Professional Documents

Culture Documents

Types of Valves

Uploaded by

RahulTewari0 ratings0% found this document useful (0 votes)

209 views11 pagesTypes of Valves Details and their working procedure

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTypes of Valves Details and their working procedure

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

209 views11 pagesTypes of Valves

Uploaded by

RahulTewariTypes of Valves Details and their working procedure

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 11

YPES OF VALVES

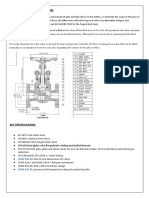

1. THE GATE VALVE (See Figure : 13)

This is the most common type of valve in use in industry and is used to start or stop the flow of

fluids. It gives a positive shut-off when closed and is often used as a 'Block Valve' for isolating

systems.

The gate valve MUT !e either "U##$ %#&'( or "U##$ &)'* and *'V'+ U'( T&

%&*T+&# "#&,- as the fluid velocity will erode the valve internals - gate and !ody seats .. etc.

. gate valve may !e of the '+II*/ T'M' type as in "igure0 12 or a '*&*-+II*/ T'M'- in

which the stem threads are '#eft-hand' threads set into the gate itself as in "igure0 13.

The valve consists of a !ody which houses the valve mechanism - the stem 4or spindle5- the

disc4s5 4or gate5- and the disc and !ody seats. /ate valves can !e operated !y a hand-wheel- an

electric motor 4M&V5- or !y an air powered diaphragm- or motor- or a piston actuator.

T6' +II*/ T'M /.T' V.#V'

"igure 0 12

*&*-+II*/ T'M

2. THE GLOBE VALVE (See Figure : 15)

The /lo!e valve is used where control of fluid flow or pressure is re7uired and it can !e operated

in any position !etween open and closed.

. /lo!e valve may !e constructed with a single or dou!le port and plug arrangement. The

dou!le port type is generally used in a %&*T+&# V.#V' where accurate control of fluid is

re7uired. (ue to the dou!le valve plug arrangement- the internal pressure acts on each plug in

opposition to each other- giving an internal pressure !alance across the plugs. 4ee "ig0 89 on

page 38 : %ontrol Valve5

This gives a much smoother operation of the valve and !etter control of the process. ome

control valves are '+everse .cting'. ,here a valve normally opens when the plug rises- in the

reverse acting valve- the valve closes on rising. The operation of the valve depends on process

re7uirements. .lso depending on re7uirements- a control valve may !e set to open or close- on

air failure to the diaphragm.

3. THE NEEDLE VALVE (See Figure : 16)

This is simply a variation of the /lo!e valve and- as its name implies consists of a narrow-

tapered plug and port arrangement. The needle valve is- in itself- small in si;e and is used for

very fine and normally manual- control of fluid flow.

4. THE ANGLE VALVE (See Figure : 1)

.nother variation of the /lo!e valve which is often used for compressor recycle systems. It is

also often used for dirty fluids. In this valve- the fluid flow enters from !elow the plug and passes

through an angle of <9= to the outlet. .n angle valve may !e manually or automatically

controlled.

5. THE PL!G "r BALL VALVE (See Figure : 1#)

These valves give a more streamline flow in their operation. The valve port is a!out the same

si;e as the internal pipe diameter. They are operated simply !y turning a handle through <9=.

They can give a fairly tight shut-off and some degree of control.

6. THE B!TTE$FLY VALVE (See Figure : 1%)

The Butterfly valve is designed to give full flow with some control capa!ility. *ormally- this type of

valve does not give positive shut-off !ut- present-day technology- using new )olymers and higher

temperature ratings- has ena!led the construction of !utterfly valves having a 'Bu!!le-tight' shut-

off.

. &HE&' "r NON($ET!$N VALVES (N$V)*) (See Figure : 2+)

These valves will allow fluid flow in &*' (I+'%TI&* &*#$. Their purpose is to prevent !ackflow

- for e>ample -in pump discharge lines and where !ack-flow is undesira!le. ,hen flow stops- the

weight of the piston- !all or flapper closes the valve. If the pressure downstream of the valve- is

higher than the upstream side- the valve will close more firmly and !ack-flow cannot occur.

There are two main types of check valve 0

1. The '#I"T' type. 4pring loaded 'B.##' ? ')IT&*' Types5.

8. The ',I*/' 4or "lapper Type5.

T6' *''(#' V.#V'

"igure 0 1@

T6' .*/#' V.#V'

"igure 0 1A

T6' )#U/ V.#V' ? B.## V.#V'

"igure 0 1B

T6' BUTT'+"#$ V.#V' 4IM)#I"I'(5

"igure 0 1<

%6'%C or *&*-+'TU+* V.#V' 4*+V's5

"igure 0 89

#. SAFETY $EL,EF VALVES (See Figure : 21)

afety valves are installed on e7uipment to prevent over-pressure 4or e>cess vacuum5- which

could cause damage- rupture or collapse of the e7uipment.

,here the type installed is to prevent e>cess vacuum- they are normally referred to as 'Vacuum

Breakers'.

. safety valve will have a lifting set pressure higher 4a!out 1.D times5 than the operating pressure

of the system !ut well !elow the design ma>imum pressure allowed.

In the conventional type- the pressure of the valve discharge line will affect the set pressure of

the valve !y giving a !ack-pressure on the valve plug.

In the !ellows type- the !ellows isolates the plug from the !ack-pressure and therefore there is

no effect on the valve setting.

The following diagram is of a conventional safety relief valve. .ll safety valves have the same

purpose of protecting e7uipment from over-pressure. (ifferent makers have their own designs.

."'T$ +'#I'" V.#V'

"igure 0 81

VALVE A&&ESSO$,ES

1. ST!FF,NG BO- ./0 PA&',NG (See Figure : 22)

)acking is a means of preventing leakage around the valve stem to atmosphere. The packing is

placed in the 'tuffing Bo>' around the stem. It is then held in place and compressed !y the

'/land' and '/land "ollower' to give a leak-tight seal.

6owever- having the packing too tight can cause the operation of the valve to !e stiff. ,hen

tightening down on the packing does not stop leakage or causes valve operation to !e stiff- the

packing should !e replaced.

In some larger valves- a '#antern +ing' is inserted !etween the turns of packing and is placed

opposite to a lu!rication point where grease can !e inEected in order to ease the valve operation.

"igure 0 88

2. VALVE OPE$ATO$S (See Figure: 23)

The most common valve operator is the '6and-wheel'. &ther methods of valve operation can !e

as follows 0

A. A Di.12r.g3

6ere- the valve is operated !y an air powered diaphragm. These are called ')neumatic %ontrol

Valves'. The air powered actuator can also take the form of a ')iston' rather than a diaphragm.

The operation of the valve- depending on re7uirements- may !e '.ir to &pen' 4.&5 or '.ir to

%lose' 4.%5.

B. A/ E4e56ri5 7"6"r

This is called a 'Motor &perated Valve' 4M&V5 and may !e installed to allow valve operation from

a remote location and may then !e referred to as a '+emote &perated Valve' 4+&V5.

&. A S"4e/"i0

This method of valve operation is used for a small valve placed in an air supply line to a shut-

down device. The solenoid will !e activated on an electrical signal from an automatic trip system

and will open or close depending upon its function.

"igure0 82 -(iaphragm &perated Valve

You might also like

- Lewis Corporation Case 6-2 - Group 5Document8 pagesLewis Corporation Case 6-2 - Group 5Om Prakash100% (1)

- Classification and Selection of Industrial ValvesDocument76 pagesClassification and Selection of Industrial ValvesABVSAI100% (6)

- Aban Ejector TrainingDocument39 pagesAban Ejector TrainingChiranjeet JenaNo ratings yet

- Financial Analysis of Wipro LTDDocument101 pagesFinancial Analysis of Wipro LTDashwinchaudhary89% (18)

- API PLAN 62 - Installation of Steam Traps in Steam QuenchDocument3 pagesAPI PLAN 62 - Installation of Steam Traps in Steam Quenchrmehta26No ratings yet

- Control ValvesDocument38 pagesControl ValvesSridhar GudapatiNo ratings yet

- Water Hammer in Steam LinesDocument5 pagesWater Hammer in Steam LinesVijaita Vikas GandhiNo ratings yet

- Industrial Valves Module 1 Functions TypesDocument66 pagesIndustrial Valves Module 1 Functions TypesUmar DrazNo ratings yet

- Block 9 Safety ValvesDocument85 pagesBlock 9 Safety ValvesBabu AravindNo ratings yet

- Valves: Presented by D.Nagababu (Get-Pp)Document54 pagesValves: Presented by D.Nagababu (Get-Pp)SatishSathyamevaJayatheNo ratings yet

- Pump in PlantDocument14 pagesPump in PlantGanesh MarkadNo ratings yet

- Globe Valve Bs 1873 and Api 602: ASME B16.10Document7 pagesGlobe Valve Bs 1873 and Api 602: ASME B16.10swapnil PATILNo ratings yet

- Boiler Operator Exam Preparation Guide pdf-1 PDFDocument27 pagesBoiler Operator Exam Preparation Guide pdf-1 PDFEmmanuel Jesus Marquez Rea100% (1)

- Fundamentals of Piping ValvesDocument32 pagesFundamentals of Piping Valvesasai100% (1)

- Valve Types and Symbols PDFDocument164 pagesValve Types and Symbols PDFHassan AlbrehawyNo ratings yet

- R - 1776 - Check Valves Side Mounted Extraction Check ValveDocument4 pagesR - 1776 - Check Valves Side Mounted Extraction Check ValvedharmendrabholeNo ratings yet

- 34 - Vacuum EjectorsDocument56 pages34 - Vacuum Ejectorssunggwan kimNo ratings yet

- Vacuum Unit Design and Operation TrainingDocument136 pagesVacuum Unit Design and Operation Trainingsunggwan kim0% (1)

- Ball Valve KnowledgeDocument40 pagesBall Valve KnowledgeMeanRat100% (1)

- CCI Power ApplicationsDocument57 pagesCCI Power Applicationssukanya_ravichandran100% (1)

- NTPC Project ReportDocument31 pagesNTPC Project ReportDeepak Ranjan ParidaNo ratings yet

- ValvesDocument42 pagesValvesSundara MoorthyNo ratings yet

- Basics of Valves Interview Questions & Answers: Directional Control ValveDocument7 pagesBasics of Valves Interview Questions & Answers: Directional Control ValveJêmš NavikNo ratings yet

- BHEL Valves PDFDocument135 pagesBHEL Valves PDFNitin Aggarwal100% (1)

- Condenser CondenserDocument36 pagesCondenser Condenserobisonandlaw100% (1)

- Steam Traps ManualDocument33 pagesSteam Traps ManualSatyajit PatilNo ratings yet

- API 612 Special Purpose Steam TurbinesDocument51 pagesAPI 612 Special Purpose Steam TurbinesAmmonia 1 Engineers100% (1)

- Seal Steam RegulatorDocument10 pagesSeal Steam RegulatorBiplab DasNo ratings yet

- Safety Valves and Relief Valves.Document17 pagesSafety Valves and Relief Valves.Shikhar SwaroopNo ratings yet

- Control Valves 91000Document16 pagesControl Valves 91000ibharNo ratings yet

- 002-Steam Turbines Basics For BeginnersDocument10 pages002-Steam Turbines Basics For BeginnersGeorge J AlukkalNo ratings yet

- A Review On Centrifugal Compressor Design MethodsDocument3 pagesA Review On Centrifugal Compressor Design MethodsIJIRSTNo ratings yet

- Turboexpanders: CompressorsDocument4 pagesTurboexpanders: Compressorsdhanu_aquaNo ratings yet

- Y2 PumpsDocument70 pagesY2 Pumpsfacebookshop100% (1)

- All Process - Pumps - Re - 014 PDFDocument21 pagesAll Process - Pumps - Re - 014 PDFWRTNo ratings yet

- Guide To Pump Types - PumpScoutDocument8 pagesGuide To Pump Types - PumpScoutmohdazanNo ratings yet

- Steam Traps & TypesDocument21 pagesSteam Traps & TypesSyed Waqas HaiderNo ratings yet

- Overview of Air Cooled Heat ExchangersDocument30 pagesOverview of Air Cooled Heat ExchangersJavier GarcíaNo ratings yet

- Compounding of Steam TurbinesDocument4 pagesCompounding of Steam Turbinessmg26thmay100% (1)

- Floating Head Heat Exchanger Maintenance GuideDocument15 pagesFloating Head Heat Exchanger Maintenance GuideASWIN.MTNo ratings yet

- PIlot Operated Safety ValveDocument6 pagesPIlot Operated Safety ValveTrisha SalinasNo ratings yet

- Proportional and Servovalves Control Hydraulic Systems PreciselyDocument14 pagesProportional and Servovalves Control Hydraulic Systems PreciselyMarius IsdrailaNo ratings yet

- 2) Piping Interview QuestionnaireDocument4 pages2) Piping Interview QuestionnaireAjaz MalikNo ratings yet

- Safety Valve LaserDocument15 pagesSafety Valve Lasersajjad_naghdi241No ratings yet

- Air Cooled CondenserDocument3 pagesAir Cooled CondenserJonathan Buenaobra100% (1)

- Valves - PresentationDocument119 pagesValves - Presentationkrahul100% (15)

- Laguna State Polytechnic University Document on Fans, Blowers and CompressorsDocument69 pagesLaguna State Polytechnic University Document on Fans, Blowers and CompressorsCllyan ReyesNo ratings yet

- Flanges General - Pressure-Temperature Ratings ASTM and ASMEDocument5 pagesFlanges General - Pressure-Temperature Ratings ASTM and ASMEjacksonbello34No ratings yet

- Single and Multistage Steam Jet Ejectors: TorinoDocument12 pagesSingle and Multistage Steam Jet Ejectors: TorinoSuman SenapatiNo ratings yet

- Guide to Valve Types, Uses, Maintenance and ControlDocument44 pagesGuide to Valve Types, Uses, Maintenance and Controlأحمد محمد قدريNo ratings yet

- Valve Selection Handbook - Check ValvesDocument16 pagesValve Selection Handbook - Check ValvesPalazzo345No ratings yet

- Compressor Surge and Operation Rev1Document28 pagesCompressor Surge and Operation Rev1KorichiKarimNo ratings yet

- API Verses Non APIDocument19 pagesAPI Verses Non APIsandeshNo ratings yet

- Valve Types and SymbolsDocument164 pagesValve Types and Symbolssantos ayala100% (3)

- Elliott Brush Ring Seals: Installation KitDocument2 pagesElliott Brush Ring Seals: Installation Kitfouzi gher100% (1)

- Valve Material Application PDFDocument16 pagesValve Material Application PDFSudherson Jagannathan100% (1)

- THE GATE VALVE (See Figure: 13)Document7 pagesTHE GATE VALVE (See Figure: 13)vikrantsingh2908No ratings yet

- Figure 7-7 - Plug Valve Detail: Ball ValvesDocument8 pagesFigure 7-7 - Plug Valve Detail: Ball ValvesEmad SaadNo ratings yet

- Valves Used in Pipelines: Valve Specification Siemens Energy Gas Turbine Inlet FiltersDocument13 pagesValves Used in Pipelines: Valve Specification Siemens Energy Gas Turbine Inlet Filtersravikumar_jamiNo ratings yet

- Pipe Fittings, ValvesDocument10 pagesPipe Fittings, Valvesaasatti100% (1)

- Crystallizers: Chapter 16 Cost Accounting and Capital Cost EstimationDocument1 pageCrystallizers: Chapter 16 Cost Accounting and Capital Cost EstimationDeiver Enrique SampayoNo ratings yet

- Mounting InstructionDocument1 pageMounting InstructionAkshay GargNo ratings yet

- Arta Kelmendi's resume highlighting education and work experienceDocument2 pagesArta Kelmendi's resume highlighting education and work experienceArta KelmendiNo ratings yet

- 7 Aleksandar VladimirovDocument6 pages7 Aleksandar VladimirovDante FilhoNo ratings yet

- Guidelines - MIDA (Haulage)Document3 pagesGuidelines - MIDA (Haulage)Yasushi Charles TeoNo ratings yet

- Meet Joe Black (1998) : A Metaphor of LifeDocument10 pagesMeet Joe Black (1998) : A Metaphor of LifeSara OrsenoNo ratings yet

- N4 Electrotechnics August 2021 MemorandumDocument8 pagesN4 Electrotechnics August 2021 MemorandumPetro Susan BarnardNo ratings yet

- Breaking NewsDocument149 pagesBreaking NewstigerlightNo ratings yet

- Day 4 Quiz - Attempt ReviewDocument8 pagesDay 4 Quiz - Attempt ReviewĐỗ Đức AnhNo ratings yet

- TJUSAMO 2013-2014 Modular ArithmeticDocument4 pagesTJUSAMO 2013-2014 Modular ArithmeticChanthana ChongchareonNo ratings yet

- Prlude No BWV in C MinorDocument3 pagesPrlude No BWV in C MinorFrédéric LemaireNo ratings yet

- AA ActivitiesDocument4 pagesAA ActivitiesSalim Amazir100% (1)

- Reading and Writing Q1 - M13Document13 pagesReading and Writing Q1 - M13Joshua Lander Soquita Cadayona100% (1)

- ITP Exam SuggetionDocument252 pagesITP Exam SuggetionNurul AminNo ratings yet

- WWW - Commonsensemedia - OrgDocument3 pagesWWW - Commonsensemedia - Orgkbeik001No ratings yet

- Ecc Part 2Document25 pagesEcc Part 2Shivansh PundirNo ratings yet

- October 2009 Centeral Aucland, Royal Forest and Bird Protecton Society NewsletterDocument8 pagesOctober 2009 Centeral Aucland, Royal Forest and Bird Protecton Society NewsletterRoyal Forest and Bird Protecton SocietyNo ratings yet

- ArDocument26 pagesArSegunda ManoNo ratings yet

- Gabinete STS Activity1Document2 pagesGabinete STS Activity1Anthony GabineteNo ratings yet

- HSSC English Model PaperDocument32 pagesHSSC English Model PaperMaryam Abdus SalamNo ratings yet

- White Box Testing Techniques: Ratna SanyalDocument23 pagesWhite Box Testing Techniques: Ratna SanyalYogesh MundhraNo ratings yet

- PEDs and InterferenceDocument28 pagesPEDs and Interferencezakool21No ratings yet

- Evaluative Research DesignDocument17 pagesEvaluative Research DesignMary Grace BroquezaNo ratings yet

- Fast Aldol-Tishchenko ReactionDocument5 pagesFast Aldol-Tishchenko ReactionRSLNo ratings yet

- Exercise-01: JEE-PhysicsDocument52 pagesExercise-01: JEE-Physicsjk rNo ratings yet

- Certification Presently EnrolledDocument15 pagesCertification Presently EnrolledMaymay AuauNo ratings yet

- Assembly ModelingDocument222 pagesAssembly ModelingjdfdfererNo ratings yet