Professional Documents

Culture Documents

Ferrolex D - 15: Technical Data

Uploaded by

ukalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ferrolex D - 15: Technical Data

Uploaded by

ukalCopyright:

Available Formats

http://www.rikochemicals.

com

TECHNICAL DATA

FERROLEX D - 15

FERROLEX D-15 is a super efficient soak cleaner for degreasing of steel, brass, copper and zinc

base diecasting. The system has long service life with very good cleaning effect. FERROLEX D-

15 is highly economical and versatile in use. The system can also be used for effective

electrolytic cleaning.

OPERATING CONDITIONS FOR SOAK CLEANING:

CONCENTRATION TEMPERATURE

Steel 30 - 50g/ltr. 65 80C

Copper and brass 20 - 40g/ltr. 60 70C

Zincbase diecasting 20 - 40g/ltr. 60 70C

OPERATING CONDITIONS FOR ELECTROLYTIC CLEANING:

CONCENTRATION CURRENT DENSITY TEMPERATURE

Steel 50 - 70g/ltr. 2 - 4 A/sq.dm. 60 - 80C

Copper and brass 40 - 70g/ltr. 1 - 2 A/sq.dm. 60 - 70C

Zincbase diecasting 40 - 50g/ltr. 1 - 2 A/sq.dm. 50 - 70C

BATH MAKE UP:

Fill the cleaning tank with warm water to 2/3

rd

of its final volume. Add the required amount

of FERROLEX D-15 and stir to dissolve completely.

Fill the tank to the working level and heat it to the operating temperature.

EQUIPMENT:

Plain steel tank is recommended. Heater made of steel or quartz can be used for heating

purpose.

CONTROL:

The cleaner solution can be easily controlled by removing floating oil over the surface either

manually or by means of circulating pump and an oil trap regularly.

The solution concentration can be maintained by analysing the alkalinity of the solution by simple

acid base titration using phenolphthalein as an indicator.

CAUTION:

FERROLEX D-15 is alkaline in nature and contact with skin or eyes should be avoided.

WASTE TREATMENT

Spent FERROLEX D 15 solutions are alkaline and may contain particles of metal proceed

through the operating solution. Spent solutions must be neutralised prior to discharge in to a

sewer system. The most economical method of neutralisation is to mix the spent solution

with effluent from acid solution prior to entering the neutralisation sump or tank to take

advantage of the mutual adjustments of final effluent. Allow the precipitate that forms to

settle or filter the solution prior to discharge into the sewer.

NOTE:

The data set forth in this bulletin is believed by RIKO CHEMICALS PVT.LTD. to be true, accurate

and complete, but not guaranteed. Our sole warranty is as in standard Terms and Conditions of

sale. We cannot warrant that our customers will achieve the same results from any bulletin

because we do not have control over customers use nor can we assume any responsibility of our

product in a manner which infringes the patents of third parties.

You might also like

- Argoshine Bright Silver: Salient FeaturesDocument3 pagesArgoshine Bright Silver: Salient FeaturesJitendra Kumar SinghNo ratings yet

- Technical Data Sheet: Steelex K-20Document2 pagesTechnical Data Sheet: Steelex K-20LuuThiThuyDuongNo ratings yet

- Technical Data Sheet: H.E.N.E. Hard Chrome ProcessDocument5 pagesTechnical Data Sheet: H.E.N.E. Hard Chrome ProcessLuuThiThuyDuong100% (1)

- TDS_T-PRO_000_ENGDocument3 pagesTDS_T-PRO_000_ENGbhavinmehta9999No ratings yet

- Non-Cyanide Alkaline Silver Plating SolutionDocument4 pagesNon-Cyanide Alkaline Silver Plating SolutionUsman ali CheemaNo ratings yet

- Stannolume Bright Acid Tin: Technical Data SheetDocument7 pagesStannolume Bright Acid Tin: Technical Data SheetLuuThiThuyDuong100% (2)

- Dyeless Ultra Cu-4040Document7 pagesDyeless Ultra Cu-4040Camila ZapataNo ratings yet

- E Brite 50 50 RTPDocument6 pagesE Brite 50 50 RTPUsman ali CheemaNo ratings yet

- Bright Acid Copper For Wire and Grounding Rods: E-Brite 202GDocument6 pagesBright Acid Copper For Wire and Grounding Rods: E-Brite 202GUsman ali Cheema100% (1)

- Iz250y PDFDocument10 pagesIz250y PDFKaRenthLuNa100% (1)

- Technical Data Sheet Bright Acid Tin Process: Solution Composition: Optimum RangeDocument4 pagesTechnical Data Sheet Bright Acid Tin Process: Solution Composition: Optimum Rangeshanmukha MechanicalNo ratings yet

- Iz260 PDFDocument6 pagesIz260 PDFKaRenthLuNaNo ratings yet

- All About CleanerDocument22 pagesAll About CleanerMarlon GlodoNo ratings yet

- Technical Service Data Sheet: Cupratech Ac 382Document5 pagesTechnical Service Data Sheet: Cupratech Ac 382Jitendra Kumar SinghNo ratings yet

- Float Level Switch GuideDocument24 pagesFloat Level Switch GuideAlbertus KaryadiNo ratings yet

- E Prep 280 NCZDocument4 pagesE Prep 280 NCZxerxeshakaNo ratings yet

- Seperator Cleaner enDocument2 pagesSeperator Cleaner eneldiego1790No ratings yet

- Hard Chrome 105 Plating ProcesDocument3 pagesHard Chrome 105 Plating ProcesKishora BhatNo ratings yet

- 704 Na OHEDocument7 pages704 Na OHEBoris KundačinaNo ratings yet

- E-Brite 50/50: Non-Cyanide Alkaline Silver PlatingDocument6 pagesE-Brite 50/50: Non-Cyanide Alkaline Silver PlatingUsman ali CheemaNo ratings yet

- ZINCO BRASS SALT TECHNICAL DATADocument2 pagesZINCO BRASS SALT TECHNICAL DATAPhutera SemeruNo ratings yet

- PT. Sinar Cemaramas Abadi Provides Cleaning and Plating ServicesDocument1 pagePT. Sinar Cemaramas Abadi Provides Cleaning and Plating ServicesSinar Cemaramas AbadiNo ratings yet

- Lab Catalouge | Goel scientific | CanadaDocument36 pagesLab Catalouge | Goel scientific | CanadaGoel ScientificNo ratings yet

- Technical Data Sheet Spectek 787 Bright Nickel Process: Salient FeaturesDocument8 pagesTechnical Data Sheet Spectek 787 Bright Nickel Process: Salient Featuresshanmukha MechanicalNo ratings yet

- High Speed Bright Tin Plating ProcessDocument5 pagesHigh Speed Bright Tin Plating ProcessRC Villeda67% (3)

- Steelex K 20 TdsDocument2 pagesSteelex K 20 TdsSYED MAZHARNo ratings yet

- Magnetic Float Level Switch Specifications and ApplicationsDocument29 pagesMagnetic Float Level Switch Specifications and ApplicationsWidhi ImranovichNo ratings yet

- 7000 - Brochure - Paste Slaker PDFDocument4 pages7000 - Brochure - Paste Slaker PDFalexituuNo ratings yet

- 50industrial Sea Water Reverse Osmosis System SwiDocument2 pages50industrial Sea Water Reverse Osmosis System SwiMohamedAlami100% (1)

- Introduction To Swas Steam and Water Analysis SystemDocument41 pagesIntroduction To Swas Steam and Water Analysis SystemvaishnaviNo ratings yet

- Eletrochemicaldesalter 191231094907Document6 pagesEletrochemicaldesalter 191231094907ShakerMahmoodNo ratings yet

- APN-4.06.07-Lead Acid Battery ManufactureDocument2 pagesAPN-4.06.07-Lead Acid Battery ManufacturePopescu George BogdanNo ratings yet

- Superglo Bright Nickel Process: Technical Data SheetDocument6 pagesSuperglo Bright Nickel Process: Technical Data SheetLuuThiThuyDuong100% (1)

- Analysis System: SteamDocument22 pagesAnalysis System: SteamGaurav KumarNo ratings yet

- Bright Nickel ProcessDocument10 pagesBright Nickel Processshanmukha MechanicalNo ratings yet

- Kemia Pte LTD: Rohs Compliance, High Phosphorous Electroless Nickel ProcessDocument4 pagesKemia Pte LTD: Rohs Compliance, High Phosphorous Electroless Nickel ProcessWin AsharNo ratings yet

- Aurocoat - FDocument2 pagesAurocoat - FNandha NiraiNo ratings yet

- Immersion Silver Processing GuideDocument11 pagesImmersion Silver Processing GuideAzema AbdelazeemNo ratings yet

- Design Basis, Treatment Scheme & Process: Parameters Unit Inlet Outlet of FiltersDocument3 pagesDesign Basis, Treatment Scheme & Process: Parameters Unit Inlet Outlet of Filtersvinodkumar khutale100% (2)

- GLOBE 2 WAY CONTROL VALVE SERIESDocument9 pagesGLOBE 2 WAY CONTROL VALVE SERIESsam123potterNo ratings yet

- Pass I VationDocument5 pagesPass I VationiggyputtyNo ratings yet

- Salt Water Etching Printmaking IntaglioDocument5 pagesSalt Water Etching Printmaking IntaglioCary BriefNo ratings yet

- Simplifying Water: Reverse OsmosisDocument3 pagesSimplifying Water: Reverse Osmosisdurgesh008No ratings yet

- Catalog Pak KuntoDocument10 pagesCatalog Pak Kuntopt tabNo ratings yet

- Dip Zinc 7-Tank ProcessDocument3 pagesDip Zinc 7-Tank ProcessAmit Chauhan100% (1)

- 38 PDFDocument3 pages38 PDFsanjay ukalkarNo ratings yet

- Parco® Lubrite Lt-10-EnDocument9 pagesParco® Lubrite Lt-10-EnbOOhOO2012No ratings yet

- ADU Desalting PDFDocument100 pagesADU Desalting PDFHARSHA DEEPTHI GUNANA (N150434)No ratings yet

- 3.0 Electrode Paste Manufacturing: 3.1 The Chemistry of PasteDocument15 pages3.0 Electrode Paste Manufacturing: 3.1 The Chemistry of Pastepurushothamkr100% (2)

- ARTCLEAN CW Neutral Liquid Cleaner Cleans at Low TempsDocument1 pageARTCLEAN CW Neutral Liquid Cleaner Cleans at Low TempsVishwanath ShettyNo ratings yet

- Qualitek 381F No Clean Flux: Technical Specifications Technical Data SheetDocument4 pagesQualitek 381F No Clean Flux: Technical Specifications Technical Data SheetteknoartistNo ratings yet

- Electronet Equipments Pvt. LTD.: Electrode Test Pen CatalogueDocument16 pagesElectronet Equipments Pvt. LTD.: Electrode Test Pen CatalogueMuhammad Surya SulilaNo ratings yet

- SurTec-650V 0922Document2 pagesSurTec-650V 0922Jihad AL-SheikhNo ratings yet

- Water Quality Package HydroDocument2 pagesWater Quality Package HydroAnderson SantosNo ratings yet

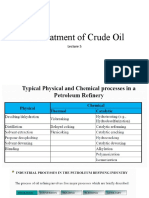

- Pre-Treatment of Crude OilDocument25 pagesPre-Treatment of Crude OilAbhisek AgarwalNo ratings yet

- 07 - FP50,FP100,FP200 Series Solenoid (先导电磁阀) (Issue 4 Feb 05)Document10 pages07 - FP50,FP100,FP200 Series Solenoid (先导电磁阀) (Issue 4 Feb 05)陆军No ratings yet

- Water Level Indicator Circuit Using Bipolar Junction TransistorFrom EverandWater Level Indicator Circuit Using Bipolar Junction TransistorRating: 4.5 out of 5 stars4.5/5 (7)

- Parts Service Brochure PDFDocument6 pagesParts Service Brochure PDFukalNo ratings yet

- ViFlow Funke GB PDFDocument8 pagesViFlow Funke GB PDFukalNo ratings yet

- Carpe Company Brochure PDFDocument8 pagesCarpe Company Brochure PDFukalNo ratings yet

- Cleaning Plate Heat Exchangers PDFDocument2 pagesCleaning Plate Heat Exchangers PDFukalNo ratings yet

- Supply Chain Management and Logistics in Construction Sample ChapterDocument29 pagesSupply Chain Management and Logistics in Construction Sample Chaptergeorgel.ghita100% (1)

- GPHE MANUAL EN - tcm11 7537 PDFDocument36 pagesGPHE MANUAL EN - tcm11 7537 PDFukalNo ratings yet

- Graham Plate Heat Exchanger ManualDocument28 pagesGraham Plate Heat Exchanger ManualFRANCISCO JOSE GARCIA IBAÑEZ100% (1)

- Plate Heat Exchanger ManualDocument20 pagesPlate Heat Exchanger ManualRosa Jasmene100% (1)

- Modeling and Design of Plate Heat ExDocument36 pagesModeling and Design of Plate Heat ExSutaTarNo ratings yet

- Robert Fox PresentationDocument27 pagesRobert Fox PresentationKapil SharmaNo ratings yet

- Aq4 Ahri Certified Plate Heat Exchanger PDFDocument2 pagesAq4 Ahri Certified Plate Heat Exchanger PDFukalNo ratings yet

- HCS Procurement Fundamentals GuideDocument17 pagesHCS Procurement Fundamentals GuideukalNo ratings yet

- PWC Supplier Relationship Management PDFDocument44 pagesPWC Supplier Relationship Management PDFDavid BusinelliNo ratings yet

- Construction Purchasing/Procurement Manager: West Coast OpportunityDocument2 pagesConstruction Purchasing/Procurement Manager: West Coast OpportunityukalNo ratings yet

- Robert Fox PresentationDocument27 pagesRobert Fox PresentationKapil SharmaNo ratings yet

- Lic Fredrik Olsson Friblick PDFDocument170 pagesLic Fredrik Olsson Friblick PDFukalNo ratings yet

- Engineering Procurement & Construction Making India Brick by Brick PDFDocument96 pagesEngineering Procurement & Construction Making India Brick by Brick PDFEli ThomasNo ratings yet

- How To Break Bad Habits: Ultimate Guide To Good Habits: Stephanie ChristopherDocument13 pagesHow To Break Bad Habits: Ultimate Guide To Good Habits: Stephanie ChristopherukalNo ratings yet

- Building and Construction Procurement GuideDocument65 pagesBuilding and Construction Procurement GuideShirley FarraceNo ratings yet

- Lectroplating Process PDFDocument32 pagesLectroplating Process PDFukalNo ratings yet

- Manual "Procurement Strategy in Construction": Leonardo Da Vinci Toi Project Train-To-CapDocument111 pagesManual "Procurement Strategy in Construction": Leonardo Da Vinci Toi Project Train-To-CapukalNo ratings yet

- 97 YokeDocument3 pages97 YokeclaupyNo ratings yet

- Design For Oil& Greese TrapDocument11 pagesDesign For Oil& Greese Trapmirza_adil99100% (1)

- Change Your Thoughts, Change Your LifeDocument276 pagesChange Your Thoughts, Change Your Lifesaya2977100% (2)

- Sector Specific Best Practice Guide: Best Practices in Metal Plating and FinishingDocument18 pagesSector Specific Best Practice Guide: Best Practices in Metal Plating and Finishingchemikas8389No ratings yet

- Ferrolex Additive No 1 2Document3 pagesFerrolex Additive No 1 2ukalNo ratings yet

- 218 1197 1 PBDocument9 pages218 1197 1 PBArus EdoNo ratings yet

- Palgrave Handbook of Research in Historical Culture and EducationDocument847 pagesPalgrave Handbook of Research in Historical Culture and EducationGonzalo Garcia100% (1)

- Credit Risk Management Practice in Private Banks Case Study Bank of AbyssiniaDocument85 pagesCredit Risk Management Practice in Private Banks Case Study Bank of AbyssiniaamogneNo ratings yet

- SQL 1: Basic Statements: Yufei TaoDocument24 pagesSQL 1: Basic Statements: Yufei TaoHui Ka HoNo ratings yet

- Manual - Sentron Pac Profibus Do Modul - 2009 02 - en PDFDocument106 pagesManual - Sentron Pac Profibus Do Modul - 2009 02 - en PDFDante Renee Mendoza DelgadoNo ratings yet

- Seminar #22 Vocabury For Speaking PracticeDocument7 pagesSeminar #22 Vocabury For Speaking PracticeOyun-erdene ErdenebilegNo ratings yet

- Policies and Regulations On EV Charging in India PPT KrishnaDocument9 pagesPolicies and Regulations On EV Charging in India PPT KrishnaSonal ChoudharyNo ratings yet

- Practical LPM-122Document31 pagesPractical LPM-122anon_251667476No ratings yet

- City of Brescia - Map - WWW - Bresciatourism.itDocument1 pageCity of Brescia - Map - WWW - Bresciatourism.itBrescia TourismNo ratings yet

- Joyful Living: (Based On Chapter 13: Advaitananda Prakaranam of Panchadashi of Sri Vidyaranya Swami)Document11 pagesJoyful Living: (Based On Chapter 13: Advaitananda Prakaranam of Panchadashi of Sri Vidyaranya Swami)Raja Subramaniyan100% (1)

- Raychem Price ListDocument48 pagesRaychem Price ListramshivvermaNo ratings yet

- Critique On A Film Director's Approach To Managing CreativityDocument2 pagesCritique On A Film Director's Approach To Managing CreativityDax GaffudNo ratings yet

- Samsung 55 Inch LCD LED 8000 User ManualDocument290 pagesSamsung 55 Inch LCD LED 8000 User ManuallakedipperNo ratings yet

- LLM DissertationDocument94 pagesLLM Dissertationjasminjajarefe100% (1)

- Obsolescence 2. Book Value 3. Depreciation 4. Depletion EtcDocument9 pagesObsolescence 2. Book Value 3. Depreciation 4. Depletion EtcKHAN AQSANo ratings yet

- Relay Coordination Using Digsilent PowerFactoryDocument12 pagesRelay Coordination Using Digsilent PowerFactoryutshab.ghosh2023No ratings yet

- Ipo Exam Revised SyllabusDocument1 pageIpo Exam Revised Syllabusজ্যোতিৰ্ময় বসুমতাৰীNo ratings yet

- Solr 3000: Special Operations Long Range Oxygen Supply 3,000 PsigDocument2 pagesSolr 3000: Special Operations Long Range Oxygen Supply 3,000 Psigмар'ян коб'ялковськийNo ratings yet

- K Series Parts List - 091228Document25 pagesK Series Parts List - 091228AstraluxNo ratings yet

- Complete Hemi Sync Gateway Experience ManualDocument43 pagesComplete Hemi Sync Gateway Experience Manualapi-385433292% (92)

- PGP TutorialDocument21 pagesPGP TutorialSabri AllaniNo ratings yet

- Fundamental Managerial Accounting Concepts 9th Edition Edmonds Solutions ManualDocument35 pagesFundamental Managerial Accounting Concepts 9th Edition Edmonds Solutions ManualDrMichelleHutchinsonegniq100% (15)

- The Bloodless GospelDocument7 pagesThe Bloodless GospelKJVNo ratings yet

- Hotel Design Planning and DevelopmentDocument30 pagesHotel Design Planning and DevelopmentTio Yogatma Yudha14% (7)

- Vintage Style Indonesian Geography Lesson For High School by SlidesgoDocument56 pagesVintage Style Indonesian Geography Lesson For High School by Slidesgoohd InstalasicontrolNo ratings yet

- Mole Concept - DPP 09 (Of Lec 13) - Yakeen 2.0 2024 (Legend)Document3 pagesMole Concept - DPP 09 (Of Lec 13) - Yakeen 2.0 2024 (Legend)Romeshchandra Class X-CNo ratings yet

- Conserve O Gram: Understanding Histograms For Digital PhotographyDocument4 pagesConserve O Gram: Understanding Histograms For Digital PhotographyErden SizgekNo ratings yet

- Rescue Triangle PDFDocument18 pagesRescue Triangle PDFrabas_No ratings yet

- The Etteilla Tarot: Majors & Minors MeaningsDocument36 pagesThe Etteilla Tarot: Majors & Minors MeaningsRowan G100% (1)

- IT SyllabusDocument3 pagesIT SyllabusNeilKumarNo ratings yet