Professional Documents

Culture Documents

Drag Coefficient

Uploaded by

Adrian John Soe MyintCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drag Coefficient

Uploaded by

Adrian John Soe MyintCopyright:

Available Formats

2014

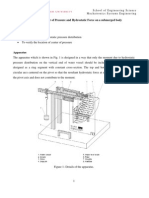

Drag Coefcient

Measurement

REVIEW OF PREVIOUS E!R"I"#

P a g e $ 2

1% INTRODUCTION

Relative motion between a particle and a surrounding fluid always involve fluid exerting

drag upon the particle Drag force is exerted in a direction parallel to the fluid velocity or

opposite to the particle velocity !or steady flow" the drag force upon the particle is given as the

following e#uation $%reen and &erry '(()*

F

D

=

C

D

A

P

u

2

2

+here !D, drag force

CD, drag coefficient

-p, pro.ected particle area in direction of motion

/ , density of surrounding fluid

u , relative velocity between particle and fluid

The drag coefficient is a dimensionless #uantity that is used to #uantify the drag or resistance

of an ob.ect in a fluid environment It is used in the e#uation above to find drag force" where

high drag coefficient corresponds to large hydrodynamic or aerodynamic drag $0oaveni '(11* It

is a function of several parameters such as shape of the body $surface area*" Reynolds number of

the flow" !roude number" 0ach number and roughness of the surface

The drag coefficient is an extremely crucial variable that determines the drag forces involved

in many aerodynamic applications such as aircraft design and automobile designs" and it helps

professionals in those fields to come up with the most energy efficient designs by minimi2ing the

drag force or utili2ing it efficiently $3enson '(1(* There are many applications in chemical

engineering that ma4e use of drag coefficients as well !or example" drag coefficients are used in

the calculation of particle terminal settling velocity of solids and therefore used where the

suspension or settling of solids particle will occur in chemical unit operations The particle

terminal settling velocity in turn can be used to calculate the hindered settling velocity" so it can

be used to help design solid5li#uid mixers" clarifiers" thic4eners" slurry transport in pipe $ie

design a slurry pump*" solid5li#uid filters It can also be used to design pneumatic transport lines

and used to help design unit operations where solid5fluid $li#uid or gas* will need to be mixed"

transported or separated

P a g e $ 3

The values of the drag coefficient for different body shapes sub.ected to different flow

conditions $laminar" transition and turbulent* are available in a wide range of literature There are

also hundreds of correlations relating the drag coefficient to the particle Reynolds number and

measure of sphericity Normally" the drag coefficients are determined through experiments !or

this pro.ect" the topic of interest involving drag coefficients is the flow over spherical ob.ects

' CONC6&T7

'1 Drag Coefficient of 7pheres

!low over spherical solid is one of the important cases to analy2e for efficient chemical

engineering design8 especially in determining the settling times of chemicals -t low Reynolds

numbers $ie" Re 99 1*" there is no flow separation" and the fluid is stuc4 to the sphere as seen in

!igure 11

Figure 1.1 Flow over sphere in low Re regions

Drag coefficient at low Re can be simply predicted by the linear function as follows8

C

D

=

24

Re

-t moderate Reynolds number between 1((( and '(((((" a boundary layer is formed around the

sphere as seen in !igure 1: - wide wa4e region is formed at the downstream of the spherical

ob.ect

Figure 1.2 Flow over sphere in moderate Re region

P a g e $ 4

The drag coefficient decreases with the increasing Re and at this region of Re" the drag

coefficient becomes constant where"

C

D

=0.44

This region is 4nown as the Newton region

Increasing the Re above '(((( will significantly reduce the boundary layer around the sphere as

shown in !igure 1;

Figure 1.3 Flow over a sphere in highly turbulent region

The flow separation is delayed and the fluid forms a relatively narrow wa4e region in which the

flow is highly unsteady and turbulent !or turbulent boundary layer flow" the drag coefficient is

decreased further until CD , ((< at Re , ;=1(

>

?ence" a turbulent boundary layer developed

along the sphere will reduce the drag force exerted upon the solid The graph of drag coefficient

of sphere as a function of Reynolds number is as illustrated in !igure 1; as follows8

Figure 1.4 Drag coefficient of a sphere as a function of Re

!irst" to find drag coefficient of a sphere" assumption is made that a solid smooth sphere

is moving along the direction of gravity The forces acting on the sphere are as illustrated as

follows8

F

D

P a g e $ 5

Figure 1.5 Free body diagram of spherical ob!ect

+here + is weight

!D is drag force

!b is buoyant force

!or an ob.ect at terminal velocity"

Drag !orce @ 3uoyant !orce A +eight , (

Therefore" the drag force can simply be found by doing force balance with above e#uation where

3uoyant force"

F

b

=V ol ume of S p her e, V Densi t y o f Fl ui d,

+eight"

!=V ol ume o f S phe r e, V De nsi t y of S pher e,

s

!or spherical ob.ects" if Re991" the drag force can be found by 7to4es BawC as shown

F

D

=" # $

f l ui d

% D

+here U is terminal velocity

D is diameter of sphere

$

f l ui d

is viscosity of li#uid

3y e#uating this e#uation to the drag force found from the force balance" the terminal velocity

e#uation can be written as

%=

D

2

&' $

f l ui d

(

P

)

Dnowing the velocity of sphere" Re can be found and subse#uently CD can be determined from

the graph in !igure 1; or from 7to4eCs Baw e#uation ?owever" if the flow is not in the 7to4eCs

P a g e $ 6

region" another method involving -rchimedesC number" -r" has to be utili2ed -r is simply found

by the following e#uation

A r=

D

"

(

P

)

$

2

Depending on the region of -r" Re values can be found by using correlations or -r vs Re graph

Re can be then used to find the CD from !igure 1;

'' Drag Coefficient of Non57pherical Ob.ects

!or flow over non5spherical ob.ects" their drag coefficient is described by their sphericity"

E $Dumar '(1:* It is the ratio of surface area of a sphere of volume e#ual to that of the particle"

to the surface area of the particle !or example" a cube has a sphericity of (F(< The Re can be

found in the same way as the method for spherical ob.ects at terminal velocity CD can be read

from the graph that shows CD as a function of Re for different sphericities $Rhodes '(1:*

': 6ffect of Near5by &articles

In realistic flows" the velocity gradients around each particle are affected by the presence

of nearby particles $Ghang nd* 7o the normal drag correlations do not apply The extent of the

effect from nearby particles can be categori2ed into three different categories depending on the

concentration of particles in the fluid and their respective CD values can be found

1. For low concentration "c#$.$5%

7low flowH

C

D

=

24

Re

?igh flowH same as for the method for single particle

2. &oderate concentration "$.$5#c#$.3%

7low flowH

C

D

=C

Do

(

&

( &()

)&

)

where N,;<>

?igh flowH

C

D

=C

Do

(

&

(&()

*

)

where

3. 'arge concentration "c($.3%

P a g e $ 7

!or large concentrations" the porous media correlations have to be used to find the I

$ReC* which is the friction factor function for the pore friction rewritten in terms of

particle diameter

&% REFERE"CES

3enson" Tom '(1( The Drag Coefficient N-7- -ccessed ;J:J'(1;"

httpsHJJwwwgrcnasagovJwwwJ451'JairplaneJdragcohtml

%reen" D" and R &erry '(() Perry's Chemical Engineers' Handbook, Eighth EditionH

0c%raw5?ill 6ducation

Dumar" &erumal '(1: Motions of Particles of Fluid" Curtin University Saraak Malaysia 0iri

0oaveni" 7 '(11 Engineering Fundamentals! "n #ntroduction to Engineering, Si EditionH

Cengage Bearning

Rhodes" 0K '(1: #ntroduction to Particle $echnologyH +iley

Ghang" Kie nd 0otions of &articles through !luid -ccessed ) -pril"

httpHJJloriennclacu4JmingJparticleJcpe1';p'html

You might also like

- Measuring Drag Coefficient of a SphereDocument13 pagesMeasuring Drag Coefficient of a SphereMuhamad Aiman0% (1)

- Motion of Particles in FluidDocument26 pagesMotion of Particles in FluidSubakti HungNo ratings yet

- Particle Drag CoefficientDocument15 pagesParticle Drag Coefficientnor_nazri_3No ratings yet

- The Loss Factor As Measure Mechanical Damping PDFDocument5 pagesThe Loss Factor As Measure Mechanical Damping PDFsalvatorgabriele100% (1)

- Drag Coefficient of Sphere - FinalDocument9 pagesDrag Coefficient of Sphere - FinalPeter BournelisNo ratings yet

- UtmDocument7 pagesUtmMirza Aqeel AhmedNo ratings yet

- (Fatigue Test) : Strength Lab Report Experiment #Document12 pages(Fatigue Test) : Strength Lab Report Experiment #john rozz bbNo ratings yet

- Drag CoefficientDocument5 pagesDrag CoefficientRaghav MainiNo ratings yet

- Finite Element Analysis of Hydraulic JackDocument7 pagesFinite Element Analysis of Hydraulic Jacksitipani100% (1)

- Tensile Test Lab ReportDocument13 pagesTensile Test Lab Reportahmad adnanNo ratings yet

- Literature Review Spur GearDocument3 pagesLiterature Review Spur Gearthai avvaiNo ratings yet

- Fatigue Test: Faculty of Mechanical EngineeringDocument9 pagesFatigue Test: Faculty of Mechanical EngineeringAlimin AnniNo ratings yet

- Fluid Flow in Rocket NozzlesDocument24 pagesFluid Flow in Rocket NozzlesVenkat AkellaNo ratings yet

- Lab Report Tensile TestDocument10 pagesLab Report Tensile TestmungutiNo ratings yet

- Cubic Equations of State-Which Is BestDocument17 pagesCubic Equations of State-Which Is BestvenkieeNo ratings yet

- Boundary LayersDocument15 pagesBoundary LayersRo Win100% (1)

- Analyzing Stresses in Thin Cylinders Using Strain GaugesDocument5 pagesAnalyzing Stresses in Thin Cylinders Using Strain GaugesAngshuman BhardwajNo ratings yet

- 11 Heat TreatmentDocument5 pages11 Heat TreatmentamokhtaNo ratings yet

- Experimental Determination of Nozzle Efficiency VariationDocument8 pagesExperimental Determination of Nozzle Efficiency VariationSunil Choudhary50% (2)

- Undamped Vibration Absorber - v3Document14 pagesUndamped Vibration Absorber - v3prem_chaurasiyaaNo ratings yet

- MEC424 Content TorsionDocument12 pagesMEC424 Content TorsionHaFiy HaZimNo ratings yet

- Friction Factor For Turbulent Pipe FlowDocument16 pagesFriction Factor For Turbulent Pipe Flowyu won hoNo ratings yet

- Determination of Mixed-Mode Stress Intensity Factors, FractureDocument16 pagesDetermination of Mixed-Mode Stress Intensity Factors, FractureSoupramanien KathirvelouNo ratings yet

- Casting Assignment: Department of Mechanical and Industrial EngineeringDocument7 pagesCasting Assignment: Department of Mechanical and Industrial EngineeringTeeNo ratings yet

- Pressure Nozzle Distribution UnitDocument16 pagesPressure Nozzle Distribution UnitAlmeghalawyNo ratings yet

- Center of Pressure and Hydrostatic Force On A Submerged Body-RevDocument7 pagesCenter of Pressure and Hydrostatic Force On A Submerged Body-RevAnkit MittalNo ratings yet

- Heat Transfer Chapter 1 IntroductionDocument68 pagesHeat Transfer Chapter 1 IntroductionsubratorajNo ratings yet

- Damped Vibration ReportDocument13 pagesDamped Vibration ReportrexNo ratings yet

- Chapter 3 - Boundary Layer TheoryDocument37 pagesChapter 3 - Boundary Layer TheoryJia EnNo ratings yet

- Impact Test Ravi Agarwal 09003017 Group GDocument8 pagesImpact Test Ravi Agarwal 09003017 Group GRavi Agarwal100% (1)

- Heat Transfer Rate ComparisonDocument19 pagesHeat Transfer Rate Comparisonangelaers100% (2)

- Motion of Particles Through Fluids 221Document27 pagesMotion of Particles Through Fluids 221SAYEENo ratings yet

- Transmission Loss in Piping From FisherDocument8 pagesTransmission Loss in Piping From FisheraruatscribdNo ratings yet

- Drag of A SphereDocument4 pagesDrag of A SphereJean-Franz Baschube100% (1)

- Gas Dynamics and Jet PropulsionDocument317 pagesGas Dynamics and Jet PropulsionVinoth RajaguruNo ratings yet

- Heat Exchanger Lab Report - Reference MaterialDocument30 pagesHeat Exchanger Lab Report - Reference MaterialFarwa RizviNo ratings yet

- Boundary LayerDocument10 pagesBoundary LayerViwek MertiyaNo ratings yet

- CH 06Document48 pagesCH 06LeonardoMadeira11No ratings yet

- Drag ForceDocument9 pagesDrag ForceImran BahaNo ratings yet

- Testing of Adhesive Joints in The Wind Industry: AbstractDocument10 pagesTesting of Adhesive Joints in The Wind Industry: AbstractL.a. MayorNo ratings yet

- MECH215 L4L6 Dynamic LoadingDocument97 pagesMECH215 L4L6 Dynamic LoadingTuanHungNo ratings yet

- Creep of Metals and Polymers Lab ReportDocument6 pagesCreep of Metals and Polymers Lab ReportamokhtaNo ratings yet

- Atomic and Ionic Arrangements Determine Material PropertiesDocument35 pagesAtomic and Ionic Arrangements Determine Material PropertiesKai NganNo ratings yet

- Experimental Analysis of Pressure VesselDocument8 pagesExperimental Analysis of Pressure VesselmusaveerNo ratings yet

- Elliptical Pressure Vesel Stress AnalysisDocument36 pagesElliptical Pressure Vesel Stress Analysisliviu333nt6132No ratings yet

- Distillation Column ModelingDocument8 pagesDistillation Column ModelingMohamed GuenouneNo ratings yet

- Impact of JetDocument8 pagesImpact of JetbandarNo ratings yet

- Lab 6 - Maximum Power Transfer and PF Improvement - 2012Document5 pagesLab 6 - Maximum Power Transfer and PF Improvement - 2012劉成No ratings yet

- Measure Strain with Rosette Strain GaugeDocument4 pagesMeasure Strain with Rosette Strain GaugeKarthikayan BalajiNo ratings yet

- Flow of Fluids through Granular and Packed BedsDocument38 pagesFlow of Fluids through Granular and Packed Bedsasaya675456No ratings yet

- ICL Aeronautics Lab Report on Boundary Layer ExperimentsDocument2 pagesICL Aeronautics Lab Report on Boundary Layer ExperimentsSheng Hong Chai0% (1)

- Radiation Heat Transfer Experiment PDFDocument11 pagesRadiation Heat Transfer Experiment PDFTuba JavedNo ratings yet

- Fluid Mechanics and Hydraulic Machines Lab Manual PDFDocument55 pagesFluid Mechanics and Hydraulic Machines Lab Manual PDFjyothiNo ratings yet

- Flow over a Lifting Cylinder Vortex SolutionDocument4 pagesFlow over a Lifting Cylinder Vortex SolutiongetsweetNo ratings yet

- Drag Coefficient - OdtDocument7 pagesDrag Coefficient - OdtRos JalinNo ratings yet

- Viscosity from Terminal Velocity of Falling SphereDocument4 pagesViscosity from Terminal Velocity of Falling SphereMAI_AAN_KURNIAWANNo ratings yet

- Drag On Ellipsoids at Finite Reynolds NumbersDocument9 pagesDrag On Ellipsoids at Finite Reynolds NumbersSamuel OnyewuenyiNo ratings yet

- Fundamentals of Structural Geology Exercise: Concepts From Chapter 10Document5 pagesFundamentals of Structural Geology Exercise: Concepts From Chapter 10firstdawn02No ratings yet

- Drag Coefficient of Hemispheres in FlowDocument29 pagesDrag Coefficient of Hemispheres in FlowAbdul RahmanNo ratings yet

- 2013 Market Research Report On Global and China Potassium Hydroxide IndustryDocument8 pages2013 Market Research Report On Global and China Potassium Hydroxide IndustryAdrian John Soe MyintNo ratings yet

- Risk Management 421 Unit OutlineDocument7 pagesRisk Management 421 Unit OutlineAdrian John Soe MyintNo ratings yet

- Ethylene GlycolDocument18 pagesEthylene GlycolNunie Puji LestariNo ratings yet

- Supercritical Carbon Dioxide Density and Viscosity CorrelationsDocument69 pagesSupercritical Carbon Dioxide Density and Viscosity CorrelationsAdrian John Soe MyintNo ratings yet

- Chicago 16th Style Guide 2013Document16 pagesChicago 16th Style Guide 2013gabuchia0% (1)

- Unit Outline and Introduction To Design: © HB Vuthaluru 2006Document41 pagesUnit Outline and Introduction To Design: © HB Vuthaluru 2006Adrian John Soe MyintNo ratings yet

- Span WagnerDocument28 pagesSpan WagnerAdrian John Soe MyintNo ratings yet

- MCCB/ELCB GuideDocument148 pagesMCCB/ELCB GuideWangunNo ratings yet

- Catalog: LORD Vibration, Shock and Motion Control ProductsDocument133 pagesCatalog: LORD Vibration, Shock and Motion Control ProductsDulanga FernandoNo ratings yet

- 320W Single Output With PFC Function: SeriesDocument4 pages320W Single Output With PFC Function: SeriesJesus HolmesNo ratings yet

- 3 Pipe Sizing 2013 3Document34 pages3 Pipe Sizing 2013 3siva anand100% (1)

- Physics Paper 2019Document2 pagesPhysics Paper 2019AlmasNo ratings yet

- Inverse Trigonometric FunctionsDocument2 pagesInverse Trigonometric FunctionsArman SinghNo ratings yet

- Medium Voltage CablesDocument5 pagesMedium Voltage CablesGualaNo ratings yet

- Technical Particular and Guarantee: Pt. Prima Indah LestariDocument2 pagesTechnical Particular and Guarantee: Pt. Prima Indah Lestaritees220510No ratings yet

- Electrical Safety Costs LittleDocument40 pagesElectrical Safety Costs LittleDragomir HoffmannNo ratings yet

- Energise 2020 - Jupiter Hospital Case StudyDocument7 pagesEnergise 2020 - Jupiter Hospital Case StudySujoy DeNo ratings yet

- Skema Trial SBP Physics 2007Document15 pagesSkema Trial SBP Physics 2007Irfan Faiz100% (1)

- IJNRD2204039Document9 pagesIJNRD2204039pomoc.pri.izradi.radaNo ratings yet

- Axial Generator Calculator MetricDocument48 pagesAxial Generator Calculator MetricCriss MereutaNo ratings yet

- Calibrate level transmitter with wet and dry methodsDocument3 pagesCalibrate level transmitter with wet and dry methodsJayJayNo ratings yet

- A R K K: Chbe 6300: Kinetics and Reactor Design Homework 1Document2 pagesA R K K: Chbe 6300: Kinetics and Reactor Design Homework 1AnnNo ratings yet

- Review of Heat TransferDocument47 pagesReview of Heat TransferNurul HanifahNo ratings yet

- Mathematics Form 1 Exam PaperDocument26 pagesMathematics Form 1 Exam Paper洛星No ratings yet

- Projectile MotionDocument4 pagesProjectile MotionaliNo ratings yet

- Chapter 7: Velocity in Mechanisms: Toggle PressDocument10 pagesChapter 7: Velocity in Mechanisms: Toggle PressGopal BhuniaNo ratings yet

- 091 Vijaya Prasaadam 01 05Document41 pages091 Vijaya Prasaadam 01 05aruna11668% (72)

- May 2004 Subject Report (TZ2)Document21 pagesMay 2004 Subject Report (TZ2)Swee Boon OngNo ratings yet

- Lovato PM CatalogueDocument10 pagesLovato PM CatalogueMiFa PNo ratings yet

- Water Flow Experiments: Single and Double Bottle SystemsDocument13 pagesWater Flow Experiments: Single and Double Bottle SystemsJiggy Lawrence BathanNo ratings yet

- HEAT ENGINES E-LEARNING LECTURE #5 MODIFICATIONS ON BRAYTON CYCLEDocument42 pagesHEAT ENGINES E-LEARNING LECTURE #5 MODIFICATIONS ON BRAYTON CYCLEMohamed KhaledNo ratings yet

- Double Inlet Airfoil Fans - AtzafDocument52 pagesDouble Inlet Airfoil Fans - AtzafDaniel AlonsoNo ratings yet

- AN5004Document5 pagesAN5004rdc02271No ratings yet

- Ficha Técnica SUPRESOR DE PICOS 40 2 POLOSDocument2 pagesFicha Técnica SUPRESOR DE PICOS 40 2 POLOSmanuel montero guerraNo ratings yet

- 48V50Ah Module SpecificationDocument4 pages48V50Ah Module SpecificationhermantoNo ratings yet

- Omron E5 JDocument69 pagesOmron E5 JVoneisisoNo ratings yet

- iRelay 60 & 50-P Protection Relays Device OverviewDocument22 pagesiRelay 60 & 50-P Protection Relays Device Overviewflyngdance100% (1)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaFrom EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNo ratings yet

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)

- The Fabric of Civilization: How Textiles Made the WorldFrom EverandThe Fabric of Civilization: How Textiles Made the WorldRating: 4.5 out of 5 stars4.5/5 (57)

- Sully: The Untold Story Behind the Miracle on the HudsonFrom EverandSully: The Untold Story Behind the Miracle on the HudsonRating: 4 out of 5 stars4/5 (103)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationFrom EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationRating: 4.5 out of 5 stars4.5/5 (46)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (241)

- Pale Blue Dot: A Vision of the Human Future in SpaceFrom EverandPale Blue Dot: A Vision of the Human Future in SpaceRating: 4.5 out of 5 stars4.5/5 (586)

- The Weather Machine: A Journey Inside the ForecastFrom EverandThe Weather Machine: A Journey Inside the ForecastRating: 3.5 out of 5 stars3.5/5 (31)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- 35 Miles From Shore: The Ditching and Rescue of ALM Flight 980From Everand35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Rating: 4 out of 5 stars4/5 (21)

- The Future of Geography: How the Competition in Space Will Change Our WorldFrom EverandThe Future of Geography: How the Competition in Space Will Change Our WorldRating: 4.5 out of 5 stars4.5/5 (4)

- A Garden of Marvels: How We Discovered that Flowers Have Sex, Leaves Eat Air, and Other Secrets of PlantsFrom EverandA Garden of Marvels: How We Discovered that Flowers Have Sex, Leaves Eat Air, and Other Secrets of PlantsNo ratings yet

- Recording Unhinged: Creative and Unconventional Music Recording TechniquesFrom EverandRecording Unhinged: Creative and Unconventional Music Recording TechniquesNo ratings yet

- Data-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseFrom EverandData-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseRating: 3.5 out of 5 stars3.5/5 (12)

- The End of Craving: Recovering the Lost Wisdom of Eating WellFrom EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellRating: 4.5 out of 5 stars4.5/5 (80)

- Packing for Mars: The Curious Science of Life in the VoidFrom EverandPacking for Mars: The Curious Science of Life in the VoidRating: 4 out of 5 stars4/5 (1395)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureFrom EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureRating: 5 out of 5 stars5/5 (124)

- Across the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsFrom EverandAcross the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsNo ratings yet

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Artificial Intelligence: A Guide for Thinking HumansFrom EverandArtificial Intelligence: A Guide for Thinking HumansRating: 4.5 out of 5 stars4.5/5 (30)

- A-level Biology Revision: Cheeky Revision ShortcutsFrom EverandA-level Biology Revision: Cheeky Revision ShortcutsRating: 5 out of 5 stars5/5 (5)

- Hands of Time: A Watchmaker’s HistoryFrom EverandHands of Time: A Watchmaker’s HistoryRating: 4.5 out of 5 stars4.5/5 (5)

- Reality+: Virtual Worlds and the Problems of PhilosophyFrom EverandReality+: Virtual Worlds and the Problems of PhilosophyRating: 4 out of 5 stars4/5 (24)