Professional Documents

Culture Documents

Aluminium Alloy Welding and Fabrication

Uploaded by

aamirapiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aluminium Alloy Welding and Fabrication

Uploaded by

aamirapiCopyright:

Available Formats

Handling of Aluminum Component During Fabrication

1

Introduction

Aluminum is highly reactive metal. It has strong affinity for

oxygen that oxidizes the surface of aluminum to form thin,

hard oxide film. This oxide film protects the metal from

corrosive atmosphere.

The surface of aluminum oxide is porous. This can retain

moisture or contaminate, which causes porosity in weld, if

proper care is not taken.

Hydrogen is highly soluble in molten Aluminum, which also

causes porosity during welding.

Aluminum melts at comparatively low temp. (660

0

C) and it

has good conductivity and coefficient of expansion. It has 6%

solidification shrinkage. All these characteristics cause

distortion.

Aluminum alloys are of two types:

a) Non Heat Treatable

b) Heat Treatable

Non Heat Treatable alloy components are not recommended to

be heat treated after welding.

Heat Treatable alloy components require to be heat treated

after welding, to achieve its properties.

Handling of Aluminum Component During Fabrication

2

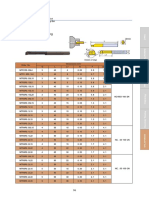

Designation system of Wrought Aluminum

Alloy

series

Principle

alloying

element

HT condition Common Filler

used for

welding

1xxx (One

thousand

series)

99.00% min Non Heat treatable 1188,1088,1068

1100

2xxx(2

thousand

series)

Copper Heat treatable

3xxx(3

thousand

series)

Manganese Non Heat treatable 1100

4xxx(4

thousand

series)

Silicon Heat treatable

5xxx(5

thousand

series)

Magnesium Non Heat treatable 5356, 5556

6xxx(6

thousand

series)

Magnesium

and silicon

Heat treatable 4043

Handling of Aluminum Component During Fabrication

3

It is important to select proper filler to get defect free weld.

Factors influencing the filler alloy selection includes following:

i) Freedom from Hot cracking

ii) Weld metal strength

iii) Weld metal ductility

iv) Corrosion resistance

v) Weld performance at elevated temp.

vi) Weld metal fluidity

vii) MIG wire feed ability

viii) Weld metal colour match with base metal after anodizing

Handling of Aluminum Component During Fabrication

4

OBJECTIVE

To process the ALUMINUM components with utmost care to

avoid any damage to the surface and quality of weld which will

deteriorate the required corrosion properties.

RESPONSIBILTY

Following good engineering practices to be followed at each stage

of operation:

Aluminum components are to be processed in isolated,

specially identified area to avoid any contamination with C.S.

components, dust and oil.

Handling of Aluminum Component During Fabrication

5

Plate handling

i) Ensure physical good and acceptable condition of the

component after receipt i.e. it should be free from Scratches,

notches, blistered surface etc.

ii) Store the plate/components separately in isolation i.e. it shall

not be stored along with any carbon steel material.

iii) The plate shall be coated with thin film of polymer to protect

the surface.

iv) Ensure that no grease, oil or any volatile material spills on

the stored material.

v) Ensure proper identification mark on the component. It shall

be engraved .(Hard Punching is not allowed)

vi) Ensure, while handling the plates/components, C.S.

slings/supporting accessories shall not come in direct contact

with the aluminum surface.

Handling of Aluminum Component During Fabrication

6

Cutting of Plates/components

i) Cutting shall be done by PLASMA cutting process

(Argon/ Nitrogen or argon/Hydrogen)

ii) There shall not be deep cut marks on the weld edges of the

components.

iii) Do not use excessive heat during cutting.

Weld edge preparation

i) Weld joint Edges shall be machined as per joint design.

ii) Min 2-4mm of edge surface shall be machined to remove

oxidized layer.

iii) Serrations on machined weld edges shall be ground by

burr wheel.

iv) Oil, grease, dust shall be cleaned by power brush.

Handling of Aluminum Component During Fabrication

7

Bending and Rolling

i) While bending and rolling, the Aluminum component shall

not come in direct contact with C.S rolls/die.

ii) Ensure, the protective material like felt, thin SS sheet shall be

provided on roll /die, while rolling or pressing the component

to avoid direct contamination.

iii) Incase of non feasibility of protection, the component shall

be passivated immediately after the rolling/bending.

iv) To avoid excessive work hardening, bending/pressing shall

be carried slowly (With gradual rise in the pressure).

Cleaning Technique

i) Weld joint /back gouged weld shall be cleaned and dried

before welding to avoid defect like porosity. This is to

remove oil/grease/ dirt.

ii) Ensure that grease/oily volatile material on the surface shall

be cleaned by solvent like CTC and then after wire brushed.

This is to avoid smearing of oil in the pores of Aluminum

weld joint.

iii) Ensure that chlorinated solvents are not used for cleaning

oil/grease.

iv) Ensure that all temporary /permanent supports, backing

should be thoroughly cleaned and wire brushed before

welding.

Handling of Aluminum Component During Fabrication

8

Preheating

i) Surrounding area of 75mm each side of the weld joint/ Back

gouged area shall be preheated to full thickness as per WPS

to remove moisture to avoid porosity (Preheating temperature

should be 75C min-120C max) and not longer than 30

minutes. (Excessive time and temp. shall affect the

properties).

ii) Check the preheat temperature by calibrated contact

thermometer /temper stick

Wire Brushing

i) Ensure Wire brushing by manual/ power brush just before

starting the welding (This removes the aluminum oxide film).

ii) Ensure that the identified SS bristles wire brushes are used

for cleaning the weld joint.

Interpass Cleaning operation

i) Ensure wire brushing/cleaning after each pass to remove the

Smut and Oxide film on weld.

Handling of Aluminum Component During Fabrication

9

Back Gouging

i) Gouging should be carried by using Rotary cutter without

lubricant. (MIG / TIG welding process calls for back gouging

of root weld.)

Weld backing

i) Weld J oint with Zero root opening is recommended when

temporary backing is provided.

ii) Temporary backing may be of Copper, aluminum with hard

anodized surface and sometimes with ceramic backing. This

is incorporated to have fast cooling of weld.

iii) In case of permanent backing, it shall be of aluminum and of

same grade as that of base material.

Fixturing

i) Ensure proper fixturing of the component to avoid distortion

during welding.

ii) Ensure that the component shall be held tightly enough for

correct alignment and yet with out enough restraint to avoid

weld crack.

iii) Ensure that fixturing is not obscure for welder, welding arc

and weld pool.

Handling of Aluminum Component During Fabrication

10

Tack welding

i) Tack weld is usually welded over to become part of the weld.

Hence it shall be welded with all precaution same as regular

joint weld.

ii) Tack weld shall be of small cross section and well penetrated.

iii) In case of stronger tack requirement, it should be longer and

closely spaced.

iv) Ensure that all tack welds are properly dresses by grinding.

And blend the ends in joint surface.

Distortion Control

i) High coefficient of expansion with localized heat

concentration during welding causes the distortion.

ii) Following recommendations are made to reduce the

distortion.

Use of optimum passes of weld.

Start the weld from neutral axes of members.

Select the welding process having

High welding speed, Possibility to weld in few passes &

Make the weld in narrowest possible groove.

Use fixture to pre-stress the component and maintain

alignment during welding and control contraction during

cooling.

Handling of Aluminum Component During Fabrication

11

Repair of Welds

i) Weld defects shall be properly analysed and its location shall

be identified.

ii) The defects shall be removed by Burr/Rotary wheel grinder.

iii) Ensure complete removal of defects and the surface shall be

made smooth.

iv) Ensure that the gouged /ground groove is shallow to have

proper access for welding.

v) Ensure complete cleaning of the joint.

vi) Use qualified WPS and welder for weld repair.

vii) Ensure all the essential parameters as per WPS are being

used during welding.

Handling of Aluminum Component During Fabrication

12

Welding Consumable Handling

i) Aluminum welding consumables are to be stored separately

in polythene bags. (There shall not be mixing with any other

consumables).

ii) Welding consumables shall be checked for its correct

identification and physical condition after opening the box.

iii) Continuous consumables such as bare wire shall be stored

separately with proper identification in a polythene bag to

avoid any contamination from dust, oil, and grease.

iv) These consumables shall be issued to the welder against the

proper requisition.

v) Cut wire shall be cleaned by passivation just before the

welding, to avoid oxidation of Al. filler. (Cleaned in hot

Caustic solution).

Handling of Aluminum Component During Fabrication

13

Welding

i) The welding of Aluminum should be carried with correct

qualified WPS Parameters.

ii) Only Qualified compatible welding consumables shall be

used for welding.

iii) Welder shall use cleaned filler during welding.

iv) Aluminum component shall be welded with optimum Heat

input. (Excessive Heat input causes reduction in strength).

v) Heat input shall be controlled by Optimum qualified Current,

Voltage and welding speed.

vi) Interpass temperature shall be kept as per qualified WPS

during welding.

vii) Cleanliness during welding is very important factor from

contamination of weld point of view i.e. Weld joint and its

vicinity shall be cleaned and free from any oil, grease and

dirt.

viii) Weld joint surface shall be free from serration.

ix) Preheating of aluminum joint shall be controlled as per WPS

and shall not be more than 30 minutes (Excessive preheating

will reduce the strength).

x) Identified Temporary supports shall be clean and to be

welded with respect to qualified WPS.

xi) Qualified welder shall be used during fabrication.

Handling of Aluminum Component During Fabrication

14

xii) Separately identified burr wheel, power wheel, wire brush

shall be used for interpass cleaning of weld.

xiii) Argon gas 99.98% pure, with qualified flow rate shall be

used during GTAW and GMAW process.

xiv) Ensure that the calibrated welding power sources are used.

xv) Double Operator Welding technique (DOT) shall be carried

out to avoid back gouging wherever possible.

Grinding

i) Weld joint, weld reinforcement shall be ground by identified

burr wheel or sander disc grinder.

ii) No hammering is allowed to remove the temporary supports.

iii) Use identified burr wheel for back gouging and defect

removal.

Radiographic Test

i) Incase of radiographic test requirement of the weld, it shall

be radiographed in accordance with ASTM E142.The quality

level of inspection shall be 2-2T.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- ASME P NumbersDocument2 pagesASME P NumbersArjun RawatNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- (EngineeringEBookspdf) Corrosion of Copper PDFDocument468 pages(EngineeringEBookspdf) Corrosion of Copper PDFFathi GabsiNo ratings yet

- Timmerhaus - Cryogenic Process EngineeringDocument24 pagesTimmerhaus - Cryogenic Process EngineeringMaria Andreina MontañezNo ratings yet

- Catalog BakerDocument152 pagesCatalog BakerArenita Wright100% (2)

- SAIC-X-3001 Rev 5Document3 pagesSAIC-X-3001 Rev 5aamirapiNo ratings yet

- Orthodontic Bracket PDFDocument38 pagesOrthodontic Bracket PDFPaola LoloNo ratings yet

- Thermo CalcDocument35 pagesThermo Calchaidv254No ratings yet

- Age Hardening Aluminium AlloyDocument31 pagesAge Hardening Aluminium AlloyMhd. Didi Endah PranataNo ratings yet

- Saic N 2033Document5 pagesSaic N 2033aamirapiNo ratings yet

- Saudi Aramco CP Accessories InspectionDocument3 pagesSaudi Aramco CP Accessories InspectionaamirapiNo ratings yet

- Saudi Aramco Inspection Checklist: Storage & Preservation of Fireclay Bricks & Mortar SAIC-N-2038 15-Dec-09 MechDocument1 pageSaudi Aramco Inspection Checklist: Storage & Preservation of Fireclay Bricks & Mortar SAIC-N-2038 15-Dec-09 MechaamirapiNo ratings yet

- Saic N 2036Document6 pagesSaic N 2036aamirapiNo ratings yet

- Bi Metallic Corrosion PDFDocument34 pagesBi Metallic Corrosion PDFDerek OngNo ratings yet

- Saic N 2037Document5 pagesSaic N 2037aamirapiNo ratings yet

- JisDocument396 pagesJiskumarawass100% (1)

- Saic N 2028Document4 pagesSaic N 2028aamirapi100% (1)

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistaamirapiNo ratings yet

- Architectural SymbolsDocument34 pagesArchitectural SymbolsNiallburke100% (2)

- Astm A890-A890m-12Document4 pagesAstm A890-A890m-12Sankar Ganesh100% (3)

- Refining Karat Gold and Silver Jewelry Using Inquarting MethodDocument9 pagesRefining Karat Gold and Silver Jewelry Using Inquarting MethodItzel HernándezNo ratings yet

- Pickling HandbookDocument32 pagesPickling HandbookPradeepNo ratings yet

- Saic N 2031Document4 pagesSaic N 2031aamirapi100% (1)

- SATIP-X-400-01 Rev 5Document3 pagesSATIP-X-400-01 Rev 5aamirapiNo ratings yet

- TCS-48 WebDocument237 pagesTCS-48 Webnidharshan100% (3)

- Astm A325-2014 PDFDocument8 pagesAstm A325-2014 PDFMuhammad Reza SeptyansyahNo ratings yet

- Carbon Dioxide Corrosion in Oil and Gas ProductionDocument25 pagesCarbon Dioxide Corrosion in Oil and Gas ProductionJosemar Costa100% (1)

- Saudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechDocument5 pagesSaudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechaamirapiNo ratings yet

- Saes N 130Document5 pagesSaes N 130aamirapiNo ratings yet

- Refractory Dry-Out Procedure For SRU Train 5 (MC-P06) Rev-ADocument107 pagesRefractory Dry-Out Procedure For SRU Train 5 (MC-P06) Rev-Aaamirapi100% (2)

- Saic N 2040Document4 pagesSaic N 2040aamirapiNo ratings yet

- Saic A 1001rev 5Document2 pagesSaic A 1001rev 5aamirapiNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechDocument5 pagesSaudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechaamirapiNo ratings yet

- Saes N 140Document10 pagesSaes N 140aamirapiNo ratings yet

- Saic N 2039Document1 pageSaic N 2039aamirapiNo ratings yet

- Saic N 2035Document9 pagesSaic N 2035aamirapiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Refractory Repair InspectionDocument4 pagesSaudi Aramco Refractory Repair InspectionaamirapiNo ratings yet

- Saudi Aramco Refractory Repair InspectionDocument4 pagesSaudi Aramco Refractory Repair InspectionaamirapiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saic N 2029Document6 pagesSaic N 2029aamirapi100% (1)

- Saic N 2030Document6 pagesSaic N 2030aamirapi100% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection Checklist: Pre-Application Inspection of Castable & Brick Refractory SAIC-N-2024 15-Dec-09 MechDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Application Inspection of Castable & Brick Refractory SAIC-N-2024 15-Dec-09 Mechaamirapi100% (1)

- LF GZTACSR 420-50 TW Data SheetDocument1 pageLF GZTACSR 420-50 TW Data SheetTú Trần TuấnNo ratings yet

- Turning TOTIME Miniature Tools PDFDocument14 pagesTurning TOTIME Miniature Tools PDFvedrenne92No ratings yet

- Metal Button Color ChartDocument9 pagesMetal Button Color Charttorsha fahadNo ratings yet

- Nace Index 2002Document7 pagesNace Index 2002Alin TomozeiNo ratings yet

- 16-GB-T 8162-1999-Seamless Steel Tubes For Structural PurposesDocument30 pages16-GB-T 8162-1999-Seamless Steel Tubes For Structural PurposesWellington AnaluisaNo ratings yet

- Safety & Reliability in Ammonia Synthesis ConvertersDocument12 pagesSafety & Reliability in Ammonia Synthesis ConvertersGaurav GuptaNo ratings yet

- Jewelry Plating TermsDocument2 pagesJewelry Plating TermsELben RescoberNo ratings yet

- Dental Base Metals and PFM AlloysDocument25 pagesDental Base Metals and PFM AlloysH. Ralph RawlsNo ratings yet

- Asme Sa 213 Grade t92 TubesDocument1 pageAsme Sa 213 Grade t92 TubesFerroPipENo ratings yet

- Carpenteria Corsi SRL BrochureDocument20 pagesCarpenteria Corsi SRL BrochureubagweNo ratings yet

- PMI and Ferrite Content Check Procedure For Manual Valve: NGL 3100 ProjectDocument10 pagesPMI and Ferrite Content Check Procedure For Manual Valve: NGL 3100 Projectmm tradingviewNo ratings yet

- Guidance on Indian Standards for Civil Engineering ProductsDocument22 pagesGuidance on Indian Standards for Civil Engineering ProductsC. M. JebinNo ratings yet

- Aircraft Construction, Repair, and Modification GuideDocument49 pagesAircraft Construction, Repair, and Modification Guide알신제인No ratings yet

- Alloy Additions To The Galvanizing Kettle and Their PurposesDocument1 pageAlloy Additions To The Galvanizing Kettle and Their Purposespbp2956No ratings yet

- Ce 241 CMT 1Document150 pagesCe 241 CMT 1Arah Louise ApostolNo ratings yet