Professional Documents

Culture Documents

Is 15539 2004

Uploaded by

ramnadh803181Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Is 15539 2004

Uploaded by

ramnadh803181Copyright:

Available Formats

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

!"#$%&# '(%)

!"# $ %& #' (")* &" +#,-.

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

/0)"1 &2 324 #' 5 *)6

Jawaharlal Nehru

Step Out From the Old to the New

7"#1 &" 8+9&"), 7:1 &" 8+9&")

Mazdoor Kisan Shakti Sangathan

The Right to Information, The Right to Live

!"# %& ;<" =7"#" > 72 &(: ?0)"@" #AB 7" <&*" A*

Bhart+hariN,ti-atakam

Knowledge is such a treasure which cannot be stolen

IS 15539 (2004): Recommended practice for magnetic particle

examination of steam turbine rotor blades [MTD 21:

Non-Destructive Testing]

-

IS 15539:2004

Indian Standard

RECOMMENDED PRACTICE FOR

MAGNETIC PARTICLE EXAMINATION OF

STEAM TURBINE ROTOR BLADES

ICS 27.040; 77.040.20

@ BIS 2004

BUREAU OF INDIAN STANDARDS

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

December 2004

Price Group 3

Non-destructive Testing Sectional Committee, MTD21

FOREWORD

This Indian Standard was adopted by the Bureau of Indian Standards, after the draft finalized by the Non-

destructive Testing Sectional Committee had been approved by the Metallurgical Engineering Division Council.

Magnetic particle flaw detection is used to locate cracks, discontinuities at orjust below the surface of ferromagnetic

turbine rotor blades.

This standard does not prescribe any acceptance criterion for turbine rotor blades, however, that after indications

have been produced, they must be interpreted or classified and then evaluated according to the specific requirement.

For the purpose of deciding whether a particular requirement of this standard is complied with, the final value,

observed or calculated, expressing the result of a test or analysis, shall be rounded off in accordance with

1S2: 1960 Rules for rounding off numerical value (revised). The number of significant places retained in the

rounded off value should be the same as that of the specified value in this standard.

IS 15539:2004

Indian Standard

RECOMMENDED PRACTICE FOR

MAGNETIC PARTICLE EXAMINATION OF

STEAM TURBINE ROTOR BLADES

1 SCOPE

This standard describes the general procedures for wet

fluorescent magnetic particle examination, a non-

destructive test method for detecting surface and

near surface cracks and other discontinuities in

ferromagnetic turbine rotor blades. This recommended

practice would produce repeatable results and also

precise enough to use as a basis for the preparation of

specific procedure to suit the individual type of turbine

blades.

This standard does not indicate, suggest, or specify

acceptance standards for turbine rotor blades inspected

it shouIdbe pointed out, however, that after indications

have been produced, they must be interpreted or

classified and then evaluated according to the specific

requirement. For this purpose, there should be a

separate standard to define the type, size, location, area

of concentration and orientation of indications that are

unacceptable in each type of turbine blade.

2 SUMMARY OF METHOD

The magnetic particle test method is based on the

principle that magnetic lines of force when present in

a ferromagnetic material will be distorted by a change

in material continuity, such as sharp dimensional

change or a discontinuity. If the discontinuity is open

or near to the surface of magnetized material, flux lines

will be distorted at the surface, a condition termed flux

leakage. When fine magnetic particles are distributed

over the area of the discontinuity while the flux leakage

exists, they will be held in place and the accumulation

of particles will be visible under proper lighting

conditions.

3 EQUIPMENT

3.1 Types

There are various types of magnetic particle equipment

available such as yokes, portable units, mobile units,

stationary units, etc. Selection of a specific type of

equipment should depend on the intended application,

the type and magnitude of the magnetizing current

required and the desired speed of inspection.

Various control test given in the Annex A are

recommended for ensuring the reliable magnetic

particle testing.

4 MAGNETIC PARTICLE MATERIALS

4.0 For the inspection of turbine rotor blades, since

very fine service induced discontinuities such as tight

fatigue cracks open to surface are expected, wet

magnetic particle examination shall be employed. Wet

magnetic particle examination technique uses fine

ferromagnetic particles which have been treated to

impart colour (fluorescent and non-fluorescent) in

order to make them highly visible against the

background of the surfaces being examined. The

magnetic particles generally have high permeabilityy

to allow ease of magnetization and low retentivity so

that they will not be attracted to each other. Wet

magnetic particles are designed to be suspended in a

vehicle such as water or oil at a given concentration

for application to the test surface by flowing, spraying

or pouring. The wet particles are available in both

fluorescent and nonfluorescent concentrates. The liquid

vehicles should not be used under the extreme

environmental conditions such as ternperature above

135 C. Some sort of mixing equipment is usually

required to keep wet particles in suspension (desirable

properties of a suspension vehicle are given in Annex

A). The wet fluorescent method usually is performed

indoors or in areas where shelter and proper applicat ion

equipment are available. Fluorescent wet particles glow

with a bright yellow-green colour when viewed under

black light. Non-fluorescent particles are usually b!ack

or reddish brown, although particles with other colours

are available. The colour often chosen for any given

examination should be one that contrasts maximum

with the blade surface.

4.1 Particle Concentration

For fluorescent particles, the recommended settling

volume is from 0.1 to 0.5 ml in a 100 ml bath sample

and from 1.2 to 2.4 ml per 100 ml of vehicle for non-

fluorescent particles unless otherwise specified by the

particle manufacturer.

5 PART PREPARATION

The surface of the rotor blades to be examined should

IS 15539:2004

be essentially clean, dry and free of contaminates such

as oil, grease, loose rust, loose scale, etc. Cleaning of

the test surface may be accomplished by detergents,

organic solvents or mechanical means.

6 SEQUENCE OF OPERATION

The sequence of operation in magnetic particle

examination is related to the application of particles

and magnetizing current. In practice, it involves bathing

the blade with the inspection medium to provide an

abundant source of suspended particles on the surface

of the test surface and terminating the bath application

simultaneously with the initiation of the magnetizing

current flowing. The duration of the magnetizing

current is typically of the order of 0.5s.

The three basic types of current used in magnetic

particle examination to establish magnetization are

alternating current a.c., single phase half wave

rectified alternating current (HW) and three phase full

wave rectified alternating current (FWRC). The

inductance associated with a.c. results in a skin effect

that confines the magnetic field to the surface of a

part Hence a.c. can be advantageously used for the

detection of surface breaking defects such as fatigue

cracks. In contrast, both HW and FWDC produce

a magnetic field having maximum penetrating

capabilities and are used when near surface

discontinuities are also of concern.

7 MAGNETIZATION TECHNIQUES

A set of turbine blades or a single blade can be

magnetized either directly or indirectly. For direct

magnetization, the magnetizing current is passed

directly into the part creating a circular magnetic field

in the part. With indirect magnetization techniques, a

magnetic field is induced in the blade which can create

a circular, longitudinal or multi-directional magnetic

field in the blade.

For the inspection of turbine blades, indirect method

of magnetization using coils and cables should be used

to avoid any possible arcing that can happen as in the

direct method of magnetization. In the coil or cable

wrap technique, the magnetic field strength is

proportional to the current and inversely proportional

to the thickness of the blade section being inspected.

Alternating current electromagnetic yokes provide

effective means of magnetization of a confined region

of interest that is the root region of the blade, for the

detection of surface discontinuities. This method is

very sensitive for the detection of service induced

fatigue type discontinuities. Half wave rectified direct

current electromagnetic yokes, however, provide an

effective means for near surface discontinuities as

well.

8 DIRECTION OF MAGNETIC FIELDS

Since indications are not normally obtained when,

discontinuities are parallel to the magnetic field, and

since discontinuities may occur in various or unknown

directions in a blade each blade must be magnetized at

least in two directions approximately at right angles to

each other.

9 MAGNETIC FIELD STRENGTH

9.1 To produce satisfactory indications, the magnetic

field in the turbine rotor blade must have sufficient

strength. For the indications to be consistent, the field

strength must be controlled within reasonable limits,

usually 25 percent. Factors that affect the strength of

the field are size, shape and material of the blade and

the technique of the magnetization. Since these factors

vary widely, it is diftlcult to establish rigid rules for

field strength for different geometries. For new

geometries it is best to experiment with a blade having

known discontinuities and by determining the actual

requirements. In general, the field indicator can be

effectively used for finding the direction and adequacy

of magnetic field for detection of discontinuities of all

possible orientations.

9.2 Overall Magnetization

Overall magnetization in the longitudinal direction

is produced by passing a current through a multi turn

coil encircling (wraping) the rotor shaft. This

produces a magnetic field on all blades of the rotor

stage(s) covered and also the surfaces of rotor and

rotor to blade root region. The direction of the

magnetic field produced is parallel to the axis of the

coil. The unit of measurement is ampere turns (NI).

The effective field extends on either side of the coil

to a distance approximately equal to the radius of the

coil being employed. Turbine rotors with many stages

should be examined, examination shall be carried out

in a shot of a few stages at a time. The basic formula

employed for determining the ampere turns when

cable wrap technique is used to produce overall

magnetization is:

NI =

K

(L ID)+2

where

I=

~=

D=

L=

K=

NI =

coil current, ampere;

number of turns in the coil or cable wrap;

part diameter, mm;

part length, mm;

35000 ampere turns; and

ampere turns.

For magnetizing the blades in the circumferential

2

direction, cable loop in the form of a garland shall be

used. Yoke may also be used for establishing field at

any required direction by properly positioning the

yoke. The field strength of yokes can be empirically

determined by measuring its litling power.

10 APPLICATION OF WET MAGNETIC

PARTICLES

Wet fluorescent magnetic particles suspended in a

vehicle at a recommended concentration may be

applied either by spraying or flowing over the areas to

be inspected during the application of the magnetizing

field current (continuous technique) or after turning

off the current (residual technique). Since fine or

weakly held indications on highly finished or polished

surfaces may be washed away, care must be taken to

prevent high-velocity flow over critical surfaces and

to cut-off the bath application before removing the

magnetic field. Since a residual field has a lower

magnetic flux intensity, for sensitive defect detection,

continuous method shall be used rather then residual

method of magnetization.

11 1NTERPRETATION OF INDICATIONS

Indications formed as a result of magnetic flux leakage

fields may be relevant or non-relevant indications

caused by particles being held by reasons other than

leakage fields are false.

Relevant indications are produced by flux leakage fields

which are the result of discontinuities that may or may

not be acceptable. Relevant indications should be

evaluated with regard to the acceptable limits as

applicable.

Non-relevant indications can occur singly or in patterns

as a result of flux leakage fields created by conditions

such as changes in section, inherent material properties,

etc.

12 RECORDING OF INDICATIONS

When required, permanent record of the indications

may be made by one or more of the following means.

12.1 Sketching the Indication(s)

indications are recorded by hand.

12.2 Covering the Indication(s)

a) With transport adhesive-backed tape,

removing the tape with the magnetic particle

indication(s) adhering to it, and placing it on

paper or other appropriate background

material, and

b) With a spray-on strippable film that fixes the

indication(s) in place. When the film is

stripped from the part, the magnetic particle

indication(s) will adhere to it.

IS 15539:2004

12.3 Photographing

The indications themselves, the tape, or the strippable

film reproductions of the indications is photographed.

Discontinuities along with relative locations on the

component are indicated in the photograph.

12.4 Recording the Location, Length and Number

of Indications

A record of the parameters listed below and as

applicable should accompany the inspection resu Its:

a) Magnetic particle technique,

b) Magnetizing process,

c) Magnetizing current,

d) Magnetic current strength, and

e) Direction of magnetic field.

13 DEMAGNETIZATION

13.1 All ferromagnetic materials will retain some

residual magnetism, the strength of which is dependent

on the retentivity of the turbine blade material. A

residual field may permit chips to adhere to the

surface affecting subsequent clean ing process. When

required, an acceptable level of residual

magnetization and its measurement method shall also

be specified. In general demagnetization is

accompanied by subjecting the turbine blade to a field

equal to or greater than that used to magnetize, then

continuously reversing the field direction while

gradually decreasing it to zero.

13.2 Decreasing Alternating Current

In this technique, the turbine blade is subjected to the

field and gradually reducing its strength to a desired

level.

13.3 Reversing Direct Current

In this technique, the blade is subjected to

consecutive steps of reversed and reduced direct

current magnetization to a desired level. This

technique requires special equipment for reversing

the current while simultaneously reducing it in small

increments.

Effectiveness of the demagnetizing operation can be

indicated by the use of appropriate magnetic tield

strength indicators. For complete demagnetization, it

is advisable to carry out circular magnetization before

longitudinal magnetization.

14 POST-INSPECTION CLEANING

Post-inspection cleaning is necessary where magnetic

particle materials could interfere with subsequent

processing or with service requirements. Typical post-

cleaning techniques employed are:

3

IS 15539:2004

a) Drying of wet particles

removal by brushing or

and

b) Removal of wet particles

solvent.

and subsequent 15 ACCEPTANCE STANDARDS

compressed air,

The acceptability of the turbine rotor blades examined

by flushing

by this method is not specified herein. Acceptance

with standard shall be detemined taking in to account the

design requirements.

ANNEX A

(Clause 3.1)

VARIOUS CONTROL TEST FOR RELIABLE MAGNETIC PARTICLE TESTING

A-1 PERFORMANCE TESTING OF MAGNETIC

PARTICLE TESTING EQUIPMENT

The following tests are recommended for ensuringjhe

reliable performance of the magnetizing equipment and

accessories.

A-1. 1 Ammeter Accuracy Tests

The equipment meter readings should be verified with

those of a control test meter incorporating a shunt or

current transformer connected to monitor the output

current. The equipment reading shall not deviate by

more than ~ 10 percent of the current values as shown

by the test meter.

A-1.2 Equipment Current Output Check

To assure the continued accuracy of the equipment,

ammeter readings at each transformer tap shouldbe made

with a calibrated ammeter shunt combination. Variations

exceeding ~ 10 percent from the equipment ammeter

readings indicate the necessity for its service or repair.

A-1.3 Internal Short Circuiting Check

Magnetic practice equipment should be checked

periodically for internal short-circuiting. With the

equipment set for maximum amperage output, any

deflection of the ammeter when the current is activated

with no conductor between the contacts is an indication

of an internal short circuit.

A-1.4 Electromagnetic Yoke Lifting Force

The magnetizing force of a yoke can be tested by

determining its lifting power on a steel plate. The lifting

force relates to the electromagnetic strength of the

yoke. Alternating current electromagnetic yokes should

have a lifting force of at least 4.5 kg and for dc yokes

it shall be 18 kg at the maximum pole spacing where

they will be used.

A-1.5 Black Light Intensity Control Test

The black light intensity at the examination surface

(380 mm from the face of the light lens filter) should

not be less than 800 p W/sq cm when measured with a

suitable backlight meter.

A-1.6 Maintenance and Calibration of Equipment

The magnetic particle equipment employed should be

maintained in proper working order at all times. The

frequency of calibration, usually once a year or

whenever a malfunction is suspected should be specified

in the general procedures of the testing facility.

Calibration tests should be conducted in accordance with

any specification that may be applicable.

A-2 DESIRABLE PROPERTIES OF SUSPENSION

VEHICLE

Generally the particles are suspended in a low viscosity

oil or conditioned water. Low viscosity, kerosine

petroleum hydrocarbon vehicles are ideal for

suspending both fluorescent and non-fluorescent

magnetic particles and are commonly employed.

Two significant advantages for the use of oil vehicles

are:

a)

b)

magnetic particles are suspended and

dispersed in oil vehicles without the use of

conditioning agent, and

oil vehicles provide a measure of corrosion

protection to turbine blades.

Oil vehicles to be used in wet magnetic particle

examination should possess the following:

a) Low viscosity in order not to impede particle

mobility;

b) Minimum flash point of 1350C in order to

minimize fire hazards;

c) Odourless, not objectionable to user

d) Low inherent fluorescence, if used with

fluorescent particles; that is, it should not

interfere significantly with the fluorescent

particle indications; and

e) Non-reactive, that is it should not degrade

suspended particles.

Water may be used as a vehicle for wet magnetic

particles provided suitable conditioning agents are

added which provide proper particle dispersion, in

addition to corrosion protection for the turbine blade

being tested and the equipment in use.

4

1S 15539:2004

A-3 LOW VISCOSITY A-5 NON-REACTIVE

The conditioned water should not exceed a maximum The conditioned water should not cause deterioration

viscosity of45 cSt at 90C. of the suspended magnetic particles.

A-4 NON-FLUORESCENT A-6 ALKALINITY

The conditioned water should not be fluorescent if The alkalinity of the conditioned water should not

intended for use with fluorescent particles. exceed a pH of 10.5.

T --

Bureau of Indian Standards

B1S is a statutory institution established under the Bureau of Indian Standards Act, 1986 to promote

harmonious development of the activities of standardization, marking and quality certification of goods

and attending to connected matters in the country.

Copyright

B]S has the copyright of all its publications. No part of these publications may be reproduced in any form

without the prior permission in writing of BIS. This does not preclude the free use, in the course of

implementing the standard, of necessary details, such as symbols and sizes, type or grade designations.

Enquiries relating to copyright be addressed to the Director (Publications), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also reviewed

periodically; a standard along with amendments is reaffirmed when such review indicates that no changes are

needed; if the review indicates that changes are needed, it is taken up for revision. Users of Indian Standards

should ascertain that they are in possession of the latest amendments or edition by referring to the latest issue of

B]S Catalogue and Standards: Monthly Additions.

This Indian Standard has been developed from Doc : No. MTD21 (4303).

Amendments Issued Since Publication

Amend No. Date of Issue Text Affected

BUREAU OF INDIAN STANDARDS

Headquarters :

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002 Telegrams : Manaksanstha

1elephones:23230131,23233375,2323 9402 (Common to all offices)

Regional Offices : Telephone

Central

Eastern

Northern

Southern

Western

Branches :

: Manak Bhavan, 9 Bahadur Shah Zafar Marg

{

23237617

NEW DELHI 110002 23233841

: 1/14 C.I.T. Scheme VII M, V. I. P. Road, Kankurgachi

{

23378499,23378561

KOLKATA 700054 23378626,23379120

: SCO 335-336, Sector 34-A, CHANDIGARH 160022

{

603843

609285

: C.I.T. Campus, IV Cross Road, CHENNAI 600113

{

22541216,22541442

22542519,22542315

: Manakalaya, E9 MIDC, Marol, Andheri (East)

{

28329295,28327858

MUMBAI 400093 28327891,28327892

AHMEDABAD. BANGALORE. BHOPAL. BHUBANESHWAR. COIMBATORE. FARIDABAD.

GHAZIABAD. GUWAHATI. HYDERABAD. JAIPUR. KANPUR. LUCKNOW. NAGPUR.

NALAGARH. PATNA. PUNE. RAJKOT. THIRUVANANTHAPURAM. VISAKHAPATNAM.

Printed at Prabhat Offset Psess, New Delhi-2

You might also like

- Npk calibration certificateDocument3 pagesNpk calibration certificateramnadh803181No ratings yet

- Detection of NPK and PH Components SoilDocument31 pagesDetection of NPK and PH Components Soilemerson elginNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Gasket Documents PDFDocument66 pagesGasket Documents PDFramnadh803181No ratings yet

- Gasket Documents PDFDocument66 pagesGasket Documents PDFramnadh803181No ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleChagar HarshpalNo ratings yet

- VSP Expo Amtec NA 131121 PDFDocument50 pagesVSP Expo Amtec NA 131121 PDFAlenJozićNo ratings yet

- 198 Modern STPDocument23 pages198 Modern STPramnadh803181No ratings yet

- The Steel Pipe Buyer'S GuideDocument8 pagesThe Steel Pipe Buyer'S Guideramnadh803181No ratings yet

- Optimal Design of Swept, Leaned and Skewed Blades in A Transonic Axial CompressorDocument11 pagesOptimal Design of Swept, Leaned and Skewed Blades in A Transonic Axial Compressorramnadh803181No ratings yet

- Guidelines For Corporates To Set Up IncubatorsDocument6 pagesGuidelines For Corporates To Set Up Incubatorsramnadh803181No ratings yet

- TP1023ENDocument5 pagesTP1023ENramnadh803181No ratings yet

- Bosch Software Innovations Iot Whitepaper StrategyDocument22 pagesBosch Software Innovations Iot Whitepaper Strategyramnadh803181No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Diet Coke & Mentos Geyser Lab 2011-2012Document4 pagesDiet Coke & Mentos Geyser Lab 2011-2012Frederick LoganNo ratings yet

- Using Dapper Asynchronously inDocument1 pageUsing Dapper Asynchronously inGiovani BrondaniNo ratings yet

- Feasibility Study of Solar Photovoltaic (PV) Energy Systems For Rural Villages of Ethiopian Somali Region (A Case Study of Jigjiga Zone)Document7 pagesFeasibility Study of Solar Photovoltaic (PV) Energy Systems For Rural Villages of Ethiopian Somali Region (A Case Study of Jigjiga Zone)ollata kalanoNo ratings yet

- SemDocument31 pagesSemkaushik4208No ratings yet

- BurnerDocument4 pagesBurnerAhmed Mohamed KhalilNo ratings yet

- Acceleration GrpahDocument14 pagesAcceleration GrpahRAFAEL TORRESNo ratings yet

- Magneto Hydro Dynamics PresentationDocument19 pagesMagneto Hydro Dynamics PresentationVipul GuptaNo ratings yet

- Stay CablesDocument22 pagesStay Cablesalex_g00dyNo ratings yet

- Preview ISO+749-1977 PDFDocument3 pagesPreview ISO+749-1977 PDFLiana GaniNo ratings yet

- Dogging Guide 2003 - WorkCover NSWDocument76 pagesDogging Guide 2003 - WorkCover NSWtadeumatas100% (1)

- Paket TrainingDocument20 pagesPaket TrainingLukman AriyantoNo ratings yet

- Chemical Thermodynamics: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenDocument43 pagesChemical Thermodynamics: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenChery-an PletNo ratings yet

- SR No Co Name Salutation Person Designation Contact NoDocument4 pagesSR No Co Name Salutation Person Designation Contact NoAnindya SharmaNo ratings yet

- HighpuritysealsDocument6 pagesHighpuritysealstuannhocutNo ratings yet

- 3310 ATF DEXRON III H PDS Vesion 3Document2 pages3310 ATF DEXRON III H PDS Vesion 3luayhabibbNo ratings yet

- Huawei: Quidway Full Series Ethernet Routing SwitchesDocument90 pagesHuawei: Quidway Full Series Ethernet Routing SwitchesWalter Aguiar0% (1)

- 1.1 General: "Processes and Environmental Management" at SUEZ LTD, BWSSB, TK HalliDocument29 pages1.1 General: "Processes and Environmental Management" at SUEZ LTD, BWSSB, TK HalliYogeesh B ENo ratings yet

- 1 Xpower Safirus Owners Manual enDocument8 pages1 Xpower Safirus Owners Manual enMarianela MasyRubiNo ratings yet

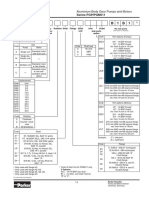

- PG 511 B 1 B 1: Ordering Code Series PGP/PGM511Document7 pagesPG 511 B 1 B 1: Ordering Code Series PGP/PGM511Four SticksNo ratings yet

- Build-A-Bard ABB - RFQ-807683Reaprovechamiento Relaves - SR For Cotejado 010A - HVACDocument18 pagesBuild-A-Bard ABB - RFQ-807683Reaprovechamiento Relaves - SR For Cotejado 010A - HVACchristianNo ratings yet

- Session 5 PDFDocument26 pagesSession 5 PDFToufic HageNo ratings yet

- Report On Automatic Phase Changer: Submitted ByDocument32 pagesReport On Automatic Phase Changer: Submitted ByAndrea JohnsonNo ratings yet

- Prospects For Alkaline Zero Gap Water Electrolysers For Hydrogen ProductionDocument16 pagesProspects For Alkaline Zero Gap Water Electrolysers For Hydrogen Productionkhan47pkNo ratings yet

- 007-013558-001 SAS PCE SPE With Support For HSM PSE2 Integration Feature Documentation RevCDocument43 pages007-013558-001 SAS PCE SPE With Support For HSM PSE2 Integration Feature Documentation RevCpietoeNo ratings yet

- KST GlueTech 44 enDocument80 pagesKST GlueTech 44 enLeandro RadamesNo ratings yet

- BPSK SimulinkDocument13 pagesBPSK SimulinkpootommyNo ratings yet

- Tharmal Analysis BasicsDocument56 pagesTharmal Analysis BasicsNetoNo ratings yet

- Simatic EKB Install 2012-03-08Document2 pagesSimatic EKB Install 2012-03-08Oton SilvaNo ratings yet

- Alien Vault Lab2Document28 pagesAlien Vault Lab2DukeNo ratings yet