FF 180 EDI B3 Grp4Document4 pagesFF 180 EDI B3 Grp4dihosid99No ratings yet

- CAE BrochureDocument8 pagesCAE BrochurecimasukNo ratings yet

- Audiocodes Mediant Sbcs For Service ProvidersDocument9 pagesAudiocodes Mediant Sbcs For Service ProvidersrAVINo ratings yet

- TERADATA Basic TABLE SCRIPTSDocument7 pagesTERADATA Basic TABLE SCRIPTSJaya SankarNo ratings yet

- OOPs Concepts - What Is Aggregation in JavaDocument15 pagesOOPs Concepts - What Is Aggregation in JavaKliu Senior Selestre VillanuevaNo ratings yet