Professional Documents

Culture Documents

Experimental Investigations On Strength, Durability

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experimental Investigations On Strength, Durability

Copyright:

Available Formats

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

Volume: 03 Issue: 06 | Jun-2014, Available @ http://www.ijret.org 115

EXPERIMENTAL INVESTIGATIONS ON STRENGTH, DURABILITY,

SUSTAINABILITY & ECONOMIC CHARACTERISTICS OF GEO-

POLYMER CONCRETE BLOCKS

Tejas Ostwal

1

, Manojkumar V Chitawadagi

2

1

UG Student, Civil Engineering, B.V.B. College of Engineering & Technology, Hubli, Karnataka, India

2

Professor, Civil Engineering, B.V.B. College of Engineering & Technology, Hubli, Karnataka, India

Abstract

With the growth in infrastructure development and boom in the housing sector, the demand for cement is bound to increase. Due

to environmental concerns of cement industry, there arises a strong need to make use of alternate technology which is sustainable.

Geopolymer, an inorganic alumina silicate polymer is synthesized predominantly from silicon and aluminum materials or from

by- product materials like fly ash. In the present work, an attempt is made to develop geopolymer concrete blocks at ambient

curing condition and to investigate strength and durability aspects. The geopolymer blocks prepared here in without the use of

cement. The materials considered are Flyash (Class F), Ground granulated blast furnace slag (GGBS), Quarry dust and sand.

Sodium hydroxide & sodium silicate were used as alkaline activators. The experimental program involves casting of geopolymer

blocks and testing the same for compressive strength. The parameter considered in this study is alkaline solution to binder ratio at

8M molarity. The result revealed that geopolymer concrete block develops strength at ambient curing conditions. The study is

further extended to understand the economic impact and sustainability of geopolymer concrete blocks.

Keywords: Geopolymer concrete blocks, Flyash, GGBS, Embodied energy.

--------------------------------------------------------------------***----------------------------------------------------------------------

1. INTRODUCTION

In recent times the emission of carbon dioxide into the air is

being increased day by day. Considerable amount of fossil

fuel, coal and oil are burnt for different reasons. This

weakens the heattrapping blanket that surrounds the planet,

causing global warming. Various alternatives can be

considered to protect the planet. The rapid increase in the

capacity of thermal power generation has resulted in the

production of a huge quantity of fly ash. The prevailing

disposal methods are not free from environmental pollution

and ecological imbalance. The CO

2

emission from the

concrete production is directly proportional to the cement

content used in the concrete mix; 900 kg of CO

2

are emitted

for the fabrication of every ton of cement[1]. The usage of

cement can be reduced by using the other possible

cementing materials without compromising the strength and

durability. It is also anticipated, that there would be

considerable short-fall in production of various building

materials. According to (TIFAC 2000) study, there would be

a large short-fall in the production of bricks to the tune of

25 billion bricks on an estimated demand of 100 billion

bricks per year in India by the turn of the century [2].

The most basic building material for construction of houses

in the Asian countries is the usual burnt clay brick. A

significant quantity of fuel is utilized in making these bricks.

Also, continuous removal of top soil, in producing

conventional bricks creates environmental problems. There

is strong need to adopt cost effective sustainable

technologies using local material and

appropriate/intermediate technologies using materials with

efficient and effective technology inputs. Different methods

are adopted to produce the building blocks using cement,

lime-fly ash, lime-slag bindings etc. The imperative need to

produce more building materials for various elements of

construction and the role of alternative options would be in

sharp focus. This is in considering the short supply,

increasing cost, energy and environment considerations for

traditional and conventional materials. The possibility of

using innovative building materials and technologies, using

waste material like fly ash & GGBS have been considered.

It is found that 180 billion tones of common burnt clay

bricks are consumed annually approximately 340 billion

tones of clay- about 5000 acres of top layer of soil dug out

for bricks manufacture, soil erosion, emission from coal

burning or fire woods which causes deforestation are the

serious problems posed by brick industry. The above

problems can be reduced to certain extent by using GPC

blocks in dwelling units. Demand for dwelling units likely

to raise to 80 million units by year 2015 for lower middle

and low income groups, involving an estimated investment

of $670 billion, according to the Associated chamber of

commerce and industry. Demand for dwelling units will

further grow to 90 million by 2020,which would requires a

minimum investment of $890billion. The Indian housing

sector at present faces a shortage of 20million dwelling units

for its lower middle and low income groups which will

witness a spurt of about 22.5million dwelling units by the

end of Tenth plan period. There is ample scope for fly ash

GPC block units [3].

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

Volume: 03 Issue: 06 | Jun-2014, Available @ http://www.ijret.org 116

Past research data have shown that geopolymeric materials

perform much better in acid resistance compared to Portland

cement [4,5,6]. A study reported that heat-cured fly ash-

based geopolymers have excellent resistance to sulphate

attack and showed that there was no mechanism to form

gypsum or ettringite from the main products of

polymerization [7]. Some other studies reports that the

geopolymer specimens exhibit good resistance when

exposed to acid and sulphate solutions[8,9]. A study

revealed that thermal cured low-calcium fly ash-based

geopolymer concrete offers several economic benefits over

Portland cement concrete[10]. The cement industry is

responsible for about 6% of all CO

2

emissions, because the

production of one ton of Portland cement emits

approximately one ton of CO

2

into the atmosphere. The

geopolymer technology could reduce the CO

2

emission to

the atmosphere caused by cement industries by about 80%

[11]. A study also made an effort in reproportioning of

geopolymer blocks by phenomenological model[12]. Thus,

the development and application of geopolymer cement and

its composites is of great significance in terms of

environmental protection.

It is in this context an effort is made to produce GPC block

(400 mm X 200 mm X 150 mm) using fly ash and GGBS as

binders with compressive strength of 4 MPa using locally

available materials i.e Quarry dust & sand at ambient

temperature. The prime factor or parameter considered in

this work is alkaline solution to binder ratio for which the

optimum ratio is found out at 8M molarity. The water

absorption test is carried out for the specimens. The

durability test of GPC blocks is carried out by immersing

them into sulphuric acid and hydrochloric acid. The

economic & sustainability analysis of GPC block was done

by calculating the cost of raw materials as well as Embodied

energy required in preparing a GPC Block. This attempt will

result in two benefits. i.e. reduced CO

2

release due to OPC

and effective utilization of industrial waste by products such

as flyash, GGBS.

2 MATERIALS

Fly ash which is obtained from Raichur Thermal Power

Station, India and GGBS obtained from JSW steel, Bellary,

India are having specific gravity of 2.4 & 2.9 respectively.

The chemical composition of Flyash & GGBS as obtained

by X-ray fluorescence (XRF) is shown in Table-1 & Table-3

respectively. The IS code requirements & composition of

Flyash is shown in Table-2. The class F fly ash used here

confirms to requirement as per 3812-2003 IS code & shown

in Table 2. Locally available sand of specific gravity 2.63 &

Quarry dust (6 mm) retained on 2.36 mm of specific gravity

2.73 is used in this experimental work.

A combination of 8M sodium hydroxide and sodium silicate

in the ratio of 2.5 was used as solution for activation.

Sodium hydroxide flakes of laboratory grade with purity of

99% were used in this work. Sodium silicate also known as

water glass is of industrial grade with SiO

2

as 34.8% by

mass and Na

2

O as 16.51% & water as 48.69%. Water used

for the mix is of potable quality.

Table-1: Chemical composition of Fly ash as determined by

XRF analysis in (mass %)

Binder Fly Ash

S.Gr 2.4

*LOI 0.90

Al

2

O

3

31.23

Fe

2

O

3

1.50

SiO

2

61.12

MgO 0.75

SO

3

0.53

Na

2

O 1.35

Chlorides 0.05

CaO 3.2

*LOI - Loss on Ignition

Table -2: Constitution of Flyash and code requirements

Constituents Composition

in %

Requirements as

per IS 3812- 2003

LOI 0.90 Max 5

(Al

2

O

3

+Fe

2

O

3

+SiO

2

) 93.85 Min 70

SiO

2

61.12 Min 35

MgO 0.75 Max 5

SO

3

0.53 Max 3

Na

2

O 1.35 Max 1.5

Chlorides 0.05 Max 0.05

Table -3: Chemical composition of GGBS as determined by

XRF analysis in (mass %)

Binder GGBS

S.Gr 2.9

LOI 0.19

Al

2

O

3

13.24

Fe

2

O

3

0.65

SiO

2

37.21

MgO 8.46

SO

3

2.23

Na

2

O - - -

Chlorides 0.003

CaO 37.2

2.1 Microstructure Analysis of Flyash & GGBS

The microstructure of flyash is analyzed using Scanning

Electron Microscope (SEM). From figure 1, the

microstructure of flyash appears to be a glassy, hollow,

spherical particle which is cenospheres (thin walled hollow

spheres). Furthermore, surface texture appears to be smooth

and dense to highly porous.

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

Volume: 03 Issue: 06 | Jun-2014, Available @ http://www.ijret.org 117

Fig - 1: SEM images of Fly ash

It is clear from figure 2 that the shape of GGBS is not really

spherical; it varies according to different grinding

techniques. It is predominantly in anomalous shape with

clear edges and angles. The reason for this shape is inter-

impacting & inter-rubbing between steel balls in Ball mill.

Fig - 2: SEM images of GGBS

3. EXPERIMENTAL WORK

3.1 Mix Design for Optimum Alkaline Solution to

Binder Ratio

From earlier studies GPC is produced with many

combinations of materials viz GGBS, flyash & binders.

Here an attempt is made initially to produce GPC of strength

4MPa [13] using locally available materials. Based on

observations made on initial trials, further trials are

modified. Initially the density of Geopolymer concrete is

assumed as 2350 kg/m

3

. The total quantity of aggregates

considered is 75% to 80% but can be taken from 72% to

80% of the entire mass in kg/m

3

. The remaining mass is

combination of Alkaline solution and Binder (Geopolymer

paste). Assuming the Alkaline solution to Binder ratio from

0.17 to 0.24, masses of Alkaline solution and Binder in

kg/m

3

are obtained. Assuming Sodium silicate solution to

Sodium Hydroxide Solution ratio as 2.5, mass Sodium

silicate solution and sodium hydroxide solution are obtained

(kg/m

3

). Assuming the molarity of sodium hydroxide

solution 8M, the geopolymer mix is designed.

The Mix designs for various combinations of alkaline

solution to binder ratio for 150X150X150mm cubes were

prepared as listed in Table - 4.

3.2 Preparation of Geopolymer Concrete

The preparation of GPC mix involves the following process

i.e preparation of alkaline solution, mixing, casting, curing

& testing of samples.

To prepare sodium hydroxide solution of 8 molarity, 480 g

(8 x 40) that is, molarity x molecular weight) of sodium

hydroxide flakes (99% purity) are dissolved in one litre of

water. The mass of sodium hydroxide solids in a solution

will vary depending on the concentration of the solution

expressed in terms of molar M. The prepared NaOH

solution is added with sodium silicate solution

proportionately according to the mix 24 hours before

casting.

The alkaline solution prepared 24 hours before is thoroughly

stirred, addition of solution has to be done in small

quantities so that there shouldnt be any wastage of solution,

wet mixing time should be about 10 to 15 minutes or

greater. The mixing of total mass will continued till the

mixture become homogeneous and uniform in color. After

this the mix is left for 10 to 15 minutes then the extra water

is added to the mix, again mix it homogenously.

To test the compressive strength of initial trials, the fresh

geopolymer concrete is casted in cubes of size 150 X150 X

150 mm in three layers and is compacted by using the

standard compaction rod so that each layer receives 25

strokes followed by further compaction on the vibrating

table. Compressive strength of cubes were determined until

it was reached to 4MPa. Later after determining the

optimum ratio (alkaline solution to binder ratio)

corresponding to 4MPa, the concrete is casted in blocks of

size 400 X 200 X 150 mm dimension.

The casted specimens after one day rest period are

demoulded and specimens are kept in lab at ambient

temperature for the curing hours of 72 hours. After required

curing period the specimens are tested as per IS 516 : 1979.

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

Volume: 03 Issue: 06 | Jun-2014, Available @ http://www.ijret.org 118

Table -4: Mix design trials with different alkaline solution to binder ratio for geopolymer

Materials GPC 1 GPC 2 GPC 3 GPC 4 GPC 5 GPC 6

Coarse Aggregate kg/m

3

1099.8 1099.8 1099.8 1099.8 1099.8 1099.8

Fine Aggregate kg/m

3

592.2 592.2 592.2 592.2 592.2 592.2

Fly ash kg/m

3

281.19 276.47 274.16 269.67 267.47 265.32

GGBS kg/m

3

281.19 276.47 274.16 269.67 267.47 265.32

NaOH Solution kg/m

3

27.31 30.01 31.33 33.90 35.15 36.38

Molarity of NaOH 8M 8M 8M 8M 8M 8M

Na

2

SiO

3

Solution kg/m

3

68.30 75.04 78.33 84.76 87.90 90.96

Temperature in C 27 27 27 27 27 27

Curing Period (hours) 72 72 72 72 72 72

Water to geopolymer

solids ratio

0.40 0.40 0.40 0.40 0.40 0.40

Alkaline solution to

Binder ratio

0.17 0.19 0.20 0.22 0.23 0.24

Rest period (hours) 24 24 24 24 24 24

Days of testing 3 3 3 3 3 3

Extra Water kg/m

3

187.67 180.21 176.57 169.47 165.99 162.59

Average load (kN) 33.52 46.05 47.55 58.20 91.97 186.90

Area (mm

2

) 22500 22500 22500 22500 22500 22500

Three day compressive strength

(N/mm

2

)

1.49 2.04 2.11 2.58 4.08 8.30

Fig -3: Compressive strength of GPC vs alkaline solution to

binder ratio

Here figure-3 shows the compressive strength of

geopolymer concrete specimen at ambient temperature at 3

rd

day of curing. The casting of blocks was carried out from

0.17 to 0.24 with increase in solution to binder ratio to

achieve the desired strength. At the alkaline solution to

binder ratio of 0.23 the strength of GPCB is around 4MPa

which is adequate for a concrete block as per IS : 2185 Part1

1979. Beyond this ratio the strength of the blocks will be

high and not required and moreover this higher ratio will be

uneconomical. Hence the geopolymer blocks can be casted

with this optimum ratio i.e as per trial No 5.

Three days compressive strength of GPC is compared with

28 days compressive strength of cement concrete. The added

advantage is that the GPC blocks are not cured with water

and moreover the time required for preparation of GPC is

relatively less. Figure 4 shows the prepared sample of GPC

block.

Here Table - 5 shows the results after casting it in blocks

(400mm X 200mm X 150mm) for optimum alkaline

solution to binder ratio i.e 0.23. Prepared GPCB5

1-3

blocks

are tested for compression (figure 5). Quantity of materials

required to prepare the Geopolymer block (for 1cum) for

optimum ratio are shown in Table-6, similar to traditional

concrete blocks.

Table -5: Strength of geo-polymer concrete blocks with

optimum ratio

Sl.

No

Specimen

name

Load

in tons

Area in

mm

2

Three day

compressive

strength (N/mm

2

)

1 GPCB5

1

26 400X150 4.25

2 GPCB5

2

25 400X150 4.08

3 GPCB5

3

25.5 400X150 4.17

0

2

4

6

8

10

0

.

1

7

0

.

1

9

0

.

2

0

.

2

2

0

.

2

3

0

.

2

4

C

o

m

p

r

e

s

s

i

v

e

s

t

r

e

n

g

t

h

i

n

N

/

m

m

2

Alkaline solution to binder ratio

Variation in

compressive

strength of

GPC at

different

alkaline

solution to

binder ratio at

8M molarity

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

Volume: 03 Issue: 06 | Jun-2014, Available @ http://www.ijret.org 119

Table -6: Quantities of materials for GPC block in kg for one m

3

Flyash GGBS Quarry

Dust

Fine

aggregate

NaOH

solution

Na

2

SiO

3

solution

Extra

water

267.47 267.47 1099.80 592.20 35.15 87.90 165.99

Fig -4: View of GPC block

Fig -5 : Testing of Geo-polymer block

4. WATER ABSORPTION TEST

To study the water absorption characteristics of geopolymer

blocks, the cast specimens GPCB5

4-6

blocks are subjected to

water absorption test. After the curing period is completed,

the specimen are immersed in the water tank and kept for 24

hours in water. The weight of the specimen is noted. The

specimen is placed in a oven at 105C temperature, then the

weight of the specimen is recorded. From these two values,

the water absorbed by the entire specimen is calculated and

tabulated.

Percentage of Water absorption = [(W

1

-W

2

) / W

1

] 100

Where,

W

1

= Weight of the wet specimen

W

2

= Weight of the dry specimen

Table -7: Water absorption test results

Sl. No Specimen name Water absorption %

1 GPCB5

4

1.58

2 GPCB5

5

1.21

3 GPCB5

6

1.42

Table-7 shows the results of Water Absorption test. The

average water absorption value is determined as 1.40 %

which is less than 10% by mass of block as per code

IS:2185 Part1 1979.

5. DURABILITY TESTS

Acid resistance test is conducted on geopolymer concrete

blocks. Because no universal or widely accepted standard

procedures for acid resistance test exist, the type and

concentration of the acid solution to which the specimens

are exposed varied. However the test procedure is carried

out using 3% of solution[14].The test specimens for acid

resistance test on geopolymer concrete are 400 X 200 X 150

mm blocks for the change in mass test.

5.1 Sulphuric Acid Resistance

To study the effects of exposure to acidic environment,

specimens are immersed in 3% solution of sulphuric acid of

98% purity. Test is carried out at regular intervals after 7

days for a period of 84 days. The solution is replaced at

regular intervals to maintain concentration of solution

throughout the test period. The evaluations are conducted

after 7, 14, 28, 56 & 84 days from the date of immersion.

After removing the specimens from the solution, the

surfaces are cleaned under the running tap water to remove

weak products and loose material from the surface. Later the

specimens are allowed to dry and measurements are taken.

From the initial measurement and measurements at

particular intervals, the loss or gain of the weight are

studied. Table - 8 shows the results of sulphuric acid

resistance test.

Table -8: Sulphuric acid resistance test by reduction of

weight

Average reduction by weight in %

Block 7 days 14 days 28 days 56 days 84 days

GPCB 0.76 0.91 1.03 1.23 1.31

5.2 Hydrochloric Acid Resistance

For the study on chloride attack, solution is prepared by

mixing 3% hydrochloric acid (HCl) in a plastic container.

The solution is stirred on alternate days to avoid deposits of

chloride in the container. The solution is replaced with fresh

one after 28 days. The evaluations are conducted after 7, 14,

28, 56 & 84 days from the date of immersion. After

removing the specimens from the solution, the surfaces are

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

Volume: 03 Issue: 06 | Jun-2014, Available @ http://www.ijret.org 120

cleaned under the running tap water to remove weak

products and loose material from the surface. Then the

specimens are allowed to dry and measurements are taken.

From the initial measurement and measurements at

particular intervals, the loss or gain of the weight are

studied. Table - 9 shows the results of Hydrochloric acid

resistance test.

Table -9: Hydrochloric acid resistance test by reduction of

weight

Average reduction by weight in %

Block 7 days 14 days 28 days 56 days 84 days

GPCB 0.21 0.46 0.59 0.65 0.72

6. SUSTAINABILITY CHARACTERISTICS OF

GPC BLOCKS

This study considers only the embodied energy consumed in

the production of GPC block. Fly ash and GGBS are waste

products from industry. The embodied energy of fly ash is

zero as collection of fly ash from flue gas is mandatory in

India. GGBS will have to be grinded after quenching. The

embodied energy of cement manufactured by dry process is

4.2MJ/kg [15]. Therefore an embodied energy of 0.31MJ/kg

(6-7% that of cement) has been considered. The embodied

energy of sodium hydroxide is 20.5MJ/kg as per SPLINE

LCI datasheet. The embodied energy of sodium silicate shall

be taken as 5.37 MJ/kg [16]. The transportation energy is

not considered here in the analysis. Table - 10 shows the

calculation of Embodied energy for one GPC block.

Table -10: Embodied energy in one GPC block

Material Embodied

energy

(MJ/kg)

Material

required for

one GPCB

(kg)

Total embodied

energy in one

GPCB (MJ)

Quarry

dust

0.10 13.19 1.31

Fine

aggregate

0.02 7.10 0.14

Flyash 0.00 3.20 0.00

GGBS 0.31 3.20 0.99

NaOH

solution

4.98 0.42 2.09

Na

2

SiO

3

solution

5.37 1.05 5.63

10.17MJ

Hence, the Embodied energy of fly- ash GGBS based

geopolymer concrete BLOCK is found to be 10.17MJ

Chart -1: Embodied energy contribution of each material in

Flyash-GGBS based GPC Block

Table -21: Comparative analysis of Embodied Energy

Sl No Blocks Total

Embodied

Energy

1 Concrete block (10N/mm

2

)

Density 1450kg/m

3

11.65 MJ

2 Steam cured block

(230x190x100)

18.09 MJ

3 Burnt brick

(230x105x70)

30.13 MJ

4 Stabilized Mud block

(230x190x100)

7.13 MJ

5 Geo-polymer Concrete

block

(400x200x150)

10.17 MJ

Based on the different technologies used, the Table-11

shows the calculation of embodied energy of various

building blocks as mentioned in Jagadish et al(2007)[17].

The total embodied energy is calculated by multiplying the

size factor of different blocks for comparative analysis. Here

it is observed that embodied energy of GPC blocks is 14.5%

less than traditional concrete block, 77.87% less than steam

cured block, 196.26% less than Burnt brick. Another study

by G.P.Hamond and C.I.Jones(2006)[18] clearly indicates

that Concrete blocks(medium density), limestone blocks and

aerated blocks have an embodied energy of 0.67MJ/kg,

0.85MJ/kg and 3.5MJ/kg respectively. But GPC blocks as

prepared above has an Embodied energy of 0.36MJ/kg

which is very low to the order of 86.11%, 136.11% 872.22%

less as compared to concrete blocks, limestone blocks and

aerated blocks respectively. Embodied energy of Mud block

is lower than GPC block but strengths are not comparable

and GPC block is much superior in all other aspects.

13%

1%

0%

10%

21%

55%

Coarse Aggregate Fine Aggregate

Fly ash GGBS

NaOH Solution Na2SiO3 Solution

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

Volume: 03 Issue: 06 | Jun-2014, Available @ http://www.ijret.org 121

7. ECONOMIC CHARACTERISTICS OF GPC

BLOCKS

Calculation of Single Unit of GPC Block:

Local market price for Sodium Hydroxide flakes, Sodium

Silicate, Flyash, GGBS and aggregates are considered to

evaluate the cost of GPC block. The cost for each material

and total cost is mentioned in the Table - 12.

The contribution of sodium silicate and sodium hydroxide to

the embodied energy and cost of geopolymer concrete is

very high (Chart-1, Chart-2) Manufacturing processes of

these materials for large scale production must be

redesigned so as to reduce the embodied energy. High

energy in sodium silicate is due to melting and drying

process involved during its manufacturing. Hence research

for alternative materials in place of sodium hydroxide and

sodium silicate is very much essential.

Table 12: Cost calculation of one GPC block

Material Cost per

kg in Rs.

Material

required for one

GPCB (kg)

Total cost

for one

GPCB in Rs.

Quarry

dust

0.40 13.19 5.27

Fine

aggregate

1.42 7.10 10.08

Flyash 1.20 3.20 3.84

GGBS 1.20 3.20 3.84

NaOH

solution

19.36 0.42 8.17

Na

2

SiO

3

solution

18.5 1.05 19.42

Cost of each GPC block 50.62

Chart -2: Cost contribution of each material to Flyash -

GGBS based GPC Block

In the analysis of cost from Table-12, we see that the cost of

single unit of GPC block is estimated to be around 50.62 .

In this estimation the cost of NaOH solution & Na

2

SiO

3

solution contributes to 54.5% of the cost of GPC blocks

(figure 7). Presently extensive research is been carried out to

produce sodium silicate by cost effective methods which

will reduce the price & also the embodied energy in due

course.

8. CONCLUSIONS

The following are the conclusions obtained after this study :

The optimum alkaline solution to binder ratio for

the preparation of geopolymer concrete blocks is

found to be 0.23 for 8M Molarity of NaOH at

ambient curing.

The strength achieved by Geopolymer blocks is

4MPa which is equivalent to the strength of cement

concrete block & the average density of the block

(400x200x150) is 23kN/m

3

.

The average water absorption percentage of GPC

block is found to be 1.40 %.

The mass reduction of GPC block due to sulphuric

acid resistance at the end of 84 days is found to be

1.31%.

The mass reduction of GPC block due to

hydrochloric acid resistance at the end of 84 days is

found to be 0.72%.

The Embodied energy of GPC block is calculated

as 10.17MJ. It is found that Sodium hydroxide &

sodium silicate together contribute to 76% of total

embodied energy.

The cost of one GPCB block is estimated to be

50.62 .

Even though the cost of GPC blocks seems to be higher as

compared to traditional cement concrete block, it is

recommended to use in place of cement concrete blocks and

burnt brick, since GPC blocks are ecofriendly, sustainable

and have lower embodied energy. Hence geopolymer blocks

can be recommended to as masonry units for non-structural

purposes. However more research is necessary to further

optimize the proportions and study the economical aspects

of such blocks.

REFERENCES

[1]. Mahasenan, Natesan; Steve Smith; Kenneth

Humphreys; Y. Kaya (2003). The Cement Industry and

Global Climate Change: Current and Potential Future

Cement Industry CO

2

Emissions. Greenhouse Gas Control

Technologies 6th International Conference. Oxford:

Pergamon. pp. 9951000.

[2]. TIFAC, Technology Information, Forecasting &

Assessment Council 2000 Fly ash bricks TMS085 (New

Delhi: TIFAC)

[3]. Sivalingam, N . (2011). Project profile on fly ash bricks

.[ONLINE] Available

at:http://dcmsme.gov.in/reports/glass/FlyashBricks.pdf

[Accessed 03 January 14]

10%

20%

8%

8%

16%

38%

Coarse aggragates Fine aggregate

Fly Ash GGBS

NaOH Solution Na2SiO3 Solution

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

Volume: 03 Issue: 06 | Jun-2014, Available @ http://www.ijret.org 122

[4]. Davidovits, J. (1994). Properties of Geopolymer

Cements. In Proceedings of 1st International Conference on

Alkaline Cements and Concretes (pp. 131149). Kiev,

Ukraine: SRIBM, Kiev State Technical University.

[5]. Song, X. J., Marosszeky, Brungs, M. M., & Munn, R.

(2005a, 17-20 April). Durability of fly ash-based

Geopolymer concrete against sulphuric acid attack. Paper

presented at the 10DBMC International Conference on

Durability of Building Materials and Components, Lyon,

France.

[6]. Gourley, J. T., & Johnson, G. B. (2005). Developments

in Geopolymer Precast Concrete. Paper presented at the

International Workshop on Geopolymers and Geopolymer

Concrete, Perth, Australia.

[7]. Wallah, S. E., and Rangan, B. V. (2006). Low-calcium

fly ashbased geopolymer concrete: Long-term properties.

Research Report GC 2, Faculty of Engineering, Curtin

University of Technology, Perth, Australia.

[8]. Bakharev, T. (2005a). Resistance of geopolymer

materials to acid attack. Cement and Concrete Research, 35,

658670.

[9]. Bakharev, T. (2005b). Durability of geopolymer

materials in sodium and magnesium sulfate solutions.

Cement and Concrete Research, 35, 12331246.

[10]. Li, Z., Ding, Z., & Zhang, Y. (2002). Development of

sustainable cementitious materials In Proceedings of

International Workshop on Sustainable Development and

Concrete Technology (pp. 5576)

[11]. Davidovits, J. (1994c). Global Warming Impact on the

Cement and Aggregates Industries World Resource Review,

6(2), 263-278.

[12]. Radhakrishna, Tirupati, V., Manjunath, G., Venugopal,

K. (2013). "Phenomenological Model to Re-proportion the

Ambient Cured Geopolymer Compressed Blocks".

International Journal of Concrete Structures and Materials. 7

(3), p193-202

[13]. Lloyd, N., and Rangan, B. V. (2010). Geopolymer

Concrete with Fly Ash. In Second International Conference

on Sustainable Construction Materials and Technologies,

Jun 28, 2010, Ancona, Italy: UWM Center for By-Products

Utilization.

[14]. Vijaysankar, P.,Anuradha, R.,Sreevidya, V., Dr. R.

Venkatasubramani. (2013). Durability Studies of

Geopolymer Concrete Solid Blocks. International Journal of

Advanced Scientific and Technical Research. 2 (3), p272-

278.

[15]. B. V. Venkatarama Reddy and K. S. Jagadish.

Embodied energy of common and alternative building

materials and technologies. Energy and buildings 35.2

(2003): 129-137.

[16]. Fawer, Matthias, Martin Concannon, and Wolfram

Rieber.(1999).Life cycle inventories for the production of

sodium silicates. The International Journal of Life Cycle

Assessment 4.4: p207-212.

[17]. Jagadish, K., Venkatarama Reddy, B. and Rao, K.

(2007). Alternative building materials and technologies. 1st

ed. New Delhi: New Age International (P) Ltd., Publishers.

[18] Hammond, G.P. and Jones, C.I. (2006) Inventory of

(Embodied) Carbon & Energy (ICE), Department of

Mechanical Engineering, University of Bath, United

Kingdom.

ACKNOWLEDGEMENTS

The authors are thankful to the faculty of Civil Engineering

Dept for promoting the Research. This Research project is

supported by B.V.B. College of Engineering & Technology,

Hubli, Karnataka, India under the R.E.U (Research

Experience for Undergraduates) programme.

BIOGRAPHIES

Mr. Tejas Ostwal, UG student, B.E, Civil

Engineering, B.V.B. College of

Engineering & Technology, Hubli,

Karnataka, India

Dr Manojkumar. V. Chitawadagi obtained

his M. E. in Structural Engg. He

completed his Ph.D. under Quality

Improvement Programme, at NITK

Surathkal. He is working as Professor at

Civil Engg. Dept. BVBCET, Hubli. He

has guided students for their M.Tech.

dissertation in the field of Fibre reinforced concrete, aerated

concrete, high strength concrete and concrete filled steel

tubes used as columns and beams. In his 25 years of service

he has several publications in the areas of his research

interest in National and International Journals.

You might also like

- Enhancing Post Disaster Recovery by Optimal Infrastructure Capacity BuildingDocument8 pagesEnhancing Post Disaster Recovery by Optimal Infrastructure Capacity BuildingInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Hudhud Cyclone - A Severe Disaster in VisakhapatnamDocument8 pagesHudhud Cyclone - A Severe Disaster in VisakhapatnamInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Flood Related Disasters Concerned To Urban Flooding in Bangalore, IndiaDocument8 pagesFlood Related Disasters Concerned To Urban Flooding in Bangalore, IndiaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Wind Damage To Trees in The Gitam University Campus at Visakhapatnam by Cyclone HudhudDocument11 pagesWind Damage To Trees in The Gitam University Campus at Visakhapatnam by Cyclone HudhudInternational Journal of Research in Engineering and TechnologyNo ratings yet

- A Geophysical Insight of Earthquake Occurred On 21st May 2014 Off Paradip, Bay of BengalDocument5 pagesA Geophysical Insight of Earthquake Occurred On 21st May 2014 Off Paradip, Bay of BengalInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Low Cost Wireless Sensor Networks and Smartphone Applications For Disaster Management and Improving Quality of LifeDocument5 pagesLow Cost Wireless Sensor Networks and Smartphone Applications For Disaster Management and Improving Quality of LifeInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Groundwater Investigation Using Geophysical Methods - A Case Study of Pydibhimavaram Industrial AreaDocument5 pagesGroundwater Investigation Using Geophysical Methods - A Case Study of Pydibhimavaram Industrial AreaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Impact of Flood Disaster in A Drought Prone Area - Case Study of Alampur Village of Mahabub Nagar DistrictDocument5 pagesImpact of Flood Disaster in A Drought Prone Area - Case Study of Alampur Village of Mahabub Nagar DistrictInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Effect of Lintel and Lintel Band On The Global Performance of Reinforced Concrete Masonry In-Filled FramesDocument9 pagesEffect of Lintel and Lintel Band On The Global Performance of Reinforced Concrete Masonry In-Filled FramesInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Likely Impacts of Hudhud On The Environment of VisakhapatnamDocument3 pagesLikely Impacts of Hudhud On The Environment of VisakhapatnamInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Wind Damage To Buildings, Infrastrucuture and Landscape Elements Along The Beach Road at VisakhapatnamDocument10 pagesWind Damage To Buildings, Infrastrucuture and Landscape Elements Along The Beach Road at VisakhapatnamInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Cyclone Disaster On Housing and Coastal AreaDocument7 pagesCyclone Disaster On Housing and Coastal AreaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Shear Strength of RC Deep Beam Panels - A ReviewDocument15 pagesShear Strength of RC Deep Beam Panels - A ReviewInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Role of Voluntary Teams of Professional Engineers in Dissater Management - Experiences From Gujarat EarthquakeDocument6 pagesRole of Voluntary Teams of Professional Engineers in Dissater Management - Experiences From Gujarat EarthquakeInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Monitoring and Assessment of Air Quality With Reference To Dust Particles (Pm10 and Pm2.5) in Urban EnvironmentDocument3 pagesMonitoring and Assessment of Air Quality With Reference To Dust Particles (Pm10 and Pm2.5) in Urban EnvironmentInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Comparative Study of The Forces in G+5 and G+10 Multi Storied Buildings Subjected To Different Wind SpeedsDocument10 pagesComparative Study of The Forces in G+5 and G+10 Multi Storied Buildings Subjected To Different Wind SpeedsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Review Study On Performance of Seismically Tested Repaired Shear WallsDocument7 pagesReview Study On Performance of Seismically Tested Repaired Shear WallsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Disaster Recovery Sustainable HousingDocument4 pagesDisaster Recovery Sustainable HousingInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Effect of Hudhud Cyclone On The Development of Visakhapatnam As Smart and Green City - A Case StudyDocument4 pagesEffect of Hudhud Cyclone On The Development of Visakhapatnam As Smart and Green City - A Case StudyInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Assessment of Seismic Susceptibility of RC BuildingsDocument4 pagesAssessment of Seismic Susceptibility of RC BuildingsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Detection of Hazard Prone Areas in The Upper Himalayan Region in Gis EnvironmentDocument9 pagesDetection of Hazard Prone Areas in The Upper Himalayan Region in Gis EnvironmentInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Can Fracture Mechanics Predict Damage Due Disaster of StructuresDocument6 pagesCan Fracture Mechanics Predict Damage Due Disaster of StructuresInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Coastal Zones - Seismic Vulnerability An Analysis From East Coast of IndiaDocument4 pagesCoastal Zones - Seismic Vulnerability An Analysis From East Coast of IndiaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Cpw-Fed Uwb Antenna With Wimax Band-Notched CharacteristicsDocument5 pagesCpw-Fed Uwb Antenna With Wimax Band-Notched CharacteristicsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Challenges in Oil and Gas Industry For Major Fire and Gas Leaks - Risk Reduction MethodsDocument4 pagesChallenges in Oil and Gas Industry For Major Fire and Gas Leaks - Risk Reduction MethodsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Developing of Decision Support System For Budget Allocation of An R&D OrganizationDocument6 pagesDeveloping of Decision Support System For Budget Allocation of An R&D OrganizationInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Rate Adaptive Resource Allocation in Ofdma Using Bees AlgorithmDocument5 pagesRate Adaptive Resource Allocation in Ofdma Using Bees AlgorithmInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Brain Tumor Segmentation Using Asymmetry Based Histogram Thresholding and K-Means ClusteringDocument4 pagesBrain Tumor Segmentation Using Asymmetry Based Histogram Thresholding and K-Means ClusteringInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Analytical Solutions For Square Shape PressureDocument4 pagesAnalytical Solutions For Square Shape PressureInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- MD - Ziaul AlamDocument2 pagesMD - Ziaul AlamAvijit DasNo ratings yet

- Advantages and disadvantages of mechanical fasteners and adhesive bondingDocument6 pagesAdvantages and disadvantages of mechanical fasteners and adhesive bondingYankie Mike PaPa100% (1)

- Unit 1 - Part A-Water Supply IDocument24 pagesUnit 1 - Part A-Water Supply IIsha SinghNo ratings yet

- Utilization of Sugarcane Bagasse Ash and Rice Husk Ash On Compressive Strength and Durability of Sustainable Pavement Quality ConcreteDocument10 pagesUtilization of Sugarcane Bagasse Ash and Rice Husk Ash On Compressive Strength and Durability of Sustainable Pavement Quality ConcreteEditor IJTSRDNo ratings yet

- Low Temp Refrigeration Oil DataDocument1 pageLow Temp Refrigeration Oil DataGeorgiana DumitruNo ratings yet

- Atomic Structure Part 6Document38 pagesAtomic Structure Part 6xenaNo ratings yet

- 04 Gue SF7 Unit2 T1 T3Document44 pages04 Gue SF7 Unit2 T1 T3Bill Wang100% (1)

- FlexEJ Brochure Elaflex 10 2011Document41 pagesFlexEJ Brochure Elaflex 10 2011harlyganNo ratings yet

- Sybron Endo Sealapex Root Canal SealerDocument7 pagesSybron Endo Sealapex Root Canal Sealerenjoy enjoy enjoyNo ratings yet

- ArcelorMittal Projects Steel Pipe ProductionDocument20 pagesArcelorMittal Projects Steel Pipe Productionanil-kumar-singh-6674No ratings yet

- Liquefied Gas HandbookDocument38 pagesLiquefied Gas HandbookAndri Suharto100% (1)

- BS en 1393 1997Document18 pagesBS en 1393 1997karthikkumar T RNo ratings yet

- A Review On Development of Stereolithography (SLA) 3D Printing in Additive Manufacturing For Biomedical IndustryDocument4 pagesA Review On Development of Stereolithography (SLA) 3D Printing in Additive Manufacturing For Biomedical IndustryFirdaus Mat SoibNo ratings yet

- Essco Product CatalogueDocument23 pagesEssco Product CatalogueMohammedAasimUmairNo ratings yet

- Ceilcote 242 Flakeline coating specification for concreteDocument2 pagesCeilcote 242 Flakeline coating specification for concretenoto.sugiartoNo ratings yet

- Lubricant Properties CalculatorDocument14 pagesLubricant Properties CalculatorzamijakaNo ratings yet

- BOF1Document3 pagesBOF1Skartini DayNo ratings yet

- UNIT III TheoryDocument6 pagesUNIT III TheoryRanchuNo ratings yet

- Extract Organometallic Chemistry PDFDocument10 pagesExtract Organometallic Chemistry PDFj pooranaNo ratings yet

- Schunk Carbon Technology Sealring Bearing SiSiC SSiC EN PDFDocument2 pagesSchunk Carbon Technology Sealring Bearing SiSiC SSiC EN PDFMUHAMMAD ASYRAAF BIN ANUARNo ratings yet

- Applied Energy: Zhang Bai, Qibin Liu, Jing Lei, Hui Hong, Hongguang JinDocument10 pagesApplied Energy: Zhang Bai, Qibin Liu, Jing Lei, Hui Hong, Hongguang JinEko RaharjoNo ratings yet

- High Performance Butterfly Valve HP 111Document4 pagesHigh Performance Butterfly Valve HP 111JOHNNo ratings yet

- Limites condenatorios aceite en MeritorDocument4 pagesLimites condenatorios aceite en MeritorJavier H Durán ValeroNo ratings yet

- NanotechnologyDocument28 pagesNanotechnologyCordelia Marisse ReyesNo ratings yet

- RAC (ME 802) by Prof. Sangeev S. TomarDocument9 pagesRAC (ME 802) by Prof. Sangeev S. Tomarapi-19832143No ratings yet

- Chemistry SBA7 ReportDocument6 pagesChemistry SBA7 ReportSam ChanNo ratings yet

- Drug Price Control Order 2013 As Good as a Leaky BucketDocument3 pagesDrug Price Control Order 2013 As Good as a Leaky Bucketcat100percentileNo ratings yet

- P-X-Y Diagram For Benzene (1) /ethylbenzene (2) at 363.15KDocument2 pagesP-X-Y Diagram For Benzene (1) /ethylbenzene (2) at 363.15Ksiti azilaNo ratings yet

- Is 10204 PDFDocument4 pagesIs 10204 PDFDimple EntertainmentNo ratings yet

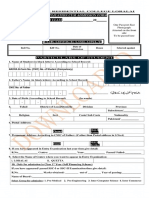

- Admission Form All 2019 1Document8 pagesAdmission Form All 2019 1Riz WanNo ratings yet