Professional Documents

Culture Documents

Development of Cassava Grating Machine - A Dual-Operational Mode From Leonardo J

Uploaded by

ryxor-mrblOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Development of Cassava Grating Machine - A Dual-Operational Mode From Leonardo J

Uploaded by

ryxor-mrblCopyright:

Available Formats

Development of Cassava Grating Machine: A Dual-Operational Mode from Leonardo J ournal of Sciences

http://ljs.academicdirect.org/A09/103_110.htm[8/11/2014 6:25:13 PM]

Development of Cassava Grating Machine: A Dual-Operational Mode

Mohammed B. NDALIMAN

Mechanical Engineering Department, Federal University of Technology, Minna

mbndaliman@yahoo.com

Abstract

Design of a Cassava grating machine which has two modes of operation was made. It can be powered

either electrically or manually. It takes care of power failure problems, and can be used in rural

settlements where electricity supply is not in existence. Cassava is fed with the Machine through the

hopper made of metal sheet to the granting drum, which rotates at a constant speed. This process grates

the cassava into cassava pulp. The chute constructed of metal sheet accepts the pulp and send it out

because of its inclination which operated manually, the efficiency of the machine was found to be

92.4%, which the efficiency of the electrically powered machine was found to be 91.9%.

Key Words

Grating Efficiency, Hopper, Delivery Chute, Cassava Pulp

Introduction

Cassava is a major source of carbohydrates in human diet, being processed into Garri, fatal and typical as a

constituent for human food. Recently other areas of uses of cassava are being implored. It is also being used as starch.

The crop tolerance makes it more popular and now replacing yam in some part of Nigeria. The sweet varieties could be

boiled for human consumption.

The tubers of cassava cannot be stored longer after harvest before decaying, and so processing follows

immediately after harvesting. Cassava processing leading t size reduction includes peeling, grating dehydrating,

milling and sieving. A typical cassava processing plant should therefore consist of units produced to achieve all the

stages or steps mentioned above. The aim of this paper is therefore to present the result of efforts made in producing a

device that is used in granting. The transformation of cassava tubers into pulp form is called grating.

Traditional tools used in Garri processing includes: Millstone, grinding stone, pestle and mortar. In these

methods have low productivities and low hygienic solution to these problems that led to the designing and construction

of machines that can grate the cassava of high quality in a short period of time and reduce human drudgery. Some of

the machines include: roller crushing mill, hammer mill, bar mill, grater etc, all having one problem or the other.

Development of Cassava Grating Machine: A Dual-Operational Mode from Leonardo J ournal of Sciences

http://ljs.academicdirect.org/A09/103_110.htm[8/11/2014 6:25:13 PM]

Oyesola (1981) reported that, the traditional method of grating involves placing of the local grater, which is

made of perforated metal sheet on the table where it is convenient for effective use and brushes sheet metal. The

cassava turns into pulp and drop into container that is being used to collect the grated pulp cassava.

Adejumo (1995) in his design used a wooden grater in which the cassava forced into a hopper is rubbed against

the grater which is being electrically power. Enhanced quantity of cassava can be grated using this method. However

the durability of grater is low because of its wooden nature.

Ndaliman (2006) described a pedal operated cassava grinder which is powered by human efforts applied to

pedal. The grinder pulverizes the cassava tubers into paste which can pass through a wine sieve. The effective

performance of the design was at 60%.

The current design consists basically of 3 units: the hopper unit, the grating drum and the delivery channel. All

these components are mounted on an angle iron frame. The machine assembly is powered mechanically or manually

incase of electricity failure. It can be use in rural settlements where electricity supply might not in existence. Apart

from faster rating rate, it required less him involvement. The grating drum is made of metallic pipe that carries a

perforated plate which served as the grater. This overcomes the problem faced in the wooden grating drum.

Design Analysis and Calculations

Design Considerations

The general consideration in designing this dual operational grating machine is producing a machine that can

be easily assembled or disassembled, a machine in which the hopper allows materials to pass through effectively with

minimum wastage; the grating drum is made of metal so as to increase its durability; the chute is sloppy to allow

grating pulp to slide downward and get discharge by gravity.

Hopper Design

A hopper with rectangular cross section was considered.

The Volume of which was obtained as follow:

V = L B H (m

3

) (1)

where V = Volume of the hopper, L = Hoppers length, B = Hoppers breath, and H = Hoppers height.

The mass of Hopper is given as:

M = V (kg) (2)

where = density of material.

Grating Drum Design

The grating drum is cylindrical in shape. The volume of the cylinder is given by:

V

c

= r

2

l (m

3

) (3)

where V

c

= volume of cylinder, R = radius of cylinder, and L = length of drum.

Development of Cassava Grating Machine: A Dual-Operational Mode from Leonardo J ournal of Sciences

http://ljs.academicdirect.org/A09/103_110.htm[8/11/2014 6:25:13 PM]

The force acting on the cylinder drum is given as:

F = V g (4)

where g = acceleration due to gravity.

Shaft Design

The shaft considered for satisfactory performance is to be rigid enough while transmitting load under various

operating conditions. To achieve this, a solid circular shaft was considered for analysis of combined torsional and

bending stresses.

For solid shaft having little or no axial load, the diameter is given by:

d

3

= 16/S

s

((K

b

M

b

)

2

+ (K

t

M

t

)

2

)

1/2

(5)

where M

t

= torsional moment, M

b

= bending moment, K

b

= combined shock and fatigue applied to bending moment

(1.5), K

t

= combine shock & fatigue applied to torsional moment (1.0), and S

s

= allowable stress.

For a shaft transmitting power (kW) at a rotational speed (rpm) the transmitting torque is given as:

M

t

= Power/Speed (6)

Speed Ratio

The speed ratio of the larger pulley on the machine shaft to the smaller pulley on the electric motor is givens

as:

N

1

D

1

= N

2

D

2

(7)

where N

1

= speed of electric motor, N

2

= speed of machine driving shaft, D

1

= diameter of motor pulley, and D

2

=

diameter of machine drived pulley.

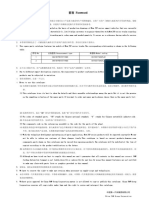

The Results of Design calculations are summarized in Table 1.

Table 1. Results of Design Calculations and Specifications

Parameter Values

Volume of Hopper

Mass of the Hopper

Shaft of diameter

Selected Shaft diameter

Speed of electric motor

Speed of Machine driven shaft

0.071232 m

555.61 kg

23.00 mm

25.00 mm

1500 rpm

1150 rpm

Construction & Performance Evaluation

Main features

The main features of the machine are: the frame and stand; the hopper, grating unit, delivery chute; the shaft

and bearings, and the power transmission unit. The assembled machine is shown in Figure 1.

Development of Cassava Grating Machine: A Dual-Operational Mode from Leonardo J ournal of Sciences

http://ljs.academicdirect.org/A09/103_110.htm[8/11/2014 6:25:13 PM]

Figure 1. A Dual - Operational Cassava Grating Machine

Table 2 gives the bill of materials used in production of one unit of the machine. The total cost of production of

one unit is estimated to be about N 23,000.00 including both manufacturing and overhead cost.

Table 2. Bill of Materials

No. Material Specification Quantity Unit price (=n=) Amount

(=n=)

1.

2.

3.

4.

5.

6.

7.

8.

9.

10

11

Metal sheet

Round plates

Angle Iron

Shaft

Round pipe

Bearing

Housing

Pulley

Bolts and nuts

Electrode

Wood

Mild steel gauge 14

Mild steel 170mm

dia

Mild steel 50 x 50

Mild steel 25mm dia

170mm dia

6305

39mm

750mm dia

M10

Gauge 12

1

I full sheet

length

2 full

length

870nn long

480m long

2

2

1

1 dozen

1

3500

1,000

1,100

1,000

1,000

500

500

1,500

500

600

500

3500

1,000

2,000

1,000

1,000

1,000

1,000

1,500

750

500

500

TOTAL

COST

14,350

Operating principle

The machine is design in such a way as to make its operation simple. When mechanically operated, the

machine is coupled to an electric motor by a V- belt pulley on the shaft. And when manually operated, the grating

Development of Cassava Grating Machine: A Dual-Operational Mode from Leonardo J ournal of Sciences

http://ljs.academicdirect.org/A09/103_110.htm[8/11/2014 6:25:13 PM]

drum is set in revolution through the turning of the steering. Cassava is fed through the hopper and an additional plank

is used to press the cassava on grater. The pulps are collected through the chute to the basin or directly on a cemented

floor.

Performance test

Series of tests were conducted using the machine. Cassava tubers were obtained from a farm and peeled

manually, thoroughly washed and weighed using weighing balance scale. The machine was operated for some minutes

to allow speed to stabilize. Peeled cassava was introduced into it through the hopper. A piece of wood was used to

press the cassava against the drum to prevent scattering of the cassava caused by machine vibration. The pulp was

collected into a sac and taking to a press for dewatering. The dewatered pulp was weighed and recorded using the

weighing balance scale. The pulp was then sieved. The weight of sieved and unsieved materials was recorded.

The grating efficiency is given as:

g

= W

r

/ W

f

100 (8)

where

g

= Grating efficiency, W

r

= Total weight recovered, and W

f

= Total weight fed in.

This was obtained for each of the manually operated and electrically powered operations.

Discussions

The fabricated grating machine can be operated both manually as well as by electric power. It is therefore

versatile and simple. The total cost of production of a unit is estimated to be about =N=23,000.00 including both

manufacturing and overhead costs. This is affordable for an average entrepreneur.

The performance tests conducted indicated that high values of grating efficiencies are attainable when powered

electrically and manually operated.

Both tests were conducted with 2.0kg of cassava. When manually operated, the grating efficiency was found to

be 92.4%. That of electrically operated machine gave the efficiency of 91.95%. These levels of performances are

satisfactory. They are even higher than that of pedal operated type (Ndaliman, 2006).

Conclusions and Recommendations

The constructed grating machine has been found to be effective and efficient. It can be powered both

electrically and manually. Therefore, it can be used by both rural as well as urban dwellers. It is also affordable since

the cost of production is low.

Efforts should be made to adopt and popularize this design, especially for the benefits of rural people who

make up a greater percentage of the nations population. It is also hoped that when mass-produced, the unit cost would

even be lower than it is now.

Acknowledgement

Development of Cassava Grating Machine: A Dual-Operational Mode from Leonardo J ournal of Sciences

http://ljs.academicdirect.org/A09/103_110.htm[8/11/2014 6:25:13 PM]

The Author expresses his gratitude to Mr. R. A. Adamu for fabricating and assisting in testing the machine.

References

[1] Adejumo S. O., Construction and Evaluation of an Engine Operated Bur, 1994.

[2] Mill Project Report Submitted to the Department of Agricultural Engineering, Federal College of Agriculture,

Ibadan, pp.1-5.

[3] Hicks T. G., Standard Handbook of Engineering Calculations, 3

rd

editions, 1995.

[4] Ndaliman M. B., Design and Construction of a Pedal Operated Cassava Grinder, Unpublished Manuscript, 2006.

[5] Oyesola G. O., Technology Processing Cassava and Utilization, Advisory Leaflet No. 3 Cassava and Garri Storage,

NCAM, Kwara State, Nigeria, 1981.

Nomenclatures and Symbols

B = Hoppers breath

D

1

= Diameter of motor pulley

D

2

= Diameter of machine drived pulley

H = Hoppers height

K

b

= Combined shock and fatigue applied to bending moment (1.5)

K

t

= Combine shock & fatigue applied to torsional moment (1.0)

L = Hoppers length.

L = Length of drum

M = Mass of the hopper

M

b

= Bending moment

M

t

= Torsional moment

N

1

= Speed of electric motor

N

2

= Speed of machine driving shaft

R = Radius of cylinder

S

s

= Allowable stress

V = Volume of the hopper

V

c

= Volume of cylinder

W

f

= Total weight fed in

W

r

= Total weight recovered

g

= Grating efficiency

= Density of material

You might also like

- 635C PeçasDocument566 pages635C PeçasGabriely MuriloNo ratings yet

- Packard-Merlin Engine - Rcaf 01Document40 pagesPackard-Merlin Engine - Rcaf 01Armando Hernández100% (1)

- HYUNDAI A4AF3, A4BF3 (Accent 2000-2007, Matrix 2003 ) 4 SPEED FWD With Lock Up (Electronic Control)Document4 pagesHYUNDAI A4AF3, A4BF3 (Accent 2000-2007, Matrix 2003 ) 4 SPEED FWD With Lock Up (Electronic Control)ArturoNo ratings yet

- 730a MotoconformadoraDocument262 pages730a MotoconformadoraAhmer Camdzic88% (32)

- 5 - Machine Tool SpindleDocument23 pages5 - Machine Tool SpindleOkan ÖzelNo ratings yet

- Eaton Ultrashift DM Heavy Duty Clutch Installation Guide Installation Instructions enDocument2 pagesEaton Ultrashift DM Heavy Duty Clutch Installation Guide Installation Instructions enSatooAtheiNo ratings yet

- Car Dolly Illustrsated Parts DiagramDocument36 pagesCar Dolly Illustrsated Parts DiagramMike Wienhold100% (4)

- Computer Aided Design of Jaw CrusherDocument50 pagesComputer Aided Design of Jaw Crusherdinesh_ypkNo ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Volvo VN, VHDDocument104 pagesVolvo VN, VHDRegistr Registr63% (8)

- 18 24 CA4181P2K15T1YA80 Q141D317U4G7LA2、Q141D317U4G7LA4 D9860P 肯尼亚、坦桑尼亚(右舵) 2020.12.5 更新Document571 pages18 24 CA4181P2K15T1YA80 Q141D317U4G7LA2、Q141D317U4G7LA4 D9860P 肯尼亚、坦桑尼亚(右舵) 2020.12.5 更新ah1choy100% (1)

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Hydraulic PressDocument11 pagesHydraulic PressAlagu EswaranNo ratings yet

- Guidelines To Fi Tting Bodies Trucknology Generation A (TGA) : Edition 2011Document167 pagesGuidelines To Fi Tting Bodies Trucknology Generation A (TGA) : Edition 2011ddanielwork206090% (21)

- Chiller Plant DesignDocument48 pagesChiller Plant Designryxor-mrbl100% (1)

- Twin Shaft ShredderDocument88 pagesTwin Shaft ShredderZach Loves Sana0% (1)

- Name: Aarsh Trivedi Roll No: 16BME176D Sub: MD 2 Case Study Topic: Worm GearDocument40 pagesName: Aarsh Trivedi Roll No: 16BME176D Sub: MD 2 Case Study Topic: Worm GearVirajNo ratings yet

- Design and Fabrication of An Improved Cassava GraterDocument10 pagesDesign and Fabrication of An Improved Cassava GraterAjay Bhalerao100% (1)

- Dana T2000 6 Speeds Long Drop Service ManualDocument209 pagesDana T2000 6 Speeds Long Drop Service Manualjccla100% (7)

- 7.0 HydraulicDocument174 pages7.0 HydraulicSergeyNo ratings yet

- Icse (KMW) PDFDocument5 pagesIcse (KMW) PDFtarrteaNo ratings yet

- Wa900 3LCDocument112 pagesWa900 3LCAlexis AguilarNo ratings yet

- EASA OEB Bell - 429 00 05072012Document21 pagesEASA OEB Bell - 429 00 05072012Haerul ImamNo ratings yet

- Cement Mill NotebookDocument32 pagesCement Mill NotebookNael92% (50)

- Roller Press FL Smidth PDFDocument27 pagesRoller Press FL Smidth PDFThaigroup Cement100% (10)

- Book - Nonlinear Estimation and Control of Automotive Drivetrains - Compressed-1Document65 pagesBook - Nonlinear Estimation and Control of Automotive Drivetrains - Compressed-1Γιάννης ΝικόλαNo ratings yet

- Development of Cassava Grating Machine: A Dual-Operational ModeDocument8 pagesDevelopment of Cassava Grating Machine: A Dual-Operational ModedharmikdobariyaNo ratings yet

- Development of Cassava Grating Machine: A Dual-Operational ModeDocument9 pagesDevelopment of Cassava Grating Machine: A Dual-Operational ModeddNo ratings yet

- Performance Analysis of Coconut De-Shelling MachineDocument8 pagesPerformance Analysis of Coconut De-Shelling Machineayesh bandaraNo ratings yet

- Motorized Pipe Bending MachineDocument8 pagesMotorized Pipe Bending Machineanon_201618867No ratings yet

- Can Crusher MechanismDocument4 pagesCan Crusher MechanismaqmbaldiwalaNo ratings yet

- Improving Engine Crane DesignDocument9 pagesImproving Engine Crane DesignKhalil AliNo ratings yet

- 908design of High Efficiency Cross-Flow TurbineDocument4 pages908design of High Efficiency Cross-Flow TurbineAdi Setiadi100% (1)

- Design Consideration of Corn Sheller MachineDocument6 pagesDesign Consideration of Corn Sheller MachineIJIRST100% (2)

- Development and Evaluation of A Motorized Peanut Shelling MachineDocument6 pagesDevelopment and Evaluation of A Motorized Peanut Shelling Machineumi fazaNo ratings yet

- An Example Design of The Crossflow TurbineDocument58 pagesAn Example Design of The Crossflow TurbineBryan NanaNo ratings yet

- Design of Cantilever Gear-Rack Driving System On Jack-UpDocument6 pagesDesign of Cantilever Gear-Rack Driving System On Jack-UpengineeringyusufNo ratings yet

- Oluyori ProjectDocument19 pagesOluyori Projectsodiqnajimu8No ratings yet

- Design Analysis of A Reciprocating Cassava Sieving MachineDocument9 pagesDesign Analysis of A Reciprocating Cassava Sieving MachineIOSRjournalNo ratings yet

- Analysis of Shaft AssemblyDocument8 pagesAnalysis of Shaft Assemblyvarshasdm1987No ratings yet

- A Novel Design of Composite Water Turbine Using CFDDocument6 pagesA Novel Design of Composite Water Turbine Using CFDNung NingNo ratings yet

- Bending MachineDocument4 pagesBending MachineRahul RathodNo ratings yet

- Technical Study On The Design and Construction of A Pedal Powered Hacksaw Cutting MachineDocument5 pagesTechnical Study On The Design and Construction of A Pedal Powered Hacksaw Cutting MachineIOSRjournalNo ratings yet

- Machine Design, Vol.3 (2011) No.2, ISSN 1821-1259 Pp. 115-120Document6 pagesMachine Design, Vol.3 (2011) No.2, ISSN 1821-1259 Pp. 115-120Edwin AlexisNo ratings yet

- Design and Fabrication of Two Way Padel Operated Hacksaw MachineDocument3 pagesDesign and Fabrication of Two Way Padel Operated Hacksaw MachineJayavarapuruchitha JayavarapuruchithaNo ratings yet

- Performance of Single Screw Archimedes Turbine Using TransmissionDocument9 pagesPerformance of Single Screw Archimedes Turbine Using TransmissionAthoriq Dias MuyasarNo ratings yet

- Dr. Akant Singh: Under The Guidance ofDocument20 pagesDr. Akant Singh: Under The Guidance ofnitendra kumarNo ratings yet

- Garg, Aamod. 'Gantry Girders in India' - IJCMES PDFDocument5 pagesGarg, Aamod. 'Gantry Girders in India' - IJCMES PDFAamod GargNo ratings yet

- Design and Construction of A Manual Food GrinderDocument10 pagesDesign and Construction of A Manual Food GrinderAlvin S Soriano Jr.No ratings yet

- Innovative Design of Crossflow Hydro Turbine SystemDocument11 pagesInnovative Design of Crossflow Hydro Turbine SystemrD. NgomaNo ratings yet

- Design and Dynamic Analysis of Flywheel: T. Raja Santhosh Kumar Suresh Babu Koppula Cr. Prakash D.V.SrikanthDocument6 pagesDesign and Dynamic Analysis of Flywheel: T. Raja Santhosh Kumar Suresh Babu Koppula Cr. Prakash D.V.SrikanthSello PhailaNo ratings yet

- PT ReportDocument12 pagesPT ReportmrkalimNo ratings yet

- PT Lab REPORT 2019ch35Document14 pagesPT Lab REPORT 2019ch35mrkalimNo ratings yet

- JournalnxDocument4 pagesJournalnxJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Case Study and Stress Analysis of A 3Document12 pagesCase Study and Stress Analysis of A 3Talha MemonNo ratings yet

- Design of Multi-Axis Welding Positioner WithDocument7 pagesDesign of Multi-Axis Welding Positioner Withsuraj dhulannavarNo ratings yet

- Samuthra Projects PDFDocument9 pagesSamuthra Projects PDFsageetha756No ratings yet

- Duel Side Sapher PDFDocument9 pagesDuel Side Sapher PDFsageetha756No ratings yet

- Kaptronics Private Limited PDFDocument9 pagesKaptronics Private Limited PDFkaptronicsNo ratings yet

- Power Generation System Through Foot Steps1Document24 pagesPower Generation System Through Foot Steps1Dasari Anuroop ReddyNo ratings yet

- Investigation of The Performance of A Cross-Flow Turbine: Int. J. Energy Res., 22, 953 - 964 (1998)Document12 pagesInvestigation of The Performance of A Cross-Flow Turbine: Int. J. Energy Res., 22, 953 - 964 (1998)DavidNo ratings yet

- D P A T M N F: P. Radziszewski, Y. Y. Quan, J. PoirierDocument6 pagesD P A T M N F: P. Radziszewski, Y. Y. Quan, J. PoirierJEANCARLOCGNo ratings yet

- G0506 01-5259 PDFDocument8 pagesG0506 01-5259 PDFTina TilatilaNo ratings yet

- Design and Construction of A Motorized TricycleDocument3 pagesDesign and Construction of A Motorized TricycleAlok Nath SharmaNo ratings yet

- Cam and FollowerDocument12 pagesCam and FollowerAjay HadaNo ratings yet

- Pedal Powered Hacksaw 1Document12 pagesPedal Powered Hacksaw 1Jefry RithikNo ratings yet

- Analysis and Optimization of Hydraulic Scissor Lift: S. D. Wankhede, S. S. Joshi, L. J. Bagwan, A.V WadmareDocument8 pagesAnalysis and Optimization of Hydraulic Scissor Lift: S. D. Wankhede, S. S. Joshi, L. J. Bagwan, A.V WadmareVedprakashNo ratings yet

- Design Aspects and Parametric Study of 3-Roll Heavy-Duty Plate-Bending MachinesDocument14 pagesDesign Aspects and Parametric Study of 3-Roll Heavy-Duty Plate-Bending Machinesjuan carlos molano toroNo ratings yet

- Performance Evaluation of A Developed Maize Sheller: Journal of Advancement in Engineering and TechnologyDocument4 pagesPerformance Evaluation of A Developed Maize Sheller: Journal of Advancement in Engineering and TechnologyKhairil HidayahNo ratings yet

- Continuous Jaw Crushers: A New Design Concept For A Double-Toggle SystemDocument2 pagesContinuous Jaw Crushers: A New Design Concept For A Double-Toggle SystemJakesNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Water Chiller ComponentsDocument5 pagesWater Chiller Componentsryxor-mrblNo ratings yet

- Bcin Document DisplayDocument1 pageBcin Document Displayryxor-mrblNo ratings yet

- Psychrometric Chart - 300M Above Sea LevelDocument1 pagePsychrometric Chart - 300M Above Sea Levelryxor-mrblNo ratings yet

- Micro Hydro DesigningDocument28 pagesMicro Hydro Designingryxor-mrblNo ratings yet

- Boiler Selection PDFDocument25 pagesBoiler Selection PDFShafqat AfridiNo ratings yet

- Boiler Selection PDFDocument25 pagesBoiler Selection PDFShafqat AfridiNo ratings yet

- Two-Speed Powershift Transmission Hyster T-40 TroubleshootingDocument47 pagesTwo-Speed Powershift Transmission Hyster T-40 TroubleshootingArmando OrtaNo ratings yet

- Design, Analysis and Fabrication of Hubless BicycleDocument10 pagesDesign, Analysis and Fabrication of Hubless BicycleIJRASETPublicationsNo ratings yet

- 01 IntroductionDocument53 pages01 IntroductionMr. MuditNo ratings yet

- ClutchesDocument46 pagesClutchesgalataataaddesaaNo ratings yet

- Pct-00007-Bolero RHD Mdi TC 3200 2wd - Ver 1 - Feb 2005Document111 pagesPct-00007-Bolero RHD Mdi TC 3200 2wd - Ver 1 - Feb 2005Aamir AshinNo ratings yet

- 205-01 Drive Shaft PICKUP JMCDocument14 pages205-01 Drive Shaft PICKUP JMCRusonegroNo ratings yet

- LT-F250L3: Parts CatalogueDocument76 pagesLT-F250L3: Parts Cataloguesdk00No ratings yet

- Inventory ManagementDocument51 pagesInventory Managementghghgh8794No ratings yet

- A005 AtosDocument4 pagesA005 AtosramabhplNo ratings yet

- Hyundai Elantra Clutch ReplacementDocument6 pagesHyundai Elantra Clutch ReplacementEngine Tuning UPNo ratings yet

- ICE Lab ManualDocument68 pagesICE Lab ManualAkhilNagNo ratings yet

- MD SeriesDocument91 pagesMD Seriesebraheem ElbrinsNo ratings yet

- GKR GKS GSS Gearboxes With MD MH AC Motors - v1-0 - ENDocument460 pagesGKR GKS GSS Gearboxes With MD MH AC Motors - v1-0 - ENIndahNo ratings yet

- Design Work 9 - Shaft Design Under Combined LoadingsDocument22 pagesDesign Work 9 - Shaft Design Under Combined LoadingsEngr Ghulam MustafaNo ratings yet

- Instruction Manual: TCR - MC TypeDocument20 pagesInstruction Manual: TCR - MC TypeKhaled RabeaNo ratings yet

- Model Answer: Important Instructions To ExaminersDocument17 pagesModel Answer: Important Instructions To ExaminersPrathamesh GothankarNo ratings yet