Professional Documents

Culture Documents

UT Testing-Section 4

Uploaded by

Charlie Chong100%(1)100% found this document useful (1 vote)

248 views146 pagesPulse-echo ultrasonic measurements can determine the location of a discontinuity in a part or structure. The two-way transit time measured is divided by two to account for the down-and-back travel path and multiplied by the velocity of sound in the test material. A wide variety of transducers with various acoustic characteristics have been developed to meet the needs of industrial applications.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPulse-echo ultrasonic measurements can determine the location of a discontinuity in a part or structure. The two-way transit time measured is divided by two to account for the down-and-back travel path and multiplied by the velocity of sound in the test material. A wide variety of transducers with various acoustic characteristics have been developed to meet the needs of industrial applications.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

248 views146 pagesUT Testing-Section 4

Uploaded by

Charlie ChongPulse-echo ultrasonic measurements can determine the location of a discontinuity in a part or structure. The two-way transit time measured is divided by two to account for the down-and-back travel path and multiplied by the velocity of sound in the test material. A wide variety of transducers with various acoustic characteristics have been developed to meet the needs of industrial applications.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 146

Section 4: Measurement Techniques

Content: Section 4: Measurement Techniques

4.1: Normal Beam Inspection

4.2: Angle Beams

4.3: Reflector Sizing

4.4: Automated Scanning

4.5: Precision Velocity Measurements

4.6: Attenuation Measurements

4.7: Spread Spectrum Ultrasonics

4.8: Signal Processing Techniques

4.9: Flaw Reconstruction Techniques

4.10: Scanning Methods

4.11: Scanning Patterns

4.12: Pulse Repetition Rate and Penetration

4.13: Interferences & Non Relevant Indications

4.14: Exercises

Expert at works

4.1: Normal Beam Inspection

Pulse-echo ultrasonic measurements can determine the location of a

discontinuity in a part or structure by accurately measuring the time required

for a short ultrasonic pulse generated by a transducer to travel through a

thickness of material, reflect from the back or the surface of a discontinuity,

and be returned to the transducer. In most applications, this time interval is a

few microseconds or less. The two-way transit time measured is divided by

two to account for the down-and-back travel path and multiplied by the

velocity of sound in the test material. The result is expressed in the well-

known relationship:

d = vt/2 or v = 2d/t

where d is the distance from the surface to the discontinuity in the test piece,

v is the velocity of sound waves in the material, and t is the measured

round-trip transit time.

d

2

= vt

d

1

= vt

= d

1

+d

2

2vt 2vt

A-Scan

A Scan

http://www.ndt-ed.org/EducationResources/CommunityCollege/Ultrasonics/MeasurementTech/applet_4_1/applet_4_1.htm

Precision ultrasonic thickness gages usually operate at frequencies between

500 kHz and 100 MHz, by means of piezoelectric transducers that generate

bursts of sound waves when excited by electrical pulses. A wide variety of

transducers with various acoustic characteristics have been developed to

meet the needs of industrial applications. Typically,

1. lower frequencies are used to optimize penetration when measuring thick,

highly attenuating or highly scattering materials,

2. while higher frequencies will be recommended to optimize resolution in

thinner, non-attenuating, non-scattering materials.

0.5 MHz ~ 100 MHz

In thickness gauging, ultrasonic techniques permit quick and reliable

measurement of thickness without requiring access to both sides of a part.

Accuracy's as high as 1 micron or 0.0001 inch can be achieved in some

applications. It is possible to measure most engineering materials

ultrasonically, including metals, plastic, ceramics, composites, epoxies, and

glass as well as liquid levels and the thickness of certain biological specimens.

On-line or in-process measurement of extruded plastics or rolled metal often

is possible, as is measurements of single layers or coatings in multilayer

materials. Modern handheld gages are simple to use and very reliable.

4.2: Angle Beams I

Angle Beam Transducers and wedges are typically used to introduce a

refracted shear wave into the test material. An angled sound path allows the

sound beam to come in from the side, thereby improving detectability of flaws

in and around welded areas.

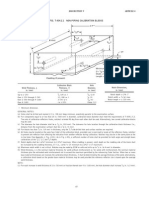

= Angle of reflection, T=Material thickness, S= Sound path,

Surface distance = Sin x S, Depth= Cos x S

A-Scan

http://www.ndt-ed.org/EducationResources/CommunityCollege/Ultrasonics/MeasurementTech/applet_4_2/applet_4_2.htm

Angle Beam Transducers and wedges are typically used to introduce a

refracted shear wave into the test material. The geometry of the sample

below allows the sound beam to be reflected from the back wall to improve

detectability of flaws in and around welded areas.

= Angle of reflection, T=Material thickness, S= Sound path,

Skip = 2(T x Tan), Leg = T/Cos, V Path = 2 x Leg

A-Scan

http://www.ndt-ed.org/EducationResources/CommunityCollege/Ultrasonics/MeasurementTech/applet_4_3/applet_4_3.htm

Flaw Location and Echo Display

Flaw Location and Echo Display

Flaw Location and Echo Display

Flaw Location and Echo Display

Flaw Location and Echo Display

Flaw Location and Echo Display

Dead Zone

Near Surface Detectability with Angle Beam Transducer

Flaw Location

Flaw Location with Angle Beam Transducer

Flaw Location with Angle Beam Transducer

Flaw Location with Angle Beam Transducer

Flaw Location with Angle Beam Transducer

Why angle beam assemblies are used

Cracks or other discontinuities perpendicular to the surface of a test piece, or

tilted with respect to that surface, are usually invisible with straight beam test

techniques because of their orientation with respect to the sound beam.

Perpendicular cracks do not reflect any significant amount of sound energy

from a straight beam because the beam is looking at a thin edge that is much

smaller than the wavelength, and tilted cracks may not reflect any energy

back in the direction of the transducer. This situation can occur in many types

of welds, in structural metal parts, and in many other critical components. An

angle beam assembly directs sound energy into the test piece at a selected

angle. A perpendicular crack will reflect angled sound energy along a path

that is commonly referred to as a corner trap, as seen in the illustration below.

http://www.olympus-ims.com/en/applications/angle-beam-transducers/

The angled sound beam is highly sensitive to cracks perpendicular to the far

surface of the test piece (first leg test) or, after bouncing off the far side, to

cracks perpendicular to the coupling surface (second leg test). A variety of

specific beam angles and probe positions are used to accommodate different

part geometries and flaw types. In the case of angled discontinuities, a

properly selected angle beam assembly can direct sound at a favorable angle

for reflection back to the transducer.

http://www.olympus-ims.com/en/applications/angle-beam-transducers/

How they work -- Snell's Law

A sound beam that hits a surface at perpendicular incidence will reflect

straight back. A sound beam that hits a surface at an angle will reflect forward

at the same angle.

Sound energy that is transmitted from one material to another bends in

accordance with Snell's Law of refraction. Refraction is the bending of a

sound beam (or any other wave) when it passes through a boundary between

two materials of different velocities. A beam that is traveling straight will

continue in a straight direction, but a beam that strikes a boundary at an angle

will be bent according to the formula:

Typical angle beam assemblies make use of mode conversion and Snell's

Law to generate a shear wave at a selected angle (most commonly 30, 45,

60, or 70 degrees) in the test piece. As the angle of an incident

longitudinal wave with respect to a surface increases, an increasing

portion of the sound energy is converted to a shear wave in the second

material, and if the angle is high enough, all of the energy in the second

material will be in the form of shear waves.

There are two advantages to designing common angle beams to take

advantage of this mode conversion phenomenon:

(1) First, energy transfer is more efficient at the incident angles that

generate shear waves in steel and similar materials.

(2) Second, minimum flaw size resolution is improved through the use of

shear waves, since at a given frequency, the wavelength of a shear

wave is approximately 60% the wavelength of a comparable longitudinal

wave, and minimum flaw size resolution increases as the wavelength of

a sound beam gets smaller.

Selecting the right angle beam assembly

The parameters that affect angle beam performance include not only the

(1)beam angle generated by the wedge, but also (2) transducer frequency

and (3) element size. The optimum beam angle will generally be governed

by the geometry of the test piece and the orientation of the discontinuities

that the test is intended to find. Transducer frequency affects penetration

and flaw resolution:

1. As frequency increases, the distance the sound wave will travel in a given

material decreases, but resolution of small discontinuities improves.

2. As frequency decreases, the distance the sound wave will travel increases

but the minimum detectable flaw size will become larger.

3. Similarly, larger element sizes may decrease inspection time by increasing

coverage area, but the reflected echo amplitude from small discontinuities

will decrease. Smaller element sizes will increase reflection amplitude from

small discontinuities, but the inspection may take longer because the

smaller beam covers less area.

These conflicting factors must be balanced in any given application, based on

specific test requirements.

Contoured wedges

The IIW recommends the use of a contoured wedge whenever the gap

between the wedge and the test surface exceeds 0.5 mm (approximately

0.020 in.). Under this guideline, a contoured wedge should be used whenever

part radius is less than the square of a wedge dimension (length or width)

divided by four:

where

R = radius of test surface

W = width of wedge if testing in axial orientation, length of wedge if testing in

circumferential orientation

Of course switching to a small wedge, if possible within the parameters of

inspection requirements, will improve coupling on curved surfaces. As a

practical matter, contouring should be considered whenever signal strength

diminishes or couplant noise increases to a point where the reliability of an

inspection is impaired.

Focused dual element angle beams

The vast majority of angle beam assemblies use single element, unfocused

transducers. However, in some tests involving highly attenuating or scattering

materials such as coarse grain cast stainless steel, focused dual element

angle beams are useful. Because they have separate transmitting and

receiving elements, dual element transducers can typically be driven at higher

excitation energies without noise problems associated with ringdown or

wedge noise. Focusing permits a higher concentration of sound energy at a

selected depth within the test piece, increasing sensitivity to discontinuities in

that region.

High temperature wedges

Standard angle beam assemblies are designed for use at normal

environmental temperatures only. For situations where metal must be

inspeced at elevated temperature, special high temperature wedges are

available. Some of these wedges will tolerate brief contact with surfaces as

hot as 480 C or 900 F. However, it is important to note that high

temperature wedges require special attention with regard to the sound path

they generate. With any high temperature wedge, sound velocity in the wedge

material will decrease as it heats up, and thus the refracted angle in metals

will increase as the wedge heats up. If this is of concern in a given test,

refracted angle should be verified at actual operating temperature. As a

practical matter, thermal variations during testing will often make precise

determination of the actual refracted angle difficult.

Surfaces as hot as 480 C / 900 F

http://www.namicon.com/products.xpg?catid=84&prodid=43

snap-in

threaded

steel with a shear wave velocity of approximately 3,250 M/S or 0.1280 in/uS.

4.3: Reflector Sizing

There are many sizing methods, these include:

4.3.1 Crack Tip Diffraction

When the geometry of the part is relatively uncomplicated and the orientation

of a flaw is well known, the length (a) of a crack can be determined by a

technique known as tip diffraction. One common application of the tip

diffraction technique is to determine the length of a crack originating from on

the backside of a flat plate as shown below. In this case, when an angle beam

transducer is scanned over the area of the flaw, the principle echo comes

from the base of the crack to locate the position of the flaw (Image 1). A

second, much weaker echo comes from the tip of the crack and since the

distance traveled by the ultrasound is less, the second signal appears earlier

in time on the scope (Image 2).

Crack Tip Diffraction Methods

No animation.

Crack height (a) is a function of the ultrasound velocity (v) in the material, the

incident angle (Q2) and the difference in arrival times between the two signal

(dt). Since the incident angle and the thickness of the material is the same in

both measurements, two similar right triangle are formed such that one can

be overlayed on the other. A third similar right triangle is made, which is

comprised on the crack, the length dt and the angle Q2. The variable dt is

really the difference in time but can easily be converted to a distance by

dividing the time in half (to get the one-way travel time) and multiplying this

value by the velocity of the sound in the material. Using trigonometry an

equation for estimating crack height from these variables can be derived as

shown below.

Crack Tip Diffraction Method

The equation is complete once

distance dt is calculated by dividing

the difference in time between the

two signals (dt) by two and

multiplying this value by the sound

velocity.

4.3.2 6 dB Drop Sizing-

For Large Reflector (greater than beam width), i.e. there is no BWE.

6 dB Drop Method

6 dB Drop Method

6 dB Drop Method

www.youtube.com/embed/hsR17WA3nHg

6 dB Drop Method

4.3.3 The 20 dB drop sizing method

We can use a beam plot to find the edge of a defect by using the edge of

the sound beam.

If we know the width of a beam at a certain distance from the crystal, we

can mark the distance across a defect from where the extreme edges of

the beam touch each end of the defect and then subtract the beamwidth to

get the defect size.

When the signal from the defect drops by 20dB from its peak, we judge

that the edge of the beam is just touching the end of the defect. We can

find the width of the sound beam at that range by consulting the beam plot

that we have made

Note: The peak of the defect is normally taken as being the last peak on

the screen before the probe goes off the end of the defect, not necessarily

the maximum signal from a defect.

20 dB Drop Method

20 dB Drop Sizing- For Small Reflector (smaller than beam width).

To use this method the transducer beam width need to be first determined.

Construction of a beam edge plot -20dB Normal Beam

Find the hole at a depth of 13mm on an IOW block with a 0 degree probe and

maximise the signal. Move the probe until you get the highest signal you

can from the hole, then turn the signal to FSH using gain. Mark the position

of the middle of the probe on the side of the block.

Move the probe to one side until the signal drops to 10%FSH (-20dB) and

mark the centre of the probe on the side of the block.

Move the probe to the other side of the hole until the signal drops to

10%FSH (-20dB) and mark the centre of the probe on the block.

Use the distances between the marks on the block to plot the beam on a

piece of graph paper. Measure 13mm depth on the paper then mark the

distances of the probe centre at -20dB from the beam centre at 100%FSH

on either side.

Now find the 25mm hole and maximise the signal, turning it to 100%FSH.

Move the probe to either side of the hole marking the centre of the probe

on the side of the block where the signal drops by 20dB.

Measure 25mm on the paper and use the distances on the block to plot the

beam dimensions at 25mm.

Repeat using the 32mm hole. J oin up the points marking the probe centre

at 20dB to obtain a beam plot.

Note that we have only drawn the beam width in one plane, so the probe

must be marked accordingly and used to measure defects in this plane.

We use knowledge of the beam spread to size defects, find the edges and

hence their width, length and sometimes orientation.

Construction of a beam edge plot -20dB Angle Beam

4.3.4 Equalization Back Wall Sizing- The probe moving off the edges of

the reflector until the amplitude is equal to the rising BWE

4.3.5 Maximum Amplitude Techniques

The technique is used for small reflector. The probe moving off the edges of

the reflector until the amplitude is maximum and the line joining the boundary

is the size of reflector cluster.

4.3.6 The DGS Method

Distance Gain Size Method. The technique is used to find the equivalent

reflector size by comparing the gain between the flaw and the known size

reflector.

4.4: Automated Scanning

Ultrasonic scanning systems are used for automated data acquisition and

imaging. They typically integrate a ultrasonic instrumentation, a scanning

bridge, and computer controls. The signal strength and/or the time-of-flight of

the signal is measured for every point in the scan plan. The value of the data

is plotted using colors or shades of gray to produce detailed images of the

surface or internal features of a component. Systems are usually capable of

displaying the data in A-, B- and C-scan modes simultaneously. With any

ultrasonic scanning system there are two factors to consider:

how to generate and receive the ultrasound.

how to scan the transducer(s) with respect to the part being inspected.

Automatic Scanning

The most common ultrasonic scanning systems involve the use of an

immersion tank as shown in the image above. The ultrasonic transducer and

the part are placed under water so that consistent coupling is maintained by

the water path as the transducer or part is moved within the tank. However,

scanning systems come in a large variety of configurations to meet specific

inspection needs. In the image to the right, an engineer aligns the heads of a

squirter system that uses a through-transmission technique to inspect aircraft

composite structures. In this system, the ultrasound travels through columns

of forced water which are scanned about the part with a robotic system. A

variation of the squirter system is the "Dripless Bubbler" scanning system,

which is discussed below.

Dripless Bubbler

It is often desirable to eliminate the need for the water coupling and a number

of state-of-the-art UT scanning systems have done this. Laser ultrasonic

systems use laser beams to generate the ultrasound and collect the resulting

signals in an noncontact mode. Advances in transducer technology has lead

to the development of an inspection technique known as air-coupled

ultrasonic inspection. These systems are capable of sending ultrasonic

energy through air and getting enough energy into the part to have a useable

signal. These system typically use a through-transmission technique since

reflected energy from discontinuities are too weak to detect.

The second major consideration is how to scan the transducer(s) with respect

to the part being inspected. When the sample being inspected has a flat

surface, a simple raster-scan can be performed. If the sample is cylindrical, a

turntable can be used to turn the sample while the transducer is held

stationary or scanned in the axial direction of the cylinder. When the sample

is irregular shaped, scanning becomes more difficult. As illustrated in the

beam modeling animation, curved surface can steer, focus and defocus the

ultrasonic beam. For inspection applications involving parts having complex

curvatures, scanning systems capable of performing contour following are

usually necessary.

http://www.ndt-ed.org/EducationResources/CommunityCollege/Ultrasonics/Graphics/Flash/AppleScan/Apple2.swf

4.5: Precision Velocity Measurements

Changes in ultrasonic wave propagation speed, along with energy losses,

from interactions with a materials microstructures are often used to

nondestructively gain information about a material's properties.

Measurements of sound velocity and ultrasonic wave attenuation can be

related to the elastic properties that can be used to characterize the texture of

polycrystalline metals. These measurements enable industry to replace

destructive microscopic inspections with nondestructive methods.

Of interest in velocity measurements are longitudinal wave, which propagate

in gases, liquids, and solids. In solids, also of interest are transverse (shear)

waves. The longitudinal velocity is independent of sample geometry when the

dimensions at right angles to the beam are large compared to the beam area

and wavelength. The transverse velocity is affected little by the physical

dimensions of the sample.

Pulse-Echo and Pulse-Echo-Overlap Methods

Rough ultrasonic velocity measurements are as simple as measuring the time

it takes for a pulse of ultrasound to travel from one transducer to another

(pitch-catch) or return to the same transducer (pulse-echo). Another method

is to compare the phase of the detected sound wave with a reference signal:

slight changes in the transducer separation are seen as slight phase changes,

from which the sound velocity can be calculated. These methods are suitable

for estimating acoustic velocity to about 1 part in 100. Standard practice for

measuring velocity in materials is detailed in ASTM E494.

ASTM E494 - 10

Measuring Ultrasonic Velocity in Materials

Active Standard ASTM E494 | Developed by Subcommittee: E07.06

Book of Standards Volume: 03.03

Precision Velocity Measurements (using EMATs)

Electromagnetic-acoustic transducers (EMAT) generate ultrasound in the

material being investigated. When a wire or coil is placed near to the surface

of an electrically conducting object and is driven by a current at the desired

ultrasonic frequency, eddy currents will be induced in a near surface region. If

a static magnetic field is also present, these currents will experience Lorentz

forces of the form

F = J x B

where F is a body force per unit volume, J is the induced dynamic current

density, and B is the static magnetic induction.

EMATs

http://www.resonic.com/emar_how_it_works.html

http://www.resonic.com/error%20scan.swf

http://www.resonic.com/scan2.swf

The most important application of EMATs has been in nondestructive

evaluation (NDE) applications such as flaw detection or material property

characterization. Couplant free transduction allows operation without contact

at elevated temperatures and in remote locations. The coil and magnet

structure can also be designed to excite complex wave patterns and

polarizations that would be difficult to realize with fluid coupled piezoelectric

probes. In the inference of material properties from precise velocity or

attenuation measurements, use of EMATs can eliminate errors associated

with couplant variation, particularly in contact measurements.

Differential velocity is measured using a T1-T2---R fixed array of EMAT

transducer at 0, 45, 90 or 0, 90 relative rotational directions depending on

device configuration:

EMAT Driver Frequency: 450-600 KHz (nominal)

Sampling Period: 100 ns

Time Measurement Accuracy:

-- Resolution 0.1 ns

-- Accuracy required for less than 2 KSI Stress Measurements:

Variance 2.47 ns

-- Accuracy required for texture: Variance 10.0 Ns

------ W440 < 3.72E-5

------ W420 < 1.47E-4

------ W400 < 2.38E-4

Time Measurement Technique

Fourier Transform-Phase-Slope determination of delta time between received

RF bursts (T2-R) - (T1-R), where T2 and T1 EMATs are driven in series to

eliminate differential phase shift due to probe liftoff.

Slope of the phase is determined by linear regression of weighted data points

within the signal bandwidth and a weighted y-intercept. The accuracy obtained

with this method can exceed one part in one hundred thousand (1:100,000).

4.6: Attenuation Measurements

Ultrasonic wave propagation is influenced by the microstructure of the

material through which it propagates. The velocity of the ultrasonic waves is

influenced by the elastic moduli and the density of the material, which in turn

are mainly governed by the amount of various phases present and the

damage in the material. Ultrasonic attenuation, which is the sumof the

(1)absorption and the (2)scattering, is mainly dependent upon the damping

capacity and scattering from the grain boundary in the material. However, to

fully characterize the attenuation required knowledge of a large number of

thermo-physical parameters that in practice are hard to quantify.

U

t

A

o

A

A

o

A

U

t

A

o

A

U

t

A

o

A

A

o

U

t

A

A

o

A

o

U

t

A

o

A

U

t

A

o

Relative measurements such as the change of attenuation and simple

qualitative tests are easier to make than absolute measure. Relative

attenuation measurements can be made by examining the exponential decay

of multiple back surface reflections. However, significant variations in

microstructural characteristics and mechanical properties often produce only

a relatively small change in wave velocity and attenuation. Absolute

measurements of attenuation are very difficult to obtain because the echo

amplitude depends on factors in addition to amplitude.

The most common method used to get quantitative results is to use an

ultrasonic source and detector transducer separated by a known distance. By

varying the separation distance, the attenuation can be measured from the

changes in the amplitude. To get accurate results, the influence of coupling

conditions must be carefully addressed. To overcome the problems related to

conventional ultrasonic attenuation measurements, ultrasonic spectral

parameters for frequency-dependent attenuation measurements, which are

independent from coupling conditions are also used. For example, the ratio of

the amplitudes of higher frequency peak to the lower frequency peak, has

been used for microstructural characterization of some materials.

Attenuation:

A

U

t

A

o

Attenuation:

4.7: Spread Spectrum Ultrasonics

Spread spectrum ultrasonics makes use of the correlation of continuous

signals rather than pulse-echo or pitch-catch techniques.

Spread spectrum ultrasonics is a patented new broad band spread-spectrum

ultrasonic nondestructive evaluation method. In conventional ultrasonics, a

pulse or tone burst is transmitted, then received echoes or through-

transmission signals are received and analyzed.

In spread spectrum ultrasonics, encoded sound is continuously transmitted

into the part or structure being tested. Instead of receiving echoes, spread

spectrum ultrasonics generates an acoustic correlation signature having a

one-to-one correspondence with the acoustic state of the part or structure (in

its environment) at the instant of the measurement. In its simplest

embodiment, the acoustic correlation signature is generated by cross

correlating an encoding sequence, with suitable cross and auto correlation

properties, transmitted into a part (structure) with received signals returning

from the part (structure).

Section of bi-phase modulated spread spectrum ultrasonic waveform

Multiple probes may be used to ensure that acoustic energy is propagated

through all critical volumes of the structure. Triangulation may be incorporated

with multiple probes to locate regions of detected distress. Spread spectrum

ultrasonics can achieve very high sensitivity to acoustic propagation changes

with a low level of energy.

Spread Spectrum UT

Two significant applications of Spread Spectrum Ultrasonics are:

1. Large Structures that allow ultrasonic transducers to be "permanently"

affixed to the structures, eliminating variations in transducer registration

and couplant. Comparisons with subsequent acoustic correlation

signatures can be used to monitor critical structures such as fracture

critical bridge girders. In environments where structures experience a

great many variables such as temperature, load, vibration, or

environmental coupling, it is necessary to filter out these effects to obtain

the correct measurements of defects.

In the example below, simulated defects were created by setting a couple of

steel blocks on the top of the bridge girder.

Spread Spectrum UT

2. Piece-part assembly line environments where transducers and couplant

may be precisely controlled, eliminating significant variations in transducer

registration and couplant. Acoustic correlation signatures may be statistically

compared to an ensemble of known "good" parts for sorting or

accepting/rejecting criteria in a piece-part assembly line environment.

Impurities in the incoming steel used to forge piece parts may result in sulfite

stringer inclusions. In this next example simulated defects were created by

placing a magnetized steel wire on the surface of a small steel cylindrical

piston used in hydraulic transmissions.

Two discrimination technique are tested here, which are SUF-1 and SUF-2,

with the latter giving the best discrimination between defect conditions. The

important point being that spread spectrum ultrasonics can be extremely

sensitive to the acoustic state of a part or structure being tested, and

therefore, is a good ultrasonic candidate for testing and monitoring, especially

where scanning is economic unfeasible.

EMATs with Spread Spectrum Ultrasonic

http://www.resonic.com/emar_how_it_works.html

http://www.resonic.com/error%20scan.swf

http://www.resonic.com/scan2.swf

4.8: Signal Processing Techniques

Signal processing involves techniques that improve our understanding of

information contained in received ultrasonic data. Normally, when a signal is

measured with an oscilloscope, it is viewed in the time domain (vertical axis is

amplitude or voltage and the horizontal axis is time). For many signals, this is

the most logical and intuitiveway to view them. Simple signal

processing often involves the use of gates to isolate the signal of interest or

frequency filters to smooth or reject unwanted frequencies.

When the frequency content of the signal is of interest, it makes sense to view

the signal graph in the frequency domain. In the frequency domain, the

vertical axis is still voltage but the horizontal axis is frequency.

Display

Time/Magnitude

domain

Frequency

/Magnitude domain

The frequency domain display shows how much of the signal's energy is

present as a function of frequency. For a simple signal such as a sine wave,

the frequency domain representation does not usually show us much

additional information. However, with more complex signals, such as the

response of a broad bandwidth transducer, the frequency domain gives a

more useful view of the signal.

Fourier theory says that any complex periodic waveform can be decomposed

into a set of sinusoids with different amplitudes, frequencies and phases. The

process of doing this is called Fourier Analysis, and the result is a set of

amplitudes, phases, and frequencies for each of the sinusoids that makes up

the complex waveform. Adding these sinusoids together again will reproduce

exactly the original waveform. A plot of the frequency or phase of a sinusoid

against amplitude is called a spectrum.

Fourier Analysis

Fourier Analysis

Fourier Analysis

The following Fourier J ava applet, adapted with permission of Stanford

University, allows the user to manipulate discrete time domain or frequency

domain components and see the relationships between signals in time and

frequency domains.

The top row (light blue color) represents the real and imaginary parts of the

time domain. Normally the imaginary part of the time domain signal is

identically zero.

The middle row (peach color) represents the the real and imaginary parts of

the frequency domain.

The bottom row (light green color) represents the magnitude (amplitude) and

phase of the frequency domain signal. Magnitude is the square root of the

sum of the squares of the real and imaginary components. Phase is the

angular relationship of the real and imaginary components. Ultrasonic

transducer manufactures often provide plots of both time domain and

frequency domain (magnitude) signals characteristic of each transducer. Use

this applet to explore the relationship between time and frequency domains.

Fourier Analysis

Exercise: Try replicating time domain signal in the upper left box with a

pattern similar to the image on the right. Note the resulting bandwidth in the

frequency domain (magnitude) in the lower left box. Next try changing the

magnitude, perhaps more of a "mountain" shape tapering to zero. Note that

"narrowing" the magnitude, results in more cycles in the time domain signal.

4.9: Flaw Reconstruction Techniques

In nondestructive evaluation of structural material defects, the size, shape,

and orientation are important flaw parameters in structural integrity

assessment. To illustrate flaw reconstruction, a multiviewing ultrasonic

transducer system is shown below. A single probe moved sequentially to

achieve different perspectives would work equally as well. The apparatus and

the signal-processing algorithms were specifically designed at the Center for

Nondestructive Evaluation to make use of the theoretical developments in

elastic wave scattering in the long and intermediate wavelength regime.

4.10: Scanning Methods

4.10.1 Pulse Echo Method

Pulse Echo Method

Amplitude loss: Inverse Square Law

Influence of Shadow on axial defects

Influence of reflector orientation on signal

Influence of reflector size on signal

4.10.2 Pitch-Catch Methods

Advantage:

Sensitive to near surface defect

Capable of penetrating thicker material due to pitch-catch mode.

Disadvantage:

It measures only sound energy loss at the receiver, without giving details

information of location.

Pitch-Catch Methods- Tandem

Pitch-Catch Methods- Tandem

Pitch-Catch Methods- Through Transmission

Video on Through Transmission Methods

www.youtube.com/embed/bRgCLb2cDU4?list=UUSOUDD4-FPV4tzqvUnquwXQ

4.10.3 Immersion Methods

For immersion testing of steel and aluminum in water, the water path shall be

at least 1for every 4thickness of the specimen (or of specimen thickness

minimum). If the transducer is too close, the 2

nd

front reflection will appeared

between the 1

st

front reflection and the 1

st

backwall echo and this may be

wrong interpreted as discontinuity.

Immersion Methods- The water path shall be of specimen thickness

minimum.

Minimum + [ (?)]

Q. In immersion testing, to remove the second water reflection (2nd entry

surface signal) from between the entry surface signal and the first back

reflection, you should:

a) Increase repetition rate

b) Decrease frequency

c) Decrease sweep length

d) Increase water depth

Immersion Methods- The water path shall be of specimen thickness

minimum. (plus 6mm)

Minimum + [ (?)]

Modified Immersion Methods- Bubbler Chamber

Modified Immersion Methods Irrigation Dam

Angle Beam Immersion Methods

Note the small front surface reflection. This due to the inclined incident angle

reflected away from the transducer.

Angle Beam Immersion Methods- Pipe & Tubing Testing

.

Angle Beam Immersion Methods- Weld Testing

Other Reading (Olympus)- Angle Beam Immersion Methods

Immersion transducers offer three major advantages over contact transducers:

1. Uniform coupling reduces sensitivity variations.

2. Reduction in scan time due to automated scanning.

3. Focusing of immersion transducers increases sensitivity to small reflectors.

Focusing Configurations

Immersion transducers are available in three different configurations:

unfocused (flat),

spherically (spot) focused, and

cylindrically (line) focused.

Focusing is accomplished by either the addition of a lens or by

curving the element itself. The addition of a lens is the most

common way to focus a transducer.

Cylindrical

Spherical

An unfocused transducer may be used in general applications or for

penetration of thick materials. A spherically focused transducer is commonly

used to improve sensitivity to small flaws and a cylindrical focus is typically

used in the inspection of tubing or bar stock. Examples of spherical and

cylindrical focusing are shown in Figure (17) below.

Unfocused transducer

By definition, the focal length of a transducer is the distance from the face

of the transducer to the point in the sound field where the signal with the

maximum amplitude is located. In an unfocused transducer, this occurs at a

distance from the face of the transducer which is approximately equivalent

to the transducers near field length. Because the last signal maximum occurs

at a distance equivalent to the near field, a transducer, by definition, can not

be acoustically focused at a distance greater than its near field.

Focus may be designated in three ways:

FPF (Flat Plate Focus) - For an FPF focus, the lens is designed to produce

a maximum pulse/echo response from a flat plate target at the distance

indicated by the focal length

PTF (Point Target Focus) - For a PTF focus, the lens is designed to produce

a maximum pulse/echo response from a small ball target at the distance

indicated by the focal length

OLF (Optical Limit Focus) - The OLF designation indicates that the lens is

designed according to the lens makers formula from physical

optics and without reference to any operational definition of

focal length. The OLF designation describes the lens and

ignores diffraction effects.

Video on Immersion Testing

www.youtube.com/embed/W07-Z9at=UUSOUDD4-FPV4tzqvUnquwXQ

Q1: Which of the following scanning methods could be classified as an

immersion type test?

A. Tank in which the transducer and test piece are immersed

B. Squirter bubbler method in which the sound is transmitted in a column of

flowing water

C. Scanning with a wheel-type transducer with the transducer inside a liquid

filled tire

D. All of the above

Q2: In an immersion test of a piece of steel or aluminum, the water distance

appears on the display as a fairly wide space between the initial pulse and

the front surface reflection because of:

A. Reduced velocity of sound in water as compared to test specimen

B. Increased velocity of sound in water as compared to test specimen

C. Temperature of the water

D. All of the above

4.11: Scanning Patterns

Scanning Patterns

4.12: Pulse Repetition Rate and Penetration

The energy of the generated sound depend on the pulse repetition rate, the

higher the repetition rate the higher the energy and the sound able to

penetrate thicker material. However if the PRR is excessive, ghost signal

may formed, this is due to the fact that the next sequence of pulse is

generated before the expected returning signal reaching the receiver.

1. The pulse repetition frequency or pulse repetition rate PRR:

is the number of pulse of ultrasonic energy that leave the probe in a given

time (per second). Each pulse of energy that leave the probe must return

before the next pulse leave, otherwise they will collide causing ghost

echoes.

2. Transit time: The time taken for the pulse to travel from the probe and

return

3. Clock interval: The time between pulse leaving the probe.

The transit time must be shorter than the Clock interval else, ghost signal may

formed. Typically the Clock interval should be 5 time the transit time.

PRR- Pulse Repetitive Frequency/Rate and Maximum Testable Thickness

Clock interval = 1/PRR

When Transit time = Clock interval

For pulse echo method:

Maximum testable length = x Velocity x Clock interval

Typically the Clock interval should be 5 time the transit time, i.e. the sound

path should travel 5 times the maximum testable length. (1st BWE, 2nd BWE,

3rd BWE, 4th BWE to 5th BWE.)

Note: The Clock interval has neglected the time occupied by each pulse.

Pulse Repetition Rate and Penetration

Pulse Repetition Rate and Penetration

Pulse Repetition Rate and Penetration

Pulse Repetition Rate and Near Surface Sensitivity

4.13: Interferences & Non Relevant Indications

Following are signal interferences that may produce non-relevant UT

indications:

1. Electrical interference

2. Transducer interference

3. Test specimen geometric interference

4. Test specimen surface interferences

5. Test material structure interferences

6. Test material internal mode conversion interference

7. UT techniques induced interferences (In correct PRR/ Band width/

Frequency selection/ Excessive Beam Spread/ etc.)

Transducer Interference- Transducer internal reflections & Mode conversion

may cause interference

Specimen Surface Interference

Excessive surface roughness,

air bubbles on the surface (on the transducer front, specimen front and back

for immersion techniques.

Surface wave for testing near the edges

Specimen Surface Interference

?

?

Specimen Surface Interference- You can determined whether the signal is

from the surface wave or the refracted wave simply by touching the surface

ahead of the wave (assuming the velocity of surface wave at 0.9 of the shear

wave)

Mode Conversion Interference

The mode conversion interference during testing of long cylindrical specimen

with longitudinal wave often appeared after the first back wall echo. The

signal can be easily distinguished and ignore.

Material Geometric Interference

False signals may generated due to the test specimen structural

configurations resulting in spurious signals.

Non Relevant Indications

Transducer with Excessive Beam Spread may generate signal, usually after

the 1

st

BWE. The example below the convex surface defocused the beam

and lead to excessive beam spread, using a proper contoured probe may

eliminate the problem. However excessive contour may results in generation

of surface wave.

Non Relevant Indication

Large grain size especially casting may cause excessive hash or grass signal.

Properly selecting probe with lower frequency may relieve the problem.

However this can only de accomplished with reduction in sensitivity.

Non Relevant Indication

Large grain size at heat affected zone HAZ (CGHAZ) may cause localized

signal due to large grain size. The signal may be wrongly assessed as a

defect.

Non Relevant Indications

The geometric abnormalities at root penetration and weld surface (crown)

may reflect the sound path, returning to the receiver as signals. To

distinguished the non relevant indications, finger touching will damped the

signals. Further testing may be necessary to ensure the signals were not from

the surface defects like surface crack. Any near surface indication that are

unusually consistent could be a non relevant indication.

4.14: Exercises

4.14-1: Compared 6 dB Drop Sizing with Equalization Technique

The 6 dB Method

For Large Reflector (greater than beam width), i.e. there is no BWE.

Compared 6 dB Drop Sizing with Equalization Technique

The Equalization Back Wall Sizing- The probe moving off the edges of the

reflector until the amplitude is equal to the rising BWE

Q1 What is the correct water path between the transducer and the steel front

surface to focused a transducer for a area of interest at below a steel

surface?

Given that:

Focal length of transducer in water = 6

Velocity of sound in water= 1484 m/s

Velocity of sound in steel = 5920 m/s

Equivalent depth in water for steel depth = 4x = 2

The water path= 6- 2= 4

Break Time

mms://a588.l3944020587.c39440.g.lm.akamaistream.net/D/588/

39440/v0001/reflector:20587?BBC-

UID=e5203c9d59fef1a79c12d8c601e839f58db16f7d5d6448f556

74c540f1856834&SSO2-UID=

You might also like

- UTT Study GuideDocument18 pagesUTT Study GuideJan Borskey Neal67% (3)

- VT For NDT - 2017Document29 pagesVT For NDT - 2017Selvakpm06No ratings yet

- Compilation of UT TestDocument34 pagesCompilation of UT TestAlex RaleighNo ratings yet

- API 1169-Part 40 CFR 112 EPA-Oil Pollution Prevention PDFDocument211 pagesAPI 1169-Part 40 CFR 112 EPA-Oil Pollution Prevention PDFCharlie Chong100% (2)

- STSMDocument278 pagesSTSMMiguel Ruiz TatajeNo ratings yet

- Ut Job Knowledge - TwiDocument10 pagesUt Job Knowledge - TwiBhanu Pratap ChoudhuryNo ratings yet

- 4 Ok RTDocument31 pages4 Ok RTAnky Fadharani100% (1)

- UT LEVEL-2 Part-1Document458 pagesUT LEVEL-2 Part-1கோகுல் இராNo ratings yet

- Ut of Austenitic WeldsDocument46 pagesUt of Austenitic Weldslinhcdt3100% (1)

- Radiographic Testing: Basic Principles and TechniquesDocument48 pagesRadiographic Testing: Basic Principles and TechniquesArjun LalitNo ratings yet

- Radiography Part 2 - Techniques for Ensuring High Quality RadiographsDocument2 pagesRadiography Part 2 - Techniques for Ensuring High Quality RadiographsTomy GeorgeNo ratings yet

- B Scan - C Scan - D ScanDocument52 pagesB Scan - C Scan - D ScanHee Wee JianNo ratings yet

- Iqi'sDocument6 pagesIqi's24inspector100% (1)

- Visual Testing: - Asme - Section 5 (NDT) - Section 5 - Article 9 (VT)Document29 pagesVisual Testing: - Asme - Section 5 (NDT) - Section 5 - Article 9 (VT)MAXX ENGINEERS100% (1)

- D-p5-Bv-pd-007 - Ect, Issue 01, Rev 00 - Eddy Current TestingDocument18 pagesD-p5-Bv-pd-007 - Ect, Issue 01, Rev 00 - Eddy Current TestingThinh NguyenNo ratings yet

- Dac CurveDocument24 pagesDac Curvesantu_23No ratings yet

- Ultrasonic Inpection-Level II Training-4Document87 pagesUltrasonic Inpection-Level II Training-4Mansoor AliNo ratings yet

- 24 Practical Visual InspectionDocument5 pages24 Practical Visual InspectionMai Anh TaiNo ratings yet

- NDT Basic PresentationDocument207 pagesNDT Basic PresentationIvan AgurtoNo ratings yet

- RT in WeldingDocument35 pagesRT in WeldingSapan KansaraNo ratings yet

- TOFD CV PDFDocument19 pagesTOFD CV PDFKarna2504No ratings yet

- Radiography Methods for Ensuring Acceptable Image QualityDocument4 pagesRadiography Methods for Ensuring Acceptable Image QualityRavindra S. Jivani100% (1)

- Visual Examination Procedure: 1 - PurposeDocument4 pagesVisual Examination Procedure: 1 - PurposeElvin MenlibaiNo ratings yet

- MFL PPT NotesDocument3 pagesMFL PPT NotesGaurav ChopraNo ratings yet

- ECHOGRAPH Ultrasonic Probes Brochure SummaryDocument4 pagesECHOGRAPH Ultrasonic Probes Brochure Summarycarlos100% (1)

- UT PROCEDURE TITLEDocument40 pagesUT PROCEDURE TITLEShyam Singh100% (3)

- NDT ExplainDocument25 pagesNDT ExplainUdaivir Yadav100% (2)

- Basics: UT Study Guide. Questions and Answers Fill In, Choose The Right Answer or Write Required Equations or AnswersDocument5 pagesBasics: UT Study Guide. Questions and Answers Fill In, Choose The Right Answer or Write Required Equations or AnswersWahEedNo ratings yet

- Ultrasonic Testing: NDT Training & CertificationDocument48 pagesUltrasonic Testing: NDT Training & CertificationMidhun K ChandraboseNo ratings yet

- TOFD - by Nicholas Bublitz - USA PDFDocument135 pagesTOFD - by Nicholas Bublitz - USA PDFhocimtm100% (1)

- DPI (Dye Penetrant Inspection) : Main PurposedDocument9 pagesDPI (Dye Penetrant Inspection) : Main PurposedAgung Prastyo WibowoNo ratings yet

- 12-UT Defect SizingDocument13 pages12-UT Defect Sizingmark_59100% (1)

- Fun With Civa Simulation Software for Ultrasonic NDT TrainingDocument12 pagesFun With Civa Simulation Software for Ultrasonic NDT Trainingmusaismail8863No ratings yet

- Fundamentals of Visual InspectionDocument49 pagesFundamentals of Visual InspectionsusanwebNo ratings yet

- UT Day1Document47 pagesUT Day1Mighel AdiNo ratings yet

- BLOQUEDocument1 pageBLOQUEAlvaro Alexis Mendoza PradaNo ratings yet

- Structural Steel Welded Connections Design ReportDocument4 pagesStructural Steel Welded Connections Design ReportChris Paulo100% (1)

- Penetrant Testing (PT)Document11 pagesPenetrant Testing (PT)Maria Cristina DijmarescuNo ratings yet

- Fundamentals of Visual ExaminationDocument84 pagesFundamentals of Visual Examinationkevin desaiNo ratings yet

- Introduction To Magnetic Particle TestingDocument58 pagesIntroduction To Magnetic Particle TestingjerryceppyNo ratings yet

- IQI Study BookDocument16 pagesIQI Study Bookqazi12No ratings yet

- Handout Ultrasonic Testing Level II - Rev. 1 - 12 May 2010Document185 pagesHandout Ultrasonic Testing Level II - Rev. 1 - 12 May 2010deari nur azisNo ratings yet

- Penetrant TestingDocument36 pagesPenetrant Testingkumarmm1234100% (1)

- NDT Technician: Circumferential Scanning in Ultrasonic InspectionDocument12 pagesNDT Technician: Circumferential Scanning in Ultrasonic InspectionmaterialsNo ratings yet

- Procedure: "Straight Beam/Angle Beam Manual Ultrasonic Testing"Document21 pagesProcedure: "Straight Beam/Angle Beam Manual Ultrasonic Testing"mangalraj900No ratings yet

- RT ProcedureDocument10 pagesRT ProcedureSandeep SundriyalNo ratings yet

- Identify Welding Defects & DiscontinuitiesDocument21 pagesIdentify Welding Defects & DiscontinuitiesJoanna AprilNo ratings yet

- RT Vol6 DraftDocument177 pagesRT Vol6 DraftJeevan R Nair100% (1)

- Viewing and Interpretation of RadiographsDocument30 pagesViewing and Interpretation of RadiographsNatrajiNo ratings yet

- Vector gas pipeline UT inspection reportDocument2 pagesVector gas pipeline UT inspection reportbacabacabacaNo ratings yet

- AWS D1.1 Weld Technique SketchDocument6 pagesAWS D1.1 Weld Technique SketchnathgsurendraNo ratings yet

- Nondestructive Examination (NDE) Technology and Codes Student Manual Introduction To Ultrasonic ExaminationDocument78 pagesNondestructive Examination (NDE) Technology and Codes Student Manual Introduction To Ultrasonic ExaminationRaj KumarNo ratings yet

- Weld DiscontinuityDocument61 pagesWeld DiscontinuityEKKACHAI PRABNAKORN0% (1)

- Ultrasonic Test Procedure1Document8 pagesUltrasonic Test Procedure1MHDNo ratings yet

- Study of Defect Characteristics Essential For ET UT RTDocument58 pagesStudy of Defect Characteristics Essential For ET UT RTaldeanucu100% (2)

- Ut IntrDocument25 pagesUt IntrJeevana Sugandha WijerathnaNo ratings yet

- Ultrasonic TransducersDocument4 pagesUltrasonic TransducersJessie Wang100% (1)

- Measurement and Calibration Techniques: Normal Beam InspectionDocument4 pagesMeasurement and Calibration Techniques: Normal Beam InspectionKevin HuangNo ratings yet

- 1998 - Ultrasonic C-Scan Standardization For Polymer-Matrix CompositesDocument8 pages1998 - Ultrasonic C-Scan Standardization For Polymer-Matrix Compositesdhiraj.biswasNo ratings yet

- Understanding Neutron Radiography Post Result Extended Reading XI-ADocument364 pagesUnderstanding Neutron Radiography Post Result Extended Reading XI-ACharlie Chong100% (2)

- Understanding Neutron Radiography Post Exam Reading IX-ADocument231 pagesUnderstanding Neutron Radiography Post Exam Reading IX-ACharlie Chong100% (3)

- An Introduction To AET Reading 2004-01Document172 pagesAn Introduction To AET Reading 2004-01Charlie ChongNo ratings yet

- API 579 - A Comprehensive Fitness-For-service Guide-ADocument11 pagesAPI 579 - A Comprehensive Fitness-For-service Guide-ACharlie Chong100% (6)

- AET-2006 Reading 3ADocument470 pagesAET-2006 Reading 3ACharlie Chong100% (1)

- Understanding API ICP653 Reading 12-Worksheet-8Document290 pagesUnderstanding API ICP653 Reading 12-Worksheet-8Charlie Chong100% (1)

- AET-2006 Reading 2Document418 pagesAET-2006 Reading 2Charlie ChongNo ratings yet

- AET-2006 Reading 9A PDFDocument234 pagesAET-2006 Reading 9A PDFCharlie Chong100% (3)

- AET-2006 Reading 8ADocument165 pagesAET-2006 Reading 8ACharlie ChongNo ratings yet

- AET-2006 Reading 1Document319 pagesAET-2006 Reading 1Charlie Chong0% (1)

- Understanding API ICP653 Reading 15-Worksheet-11a Revision1Document180 pagesUnderstanding API ICP653 Reading 15-Worksheet-11a Revision1Charlie Chong100% (3)

- Understanding API ICP653 Reading 18-Worksheet-12Document144 pagesUnderstanding API ICP653 Reading 18-Worksheet-12Charlie Chong100% (2)

- Understanding API ICP653 Reading 8-Worksheet-05 Part2bDocument167 pagesUnderstanding API ICP653 Reading 8-Worksheet-05 Part2bCharlie Chong100% (3)

- Understanding API ICP653 Reading 11-Worksheet-7Document182 pagesUnderstanding API ICP653 Reading 11-Worksheet-7Charlie Chong100% (1)

- Understanding API ICP653 Reading 8-Worksheet-05 Part2aDocument409 pagesUnderstanding API ICP653 Reading 8-Worksheet-05 Part2aCharlie Chong100% (3)

- Understanding API SIRE Reading-1 Part 2 of 2Document358 pagesUnderstanding API SIRE Reading-1 Part 2 of 2Charlie Chong83% (6)

- Understanding Apiicp653 Reading 9 Worksheet-04Document236 pagesUnderstanding Apiicp653 Reading 9 Worksheet-04Charlie Chong100% (1)

- Understanding API ICP653 Reading 8-Worksheet-05 Part1Document231 pagesUnderstanding API ICP653 Reading 8-Worksheet-05 Part1Charlie Chong100% (4)

- API 653 Study GuideDocument19 pagesAPI 653 Study GuideSubramaniam Ramasamy86% (7)

- Understanding API ICP653 Reading 8-Worksheet-03Document231 pagesUnderstanding API ICP653 Reading 8-Worksheet-03Charlie Chong100% (5)

- API578 - My Self Study NotesDocument180 pagesAPI578 - My Self Study NotesCharlie Chong100% (1)

- Understanding API ICP653 Worksheet-02 PDFDocument223 pagesUnderstanding API ICP653 Worksheet-02 PDFCharlie Chong100% (2)

- 最棒的工作简历Document40 pages最棒的工作简历Charlie Chong100% (2)

- Physics of Eddy Current-An IntroductionDocument49 pagesPhysics of Eddy Current-An IntroductionCharlie Chong75% (4)

- VI - Self Study Exam Preparatory Note-Part 1Document148 pagesVI - Self Study Exam Preparatory Note-Part 1Charlie Chong100% (1)

- Understanding Neutron Radiography Reading III-Level1-NRTDocument222 pagesUnderstanding Neutron Radiography Reading III-Level1-NRTCharlie Chong100% (4)

- Introduction To Eddy CurrentDocument401 pagesIntroduction To Eddy CurrentCharlie Chong100% (7)

- API 1169-Part 29 CFR 1910 OSHA-Occupational Safety and Health Standards Subpart H & I PDFDocument288 pagesAPI 1169-Part 29 CFR 1910 OSHA-Occupational Safety and Health Standards Subpart H & I PDFCharlie Chong100% (8)

- VI - Self Study Exam Preparatory Note-Part 2Document136 pagesVI - Self Study Exam Preparatory Note-Part 2Charlie ChongNo ratings yet

- Instructions for use and installation of a washing machineDocument16 pagesInstructions for use and installation of a washing machineVale MocanuNo ratings yet

- High Voltage Engineering Ref ManualDocument147 pagesHigh Voltage Engineering Ref Manualzeus009100% (1)

- Nissan Skyline R34 Workshop Manual EnglishDocument401 pagesNissan Skyline R34 Workshop Manual Englishrecklessone0% (2)

- PC400 400LC-8R PDFDocument8 pagesPC400 400LC-8R PDFAsmar FixNo ratings yet

- Red Highlighted Red Highlighted: Refer Calculation Given Below (Note-8)Document5 pagesRed Highlighted Red Highlighted: Refer Calculation Given Below (Note-8)Víctor RojasNo ratings yet

- Cambridge International AS Level: Environmental Management 8291/12Document12 pagesCambridge International AS Level: Environmental Management 8291/12zohaibNo ratings yet

- 7.MMCR JuliDocument5,281 pages7.MMCR JuliAngga StwnNo ratings yet

- Zenit Compact Setup Manual En3Document26 pagesZenit Compact Setup Manual En3Garage Lifestyle BVGNo ratings yet

- Power Generating Floor PDFDocument3 pagesPower Generating Floor PDFMeghjit MazumderNo ratings yet

- Electrodynamometer-Type Wattmeter: 1. Fixed Coil SystemDocument21 pagesElectrodynamometer-Type Wattmeter: 1. Fixed Coil SystemJebas ManovaNo ratings yet

- Project Report of POL Terminals2 PDFDocument31 pagesProject Report of POL Terminals2 PDFRashmi RanjanNo ratings yet

- Fermentor TypesDocument33 pagesFermentor TypesFahad MukhtarNo ratings yet

- Calculating monthly electricity consumptionDocument2 pagesCalculating monthly electricity consumptionStella KazanciNo ratings yet

- Current Monitoring Series CMR - Current Control: Ordering InformationDocument5 pagesCurrent Monitoring Series CMR - Current Control: Ordering InformationPrasadPurohitNo ratings yet

- 21st Refinery Technology Meet - The CompendiumDocument474 pages21st Refinery Technology Meet - The CompendiumAnurag Ingle100% (5)

- Thermal Protector For Motor: Ballast For Fluorescent and Temperature Sensing ControlsDocument1 pageThermal Protector For Motor: Ballast For Fluorescent and Temperature Sensing ControlsPasilius OktavianusNo ratings yet

- Asco Avtron 2000 Series With Sigma LT User Manual PDFDocument43 pagesAsco Avtron 2000 Series With Sigma LT User Manual PDFfernandoNo ratings yet

- Starting - Rav4 Sxa1Document19 pagesStarting - Rav4 Sxa1Christian Linares AbreuNo ratings yet

- FP2 FP3 CRP 49691A Sanitary PumpDocument6 pagesFP2 FP3 CRP 49691A Sanitary PumpetmvmartNo ratings yet

- Thermiculite BrochureDocument8 pagesThermiculite BrochureXuan TruongNo ratings yet

- PAES 233: Multicrop Washer-Peeler StandardDocument16 pagesPAES 233: Multicrop Washer-Peeler StandardFaroukNo ratings yet

- Methods of Test For Cables: Indian StandardDocument2 pagesMethods of Test For Cables: Indian StandardARUN BNo ratings yet

- 0401544-Hydraulic StructuresDocument38 pages0401544-Hydraulic StructuresEfremWakjiraHodeNo ratings yet

- Underground Facilities for Better Environment and Safety - IndiaDocument8 pagesUnderground Facilities for Better Environment and Safety - Indiafini1968No ratings yet

- rr320801 Mass Transfer Operations IIDocument7 pagesrr320801 Mass Transfer Operations IISRINIVASA RAO GANTANo ratings yet

- Fire Safety Procedures: Prevention, Equipment & AlarmsDocument11 pagesFire Safety Procedures: Prevention, Equipment & AlarmsCyrus SantosNo ratings yet

- Chemical ThermodynamicsDocument46 pagesChemical ThermodynamicsHardik0% (1)

- Electromagnetic Relays - ManiDocument17 pagesElectromagnetic Relays - ManipraveenaprabhuNo ratings yet