Professional Documents

Culture Documents

Ultrasonic thickness gauge manual

Uploaded by

Lenin Miranda0%(1)0% found this document useful (1 vote)

1K views12 pagesUltrasonic thickness gauge is an intelligent handhold product, which adopts ultrasonic measuring principle, and is controlled by microprocessor. One of its important application is to monitor thelevel of thickness-decreasing during Operation of various andpressure container. The material that conduct and reflect constant sonic velocity, this product is to be applicable used.

Original Description:

Original Title

GM100 Manual En

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentUltrasonic thickness gauge is an intelligent handhold product, which adopts ultrasonic measuring principle, and is controlled by microprocessor. One of its important application is to monitor thelevel of thickness-decreasing during Operation of various andpressure container. The material that conduct and reflect constant sonic velocity, this product is to be applicable used.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0%(1)0% found this document useful (1 vote)

1K views12 pagesUltrasonic thickness gauge manual

Uploaded by

Lenin MirandaUltrasonic thickness gauge is an intelligent handhold product, which adopts ultrasonic measuring principle, and is controlled by microprocessor. One of its important application is to monitor thelevel of thickness-decreasing during Operation of various andpressure container. The material that conduct and reflect constant sonic velocity, this product is to be applicable used.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 12

VERSION 100-0

ULTRASONIC THICKNESS GAUGE

INSTRUCTION MANUAL

Ultrasonic thickness gauge

CAL

VEL

STORE

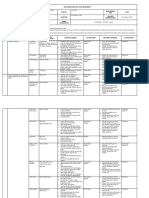

CONTENTS

1 Introduction-------------------------------------(01)

2 Operation codition-----------------------------(04)

3 Operation instruction--------------------------(05)

4 Measurement tips------------------------------(09)

5 Precautions for accurcy-----------------------(11)

6 Maintenance------------------------------------(13)

7 Notice --------------------------------------------(14)

8 Table of sound velocity------------------------(15)

-21-

8. Table of sound velociey

Sound velocities of common materials

Aluminum

Zinc

Silver

Glod

Tin

Iron/Steel

Brass

Copper

SUS

Acrylic resin

Water 20

Glycerinl

soluble glass

2670

3530

4430

5440

5720

6310

6020

5630

5850

5660

6070

4650

2620

Acetate resin

Phosphor bronze

Turpentine

Glass

Incoloy alloy

Magnesium

Monel alloy

Nickle

Steel 4330 mild

Steel 330

Titanium

Zirconium

Nylon

6320

4170

3600

3240

3230

5900

4640

4700

5790

2730

1480

1920

2350

Material Velocity(m/s) Material Velocity(m/s)

-20-

1. Introduction

-01-

7. Notice

This ultrasonic thickness gauge is an intelligent handhold

product, which adopts ultrasonic measuring principle, and is

controlled by microprocessor, provides quick and precise

measurement of thickness for most of industrial material.

This unit is widely usedin various precisemeasurement

for different hardware / parts in industrial realm; one of its

important application is to monitor thelevel of thickness-de-

creasing during operationof various andpressure container.

Diffusely applied in manufacture fields, metal processing,

and commercial inspection. The material that conduct and

reflect constant sonic velocity, this product is to be applica-

ble to used.

1.1. Scope of application

This unit is suitable for measuring materials that are good

ultrasonic conductor suchas metal, plastic, ceramic, glass

etc., as longas the measuredpart in twoparallel surfaces

for measurement of thickness.

This unit is not suitablefor cast irondue to its big crystall-

oid composition.

1.2. How it work

This unit is comprised of transimtting circuit, receiving

circuit, Hi-frequency oscillator, counter, central unit proces-

sor, keypad, and moniter etc., adopting ultrasonic pulseref-

lect principle. Similar to light-wave measureprincipal, the

sonic pulse occurs form the unit travels through thematerial

being measured till reach the interfaceand reflects back to

determine the thickness of the target material.

See the diagrambelow:

7.1. Warranty and warranty policy

Please fill thewarranty card withyour cachet/chop after

purchasing this products, the warranty periodfor repaired is

12 months formthe date of original purchase. Duringwarra-

nty period, product must be returnedwith the invoice(copy)

and warranty cardto our customer service department. The

product will not be warranted whichwithout the warranty

card.

Over warranty period, any repairing / maintenance will ch-

arge the feeon the buyer in standard rateby local distributor.

The standard rate is not including the accessories which

not packing instandard package(For example, abnormity

transducer, lengthenlead-wire, special software) .

We disclaims any liability dueto: transportation damages;

incorrect use or operation; manipulation, alterations or rep-

air attempts; without warranty card, invioce.

7.2. Non-warranty list

LCD, battery, probe, sampleblock, plastic case,

coupling agent

VEL

STORE CAL

Ultrasonic thickness gauge

-02- -19-

H

a

r

d

w

a

r

e

D

i

s

p

l

a

y

d

r

i

v

e

r

Transmitting

Receiving Feedback wave

C

P

U

L

C

D

d

i

s

p

l

a

y

K

e

y

p

a

d Counter Hi-frequency oscillator

1.3. Standard packing& Parts description:

1>. Standard packing:

Main unit-1PCS

Transducer: ( 10mm 5MHz ) 1PCS

Coupling agent: 1PCS 50ml

4mm Sample block: 1PCS

Optional accesseries: ( 10mm 2.5MHz ) 1PCS

2>. Parts description:

be cleaned for preventing rust. Inhigher temperature envir-

onment, be sureprotect the block form the droplet of water.

If the gaugeis not usefor a longperiod, please apply some

antirust on thesample block.

6.5. Avoid shocking/impact. Donot store theunit in highhum-

idity enviroment.

6.6. When thetolerance is over than stated inthis manual,

please refer tothe 3, 4, 5 chapter, in this manual.

6.7. Please contact us or our distributor if thefollowing occurs:

A. Component being destroyed, noreadout and enableto

measure.

B. Abnormal LCD display.

C. The tolerance is toobig in proper operation.

D. Malfunction of keypad.

6.8. This gauge is aadvanced technology product, the repair-

ing only by technician authorized by us, do not try any alter-

ations or repair attempts.

LCD

Keypad

Receive socket Transmit socket

Transducer

Case

Sample block

Battery compartment

(rear case)

-18- -03-

LCD display

3>. LCD diagram

-- Low battery indicator

-- Coupling indicator

m/s -- Sound velocity unit

mm - - Thickness unit

VEL -- Sound velocity indicator

-- Thickness indicator

-- Store / recall indicator

-- -- Storedunit indicator

-- Calibration indicator

4>. Keypad diagram

-- ON/OFF key

CAL -- Calibration key

VEL -- Sound velocity key

STORE -- Mode shift key

CAL+ --Back light active key

--Sound velocity, thickness,

thickness unit adjust/recall key

--Sound velocity, thickness,

thickness unit adjust/recall key

KEYPAD

VEL

STORE CAL

6. Maintenance

6.1. Battery replacement

When low battery icon is showed, please replace the

batteries.

A. Press to turn off.

B. Open thebattery door properly.

C. Replace thelow power batteries by new batteries in

correct polarity.

When the gaugeis not usedfor a longtime, please take

out the batteries.

6.2. Protection of transducer

Because the wear face of transducer is propylene mat-

erial which easy to be scratched. During taking measure-

ment on roughmaterial, please usingthe transducer in

gentle motion.

The temperature of the hardwareshould not over 60 ,

otherwise it will cause damage onthe transducer.

Adhering oil, dust on thewear face will speed up aging

of transducer andlead to rupture. Clean the lead-wire&

transducer after use.

6.3. Cleaning thecabinet

Do not usesolvent/alcohol for cleaningwhich erode

the cabinet &LCD window, brush and sweeponly with a

moist cotton cloth.

6.4. Cleaning thesample block

Because of couplingagent should beput on thesample

block during calibration, after use thesample block should

-04- -17-

sample block by using micrometer/caliber.

5.8. Abnormal reading

Aseasoned operator shouldbe capable todistinguish the

abnormal reading, practically result from rusting, erosive

recess surface / incorrect calibrate sampleblock/ the inner

flaw of material.

5.9. Choose andusing coupling agent

Coupling agent serves the high frequency ultrasonic wave

transmitting between thetransducer to thehardware. Choo-

se incorrect agent or wrong operationman cause error or

poor coupling whichlead to failureof measuring. The coupl-

ing agent shouldbe used inproper way, typiccally, a single

droplet of agent is sufficient.

It is important to use proper coupling agent, lowviscosity

agent(the provided agent / machining oil) is suitable for sm-

ooth surface. For rough / veritcal / aluminum surface, high

viscosity agent likeglycerin and lubricationgrease is appli-

cable. All kinds of couplingagent is availablein local market,

you can buy it form local distributor as well.

1.4. Specification

Display: 4-digital LCDdisplay

Minimum display unit: 0.1 mm

Working frequency: 5MHz

Measuring range: 1.2to 225.0mm (steel)

Minimum limit for tube measuring: 20*3mm (steel)

Accuracy: +/- (1%H+0.1)mm H denotes the measured

thickness.

Sound velocity range: 1000 to 9999m/s

Measuring sound velocity with a giventhickness:

measuring range:1000 to9999 m/s.

When the giventhickness over 20mm, the accuracyis

+/-1%; when thegiven thickness less than 20mm, the

accuracy is+/-5%.

Operation temperature: 0 to 40

Power supply: 3*1.5VAAAalkaline batteries

Operation current: Normal operation current 50mA

With Backlight turnon current 120mA

Stand-by current: 20uA

Size: 72*146*29mm

Weight: 202g

-16- -05-

the calibrated value.

5.4. Abrasionfo the transducer

Because the transducer is made of propylene, long period

use will causethe surface of transducer became morerough

which will declinethe sensitivity leadto the wrongreading.

Please polish thesurface with sandpaper or whetstoneto

assure the smoothness and parallel. If the reading still uns-

teady, the transducer shouldbe replaced withnew one.

5.5. CAL function

CAL (calibration) is usedto calibrate theunit with thestan

dard block onthe panel, dopress this key for calibration with

other materials or will the wrongmeasuring will takeplace.

5.6. Multilayer / composite material

It is impossibleto read out the thickness of the uncoupled

multilayer for theultrasonic wave cannot go throughthe un-

coupled space. Further more, the sonic wave cannot travel

in the compositematerial at aneven speed, soultrasonic

reflect principle cannot be applied for measuring the multil-

ayer/composite material.

5.7. Influence fromthe oxidized surface

For some metals, such as aluminuma layer of oxide being

generated on their surface. The oxidized layer combinedwith

the substrate tightly,but the sonic wave travel within2 differ-

ent material whichwill lead toerror reading, themore oxidi-

zed layer thereading will bemore tolerant.

Please calibrated theunit with thesample block that pick up

along the hardwareto be measured, and obtain thethick of

1.5. Features

Auto calibrationto assure theaccuracy.

Auto linear compensation: this advancedsoftware progr-

am enhances theprecision by correctingthe non-linear

accuracy of transducer.

Use and keys to make aquick adjustment for the so-

und velocity /thickness,anda quick recall to the stored

data.

Coupling status indication: Observing the couplingicon to

learn if thecoupling is accomplishedor not.

10 thickness measurement storage and recall function

available, which facilitates the height work or working in

wild area.

Sound velocity measurement: With a giventhickness by

a sample hardwareto measure thesound velocity, which

avoid the further conversion or consultationof the table.

12 sound velocity for different material which alsoadjus-

table.

Low battery indication

Auto power off mode designed to conservebattery life.

More than 10000times long lift keys.

The unit has a special memory that retains all of its setting

even when thepower is off.

-06- -15-

5.1. For very thin material

Any ultrasonic thickness gauge, when thethickness of the

material to bemeasured is less than the minimumlimit the

fault reading will occurs.

Using sample block compare method toget a minimumlimit

of this material.

In measuring thethin material, anerror may happenthat

the reading is two times as the actual dimension. Another

error which display the reading muchmore bigger thanthe

actual. To prevent thewrong reading by double check out

the minimum limit in the thinmaterial.

5.2. For stained, rusting surface

The stained/rusting surface on thecontra side will occurs

the ruleless wrongreadings. Sometimes asmall stained

spot is hardto find out.

Takecare for measurement while measuring theknown thr-

oughsting spot/suspicious area. Or using soundinsulation

boardcelotex to locates the spot indifferent testing angles.

5.3. Identify different velocity withvary material

Afault reading wouldobtains, when measuringthe hard-

ware with thevelocity calibrated by prior material. Soa co-

rrect velocity shouldbe adopted. The fault readingmay also

result form thedifference between the actual velocity with

5. Precautions for accuracy

2. Operation condition

2.1. Operation area condition: For areas that is equal or

bigger than thearea, this unit is suitable for measurement.

To measure the slimparts axially that is not vertical to the

surface, the areashall not betoo small, otherwisethe error

measure may happen.

2.2. Curved surface condition: When the material is curved

surface like boiler wall or tubing, the curvature radius must

be more thanor equal to10mm, and thewall thickness must

be more thanor equal to3 mm. This requirements is referring

to steel material, as for thecurve surface of other materials

measuring requirements westill can not provide exact data,

we highly appreciateif you feedback us and sharewith your

precious experience.

2.3. Roughness condition: This gauge wildly applies upon the

rough hardware/material, for most cases, our provided tra-

nsducer can makeexact measurement. However, if therou-

ghness is toobig due tothe rust etc. the error measuremay

happen, in suchcase, please try to minimize theroughness

or select the2.5MHz transducer (optional accesseries). If

the transducer is worn out, pleasere-purchase on thelocal

distributor.

2.4. Working temperature condition

Material thickness andsound velocity will change along with

temperature. In normal measurement, environment tempe-

rature impact canbeignored.

The transducer is made of propylenematerial, considering

This gauge with the functionto measure thesound veloc-

ity, so the velocity can be obtainedbefore thickness measu-

rement, and thenproceed with measurement of thickness.

-14- -07-

the protection of the transducer and its precision we rec-

ommend that the surface temperature of the hardware/

workpiece should not be over 60 , otherwise the transd-

ucer can not put into use.

Operation temperature: 0~40

Relative humidity: <90%RH

Hardware/workpiece/material temperature: <60

Do not apply in violent vibration / erosive material.

Avoid impact and humidity.

3.1. Before measurement

1>. Connect the transducer with the main unit, press

to turn on,LCDdisplay full screen for 0.5 second with

back light, then icon will keep scanning with figure

testing in 2 times. After that, LCD display the last

applied sound velocity with registered memory unit,

indicating the gauge is ready for use.

3. Operation instruction

Full screen

Last applied sound

velocity & registered unit

please see for calibration operations.

In different material & situation, only one sampleblock

may not satisfy every calibration. The more similar sample

block, the moreexact reading obtained. Ideally, referring

block is agroup of different thickness andsame material, by

calibrating to thereferring block, theeffect of variation of

sound velocity will be minimized. To get the most exact me-

asure, a set of referring block is very important.

In most situations, using one referringblock will get a sat-

isfying measurement. This referring block must be thesame

material with samethickness as theparts to betested. The

referring block shouldbe read out the thickness by

micrometer.

When measuring thinmaterial which thickness close to

the minimum limit range of this unit, please usea referring

block to defineexact limit of this material( 1.2mmfor steel

material). Do not measuring the material that the thickness

under the minimumlimit.

When material is a complex alloy in a largesize. Ablock

that has asimilar thickness withthe material shouldbe

selected for calibration.

For most hardwareby forging / casting, their havediffer-

ent inner structure, so that thesound velocity slight different.

To reach the exact reading, the referringblock has similar

structure as thehardware.

In comment measurement, you check thesound velocity

on the tablestated on this manual instead of taking calibrat-

ion for thereferring block. However, this tablejust for refer-

ence, sometimes thesound velocity will be different cause

by different physical / chemical factors. The sound velocity

of mild steel is adopted onthe reference table.

-08- -13-

3.2. Calibration

Acalibration should be made for every replacement of

transducer or batteries, this operation is sufficiently impor-

tant to assure the measuring precision. If necessary, this

step should repeated when the accuracy is critical. Before

calibration, put fewprovided coupling agent on the standard

sample block to couple the transducer and the sample block.

Press CAL to enter calibration mode, the vertical bar will

keep scanning with CAL, VEL, m/s display, until the LCD

display 4.0mm indicating the calibration is completed.

After calibration, sound velocity will back to your selected

value, and ready to measure.

2>. Sound velocity adjustment & revision

Press VEL to entre sound velocity adjustment, press

or to select your desired velocity (There are 12 velocity

stored in this unit). If you need to customize the sound

velocity, during the adjustment press VEL again to enter

velocity revision, while pressing or to revise the

velocity, VEL and m/s icon will keep blinking.

Press VEL to confirm and save the revised velocity, the

unit will go back to normal status.

Velocity adjustment Velocity revision

4.5. Complex shapematerial

For complex shapematerial measurement, pleaserefer to

the 4.4,the smaller of the tworeading should thenbe taken

as the thickness.

4.6. Non-parallel surface

To get asatisfying ultrasonic response, the surface must

have its onemeasuring side parallel with another, otherwise

will obtain wrongresult.

4.7. Influence of the material temperature

The size &sound velocity of material will changewith the

temperature, when theprecision is critical, please make m-

easurement in 2samples of thematerial under thesame te-

mperature to determinethe proper readingresulting from

the temperature. Whentaking measurement for steel parts

in high temperature, this method may be adopted toobtain

the correct reading.

4.8. High acoustic reduction material

For materials infiber, poriferous or big granular, acoustic

dispersion will causethe energy attenuationthat may result

in abnormal readings (practically the readingless than the

actual thickness), inthis case, thematerial is not suitable

for the gauge.

4.9. Reference sampleblock

For calibration for the gauge, agiven thickness or sound

velocity of thematerial is very import. Calibration needs at

lest one referringstandard sample block. This gauge is pr-

ovided with a4.0mm sample block on the front cabinet,

Calibration statu Calibration accomplished

3.3. Thickness measurement

Put the couplingagent on thearea to bemeasured to co-

uple the transducer with the hardware/workpiece, LCD will

display the thickness reading.

Notes: icon onthe screen indicates a well coupling, if

the icon flashes or not shows that means apoor coupling.

After remove thetransducer, thereading will behold.

3.4. Sound velocity measurement

With a giventhickness to readout sound velocity of mat-

erial: Obtains thethickness of material by using vernier ca-

liper / micrometer, then couplethe transducer withthat sa-

mple material until a reading displays on the LCD, remove

the transducer andpress or toadjust the readingto

In a well coupling

measurement

Measurement

accomplished

-12- -09-

4.1. Cleaning surface

Before measuring, the dust, dirt, rusting and grease etc

that adheres on the hardware/workpiece must be removed

off and cleaned.

4.2. Decreasing the roughness of surface

Too rough surface may result in measure error/ fault rea-

ding. Please try to make the surface smooth by milling, pol-

ishing, filling or using high viscosity coupling agent.

4.3. Rough machining surface

The regular tiny texture/slots resulting form rough machi-

ning process may cause error, and the compensation meth-

od is the same as in 4.2,adjusting the angle between the

crosstalk segregating board of the transducer a metal mem-

brane crossing the detector bottom centre and linear texture

/slots (parallel or vertically) may also get a better result.

4.4. Measuring pipe and tubing

When measuring cylindrical parts to determine the thick-

ness of the pipe wall, orientation of the transducers is impo-

rtant. If thediameter of the pipe is large than approximately

4 inches, measurements should be made with the transducer

oriented so that the gap in the wearface is perpendicular (

at right angle) to long axis of the pipe. For smaller pipe dia-

meters, two measurements should be performed, one with

the wearface gap perpendicular, another with the gap para-

llel to the long axis of the pipe.

The smaller of the two displayed values should then be

taken as the thickness at that point.

4. Measurement Tips

-10- -11-

match the thickness by caliper/mirometer, then press VELto

display the sound velocity and save in current soud velocity

memory unit.

Measuring

the thickness

Adjusting

actual thickness

Velocity read out

3.5.Data storage

1>. Keeppressing STORE for 2 secondto enter thedata

store mode ,LCDdisplay THICKNESS, mm, M icon

with first memory unit. If thefirst memory unit is not

being registered, soLCD will display 0.0.

2>. Press or to select your desired memory unit

(1-10).

3>. After picked up thememory unit, thenew measurement

will be renewthe memory unit, when the measurement

completed the last reading will bestored in theselected

memory unit.

Select memory unit Taking measurement

& saving data

Measurement &

storage accomplished

Review saved data

3.6. Review the saved data

In normal status, press STORE for 2 seconds will enter

into review data mode, press or will display saved

data orderly.

Press STORE to exit the review mode and back to normal

status.

3.7. Low battery indication

When icon flashes, please replace the batteries for

further measurement.

3.8. LCD back light & Automatic power off

Before turn on the gauge, hold pressing CAL, and press

button to turn on, the back light will be activated every

operation will turn on the back light for 7 seconds .

This unit will be turned off automatically in 2 minutes

without any operation.

You might also like

- F-035 (Valve Erection Format)Document1 pageF-035 (Valve Erection Format)Rajeev Kumar100% (1)

- Lot Inspection Report For LPG New CylindersDocument3 pagesLot Inspection Report For LPG New CylindersJagannath MajhiNo ratings yet

- Radiation Safety Distance DiagramDocument3 pagesRadiation Safety Distance DiagramEswaranNo ratings yet

- Welding Report For Tank 1Document1 pageWelding Report For Tank 1Rifki HasyaNo ratings yet

- 16 - SGU - RT - ASME - 16 - Radiographic - REV - 00Document53 pages16 - SGU - RT - ASME - 16 - Radiographic - REV - 00pankrasius herbudiNo ratings yet

- Certificate of Origin Form F For China-Chile FTADocument2 pagesCertificate of Origin Form F For China-Chile FTAinspectormetNo ratings yet

- SFPS For HDPE 90 MMDocument1 pageSFPS For HDPE 90 MMraajc2No ratings yet

- Weld RepairDocument2 pagesWeld RepairAnurag YadavNo ratings yet

- Blasting and Painting ProcedureDocument6 pagesBlasting and Painting Procedureanon_994898767No ratings yet

- Proc SopDocument90 pagesProc SopJohn Dolan100% (1)

- Procedure of UT-TestDocument2 pagesProcedure of UT-TestJohn ShermanNo ratings yet

- Penguard ZP AO - English (Uk) - Issued.06.12.2007Document3 pagesPenguard ZP AO - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- Hydro test processDocument7 pagesHydro test processjeswinNo ratings yet

- Jsa For TIE INS in Accommodation BlockDocument4 pagesJsa For TIE INS in Accommodation BlockAliNo ratings yet

- RFI Welding TestDocument18 pagesRFI Welding TestDimas agungNo ratings yet

- ISO 9001, ISO 14001 & OHSAS 18001 Certified Product Data SheetDocument3 pagesISO 9001, ISO 14001 & OHSAS 18001 Certified Product Data SheetHendri Dwi cahyonoNo ratings yet

- Painting & Inspection FormatDocument1 pagePainting & Inspection FormatABEC Trombay siteNo ratings yet

- SWP CHECKLISTS - Welding Cutting and HeatingDocument3 pagesSWP CHECKLISTS - Welding Cutting and HeatingSrinivas Dumpala HSE100% (1)

- GRP Inspection Report SummaryDocument2 pagesGRP Inspection Report SummaryJoseph Perez100% (1)

- Millsheet Pipa Spindo - 01Document4 pagesMillsheet Pipa Spindo - 01Mellany SeprinaNo ratings yet

- Pressure Vessel Inspection PlanDocument8 pagesPressure Vessel Inspection Plansuratno 25100% (1)

- Circularity Inspection Report: Shell Course (LW) CW CWDocument14 pagesCircularity Inspection Report: Shell Course (LW) CW CWaszlizaNo ratings yet

- QAF5153 Rev.0 Pre-Mobilization Inspection Checklist - Guidelines - 1Document1 pageQAF5153 Rev.0 Pre-Mobilization Inspection Checklist - Guidelines - 1Mohamed El-SawahNo ratings yet

- ITP For Under Ground Firewater SystemDocument4 pagesITP For Under Ground Firewater SystemjaseelNo ratings yet

- Material Safety Data Sheet: Poly Cell AdhesiveDocument8 pagesMaterial Safety Data Sheet: Poly Cell AdhesiveMinh BảoNo ratings yet

- 6 MM TCDocument1 page6 MM TCpranesh kadamNo ratings yet

- Prosedur Penetran TestingDocument11 pagesProsedur Penetran TestingIkhsan DalimuntheNo ratings yet

- SOP Pipe WeldingDocument1 pageSOP Pipe WeldingAndre Mars100% (1)

- Hydrotest - 333 AG FW 0001 - Rev03 PDFDocument26 pagesHydrotest - 333 AG FW 0001 - Rev03 PDFIhsan IchwansyahNo ratings yet

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDocument3 pagesBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNo ratings yet

- Lish No Certificate Po 4008 0111 00 Imn 8000 2019 PDFDocument1 pageLish No Certificate Po 4008 0111 00 Imn 8000 2019 PDFliving goodNo ratings yet

- Sample WPS 1Document13 pagesSample WPS 1waqas pirachaNo ratings yet

- Walk Down Punch ListDocument7 pagesWalk Down Punch ListGomathyselviNo ratings yet

- Sample PQR Form (GTAW & SMAW - Page 1) Procedure Qualification Record (PQR)Document2 pagesSample PQR Form (GTAW & SMAW - Page 1) Procedure Qualification Record (PQR)Luis Carlos Clericci LimonNo ratings yet

- MSDS Polyken 955Document5 pagesMSDS Polyken 955raditia2205No ratings yet

- INSPECTION REPORT TITLEDocument7 pagesINSPECTION REPORT TITLEABEC Trombay siteNo ratings yet

- Colour Coding of Piping MaterialDocument2 pagesColour Coding of Piping MaterialRajeev KumarNo ratings yet

- 1 Imran Piping QC CVDocument4 pages1 Imran Piping QC CVkazim MirzaNo ratings yet

- Dimensional Inspektion ReportDocument6 pagesDimensional Inspektion Reportdidi sudiNo ratings yet

- List of Qualified Welder Summary BLCPDocument2 pagesList of Qualified Welder Summary BLCPpstechnical_43312697No ratings yet

- WPS Format For Asme Ix - Wps - Fcaw GmawDocument1 pageWPS Format For Asme Ix - Wps - Fcaw GmawThe Welding Inspections CommunityNo ratings yet

- ITP - Fire Hydrant InstallationDocument9 pagesITP - Fire Hydrant InstallationGultom Juliana LiliesNo ratings yet

- Hardness Test Quality Control and Inspection Report FormDocument17 pagesHardness Test Quality Control and Inspection Report FormAlif Rahmat Febrianto0% (1)

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Method Statement For Blasting and PaintingDocument11 pagesMethod Statement For Blasting and PaintingAbdullah Abdullah100% (2)

- Ultrasonic Wall Thickness Report Feb.27-28,20062 - 2Document32 pagesUltrasonic Wall Thickness Report Feb.27-28,20062 - 2Endickk Screamo PoreperrNo ratings yet

- Bolt stress and torque values for common flange gasketsDocument1 pageBolt stress and torque values for common flange gaskets심판자No ratings yet

- Welding HISTORY SHEETDocument9 pagesWelding HISTORY SHEETAhmedNo ratings yet

- Rigaku Radioflex RF-EGM2 Series Brochure - VISCODocument4 pagesRigaku Radioflex RF-EGM2 Series Brochure - VISCOrhinemineNo ratings yet

- ACG 22 Requirements For Lifting Equipment Inspection BodiesDocument14 pagesACG 22 Requirements For Lifting Equipment Inspection BodiesramodNo ratings yet

- 10.1 Jha Box-Up Spool or Valve 19.11.15Document6 pages10.1 Jha Box-Up Spool or Valve 19.11.15RahimNo ratings yet

- WPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0Document1 pageWPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0คุณพ่อน้อง บิ๊กบอส100% (1)

- Weld History SheetDocument2 pagesWeld History SheetAjin S100% (1)

- Sand Blast and Painting Work ProsedurDocument8 pagesSand Blast and Painting Work ProsedurRizki AgustiarNo ratings yet

- WeldingDocument73 pagesWeldingTeodor EzaruNo ratings yet

- Exertus Circa Operation Manual MKT - OM - CIRCA (Rev.01) - enDocument32 pagesExertus Circa Operation Manual MKT - OM - CIRCA (Rev.01) - enmuni fatuzzahrohNo ratings yet

- OCS Engineering & Construction Visual Inspection ReportDocument1 pageOCS Engineering & Construction Visual Inspection ReportvinothNo ratings yet

- Daily structural concrete reportDocument2 pagesDaily structural concrete reportAli RazaNo ratings yet

- JC378UB11E Service ManualDocument54 pagesJC378UB11E Service ManualHomero EstradaNo ratings yet

- Service Guide SpecificationDocument34 pagesService Guide SpecificationliviucatalinNo ratings yet

- Metals and Its Alloys MCQDocument2 pagesMetals and Its Alloys MCQsrj sNo ratings yet

- Bonding Exam Style Questions (Chemistry)Document30 pagesBonding Exam Style Questions (Chemistry)Temilola OwolabiNo ratings yet

- Technical Data Sheet 15cdv6Document2 pagesTechnical Data Sheet 15cdv6mahmood750No ratings yet

- Is 617Document15 pagesIs 617Anupam0103No ratings yet

- Projection WeldingDocument23 pagesProjection WeldingFernandoNo ratings yet

- Multi-Scale Modeling in Materials Science and EngineeringDocument12 pagesMulti-Scale Modeling in Materials Science and EngineeringonebyzerooutlookNo ratings yet

- ISO pipe and tube standards reference guideDocument2 pagesISO pipe and tube standards reference guideMostafa HalawaNo ratings yet

- HR Project On Stress ManagementDocument105 pagesHR Project On Stress ManagementKarthik RaoNo ratings yet

- CAST COPPER ALLOYS PROPERTIES AND USESDocument29 pagesCAST COPPER ALLOYS PROPERTIES AND USESniceweather157No ratings yet

- Ch3 - BBM 10103 Phase DiagramDocument86 pagesCh3 - BBM 10103 Phase DiagramschaNo ratings yet

- Minecraft MetallurgyDocument5 pagesMinecraft MetallurgyBrian BarkerNo ratings yet

- Process Variations in ESRDocument13 pagesProcess Variations in ESRPranesh Rao KmNo ratings yet

- CPHFD 011Document7 pagesCPHFD 011Napoleon DasNo ratings yet

- NZMRM Code of Practice v3 03.22Document525 pagesNZMRM Code of Practice v3 03.22benjaminsigabalavuNo ratings yet

- Batterycontacts DuracellDocument9 pagesBatterycontacts DuracellwilliaqNo ratings yet

- Density Chart for Common Metals and AlloysDocument6 pagesDensity Chart for Common Metals and AlloysbveNo ratings yet

- ASTM G31-72 - Laboratory Immersion Corrosion Testing of MetalsDocument8 pagesASTM G31-72 - Laboratory Immersion Corrosion Testing of Metalsnengsintanovita100% (17)

- HovedkatalogccDocument352 pagesHovedkatalogccibraheemNo ratings yet

- Influence of Welding Speed On Corrosion Behaviour of Friction Stir Welded AA5086 Aluminium AlloyDocument11 pagesInfluence of Welding Speed On Corrosion Behaviour of Friction Stir Welded AA5086 Aluminium AlloysaifbenNo ratings yet

- Ferrous Alloys: Printed: September Author: R. KattusDocument34 pagesFerrous Alloys: Printed: September Author: R. KattussunsirNo ratings yet

- Prof. Dr. Zainul Huda: Resume ofDocument31 pagesProf. Dr. Zainul Huda: Resume ofMuhammed ThanzeelNo ratings yet

- Ahmedabad and Gujarat Sample DataDocument20 pagesAhmedabad and Gujarat Sample DataPriya Shinde100% (1)

- 22 Metallic Glasses, Dr. T. HufnagelDocument30 pages22 Metallic Glasses, Dr. T. HufnagelSam AkinaNo ratings yet

- Sec 3 Chemistry NotesDocument66 pagesSec 3 Chemistry NotesJasper WongNo ratings yet

- C - LA Steel Market Analysis - 2011Mar10-FINALDocument14 pagesC - LA Steel Market Analysis - 2011Mar10-FINALSaurabhShrivastavaNo ratings yet

- MIL-PRF-85704C Turbin CompressorDocument31 pagesMIL-PRF-85704C Turbin CompressordesosanNo ratings yet

- Kent. 1913. The Mechanical Engineers' Pocket-Book. A Reference-Book of Rules, Tables, Data, and Formulæ, For The Use of Engineers, Mechanics, and StudentsDocument1,505 pagesKent. 1913. The Mechanical Engineers' Pocket-Book. A Reference-Book of Rules, Tables, Data, and Formulæ, For The Use of Engineers, Mechanics, and StudentsDougKneNo ratings yet

- Arch Wires Used in OrthodonticsDocument47 pagesArch Wires Used in Orthodonticsavanthika krishnaraj100% (1)

- En 08 Mild Steel and Alloy Steels PropertiesDocument2 pagesEn 08 Mild Steel and Alloy Steels PropertiesSamratNo ratings yet

- Alloy Properties and Heat TreatmentDocument13 pagesAlloy Properties and Heat TreatmentSathish KumarNo ratings yet