Professional Documents

Culture Documents

Asbestos Safety

Uploaded by

safety860 ratings0% found this document useful (0 votes)

92 views3 pagesThe EPA regulates emissions from asbestos mills and various manufacturing and fabricating operations. The Occupational Safety and Health Administration (OSHA) sets limits for worker exposure to hazardous substances and materials. Commercial products have the potential to release asbestos fbers into the environment if mishandled or misused.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe EPA regulates emissions from asbestos mills and various manufacturing and fabricating operations. The Occupational Safety and Health Administration (OSHA) sets limits for worker exposure to hazardous substances and materials. Commercial products have the potential to release asbestos fbers into the environment if mishandled or misused.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

92 views3 pagesAsbestos Safety

Uploaded by

safety86The EPA regulates emissions from asbestos mills and various manufacturing and fabricating operations. The Occupational Safety and Health Administration (OSHA) sets limits for worker exposure to hazardous substances and materials. Commercial products have the potential to release asbestos fbers into the environment if mishandled or misused.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

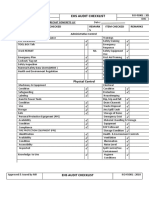

Texas Department of Insurance

Division of Workers Compensation

Safety Education and Training Programs

Asbestos Safety

HS93-003E (11-06)

Goal

This program provides information on asbestos exposure

hazards.

Objective

Employees will gain knowledge and demonstrate safe work

practices when handling asbestos containing material (ACM).

Regulations/Standards

The Environmental Protection Agency (EPA) regulates the

use and disposal of toxic substances in air, water, and on land.

(See 40 CFR 763.) The EPA regulates emissions from asbestos

mills and various manufacturing and fabricating operations

based on the National Emissions Standard for Hazardous Air

Pollutants (40 CFR 61 Subparts A & M).

The Occupational Safety and

Health Administration (OSHA) sets

limits for worker exposure to haz-

ardous substances and materials.

Prevention of asbestos contamina-

tion in foods, drugs, and cosmetics

is the responsibility of the Food and Drug Administration

(FDA).

The use of asbestos in any consumer product including dry-

wall patching compounds, ceramic logs, and clothing is regu-

lated by the Consumer Product Safety Commission (CPSC).

The CPSC is also considering a ban on all nonessential prod-

uct uses that can result in the release of asbestos fbers.

Asbestos mining and milling operations are regulated by the

Mine Safety and Health Administration (MSHA). MSHA pro-

cedures cover asbestos containment once it is mined, and its

processing into workable fbers for construction and industry.

Background

Most new products do not contain asbestos as an ingredient.

However, enough ACM still remains to pose a potential health

hazard. In the past, asbestos has been used in over 3,000 com-

mercial products ranging from pipe insulation to clothing for

fre fghters. Commercial products have the potential to release

asbestos fbers into the environment if mishandled or misused.

The following are at risk for potential exposure:

mechanics working on older automotive clutch and brake

systems;

plumbers working on asbestos insulated pipe;

construction and demolition personnel working on building

materials containing asbestos; and

maintenance personnel working on freproofng insulation,

pipe insulation, spray-on acoustic insulation, textured wall

plaster, ceiling plaster, and vinyl foor tile, all of which may

contain asbestos.

Once ACM has been identifed, OSHA strictly regulates the

handling, the use of personal protective equipment, the use of

monitoring devices, and hazardous area postings.

Identification

Asbestos is a naturally occurring mineral, composed of

fbrous mineral silicates. It is freproof and almost chemically

inert. These properties make it a valuable component in fre-

proofng insulation and as an inert, non-reactive ingredient in

many industrial processes.

Microscopic examination is required to determine the pres-

ence of asbestos in a material. ACM is often

found in several materials:

use of materialpipe insulation, freproofng

insulation, fbrous cement components, and

acoustical plasters;

age of materialif it was installed between

1920 and the late 1980s; and

appearance of materialpipe insulation, fre

proofng insulation that is a light tan, grey-

white or blue tinted off-white.

The only way to confrm the presence of

asbestos is in a licensed and certifed laboratory.

Always treat the suspected material as asbestos

until proven otherwise.

Health Concerns

Asbestos is most dangerous when the micro

fbers are disturbed by sawing, drilling, nailing,

cutting, bumping or tearing the asbestos-contain-

ing material. When disturbed, the fbers can travel

throughout an entire building in air ducts, under

doors, and down hallways and stairs. Asbestos

fbers continue to foat in the air for days following

a disturbance.

Inhaled microscopic fbers penetrate deeply into the lungs

where they remain lodged. The fbers will not dissolve and

cannot be expelled by normal physiological reaction. There

are no physical warning signs such as sneezing, coughing, or

itching from the inhalation of asbestos. The fbers are very

durable and will remain in the body.

It is generally agreed

that the asbestos fbers

change the basic cell

chemistry that may result

in asbestosis or cancer.

The diseases caused by

exposure may not surface

for twenty to forty years.

Asbestosis is a chronic

disease of the lungs that makes breathing progressively more

diffcult and can result in death. Mesothelioma is an incur-

able cancer found in the chest and abdominal membranes.

When working with asbestos exposure rates above the

permissible exposure limit, OSHA requires employers to

provide medical exams to establish a baseline. This data is

used to compare results from subsequent required annual ex-

ams. A doctor who specializes in occupational diseases must

give each exam. The exam includes three parts:

a work history obtained by questionnaire which examines

any background of lung disease, damage to lungs through

smoking, and/or previous work habits that may have

contributed to lung damage;

a general physical exam which concentrates on the lungs,

heart, and stomach to determine whether the employee

can work with asbestos; and

a breathing test Pulmonary Function Test (PFT) de-

termines if damage to the lungs currently exists and is the

frst indication of damage to healthy lungs.

Asbestos Removal

The EPA is encouraging states to adopt licensing regu-

lations and training programs for asbestos abatement. A

revised licensing program has been in effect in Texas since

1992. This program includes standardized training courses

on technical knowledge of asbestos, abatement practices,

and abatement monitoring. Regular retraining is required.

Special precautions should be taken when working with

asbestos:

do not disturb any material that may contain asbestos un-

less absolutely necessary;

treat any suspicious material as if it contains asbestos;

if removal of fri-

able materials is

essential, do so

before demolition

or renovation;

enclose the work

area with plastic

sheeting and duct

tape;

always wear a

National Institute

for Occupational Safety and Health (NIOSH) approved

respirator and protective clothing which includes cover-

alls, gloves, hats, boots, and a mask;

airborne asbestos fbers can be prevented by moistening the

material with a hand sprayer;

combining a low-sudsing detergent with the water improves

fber saturation and makes cleanup easier and

safer;

remove the material in complete pieces if

possible, as smaller pieces are more likely to

release asbestos fbers;

thoroughly clean the area with wet mops,

sponges, or rags after removal;

repeat the procedure; and

do not vacuum as the fbers can pass through

normal vacuum cleaning flters.

Disposal and Transportation

Disposal of asbestos products must be in accordance with EPA

regulations. The materials must be placed in plastic bags and

enclosed in sturdy, leakproof containers. The containers must be

properly labeled. The personal protective equipment and clean-

ing supplies should also be properly disposed of immediately

after use.

A custody form passes from the ACM originator to the

transporter and fnally to the person receiving the wastes at the

disposal site.

EPA transportation regulations state that there should be no

visible emissions of the asbestos wastes. EPA recommends

vehicles transporting ACM to have enclosed compartments or

canvas covers.

The landfll operator must be notifed of any load containing

asbestos wastes and must inspect the load to ensure the wastes

are in leakproof containers and properly labeled. He is also

responsible for notifying EPA of any suspected fber releases dur-

ing disposal. The landfll site must have a designated area and

trench for disposing of asbestos wastes. EPA regulations state

that there must be no visible dust emissions from the site during

disposal. Once deposited in a designated area, at least six inches

of non-asbestos material must be placed over the waste within

24 hours of disposal.

When closing an asbestos waste site, a 30 inch cover of non-

asbestos material must be placed on top of the existing six inch

cover. Erosion prevention measures, like proper grading and

vegetation, must also be added.

Review

1. What qualities make asbestos preferable to use?

A. Fireproof

B. Color

C. Almost chemically inert

D. Both A & C

2. When is asbestos especially dangerous?

A. When mixed in a solution

B. When it is airborne

C. When it is locked inside of a solid

Safety Violations Hotline

1-800-452-9595

safetyhotline@tdi.state.tx.us

The Texas Department of Insurance,

Division of Workers Compensation (TDI/DWC)

E-mail resourcecenter@tdi.state.tx.us

or call 1-800-687-7080 for more information.

Resources

The Texas Department of Insurance, Division of Workers

Compensation (TDI/DWC) Resource Center offers a workers

health and safety video tape library. Call (512) 804-4620 for

more information or visit our web site at www.tdi.state.tx.us.

Disclaimer: Information contained in this training program is

considered accurate at time of publication.

D. None of the above

3. What are the adverse health effects of asbestos?

A. Asbestosis

B. Mesothelioma

C. Other cancers

D. All of the above

4. What personal protective equipment should be worn

when working with asbestos?

A. NIOSH approved respirator and protective clothing

B. No personal protective equipment is needed

C. Surgical mask and coveralls

D. Safety glasses, hard hat, and steel toe shoes

Review Answers

ANS: 1.D; 2.B; 3.D; 4.A

You might also like

- Safety in the Chemical Laboratory and Industry: A Practical GuideFrom EverandSafety in the Chemical Laboratory and Industry: A Practical GuideNo ratings yet

- Asbestos Removal RockhamptonDocument7 pagesAsbestos Removal RockhamptonAsbestos Watch RockhamptonNo ratings yet

- Asbestos and NARF Hazards ExplainedDocument64 pagesAsbestos and NARF Hazards Explainedneeta_aaNo ratings yet

- HSE A Short Guide To Managing Asbestos in PremisisDocument12 pagesHSE A Short Guide To Managing Asbestos in PremisisCarmenRomanNo ratings yet

- SP 05 Hazard Identification Risk Assessment and Control HIRAC PDFDocument8 pagesSP 05 Hazard Identification Risk Assessment and Control HIRAC PDFDJOERI WANDHAWANo ratings yet

- Supervisor Training Root Cause InvestigationsDocument44 pagesSupervisor Training Root Cause InvestigationsSHANZAY21111111No ratings yet

- Confronting Blame The Worker Safety ProgramsDocument211 pagesConfronting Blame The Worker Safety ProgramsHelp Tubestar CrewNo ratings yet

- A Guide To ErgonomicsDocument35 pagesA Guide To Ergonomicsarun7sharma78No ratings yet

- Plant Hazard ChecklistDocument11 pagesPlant Hazard Checklistapi-13128341100% (1)

- ISO-OHSMS guideDocument10 pagesISO-OHSMS guidesanjeev kumar0% (1)

- 10 Industrial Accidents Where Poor Shift Handover Was A Contributory FactorDocument2 pages10 Industrial Accidents Where Poor Shift Handover Was A Contributory FactorsgraureNo ratings yet

- Risk BowTie AnalysisDocument21 pagesRisk BowTie AnalysischatraqnNo ratings yet

- Iso Dis 45001Document46 pagesIso Dis 45001gmg210981No ratings yet

- Incidentinvestigation RecommendationDocument24 pagesIncidentinvestigation RecommendationEmmanuel AnsahNo ratings yet

- Hazard Identification at A Major Hazard Facility: Guidance NoteDocument25 pagesHazard Identification at A Major Hazard Facility: Guidance NotetemterNo ratings yet

- Slide No 01 SF 06 Safety Awareness & PPEDocument59 pagesSlide No 01 SF 06 Safety Awareness & PPETusharShuvroNo ratings yet

- Risk Assessment Guidance Note Ver2aDocument11 pagesRisk Assessment Guidance Note Ver2aSalim MuftahNo ratings yet

- Chemical Management PlanDocument64 pagesChemical Management PlanyahyaNo ratings yet

- 001 - JobcardDocument4 pages001 - JobcardLoh Siong FattNo ratings yet

- SP-39 Employee Participation ProgramDocument4 pagesSP-39 Employee Participation ProgramJudy PerryNo ratings yet

- Hon HF Safety49Document30 pagesHon HF Safety49Nguyễn Ngọc SơnNo ratings yet

- Eye Protection Safety GuideDocument17 pagesEye Protection Safety GuideDrPradeep JoshiNo ratings yet

- Form - OHS - Have Health and Safety Representatives Been Appointed at Your WorkplaceDocument1 pageForm - OHS - Have Health and Safety Representatives Been Appointed at Your WorkplaceJason FourieNo ratings yet

- Struck by Falling Objects GuidelinesDocument26 pagesStruck by Falling Objects GuidelinesLouise Andrea OliquianoNo ratings yet

- Leadership Leadership and Commitment Leadership and CommitmentDocument11 pagesLeadership Leadership and Commitment Leadership and Commitmentwf4sr4rNo ratings yet

- Safety Shoe: Annexure-5 List of Approved PPE's & PPE MatrixDocument56 pagesSafety Shoe: Annexure-5 List of Approved PPE's & PPE MatrixBorislav VulićNo ratings yet

- HSE REMINDER-March 2012-Plant Turnaround SafetyDocument1 pageHSE REMINDER-March 2012-Plant Turnaround SafetyDarius DsouzaNo ratings yet

- Draft Report For Public Comment - Chevron Richmond Refinery FireDocument68 pagesDraft Report For Public Comment - Chevron Richmond Refinery Firekanakarao1100% (1)

- Safety Incident ProcedureDocument15 pagesSafety Incident Proceduresivaguruaks100% (1)

- Managing OSH at WorkDocument12 pagesManaging OSH at WorkShaira Sto TomasNo ratings yet

- Common Cause and Common SenseDocument14 pagesCommon Cause and Common SenseRomel RodriguezNo ratings yet

- Bosh Machine Safety 2Document9 pagesBosh Machine Safety 2Rovic VistaNo ratings yet

- Annex SL Excerpt - 2015 6th Edition - Hls and Guidance Only PDFDocument23 pagesAnnex SL Excerpt - 2015 6th Edition - Hls and Guidance Only PDFSelvaraj SimiyonNo ratings yet

- Hsg245 Investigating Accidents&IncidentsDocument89 pagesHsg245 Investigating Accidents&IncidentsVan SotNo ratings yet

- Pressure Testing Safety ProcedureDocument20 pagesPressure Testing Safety Procedurenaren_013No ratings yet

- LOPA and Human Factors 2Document26 pagesLOPA and Human Factors 2sandhyakasturiNo ratings yet

- Ehs Audit ChecklistDocument8 pagesEhs Audit ChecklistSubhadatta NayakNo ratings yet

- Hazard IdentificationDocument43 pagesHazard IdentificationMANISH BHADAURIANo ratings yet

- Mike Boudreaux Deltav Sis Brand ManagerDocument111 pagesMike Boudreaux Deltav Sis Brand ManagerbariNo ratings yet

- COSHH Sodium MetabisulfiteDocument3 pagesCOSHH Sodium MetabisulfiteAhmad OmarNo ratings yet

- Model Exposure Control Safety PlanDocument21 pagesModel Exposure Control Safety PlanRitter Vonali HernandezNo ratings yet

- OSHA Fire Safety Requirements - Protecting Life and PropertyDocument8 pagesOSHA Fire Safety Requirements - Protecting Life and PropertyhjsdgfnNo ratings yet

- 1.procedure For Envi Aspect and Impact AssessmentDocument15 pages1.procedure For Envi Aspect and Impact AssessmentDendi Pradeep ReddyNo ratings yet

- First Aid Program OSHA Compliant From GDIDocument14 pagesFirst Aid Program OSHA Compliant From GDIGrant Davis100% (2)

- WWW - Hse.gov - Uk Comah Buncefield Bstgfinalreport PDFDocument118 pagesWWW - Hse.gov - Uk Comah Buncefield Bstgfinalreport PDFhulmanNo ratings yet

- CDM 2015 Simplified - What You Need To KnowDocument118 pagesCDM 2015 Simplified - What You Need To KnowAchilleas21No ratings yet

- Risk Assessment Sheet For WorkshopDocument9 pagesRisk Assessment Sheet For Workshopsam lissenNo ratings yet

- Need for Effective HSE ManagementDocument59 pagesNeed for Effective HSE ManagementtissaanuradhaNo ratings yet

- Campbell Institute An Implementation Guide To Leading IndicatorsDocument24 pagesCampbell Institute An Implementation Guide To Leading IndicatorsjrcoachNo ratings yet

- Process Safety ElementsDocument2 pagesProcess Safety ElementsDidik SokoNo ratings yet

- Disaster Aniversaries PDFDocument40 pagesDisaster Aniversaries PDFHarold Fernando Guavita ReyesNo ratings yet

- Audit Checklist For ConcessionsDocument10 pagesAudit Checklist For ConcessionsbangladragosNo ratings yet

- Cornell University Laboratory Safety Manual & Chemical Hygiene Plan - 261ppDocument261 pagesCornell University Laboratory Safety Manual & Chemical Hygiene Plan - 261ppcher28100% (1)

- Painting: S P R A YDocument64 pagesPainting: S P R A YShabir Shuhood100% (3)

- Organ Izasyo N Standart No Document Name Kabul TarihiDocument4 pagesOrgan Izasyo N Standart No Document Name Kabul TarihitalhadikenNo ratings yet

- PSM 22.1 - Element 17 - Incident Investigation - BSCAT (v2)Document27 pagesPSM 22.1 - Element 17 - Incident Investigation - BSCAT (v2)Ahmed AdelNo ratings yet

- HIRAC Guidelines for HazardsDocument5 pagesHIRAC Guidelines for HazardspapawhiskeyNo ratings yet

- Unsafe Acts Safety TalkDocument1 pageUnsafe Acts Safety Talksafety86No ratings yet

- Unsafe Acts Safety TalkDocument1 pageUnsafe Acts Safety Talksafety86No ratings yet

- Fire Crisis - PPSXDocument17 pagesFire Crisis - PPSXsafety86No ratings yet

- 3% Fluoroprotein Foam Concentrate.: PH: 7 0.5 Viscosity at 20 c5: Minimum 7 Cs. Storage Temperature: (-5 To 49) c5Document2 pages3% Fluoroprotein Foam Concentrate.: PH: 7 0.5 Viscosity at 20 c5: Minimum 7 Cs. Storage Temperature: (-5 To 49) c5safety86No ratings yet

- 04 Flame TemperatureDocument38 pages04 Flame TemperatureGnanasambandan SwaminathanNo ratings yet

- Accident Report FormDocument1 pageAccident Report Formsafety86No ratings yet

- توابت حسابات الحريق وجداولهاDocument26 pagesتوابت حسابات الحريق وجداولهاsafety86No ratings yet

- HSE Tool Box TalkDocument47 pagesHSE Tool Box TalkAbdulKather100% (10)

- Safety MomentsDocument1 pageSafety Momentssafety86100% (1)

- Fire Fighting Course - PPSXDocument58 pagesFire Fighting Course - PPSXsafety86No ratings yet

- 3% Fluoroprotein Foam Concentrate.: PH: 7 0.5 Viscosity at 20 c5: Minimum 7 Cs. Storage Temperature: (-5 To 49) c5Document2 pages3% Fluoroprotein Foam Concentrate.: PH: 7 0.5 Viscosity at 20 c5: Minimum 7 Cs. Storage Temperature: (-5 To 49) c5safety86No ratings yet

- Fire Fighting: Shabbir ChannaDocument20 pagesFire Fighting: Shabbir Channasafety86No ratings yet

- Accident Report FormDocument1 pageAccident Report Formsafety86No ratings yet

- Accident Reporting Procedure 1Document2 pagesAccident Reporting Procedure 1safety86No ratings yet

- Safety at Work: and Here Are The Winners of The CompetitionDocument23 pagesSafety at Work: and Here Are The Winners of The Competitionsafety86No ratings yet

- 3% Fluoroprotein Foam Concentrate.: PH: 7 0.5 Viscosity at 20 c5: Minimum 7 Cs. Storage Temperature: (-5 To 49) c5Document2 pages3% Fluoroprotein Foam Concentrate.: PH: 7 0.5 Viscosity at 20 c5: Minimum 7 Cs. Storage Temperature: (-5 To 49) c5safety86No ratings yet

- Safety at Work AwardsDocument37 pagesSafety at Work Awardssafety86No ratings yet

- 27k Crane Lifting PermitDocument1 page27k Crane Lifting Permitsafety86No ratings yet

- Human Factors in Accident Investigation: David BirkbeckDocument30 pagesHuman Factors in Accident Investigation: David Birkbecksafety86No ratings yet

- Topic One: An Introduction To Health & Safety in IndustryDocument19 pagesTopic One: An Introduction To Health & Safety in IndustrysrkamNo ratings yet

- Generic PpeDocument32 pagesGeneric Ppesafety86No ratings yet

- IMS PolicyDocument2 pagesIMS Policysafety86No ratings yet

- Editable Health and Safety FormsDocument32 pagesEditable Health and Safety FormsFlavia Rodrigo Guedes100% (1)

- Bauer Hse Policy enDocument1 pageBauer Hse Policy ensafety86No ratings yet

- Foot ProtectDocument29 pagesFoot Protectjinyuan74100% (1)

- China Hydrotest FailureDocument7 pagesChina Hydrotest FailureaatkhoNo ratings yet

- Testing of Lifts: Simple Guidance For Lift Owners (INDG339) )Document2 pagesTesting of Lifts: Simple Guidance For Lift Owners (INDG339) )safety86No ratings yet

- 2fse Hierarchy of ControlDocument17 pages2fse Hierarchy of ControlredbireNo ratings yet

- Welding, Cutting and Brazing ChecklistDocument11 pagesWelding, Cutting and Brazing ChecklistokamoNo ratings yet

- Fall Protection Program Sample for Construction SitesDocument25 pagesFall Protection Program Sample for Construction Sitessafety86No ratings yet

- Asbestos Contamination in Talc-Based Cosmetics: An Invisible Cancer RiskDocument3 pagesAsbestos Contamination in Talc-Based Cosmetics: An Invisible Cancer RiskAlexia GonzalezNo ratings yet

- Asbestos Exposure Assessments For Repetitive Maintenance and Installation TasksDocument12 pagesAsbestos Exposure Assessments For Repetitive Maintenance and Installation TasksasmaNo ratings yet

- LSAT Logical ReasoningDocument36 pagesLSAT Logical Reasoningyannie11No ratings yet

- Reading With Answer 5Document6 pagesReading With Answer 5Xuân Anh PhanNo ratings yet

- Partial AutopsiesDocument5 pagesPartial AutopsiesTifano Prasali ArianNo ratings yet

- Test 18 2Document30 pagesTest 18 2Temesgen M. MandersoNo ratings yet

- Causes, Symptoms and Treatment of PneumoconiosisDocument25 pagesCauses, Symptoms and Treatment of Pneumoconiosismnajeeb807196No ratings yet

- 300 Single Best Answers For The Final FRCR Part ADocument161 pages300 Single Best Answers For The Final FRCR Part Asalah subbah100% (2)

- Marrow High Yield Pathology Slides @docinmaykingDocument21 pagesMarrow High Yield Pathology Slides @docinmaykingprasannaipad324No ratings yet

- Construction Health and Safety ManualDocument354 pagesConstruction Health and Safety ManualMahmoud Abdallah100% (6)

- Objectives: Occupational Health Nursing & SafetyDocument45 pagesObjectives: Occupational Health Nursing & SafetyBsoom .iNo ratings yet

- Reading Materials PDFDocument78 pagesReading Materials PDFNirmala P73% (26)

- Cp964 Review and Update of Prescribed Disease d1 PneumoconiosisDocument37 pagesCp964 Review and Update of Prescribed Disease d1 Pneumoconiosisoliver.b.dhillonNo ratings yet

- Asbestos - OverviewDocument4 pagesAsbestos - Overviewapi-328418463No ratings yet

- MS RESPIbfrDocument13 pagesMS RESPIbfrEmeroot RootNo ratings yet

- Living and Dying With AsbestosDocument6 pagesLiving and Dying With AsbestosYanto100% (1)

- SATBHSS Presentation Template DR Moyo 19Document109 pagesSATBHSS Presentation Template DR Moyo 19Victor Kbx Kachepa JnrNo ratings yet

- ASBESTOS RISKSDocument24 pagesASBESTOS RISKSVijayakumarVageesanNo ratings yet

- Lung MCQDocument7 pagesLung MCQArvinth Guna Segaran100% (2)

- Resprn in Humns-KDBDocument52 pagesResprn in Humns-KDBKiranNo ratings yet

- Criminality and Asbestos IndustryDocument24 pagesCriminality and Asbestos IndustryGuillermo VillamizarNo ratings yet

- Palm Kernel Reinforced Composites for Brake Pad ApplicationsDocument18 pagesPalm Kernel Reinforced Composites for Brake Pad ApplicationsSachin SukumaranNo ratings yet

- Kinesiología y Sus AlcancesDocument16 pagesKinesiología y Sus AlcancesEzequiel SosaNo ratings yet

- Interstitial Lung DiseaseDocument26 pagesInterstitial Lung DiseaseEnimia ShyNo ratings yet

- Asbestos Safety: Handling Cement SheetingDocument2 pagesAsbestos Safety: Handling Cement SheetingTFattahNo ratings yet

- 2009 Egilman Ford GM and Sane Appreciation of RiskDocument2 pages2009 Egilman Ford GM and Sane Appreciation of RiskDavid EgilmanNo ratings yet

- Dust PostersDocument5 pagesDust PostersAli MohdNo ratings yet

- Toxicology TheoryDocument44 pagesToxicology TheoryThiago CarvalhoNo ratings yet

- Asbestos, Asbestosis and Cáncer. Helsinski Critera For Diagnosis and Attribution2014 para - WebDocument155 pagesAsbestos, Asbestosis and Cáncer. Helsinski Critera For Diagnosis and Attribution2014 para - Webmarec100% (1)

- IVMS-Gross Pathology, Histopathology, Microbiology and Radiography High Yield Image PlatesDocument151 pagesIVMS-Gross Pathology, Histopathology, Microbiology and Radiography High Yield Image PlatesMarc Imhotep Cray, M.D.100% (2)