Professional Documents

Culture Documents

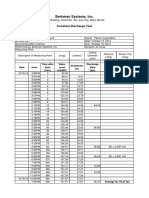

A9rc397-Gamesa G90

Uploaded by

atguintuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A9rc397-Gamesa G90

Uploaded by

atguintuCopyright:

Available Formats

Gamesa

G90-2.0 MW

Maximum output

at minimum cost

per kWh for

low wind sites

Class IIIA/WZII.

Pitch and variable speed

technology to maximize

energy production.

Production of lighter blades

using fiberglass, carbon fiber

and prepreg method.

Compliance with the main

international Grid Codes.

Aerodynamic design and

Gamesa NRS

control

system to minimize noise

emissions.

Gamesa WindNet

:

Remote monitoring and

control system with Web

access.

Benefits

BENEFITS

G90-2.0 MW

Diameter 90 m

Swept area 6,362 m

2

Rotational speed 9.0 - 19.0 rpm

Rotational direction Clock Wise (front view)

Weight (incl. Hub) Approx. 36 T

Top head mass Approx. 106 T

Number of blades 3

Length 44 m

Airfoils DU (Delft University) + FFA-W3

Material Preimpregnated epoxy glass fiber +

carbon fiber

Total blade weight 5,800 kg

Modular type Height Weight

4 sections 78 m 203 T

5 sections 100 m 255 T

Type Doubly-fed machine

Rated power 2.0 MW

Voltage 690 V ac

Frequency 50 Hz / 60 Hz

Protection class IP 54

Number of poles 4

Rotational speed 900:1,900 rpm (rated 1,680 rpm) (50 Hz)

1,080:2,280 rpm (rated 2,016 rpm) (60 Hz)

Rated Stator Current 1,500 A @ 690 V

Power factor (standard) 0.98 CAP - 0.96 IND at partial loads and

1 at nominal power.*

Power factor (optional) 0.95 CAP - 0.95 IND throughout

the power range.*

*

Power factor at generator output terminals, on low voltage side before transformer input

terminals.

Rotor

Blades

Tubular Tower

Generator 2.0 MW

Mechanical design

Drive train with main shaft supported by two spherical

bearings that transmit the side loads directly to the

frame by means of the bearing housing. This prevents

the gearbox from receiving additional loads, reducing

malfunctions and facilitating its service.

Brake

Aerodynamic primary brake by means of full-feathering

blades. In addition, a hydraulically-activated mechanical

disc brake for emergencies is mounted on the gearbox

high speed shaft.

Lightning protection

The Gamesa G90 -2.0 MW wind turbine generator uses

the "total lightning protection" system, in accordance

with standard IEC 61024-1. This system conducts the

lightning from both sides of the blade tip down to the

root joint and from there across the nacelle and tower

structure to the grounding system located in the

foundations. As a result, the blade and sensitive

electrical components are protected from damage.

Control System

The Generator is a doubly fed machine (DFM), whose

speed and power is controlled through IGBT converters

and PWM (Pulse Width Modulation) electronic control.

Benefits:

Active and reactive power control.

Low harmonic content and minimal losses.

Increased efficiency and production.

Prolonged working life of the turbine.

Gamesa WindNet

The new generation SCADA System (a wind farm control

system) entirely developed by Gamesa allows realtime

operation and remote control of wind turbines,

meteorological mast and the electrical substation. This

innovative modular design based on TCP/IP architecture

has tools for controlling active and reactive energy,

voltage and frequency. It also contains environmental

options to optimize the production to perfectly comply

with regulations currently in force. The intuitive remote

web client employs a very friendly user interface. The

system includes analytical tools for decision-making,

Report Generator and Information Manager and

TrendViewer, to give a sharp, clear view of trends.

SMP Predictive

Maintenance System

Predictive Maintenance System for the early detection

of potential deterioration or malfunctions in the wind

turbines main components.

Benefits:

Reduction in major corrective measures.

Increase in the machines availability and working life.

Preferential terms in negotiations with insurance

companies

Integration within the control system.

Type 1 planetary stage /

2 parallel stages

Ratio 1:100.5 (50 Hz)

1:120.5 (60 Hz)

Cooling Oil pump with oil cooler

Oil heater 2.2 kW

Gearbox

3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18-21 22 23 24 25

0

500

1000

1500

2000

Cut-in speed: 3 m/s

Cut-out speed: 25 m/s

P

o

w

e

r

k

W

Wind speed m/s

Blade

Blade bearing

Hydraulic pitch actuator

Hub cover

Hub

Active yaw control

Tower

Main shaft with two

bearing houses

Shock absorbers

Gearbox

Main disc brake

Nacelle support frame

Transmission:

High speed shaft

Doubly-fed generator

Transformer

Anemometer and wind

vane

Top controller

Nacelle cover

Hydraulic unit 19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Noise control

Aerodynamic blade tip and mechanical component design

minimize noise emissions. In addition, Gamesa has developed

the Gamesa NRS

noise control system, which permits

programming the noise emissions according to criteria such

as date, time or wind direction. This achieves the goals of

local regulation compliance as well as maximum production.

Grid connection

Gamesas doubly-fed wind turbines and Active Crowbar and

over sized converter technologies ensure compliance with the

most demanding grid connection requirements.

Low voltage ride-through capability and dynamic regulation

of active and reactive power.

Power Curve Gamesa G90-2.0 MW

(for an air density of 1.225 kg/m

3

)

Power curve calculation based on DU (Delft University) and

FFAW3 airfoils.

Calculation parameters: 50 Hz grid frequency; tip angle

pitch regulated; 10% turbulence intensity and a variable

rotor speed ranging from 9.0-19.0 rpm.

18

16

17

14

13

10

9 8

1

2

3

4

5

19

6

7

11 12 15

C/ Ciudad de la Innovacin, 9-11

31621 Sarriguren (Spain)

Tel: +34 948 771000

Fax: +34 948 165039

info@gamesacorp.com

www.gamesacorp.com

The present document, its content, its annexes and/or amendments has been drawn up by Gamesa Corporacin Tecnolgica, S.A. for information purposes

only and could be modified without prior notice. All the content of the Document is protected by intellectual and industrial property rights owned by Gamesa

Corporacin Tecnolgica, S.A. The addressee shall not reproduce any of the information, neither totally nor partially.

Printed date: December 2009

ITALY

Via Mentore Maggini 48/50

00143 Rome

Tel: +39 0645543650

Fax: +39 0645553974

JAPAN

Daiwa Jisho Building 4F 411

74-1 Naka-ku,

Yamashita-cho

Yokohama-city 231-0023

Kanagawa

Tel: +81 45 680 50 80

Fax: +81 45 680 50 81

MOROCCO

345, Lot Gzennaya A B.P 397

Tanger (Boukhalef)

Tel: +212 539 393308/09

Fax: +212 539 393312

UNITED STATES

2050 Cabot Boulevard West

Langhorne, PA 19047

Tel: +1 215 710 3100

Fax:+1 215 741 4048

CHINA

Room 605,

CBD International Building

N.

o

16, Yong An Dong Li,

Chaoyang District

Beijing 100022

Tel.: +86 10 6567 9888

Fax: +86 10 6566 9666

DENMARK

Vejlsvej 51

8600 Silkeborg

Tel: +45 87 229205 / 9204

Fax: +45 87 229201

EGYPT

12 Dar el Shefa Street 3th. Floor,

Garden City- Cairo

Tel: +20 166642424

Fax: +20 227951866

FRANCE

Paris

Tel: +33 (1) 4646 11 61

GERMANY

Wailandtstrasse 7

63741 Aschaffenburg

Tel: +49 (0) 6021 15 09 0

Fax: +49 (0) 6021 15 09 199

germany.wind@gamesacorp.com

In order to minimize the environmental impact, this document has been printed on paper made from 50% pure cellulose fiber (ECF), 40% selected

pre-consumer recycled fiber, and 10% post-consumer deinked recycled fiber inks based exclusively on vegetable oils with a minimum volatile organic

compound (VOC) content. Varnish based predominantly on natural and renewable raw materials.

You might also like

- Goldwind 15MW Product Brochure 2013Document4 pagesGoldwind 15MW Product Brochure 2013diegoxis24No ratings yet

- ... The Alternative: Dewind D6Document8 pages... The Alternative: Dewind D6BingJieZhaoNo ratings yet

- 3.5kW Spec Sheet (Data)Document2 pages3.5kW Spec Sheet (Data)Nishant SaxenaNo ratings yet

- Hummer Dynamo Co - LTD Anhui China Hummer Wind TurbineDocument6 pagesHummer Dynamo Co - LTD Anhui China Hummer Wind TurbinefazarNo ratings yet

- RFC 430Document96 pagesRFC 430birinderNo ratings yet

- 1 5kW Raum Energy System Specs 2009Document2 pages1 5kW Raum Energy System Specs 2009LucasZheNo ratings yet

- Wind and Solar Hybrid Street Lights Rev-01-Feb-11Document28 pagesWind and Solar Hybrid Street Lights Rev-01-Feb-11TERASAT SANo ratings yet

- Ge Gas Engine 18 MWDocument1 pageGe Gas Engine 18 MW123habib123fikriNo ratings yet

- Aeolos H 5kw BrochureDocument4 pagesAeolos H 5kw BrochureNelson Porco MolloNo ratings yet

- Data Sheet Wind Turbine SWT 3-6-120Document3 pagesData Sheet Wind Turbine SWT 3-6-120ermarmonNo ratings yet

- 01 Hydraulic GroupDocument81 pages01 Hydraulic Groupgica100% (1)

- AerodynamicsDocument99 pagesAerodynamicsKarthi KeyanNo ratings yet

- Dynamic Shape Optimization of A Vertical-Axis Wind Turbine Via Blade Morphing Technique PDFDocument35 pagesDynamic Shape Optimization of A Vertical-Axis Wind Turbine Via Blade Morphing Technique PDFJorge Arturo Pulido PerezNo ratings yet

- Seatitan 10 MW Wind Turbine: Maximum Power Per Tower For Offshore EnvironmentDocument2 pagesSeatitan 10 MW Wind Turbine: Maximum Power Per Tower For Offshore EnvironmentMiguel MartínezNo ratings yet

- On The Performance Analysis of Savonius Rotor With Twisted BladesDocument13 pagesOn The Performance Analysis of Savonius Rotor With Twisted BladesSatya PrakashNo ratings yet

- Hydrogen PinchDocument68 pagesHydrogen PinchSzideritNo ratings yet

- Manual Book Relay GE F35man-E2Document310 pagesManual Book Relay GE F35man-E2Khoirin NidaNo ratings yet

- 0.9PF PW 380v 3phase HF UPS10-120kvaDocument8 pages0.9PF PW 380v 3phase HF UPS10-120kvaArmandinho CaveroNo ratings yet

- Ijriet: Analysis of Blade Design Horizontal Axis Wind TurbineDocument6 pagesIjriet: Analysis of Blade Design Horizontal Axis Wind TurbineHarshad Pawar PatilNo ratings yet

- Plexos 6205Document6 pagesPlexos 6205Horacio EneroNo ratings yet

- 1905 - Carrier 30 GZ 190 PDFDocument6 pages1905 - Carrier 30 GZ 190 PDFbilal almelegyNo ratings yet

- Steam Turbines A Full Range To Fit Your Needs PDFDocument20 pagesSteam Turbines A Full Range To Fit Your Needs PDFvcharles100% (1)

- Data Sheet (500w VAWT)Document3 pagesData Sheet (500w VAWT)invic7usNo ratings yet

- Delta Es48 200 Uqa02Document2 pagesDelta Es48 200 Uqa02Aey PalakornNo ratings yet

- 1.3kW Spec SheetDocument2 pages1.3kW Spec SheetArkan Ahmed100% (1)

- Aeolos-V 2kW Brochure PDFDocument5 pagesAeolos-V 2kW Brochure PDFAnonymous U7o8tht51KNo ratings yet

- Improved BEMDocument10 pagesImproved BEMMurali Kuna ShekaranNo ratings yet

- CE 19 Data Interface Expansion Unit03 CZ1205Document1 pageCE 19 Data Interface Expansion Unit03 CZ1205Daniel GureanuNo ratings yet

- 3bnm005401 D101 PresentationDocument65 pages3bnm005401 D101 Presentationfloreabanciu100% (1)

- En Delphys Xtend GP BrochuresDocument12 pagesEn Delphys Xtend GP Brochuresjbperfecto_csciNo ratings yet

- Requirement of Protection Systems Engineering: Knowledge Management SystemDocument27 pagesRequirement of Protection Systems Engineering: Knowledge Management SystemSamNo ratings yet

- PRES - SIS GatewayA4 - VE - ENDocument1 pagePRES - SIS GatewayA4 - VE - ENdienlangchu100% (1)

- Instalare Si Service PDFDocument8 pagesInstalare Si Service PDFmicon75_tlNo ratings yet

- DS150E DataSheetDocument1 pageDS150E DataSheetwilmanzitoNo ratings yet

- Upgrade AMS 6500 ATG Firmware From Version 1.x To 2.xDocument12 pagesUpgrade AMS 6500 ATG Firmware From Version 1.x To 2.xPaulo LeiteNo ratings yet

- Datasheet Flatpack2 48V HE RectifiersDocument2 pagesDatasheet Flatpack2 48V HE Rectifiersmichaelliu123456No ratings yet

- C SoftwareDocument62 pagesC SoftwareJimmy ContarinoNo ratings yet

- Estacion HAWE Compacta HKDocument26 pagesEstacion HAWE Compacta HKJasierNo ratings yet

- Satyendra ' S ReportDocument24 pagesSatyendra ' S ReportSatyendra Singh100% (1)

- Tcgbutopia G8Document216 pagesTcgbutopia G8faffsNo ratings yet

- Namco Limit SwitchDocument4 pagesNamco Limit SwitchprabumunishNo ratings yet

- Stanford Paper On Wake EffectDocument6 pagesStanford Paper On Wake Effectdulika_12No ratings yet

- A/V System Controller: Service ManualDocument60 pagesA/V System Controller: Service ManualafraniobatistaNo ratings yet

- FLXR5 Aerodynamic Tutorial v2Document10 pagesFLXR5 Aerodynamic Tutorial v2sadeepa sooriyaarachchiNo ratings yet

- sm1600 GBDocument4 pagessm1600 GBTran Hong HiepNo ratings yet

- Analysis of Hybrid Systems Software ToolsDocument5 pagesAnalysis of Hybrid Systems Software ToolssoualmiaNo ratings yet

- Surgearresters Monitoring Eng Final PDFDocument12 pagesSurgearresters Monitoring Eng Final PDFCao Thanh TuanNo ratings yet

- Epcos PFC Catalog 14Document1 pageEpcos PFC Catalog 14Ursula JohnsonNo ratings yet

- A Review of Commonly Used DC Arc Models PDFDocument10 pagesA Review of Commonly Used DC Arc Models PDFMrn PNo ratings yet

- Fujitsu VRVDocument20 pagesFujitsu VRVSlobodan AnticNo ratings yet

- WindDocument3 pagesWindhuma tehreemNo ratings yet

- Zelio-Logic Relays: File 8501Document16 pagesZelio-Logic Relays: File 8501Claudio Valdes GutierrezNo ratings yet

- Talon RT-8200 Data SheetDocument2 pagesTalon RT-8200 Data SheetVinilNo ratings yet

- AC31 ConnectDocument40 pagesAC31 ConnectNenoNo ratings yet

- PS1000 - PCS DatasheetDocument7 pagesPS1000 - PCS DatasheetgoalexNo ratings yet

- Productbrochurev52 UKDocument6 pagesProductbrochurev52 UKjavier8970No ratings yet

- Gamesa G87 Detalii TehniceDocument24 pagesGamesa G87 Detalii TehniceAdrian StangaNo ratings yet

- DeWind D9 Series EnglishDocument7 pagesDeWind D9 Series EnglishjorgesantmontNo ratings yet

- Nordex N60: Long-Term Experience All Over The WorldDocument8 pagesNordex N60: Long-Term Experience All Over The Worldandy131078No ratings yet

- Datasheet HSIx0020 V16 EngDocument2 pagesDatasheet HSIx0020 V16 EngChiana PetreNo ratings yet

- Ambulong Climatological Extremes (As of 2016)Document1 pageAmbulong Climatological Extremes (As of 2016)atguintuNo ratings yet

- Sample - Construction Site PlanDocument3 pagesSample - Construction Site Planatguintu100% (1)

- Soil Sample Preparation: 1. ApplicationDocument3 pagesSoil Sample Preparation: 1. ApplicationatguintuNo ratings yet

- CReps Profile Form 2016Document1 pageCReps Profile Form 2016atguintuNo ratings yet

- Interview Guide: Personal/Family BackgroundDocument1 pageInterview Guide: Personal/Family BackgroundatguintuNo ratings yet

- Formulation of SSPI Social Development Plan: Process FlowchartDocument1 pageFormulation of SSPI Social Development Plan: Process FlowchartatguintuNo ratings yet

- Interview Review SheetDocument1 pageInterview Review SheetatguintuNo ratings yet

- Supplemental EISDocument207 pagesSupplemental EISatguintuNo ratings yet

- AP-202 ABCs of Gases PDFDocument3 pagesAP-202 ABCs of Gases PDFatguintuNo ratings yet

- Pbr-20 Constant Discharge Test-RevDocument1 pagePbr-20 Constant Discharge Test-RevatguintuNo ratings yet

- Do Wind Forecasts Make Good Generation SchedulesDocument13 pagesDo Wind Forecasts Make Good Generation SchedulesatguintuNo ratings yet

- Draft Eprmp Checklist For Expansion of Primary Hospital or Medical Facilities - RevisedDocument15 pagesDraft Eprmp Checklist For Expansion of Primary Hospital or Medical Facilities - Revisedatguintu80% (5)

- FinalReportRule28 20Document37 pagesFinalReportRule28 20atguintuNo ratings yet

- Conservation: Preservation or Working Landscapes?: Coffee Beneath A Primary Forest, Moa, SulawesiDocument20 pagesConservation: Preservation or Working Landscapes?: Coffee Beneath A Primary Forest, Moa, SulawesiatguintuNo ratings yet

- Vermiculture Made Easy - Vermiculture and Vermicomposting in The PhilippinesDocument22 pagesVermiculture Made Easy - Vermiculture and Vermicomposting in The Philippinesatguintu100% (1)

- Army - fm20 11 - Military Diving - U S Navy Diving Manual-Volume 5Document931 pagesArmy - fm20 11 - Military Diving - U S Navy Diving Manual-Volume 5Meowmix100% (1)

- NSDB - Sampling - Analysis - Manual (Soil Sampling and Analysis Procedures Used For NSDB)Document18 pagesNSDB - Sampling - Analysis - Manual (Soil Sampling and Analysis Procedures Used For NSDB)atguintuNo ratings yet

- A AD DB B T T: R RA Annssppa AR RE Ennc CYYDocument29 pagesA AD DB B T T: R RA Annssppa AR RE Ennc CYYatguintuNo ratings yet

- Combined Enr Stat2000 2008Document301 pagesCombined Enr Stat2000 2008atguintuNo ratings yet

- List of Requirements - DENR & LLDA Certificates/permitsDocument3 pagesList of Requirements - DENR & LLDA Certificates/permitsatguintu50% (2)

- TrapsDocument11 pagesTrapsAmandeep AroraNo ratings yet

- Brochure Exterior LightingDocument49 pagesBrochure Exterior Lightingmurali_227No ratings yet

- SRM OverviewDocument37 pagesSRM Overviewbravichandra24No ratings yet

- Introduction To Multistage Car Parking SystemDocument4 pagesIntroduction To Multistage Car Parking SystemInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Assignment ProblemsDocument22 pagesAssignment ProblemsPooja Yadav100% (1)

- Briefing Evaluation: Yes / No High / Low Yes / No High / Low Good / Inferior Yes / NoDocument4 pagesBriefing Evaluation: Yes / No High / Low Yes / No High / Low Good / Inferior Yes / NoAmmarah AzharNo ratings yet

- PVTP Complete PDF FreeDocument680 pagesPVTP Complete PDF FreemaxliraNo ratings yet

- Pricing and Marketing Strategy: Rahul Mishra, Narendra Singh, Dinesh KumarDocument12 pagesPricing and Marketing Strategy: Rahul Mishra, Narendra Singh, Dinesh KumarGaurav ChauhanNo ratings yet

- LV SWBDQualityInspectionGuideDocument72 pagesLV SWBDQualityInspectionGuiderajap2737No ratings yet

- Stearic Acid MSDSDocument6 pagesStearic Acid MSDSJay LakhaniNo ratings yet

- Long PassagesDocument12 pagesLong PassagesAml AmlNo ratings yet

- Critical and Creative ThinkingDocument26 pagesCritical and Creative Thinkingjoaquinricardo20153461No ratings yet

- JMPGuitars 18 Watt Tremolo TMB Reverb LayoutDocument1 pageJMPGuitars 18 Watt Tremolo TMB Reverb LayoutRenan Franzon GoettenNo ratings yet

- Final ExaminationDocument15 pagesFinal ExaminationMAY ANN CATIPONNo ratings yet

- (Checked) 12 Anh 1-8Document9 pages(Checked) 12 Anh 1-8Nguyễn Khánh LinhNo ratings yet

- ZEOS-AS ManualDocument2 pagesZEOS-AS Manualrss1311No ratings yet

- Snap-Tite75 Series-Catalog 3800 - SectionBDocument3 pagesSnap-Tite75 Series-Catalog 3800 - SectionBfrancis_15inNo ratings yet

- Gaara Hiden Series Light NovelDocument127 pagesGaara Hiden Series Light NovelartfardadNo ratings yet

- BUCA IMSEF 2021 Jury Evaluation ScheduleDocument7 pagesBUCA IMSEF 2021 Jury Evaluation SchedulePaulina Arti WilujengNo ratings yet

- July 2014 GEARSDocument76 pagesJuly 2014 GEARSRodger BlandNo ratings yet

- Imarest 2021 Warship Development 1997Document43 pagesImarest 2021 Warship Development 1997nugrohoNo ratings yet

- Teacher Empowerment As An Important Component of Job Satisfaction A Comparative Study of Teachers Perspectives in Al Farwaniya District KuwaitDocument24 pagesTeacher Empowerment As An Important Component of Job Satisfaction A Comparative Study of Teachers Perspectives in Al Farwaniya District KuwaitAtique RahmanNo ratings yet

- Comsigua HBIDocument0 pagesComsigua HBIproxywarNo ratings yet

- Load Dwe Eigh Ing D Devi Ice: For R Elev Vators SDocument28 pagesLoad Dwe Eigh Ing D Devi Ice: For R Elev Vators SNaren AnandNo ratings yet

- Piramal Revanta - Tower 3Document13 pagesPiramal Revanta - Tower 3bennymahaloNo ratings yet

- Human Resource Development Multiple Choice Question (GuruKpo)Document4 pagesHuman Resource Development Multiple Choice Question (GuruKpo)GuruKPO90% (20)

- Pism Pub Line Up - Jul-Dec - 2022Document1 pagePism Pub Line Up - Jul-Dec - 2022Yus CeballosNo ratings yet

- Headworks & Barrage: Chapter # 09 Santosh Kumar GargDocument29 pagesHeadworks & Barrage: Chapter # 09 Santosh Kumar GargUmer WaheedNo ratings yet

- MS Y7 Spelling Bee Memo & List 21 22Document9 pagesMS Y7 Spelling Bee Memo & List 21 22Muhammad Akbar SaniNo ratings yet

- SAGC Compliance Awareness-Grid UsersDocument66 pagesSAGC Compliance Awareness-Grid Userskamal_khan85No ratings yet