Professional Documents

Culture Documents

Multiphase Flow Modeling

Uploaded by

karamniaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Multiphase Flow Modeling

Uploaded by

karamniaCopyright:

Available Formats

Computational Fluid Dynamics I

Multiphase Flow Modeling

Grtar Tryggvason

Worcester Polytechnic Institute,

Spring 2009

http://users.wpi.edu/~gretar/me612.html

Computational Fluid Dynamics I

Spray drying

Pollution control

Pneumatic transport

Slurry transport

Fluidized beds

Spray forming

Plasma spray coating

Abrasive water jet cutting

Pulverized coal red furnaces

Solid propellant rockets

Fire suppression and control

Examples:

Computational Fluid Dynamics I

Single component Multicomponent

Single water ow air ow

phase Nitrogen ow emulsions

Multiphase Steam-water ow air-water ow

Freon-Freon slurry ow

vapor ow

Computational Fluid Dynamics I

Disperse ow

Solid-liquid: Slurries, quicksand, sediment transport

Solid-air: dust, uidized bed, erosion

Liquid-air: sprays, rain

Air-liquid: bubbly ows

Computational Fluid Dynamics I

Mixed

Stratied

Dispersed

Slugs

Flow in pipes

Computational Fluid Dynamics I

This gure shows schematically one

of several di!erent congurations of a

circulating uidized bed loop used in

engineering practice. The particles

ow downward through the aerated

standpipe, and enter the bottom of a

fast uidized bed riser. The particles

are centrifugally separated from the

gas in a train of cyclones. In this

diagram, the particles separated in the

primary cyclone are returned to the

standpipe while the fate of the

particles removed from the secondary

cyclone is not shown.

From: Computational Methods for

Multiphase Flow, Edited by

A.Prosperetti and G.Tryggvason

Computational Fluid Dynamics I

Need model equations to predict ow rates, pressure

drop, slip velocities, and void fraction

Mixture models: one averaged phase

Two-uid models: two interpenetrating continuum

Computational Fluid Dynamics I

Euler/Euler approach

All phases are treated as interpenetrating continuum

The dispersed phase is averaged over each control volume

Each phase is governed by similar conservation equations

Modeling is needed for

interaction between the phases

turbulent dispersion of particles

collision of particles with walls

A size distribution requires the solution of several sets of

conservation equations

Numerical diffusion at phase boundaries may result in errors

This approach is best suited for high volume fraction of the

dispersed phase

Computational Fluid Dynamics I

Euler/Lagrange approach

The uid ow is found by solving the Reynolds-averaged

Navier-Stokes equations with a turbulence model.

The dispersed phase is simulated by tracking a large number of

representative particles.

A statistically reliable average behavior of the dispersed phase

requires a large number of particles

The point particles must be much smaller than the grid spacing

Modeling is needed for

collision of particles with walls

particle/particle collisions and agglomeration

droplet/bubble coalescence and breakup

A high particle concentration may cause convergence problems

Computational Fluid Dynamics I

Although commercial codes will let you model relatively

complex multiphase ows, it is really only in the limit of

dispersed and dilute ows where we can expect reasonable

accuracy

To treat systems like this, the

two-uid model is usually

used. The continuous phase

is almost always used in an

Eularian way where the

continuity, momentum, and

energy equations are solved

on a xed grid.

Computational Fluid Dynamics I

The void fraction !

p

describes how much

of the region is occupied by phase p.

Obviously,

Similarly, the effective

density of phase p is

!

"

p

=1

#

!

" =#

p

"

p

Computational Fluid Dynamics I

While the averaging is similar to turbulent ows,

here we must account for the different phases

!

"

p

=

1 inside phase p

0 otherwise

#

$

%

!

"

p

=

1

V

#

p

dv

V

$

The void fraction is found by

Computational Fluid Dynamics I

!

"

p

=

1

#

p

V

$

p

" dv

V

%

Averages are found by

Where the volume

V goes to zero in

some way

The velocity is found by

!

u

p

=

1

"

p

V

u

p

#

p

dv

V

$

The averages can also be interpreted as time or

ensemble averages

Computational Fluid Dynamics I

!

"

p

#

p

dv

V

$

The total mass of phase p in a control volume is

And the mass conservation equation can be

averaged to yield

!

"

"t

#

p

$

p

+ %& #

p

$

p

u

p ( )

= m

p

Here

Since a mass that leaves one phase

must add to another phase

!

m

p

= 0

"

Computational Fluid Dynamics I

The conservation of momentum equation becomes

!

"

"t

#

p

$

p

u

p ( )

+ %& #

p

$

p

u

p

u

p ( )

= '#

p

%p

p

+%& #

p

p

D

p ( )

+#

p

$

p

g + %& #

p

$

p

< uu >

( )

+ F

int

In addition to the Reynolds stresses, it is now necessary

to model the interfacial forces. The kinetic energy is

often neglected, even though the uctuations are non-

zero in laminar ow

interfacial

forces

Reynolds

stresses

Computational Fluid Dynamics I

If there is no mass transfer m=0 and F is the force that

one phase exerts on the other

!

F

p

= 0

"

In principle the conservation equations can be

solved for both the continuous and the dispersed

phase (Euler/Euler approach).

Computational Fluid Dynamics I

However, the dispersed phase is not all that continuous

and an other approach is to explicitly tract

(representative) particles by solving

!

du

dt

= F

p

If the particles have no inuence on the uid: one way

coupling

If the particles exert a force on the uid: Two way

coupling

Computational Fluid Dynamics I

Usually the force is written:

!

F

p

= k

D

u"u

p ( )

+ g

#

D

" #

#

+ F

other

Other forces due

to added mass,

pressure, lift, etc

Gravity

buoyancy

Drag

force

Computational Fluid Dynamics I

For the drag:

!

F

p

= k u

r

" u

p ( )

where

!

k =

3

4

C

D

"

r

#

q

u

r

$ u

p ( )

d

r

!

C

D

= C

D

Re ( )

is obtained from experimental correlations, such as

and

!

C

D

=

24

Re

1+ 0.15Re

0.687

( )

Re <10

3

For solid particles Re based on slip velocity

Computational Fluid Dynamics I

!

du

p

dt

= F

p

!

dx

p

dt

= u

p

Find particle trajectories by solving

The force allows us to nd the particle

velocity by integrating:

Computational Fluid Dynamics I

Turbulent ow

Set particle velocity

!

u

p

+ u'

Random velocity uctuations

from

This allows particles to cross streamlines

as they do in turbulent ow

Particles can

accumulate here

!

k

p

= u' u'

"

Computational Fluid Dynamics I

Usually a large number of particles is used to get a

well converged particle distribution

Notice that almost all the interactions (particles/ow)

particle/particle, particle/wall) are highly empirical

Computational Fluid Dynamics I

Similar approach can be taken for the temperature

and the size of a particle (heat and mass transfer)

!

m

p

c

p

dT

p

dt

= hA

p

(T

f

"T

p

) +#

p

A

p

$(T

%

4

"T

p

4

)

!

dm

p

dt

= m

p

For dilute ows this does work reasonably well if

the initial or inlet conditions are knows

Mass transfer due

to evaporation, for

example

Computational Fluid Dynamics I

Turbulent in the continuous phase

!

Dk

Dt

=!!+ < U" F

p

>

!

< U" F

p

>=

#

$

< u

f

(u

f

% u

p

) >=

#

$

(< u

f

u

f

> % < u

f

u

p

>)

This term can lead to both reduction and increase in the

turbulence in the liquid

Either ignore the contributions of the dispersed phase

when computing the ow, or use a k-! model

Solve for k and ! in the liquid and k

p

. Called k ! k

p

models.

The k equation is

Computational Fluid Dynamics I

Modeling of Laminar Flow

in a Vertical Channel

Computational Fluid Dynamics I

Flow Gravity

Bubbly ow in a vertical channel

Need to know

The bubble distribution

The velocity prole and

the ow rate

x

y

!

"

"y

= 0

Assume that the ow is

independent of y, so

!

"p

l

"y

is given

but

S.P. Antal, R.T. Lahey and J.E.

Flaherty. Int!l. J. Multiphase Flow

17 (1991), 635-652.

Computational Fluid Dynamics I

!

"

#"

#x

U

r

2

5

1$" ( ) = $"C

L

U

r

#u

l

#x

$" C

w1

+ C

w2

R

b

s

%

&

'

(

)

*

U

r

2

R

b

!

(1"#)

dp

l

dy

+ 1"# ( )$

l

g

y

= (1"#)

l

%

2

v

l

%x

2

+

3

8

#

R

b

C

D

$

l

U

r

U

r

!

" x ( ) =

1

L

"dx

0

L

#

, u

l

0 ( ) = u

l

H ( ) = 0

Simple two-uid model for laminar multiphase ow

Comparison with a two-uid model

!

"

dp

dy

+"#

g

g

y

= $

3

8

"

R

b

C

D

#

l

U

r

U

r

!

dp

g

dy

=

dp

l

dy

=

dp

dy

Bubble vertical momentum

Liquid vertical

momentum

Bubble

horizontal

momentum

Lift Wall repulsion

(away from wall or zero)

!

C

D

=

24

Re

1+ 0.1Re

0.75

( )

!

Re =

2R

b

"

l

U

r

m

!

m

=

l

1"#

Computational Fluid Dynamics I

Comparison with a two-uid model

Comparison with experimental results. Graph from: S.P. Antal, R.T. Lahey and

J.E. Flaherty. Int!l. J. Multiphase Flow 17 (1991), 635-652.

Computational Fluid Dynamics I

For more information about computing multiphase ow, see:

Modeling of multiphase ows is still a very immature area.

Interpret the results with care!

Computational Fluid Dynamics I

Combustion Modeling

Grtar Tryggvason

Worcester Polytechnic Institute,

Spring 2009

http://users.wpi.edu/~gretar/me612.html

Computational Fluid Dynamics I

Gas combustion

Gasoline engines,

gas burners

Spray combustion

Jet engines,

diesel engines

Combustion of solids

coal,

wood,

polymers

Examples

Computational Fluid Dynamics I

Diffusion ames

Most burners, candle

Flame stays at the

boundary between the

fuel and the oxidizer

Premixed ames

Some burners

Hazards

IC engines

The ame separates

unburned and burned

mixture of fuel and oxidizer

Computational Fluid Dynamics I

Diffusion Flames

Computational Fluid Dynamics I

Diffusion ames

Fuel, CH

4

(methane), for

example

Oxidizer, O

2

The thickness of the

ame depends on

the ratio of the

reaction rates to the

diffusion times

(Dahmkler number)

Computational Fluid Dynamics I

Diffusion ames

CH

4

O

2

Interim

species

The thickness of the

ame depends on

the ratio of the

reaction rates to the

diffusion times

(Dahmkler number)

CH

4

O

2

Interim

species

Fast Reaction

Slow Reaction

Computational Fluid Dynamics I

In turbulent ows the

ame sheet usually

folds in complex ways

P = 4,

!

inj

=

0.3

P = 4,

!

inj

=

0.1

P = 4,

!

inj

=

0.5

Computational Fluid Dynamics I

In general, the combustion is a very complex

process involving O(100) species and reaction rates.

These are reasonably well known for a number of

reaction, but still an open research eld in general.

For combustion of natural gas, GRIMech, for

example

Computational Fluid Dynamics I

For the full problem it is necessary to track the mass

fraction of every species along with the momentum,

mass, and energy conservation equations

!

"

"t

#m

i

+ $% u#m

i

= $% J + R

!

"

"t

c

i

+ #$ uc

i

= R

!

R = T

n

AE

"E

k

/ RT

#c

i

i

Arrenius reaction rates

Only a handful of computations of the full problem

have been done so far

Computational Fluid Dynamics I

For realistic situations, the problem must be simplied

Diffusion Flames

Use one-step (overall) reaction rates

(if Da"#, Burke Shuman limits)

Use a reduced set of chemical reactions

Can work very well for laminar ames. For

turbulent ows the reaction rates have to be

modied to account for stretching and folding of

ame sheets.

Computational Fluid Dynamics I

This is a conserved variable that is simply advected with

the ow

Given f, we can nd each species fraction by

For a simple one step reaction it can be shown that it is

sufcient to follow one variable, called the mixture fraction

!

"

i

= "

i

( f )

!

"

"t

(#f ) + $% (#fu) = $% D$f !

f =

m

f

m

f

+ m

o

Computational Fluid Dynamics I

The $ function can be constructed either assuming innitely

fast reactions (ame sheets) or equilibrium. The library is

constructed once only. If the system is non-adiabatic, $ is a

function of the enthalpy also

The chemical system must be a diffusion ame and

consists of a fuel and an oxidizer

The Lewis number must be unity (all diffusion

coefcients equal)

Only one fuel type (can be a mixture)

Only one type of oxidizer (can be a mixture)

Incompressible turbulent ow

Computational Fluid Dynamics I

For turbulent ows we solve for both f and the uctuations of

f and use those to determine the species fraction

Determines how f

is distributed and

therefore how the

species are

distributed

In the actual code a 2D look up table is rst

constructed, given the shape of the pdf

!

f ' ( )

2

smaller

pdf

f

!

" = " f , f ' ( )

2 #

$

%

&

'

(

Computational Fluid Dynamics I

pdf

f

f

t

Constructing the pdf from measurements

Computational Fluid Dynamics I

Premixed Flames

Computational Fluid Dynamics I

Premixed ames

!

"

"t

#G+ u$ %#G =U

f

%#G

Motion

due to

uid

ow

Motion

due to

burning

For turbulent ow the ame speed is different from

laminar ow due to wrinkling

The ame speed is found experimentally

or by detailed computations

!

U

f

Flame is marked

by G=0

G<0

G<0

Computational Fluid Dynamics I

Other combustion models

Droplets Solid particles

Evaporation

Burning

(usually)

Gasication

Burning

Computational Fluid Dynamics I

As for multiphase ows, many issues are still unresolved in

modeling of combustion and these models should be

applied with care

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Sizing ImpellersDocument7 pagesSizing ImpellerskaramniaNo ratings yet

- Free Surface FlowsDocument27 pagesFree Surface Flowsm_b_sNo ratings yet

- Introduction, Mathematical Preliminaries, Weak FormDocument25 pagesIntroduction, Mathematical Preliminaries, Weak FormkaramniaNo ratings yet

- 20Document11 pages20irfanNo ratings yet

- In Depth SolutionDocument4 pagesIn Depth SolutionkaramniaNo ratings yet

- Monte Carlo SimulationsDocument30 pagesMonte Carlo SimulationskaramniaNo ratings yet

- Lessons Learned From Execution of SAGDDocument62 pagesLessons Learned From Execution of SAGDkaramniaNo ratings yet

- Alberta UpgradingDocument6 pagesAlberta UpgradingkaramniaNo ratings yet

- Lessons Learned From Execution of SAGDDocument62 pagesLessons Learned From Execution of SAGDkaramniaNo ratings yet

- Hydraulic CalculationsDocument4 pagesHydraulic Calculationskaramnia100% (1)

- Alberta UpgradingDocument6 pagesAlberta UpgradingkaramniaNo ratings yet

- Well LogDocument60 pagesWell LogkaramniaNo ratings yet

- PishvaeiDocument10 pagesPishvaeikaramniaNo ratings yet

- Applications of CFD in The Oil Sand IndustryDocument31 pagesApplications of CFD in The Oil Sand IndustrykaramniaNo ratings yet

- Lessons Learned From Execution of SAGDDocument62 pagesLessons Learned From Execution of SAGDkaramniaNo ratings yet

- CFD Modeling of Solid Suspension in A Stirred Tank Effect of Drag Models and Turbulent Dispersion On Cloud HeightDocument9 pagesCFD Modeling of Solid Suspension in A Stirred Tank Effect of Drag Models and Turbulent Dispersion On Cloud HeightkaramniaNo ratings yet

- Lessons Learned From Execution of SAGDDocument62 pagesLessons Learned From Execution of SAGDkaramniaNo ratings yet

- Incoloy Alloys 800H 800HTDocument16 pagesIncoloy Alloys 800H 800HTkaramniaNo ratings yet

- VLE ProblemDocument3 pagesVLE ProblemkaramniaNo ratings yet

- NRTL ParametersDocument3 pagesNRTL ParameterskaramniaNo ratings yet

- ANSYS Applications in Ocean Science and EngineeringDocument62 pagesANSYS Applications in Ocean Science and EngineeringkaramniaNo ratings yet

- Vol 43 - 3 0004Document112 pagesVol 43 - 3 0004karamniaNo ratings yet

- Alshareef Ali Spring+2012Document279 pagesAlshareef Ali Spring+2012karamniaNo ratings yet

- Chemical Treatment Prior To Physical Coal BeneficiationDocument4 pagesChemical Treatment Prior To Physical Coal BeneficiationkaramniaNo ratings yet

- AspenDocument156 pagesAspenapi-3750488No ratings yet

- "Carbon Capture and Sequestration: in The Canadian Context": Sura Abdul-Razzak April 14 2008Document25 pages"Carbon Capture and Sequestration: in The Canadian Context": Sura Abdul-Razzak April 14 2008karamnia100% (1)

- Catalytic Coal Gasification An Emerging Technology For SNGDocument30 pagesCatalytic Coal Gasification An Emerging Technology For SNGkaramniaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 4 Cs of Dust Control InformationalDocument5 pages4 Cs of Dust Control Informationalabu_shofiaNo ratings yet

- Nuova Fima MGS18 - 63mmDocument2 pagesNuova Fima MGS18 - 63mmPaweł HejmowskiNo ratings yet

- SWDocument7 pagesSWJose MontesNo ratings yet

- Assignment 02Document1 pageAssignment 02parul tyagiNo ratings yet

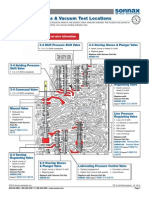

- 722 6 VacTestLocationsDocument4 pages722 6 VacTestLocationsUrszula WalczewskaNo ratings yet

- Oil Well CementingDocument20 pagesOil Well CementingDozie Kesieme100% (7)

- Hd26000 Casing TongDocument121 pagesHd26000 Casing TongTerry Smith100% (1)

- Machining Recommendations: Advice For Reducing Vibrations and Increasing The Drill Life LengthDocument3 pagesMachining Recommendations: Advice For Reducing Vibrations and Increasing The Drill Life LengthbasaricaNo ratings yet

- Kaup T411 T411D ENDocument8 pagesKaup T411 T411D ENJuan Francisco Canto DiezNo ratings yet

- Comitrol Processor Model 1700: Controlled Particle Size ReductionDocument2 pagesComitrol Processor Model 1700: Controlled Particle Size ReductionNguyễn Lê Anh KhoaNo ratings yet

- Candy CB 82 TDocument33 pagesCandy CB 82 TIsabel Belmonte CiborroNo ratings yet

- FYP Allocation AY 2012-2013 Sem 1Document7 pagesFYP Allocation AY 2012-2013 Sem 1Yandi LayadiNo ratings yet

- ARE Non-Stick Utensils Safe For HumanDocument13 pagesARE Non-Stick Utensils Safe For HumanSoft TechNo ratings yet

- Lenovo t400 Service Manual PDFDocument386 pagesLenovo t400 Service Manual PDFJosé Fabio Lou100% (1)

- The Importance of Cleaning and Deposit Control in Improving Paper Machine EfficiencyDocument4 pagesThe Importance of Cleaning and Deposit Control in Improving Paper Machine EfficiencySelly YunitaNo ratings yet

- Flare SystemDocument29 pagesFlare SystemLuis EnriqueNo ratings yet

- 690+ ParkerDocument148 pages690+ Parkerjohxav10No ratings yet

- Zelio Time Re8ta21buDocument2 pagesZelio Time Re8ta21buJonathan Meza FlorNo ratings yet

- Slurry Pump The KproDocument11 pagesSlurry Pump The Kpro4lk0nNo ratings yet

- Astm21 1510Document18 pagesAstm21 1510Robert ChenNo ratings yet

- PACCON18 ProceedingBK FullpaperDocument1,486 pagesPACCON18 ProceedingBK FullpaperDo Ngoc Tram67% (3)

- Legrand Cable Lighting & Data Trunking Technical PDFDocument35 pagesLegrand Cable Lighting & Data Trunking Technical PDFHarshith KunjathurNo ratings yet

- Document: Structural CalculationDocument209 pagesDocument: Structural CalculationStephen Mari CanoNo ratings yet

- Sterilization MethodsDocument18 pagesSterilization MethodsRasika RathnayakaNo ratings yet

- GearsDocument22 pagesGearsAnurag MidhaNo ratings yet

- Internal Sizing of Paper - AKD - ASADocument71 pagesInternal Sizing of Paper - AKD - ASAelgendawyNo ratings yet

- 0354-98361800278F Dolomite Sintering in Shaft Kiln PDFDocument13 pages0354-98361800278F Dolomite Sintering in Shaft Kiln PDFtaghdirimNo ratings yet

- Astm D473. SedimentosDocument6 pagesAstm D473. SedimentosgeralNo ratings yet

- 1-Mix Design UHPGC (W-B (0.35) (Ca 0.3) - Effect of MolarityDocument93 pages1-Mix Design UHPGC (W-B (0.35) (Ca 0.3) - Effect of MolaritySawa Zayia MichaelNo ratings yet