Professional Documents

Culture Documents

Chapter 4-Diseño Por Cortante

Uploaded by

Daniel LopeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 4-Diseño Por Cortante

Uploaded by

Daniel LopeCopyright:

Available Formats

CHAPTER 4: SHEAR IN BEAMS

5.1 Introduction

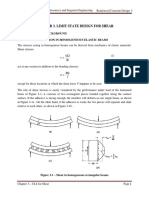

Loads applied to beams produce bending moments, shearing forces, as shown in Figure

5.1, and in some cases torques. Design for bending has been elaborately discussed in

chapter 4 and torsion will be discussed in chapter 6. In this chapter, design of beams for

shear will be dealt with.

Figure 5.1: Shear in beams: (a) loaded beam; (b) internal forces at section A-A

Beams are usually designed for bending moment first; thus cross sectional dimensions

are evaluated along with the required amounts of longitudinal reinforcement. Once this

is done, sections should be checked for shear to determine whether shear reinforcement

is required or not. This by no means indicates that shear is less significant than bending.

On the contrary, shear failure which is usually initiated by diagonal tension is far more

dangerous than flexural failure due to its brittle nature.

5.2 Shear in Homogeneous, Elastic Beams

For good understanding of the subject, consider a simply supported beam subjected to a

uniformly distributed load as shown in Figure 5.2.a. Furthermore, it is assumed that the

beam is made of elastic, homogeneous material.

Figure 5.2.a : Loaded beam and orientation of cracks

The normal stresses

x

f resulting from bending are given by the following equation as

proved by the classical bending theory;

x

x

x

M y

f

I

(4.1)

where

x

M is the bending moment at the section under consideration, y is the distance

from the point under consideration to the neutral axis, and

x

I is the moment of inertia

about the neutral axis.

The shearing stresses

x

are given by the following equation proved in the most

classical mechanics of materials books:

x x

x

x

V Q

I b

(4.2)

where

x

V is the shearing force at the considered section,

x

Q is the moment of the area of

the section located between the point where the shearing stresses are calculated and the

extreme fiber of the section about the neutral axis,

x

I is the moment of inertia about the

neutral axis, and b is the width of the section at the point where shearing stresses are

calculated.

In an attempt to establish the cracking pattern, four elements situated at different

distances from the neutral axis are studied.

Element (1):

It is subjected only to normal, tensile stresses resulting from bending, as shown in

Figure 5.2.b. The principal tensile stress is in the same direction as the normal tensile

stress. Thus cracking takes place on a vertical plane due to the weakness of concrete in

tension.

Figure 5.2.b: Principal stresses on elements 1,2,3 and 4

Element (2):

Element (2) that is located below the neutral axis is subjected to normal tensile stresses

in addition to shearing stresses. The cracking surface makes an angle larger than 45

degrees with the horizontal axis. Cracking takes place on a plane perpendicular to the

plane on which principal tensile stresses occur. See Figure 5.2.b for the orientation of

principal tension stresses along a diagonal crack.

Element (3):

Element (3) that is located at the neutral axis is only subjected to pure shearing stresses.

The cracking surface makes an angle of 45 degrees with the horizontal axis. Thus

cracking takes place on a plane perpendicular to the principal tensile stress, as shown in

Figure.5.2.b.

Element (4):

Element (4) that is located above the neutral axis is subjected to normal compressive

stresses in addition to shearing stresses. The cracking surface makes an angle smaller

than 45 degrees with the horizontal axis. Cracking takes place on a plane perpendicular

to the plane on which principal tensile stresses occur. See Figure 5.2.b for the

orientation of principal tension stresses along a diagonal crack.

It is concluded that the shearing force acting on a vertical section in a reinforced

concrete beam does not cause direct rupture of that section. Shear by itself or in

combination with flexure may cause failure indirectly by producing tensile stresses on

inclined planes. If these stresses exceed the relatively low tensile strength of concrete,

diagonal cracks develop. If these cracks are not checked, splitting of the beam or what is

known as diagonal tension failure will take place.

5.3 Types of Shear Cracks

Two types of inclined cracking occur in beams: flexure-shear cracking and web-shear

cracking, shown in Figure 5.3.

A. Flexure-Shear Cracks

The most common type, develops from the tip of a flexural crack at the tension side of

the beam and propagates towards mid depth until it is checked on the compression side

of the beam. For these cracks to form, the bending moment must exceed the cracking

moment of the cross section and a significant shear must exist.

Figure 5.3: Types of cracks and associated internal forces: (a) orientation

of cracks; (b) shear force diagram; (c) bending moment diagram

B. Web Shear Cracks

Web shear cracking begins from an interior point in a member at the level of the

centroid of uncracked section and moves on a diagonal path to the tension face when the

diagonal tensile stresses produced by shear exceed the tensile strength of concrete. This

type of cracking is common on beams with thin webs and in regions of high shear and

small moment. This combination exists adjacent to simple supports or at points of

inflection in continuous beams.

5.4 Nominal Shear Stress

The only equation available to relate shear stress to shearing force is derived for a beam

of constant cross section constructed of a homogeneous elastic material. Unfortunately,

Eq. (5.2) can not be applied to reinforced concrete beams for the following reasons:

Reinforced concrete is non-homogeneous material.

Concrete is not elastic.

Variable extent of cracking along the length of a beam, making it impossible to

determine cross-sectional properties.

Therefore, the ACI Code has adopted a simple procedure for establishing the magnitude

of shear stress v on a cross section

You might also like

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- ECIV 3316 - Chapter 05 - Shear in Beams + ExampleDocument30 pagesECIV 3316 - Chapter 05 - Shear in Beams + Examplebuffyto5377No ratings yet

- Strength of Materials: An Introduction to the Analysis of Stress and StrainFrom EverandStrength of Materials: An Introduction to the Analysis of Stress and StrainRating: 5 out of 5 stars5/5 (1)

- Chp5 Shear in BeamsDocument20 pagesChp5 Shear in BeamsRocio LiscanoNo ratings yet

- Chapter 5: Shear in Beams: Figure 5.1: Shear in Beams: (A) Loaded Beam (B) Internal Forces at Section A-ADocument20 pagesChapter 5: Shear in Beams: Figure 5.1: Shear in Beams: (A) Loaded Beam (B) Internal Forces at Section A-Aravi1214No ratings yet

- Chapter 5: Shear in Beams: Figure 5.1: Shear in Beams: (A) Loaded Beam (B) Internal Forces at Section A-ADocument20 pagesChapter 5: Shear in Beams: Figure 5.1: Shear in Beams: (A) Loaded Beam (B) Internal Forces at Section A-AIraya DavidNo ratings yet

- Shear and Diagonal Tension in BeamsDocument13 pagesShear and Diagonal Tension in Beamsdilnessa azanawNo ratings yet

- Chapter Four: Shear and Diagonal Tension in BeamsDocument12 pagesChapter Four: Shear and Diagonal Tension in BeamsMintesnot WondimuNo ratings yet

- 5-Shear Design of BeamsDocument53 pages5-Shear Design of Beamshamadamjad047No ratings yet

- 5.0 Bending PDFDocument9 pages5.0 Bending PDFLEONARD NYIRONGONo ratings yet

- rc-1 2015-16 Chapter Three 080116Document28 pagesrc-1 2015-16 Chapter Three 080116ABAMELANo ratings yet

- Design of Rc-Beams For ShearDocument36 pagesDesign of Rc-Beams For ShearAkli Ale ManNo ratings yet

- TorsionDocument17 pagesTorsionkalpanaadhi100% (1)

- Chapter 5: TorsionDocument106 pagesChapter 5: Torsionprabin gautamNo ratings yet

- Chapter 5Document49 pagesChapter 5ISRAEL HAILUNo ratings yet

- Chapter - 5 Torsion in Reinforced Concrete MembersDocument8 pagesChapter - 5 Torsion in Reinforced Concrete MembersHelen NegashNo ratings yet

- Beton Prategang: Members Analysis Under ShearDocument45 pagesBeton Prategang: Members Analysis Under Shearzacoeb_a1669No ratings yet

- Shear Stresses in BeamsDocument37 pagesShear Stresses in BeamsrpsirNo ratings yet

- Shear LagDocument17 pagesShear LagSukhwinder Singh GillNo ratings yet

- RC II Chapter 5Document18 pagesRC II Chapter 5Wendimu TolessaNo ratings yet

- CIV6235 - Shear (MG)Document26 pagesCIV6235 - Shear (MG)friendycalls100% (1)

- LA Clark App BDocument5 pagesLA Clark App Bmatie12345No ratings yet

- TorsionDocument69 pagesTorsionpengniumNo ratings yet

- Compression Members in Rigid FramesDocument74 pagesCompression Members in Rigid Framesjuan jr lucenaNo ratings yet

- Reinforced Concrete Beam Shear DesignDocument46 pagesReinforced Concrete Beam Shear DesignashenafiNo ratings yet

- Strength of Materials - Part 2: Horizontal Shear StressDocument10 pagesStrength of Materials - Part 2: Horizontal Shear StressAnay KarambelkarNo ratings yet

- DCC20053 - Topic 5 Shear Stress in Beam and Connection 2019Document6 pagesDCC20053 - Topic 5 Shear Stress in Beam and Connection 2019nur hidayah08No ratings yet

- RCC Lecture Series 4 2018-19Document33 pagesRCC Lecture Series 4 2018-19Mansa ArthurNo ratings yet

- Behaviour of Box Girder BridgesDocument14 pagesBehaviour of Box Girder BridgesSachin MoreNo ratings yet

- 2lec3&4 With Assignment 2 Reinf Conc 412Document42 pages2lec3&4 With Assignment 2 Reinf Conc 412Emmanuel MwabaNo ratings yet

- Reinforced Concrete Shear Design PrinciplesDocument27 pagesReinforced Concrete Shear Design PrinciplesFekadu DebelaNo ratings yet

- Chapter 3( Torsion)Document12 pagesChapter 3( Torsion)znabu asefaNo ratings yet

- CHAPTER V Engineering Mechanics-I 2015Document16 pagesCHAPTER V Engineering Mechanics-I 2015nvnrevNo ratings yet

- Chapter Six, Deep Beams and CorbelsDocument8 pagesChapter Six, Deep Beams and CorbelsHaftom Gebreegziabiher50% (2)

- Steel Column Buckling Axial and Transverse LoadingDocument31 pagesSteel Column Buckling Axial and Transverse LoadingTor GrimlundNo ratings yet

- Chapter 5 Shear, Bond and TorsionDocument82 pagesChapter 5 Shear, Bond and TorsiondavidNo ratings yet

- Chapter 3Document18 pagesChapter 3gossayeNo ratings yet

- Bending Stresses in BeamsDocument30 pagesBending Stresses in BeamsdvarsastryNo ratings yet

- Tension Members - Notes Mohit JaiswalDocument5 pagesTension Members - Notes Mohit JaiswalPiyush GuptaNo ratings yet

- Chapter IV Shear and Moment in Beams 4.1 4.2 4.3Document8 pagesChapter IV Shear and Moment in Beams 4.1 4.2 4.3Joshua John Julio100% (1)

- Verification of Bending Stress and Shear Stress Distribution Across The Depth For Slender BeamDocument7 pagesVerification of Bending Stress and Shear Stress Distribution Across The Depth For Slender BeamAditiDeshpandeNo ratings yet

- Chapter Five, Torsion of BeamsDocument7 pagesChapter Five, Torsion of BeamsTemesgenAbiyNo ratings yet

- 1) Cross-Section Particularities: Teorie Steel 2 - Partea Lui StefanescuDocument19 pages1) Cross-Section Particularities: Teorie Steel 2 - Partea Lui StefanescuIsmail ErvinNo ratings yet

- Hwang Et All - Analytical Model For Predicting Shear Strengths of Interior Reinforced Concrete Beam-Column Joints For SeismicDocument14 pagesHwang Et All - Analytical Model For Predicting Shear Strengths of Interior Reinforced Concrete Beam-Column Joints For Seismicbllld100% (1)

- Design of Reinforced Concrete Struture Lec 02Document238 pagesDesign of Reinforced Concrete Struture Lec 02husseinqahtan09No ratings yet

- 5.transverse ShearDocument15 pages5.transverse ShearEden HazardNo ratings yet

- Torsion in Closed SectionsDocument11 pagesTorsion in Closed SectionsJason GarnerNo ratings yet

- Design of Compression Members as per IS 800:2007Document119 pagesDesign of Compression Members as per IS 800:2007umeshapkNo ratings yet

- Verification of bending and shear stresses in a slender beamDocument6 pagesVerification of bending and shear stresses in a slender beamAditiDeshpandeNo ratings yet

- MOS ReportDocument9 pagesMOS Reportthorkhan42No ratings yet

- 8/1/13 Beam Part 2Document50 pages8/1/13 Beam Part 2Macqui MaciasNo ratings yet

- ACI TorsionDocument8 pagesACI TorsionNeil Duldulao100% (1)

- Design For shear-LSDDocument11 pagesDesign For shear-LSDAmanuelNo ratings yet

- Chapter 2 STR 4 Torsion in BeamsDocument17 pagesChapter 2 STR 4 Torsion in BeamsAbera MamoNo ratings yet

- Lecturenote - 1714126640chapter Six, Deep Beams and CorbelsDocument8 pagesLecturenote - 1714126640chapter Six, Deep Beams and CorbelsTmiky GateNo ratings yet

- Chap5 1Document53 pagesChap5 1Fernando LopezNo ratings yet

- Behavior of Reinforced Concrete ElementsDocument9 pagesBehavior of Reinforced Concrete ElementsAwab AfifiNo ratings yet

- Stresses in Beams LectureDocument44 pagesStresses in Beams LectureKit Meng LimNo ratings yet

- Hitachi Flexi Split AcDocument4 pagesHitachi Flexi Split AcVishal BansalNo ratings yet

- Large Commercial Split System RAUP-TTV Product CatalogDocument44 pagesLarge Commercial Split System RAUP-TTV Product CataloghungstampNo ratings yet

- Condensate SystemDocument35 pagesCondensate SystemSam100% (6)

- Bollard Catalog - SPDocument28 pagesBollard Catalog - SPrisiana_limuriaNo ratings yet

- Gi Duct Works WMSDocument8 pagesGi Duct Works WMSpuwe qiheNo ratings yet

- Manufacturers and Suppliers List for Construction ProjectDocument22 pagesManufacturers and Suppliers List for Construction ProjectThanuja WijesingheNo ratings yet

- Butterfly ValveDocument30 pagesButterfly ValvesaifulNo ratings yet

- Typical Properties of Copper & AluminiumDocument5 pagesTypical Properties of Copper & AluminiumamoghnawatheNo ratings yet

- Understanding Elevated Copper Levels in Used Oil SamplesDocument3 pagesUnderstanding Elevated Copper Levels in Used Oil SamplesYuszra SabillaNo ratings yet

- Introduction of IS2062 E250 Grade ADocument2 pagesIntroduction of IS2062 E250 Grade AnareshNo ratings yet

- Copeland KapacitetsregleringDocument27 pagesCopeland KapacitetsregleringEmmanuel MunozNo ratings yet

- Is 15499Document19 pagesIs 15499ajith chandranNo ratings yet

- Baine Hospital Details Scope of Work 25082017Document3 pagesBaine Hospital Details Scope of Work 25082017kumarjit kolayNo ratings yet

- CPVC Fire Sprinkler Products: Installation Instructions & Technical HandbookDocument106 pagesCPVC Fire Sprinkler Products: Installation Instructions & Technical HandbookMark FessendenNo ratings yet

- Aluminum 6061Document3 pagesAluminum 6061Achmad Rizal MustaqimNo ratings yet

- 1.0 Specification of Equipment / Material and Installation Standards 1.1 Specifications For Water Cooled Centrifugal Chiller Performance ParametersDocument8 pages1.0 Specification of Equipment / Material and Installation Standards 1.1 Specifications For Water Cooled Centrifugal Chiller Performance Parametersعامر شیخNo ratings yet

- Bond Stress and Slip Modeling PDFDocument269 pagesBond Stress and Slip Modeling PDFraduga_fbNo ratings yet

- Beam force summaryDocument1 pageBeam force summaryMichael John MolinaNo ratings yet

- Camesa EMC CatalogDocument40 pagesCamesa EMC CatalogRoger DenegriNo ratings yet

- Artic Mist: Product Data SheetDocument1 pageArtic Mist: Product Data SheetKeith RawlinsNo ratings yet

- Construction of Toilet with Running WaterDocument26 pagesConstruction of Toilet with Running WaterJanardhanReddyNo ratings yet

- Introduction To Structural Analysis-Part 1Document30 pagesIntroduction To Structural Analysis-Part 1Hiew Ching YongNo ratings yet

- (Problem) Soft Storey Check in Etabs - Printable VersionDocument2 pages(Problem) Soft Storey Check in Etabs - Printable VersionkilmasterNo ratings yet

- FM Global Property Loss Prevention Data Sheets: Paper Machines and Pulp DryersDocument37 pagesFM Global Property Loss Prevention Data Sheets: Paper Machines and Pulp DryersDiego MarquinaNo ratings yet

- FMDS0793NDocument6 pagesFMDS0793NCHANDANNo ratings yet

- Catalog Blum ADocument236 pagesCatalog Blum AcriuvosNo ratings yet

- Buildability Score - December 2015 Edition - 54Document1 pageBuildability Score - December 2015 Edition - 54Eric HartonoNo ratings yet

- Tle10 Eim10 Q1 M15Document11 pagesTle10 Eim10 Q1 M15Isabelle BanogonNo ratings yet

- Buckling On Stiffened PanelDocument47 pagesBuckling On Stiffened PanelandriaerospaceNo ratings yet

- Iso 06944-1-2008Document40 pagesIso 06944-1-2008Quốc Đạt100% (2)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- Advanced Modelling Techniques in Structural DesignFrom EverandAdvanced Modelling Techniques in Structural DesignRating: 5 out of 5 stars5/5 (3)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Marine Structural Design CalculationsFrom EverandMarine Structural Design CalculationsRating: 4.5 out of 5 stars4.5/5 (13)

- The Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityFrom EverandThe Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityRating: 4.5 out of 5 stars4.5/5 (115)

- Dark Aeon: Transhumanism and the War Against HumanityFrom EverandDark Aeon: Transhumanism and the War Against HumanityRating: 5 out of 5 stars5/5 (1)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceFrom EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceRating: 5 out of 5 stars5/5 (9)

- In the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkFrom EverandIn the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkRating: 5 out of 5 stars5/5 (1)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsFrom EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNo ratings yet

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (3)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingFrom EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNo ratings yet

- Artificial You: AI and the Future of Your MindFrom EverandArtificial You: AI and the Future of Your MindRating: 4 out of 5 stars4/5 (3)

- Offshore Pipelines: Design, Installation, and MaintenanceFrom EverandOffshore Pipelines: Design, Installation, and MaintenanceRating: 4.5 out of 5 stars4.5/5 (2)

- Design and Operation of Human Locomotion SystemsFrom EverandDesign and Operation of Human Locomotion SystemsMarco CecarelliNo ratings yet

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.From EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Rating: 4 out of 5 stars4/5 (5)

- Create Profitable Side Hustles with Artificial IntelligenceFrom EverandCreate Profitable Side Hustles with Artificial IntelligenceNo ratings yet