Professional Documents

Culture Documents

Design and Analysis of Composite Drive Shaft

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Analysis of Composite Drive Shaft

Copyright:

Available Formats

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 03 | May-2014 | NCRIET-2014, Available @ http://www.ijret.org 738

DESIGN AND ANALYSIS OF COMPOSITE DRIVE SHAFT

V. S. BHAJANTRI

1

, S. C. BAJANTRI

2

, A. M. SHINDOLKAR

3

, S. S. AMARAPURE

4

1

Assistant Professor, Dept. Of Mech. Engg., SCET, Belgaum-591156

2

Assistant Professor, Dept. Of Mech. Engg., SCET, Belgaum-591156

3

Assistant Professor, Dept. Of Mech. Engg., SCET, Belgaum-591156

4

Assistant Professor, Dept. Of Mech. Engg., SCET, Belgaum-591156

Abstract

Substituting composite structures for conventional metallic structures has much advantage because of higher specific stiffness and

strength of composite materials. This work deals with replacement of conventional two piece steel drive shaft with a single-piece e-

glass/epoxy, high strength carbon/epoxy and high modulus carbon/epoxy composite drive shaft for automobile shaft for an automotive

application. The design parameters were optimized with the objective on minimizing the weight of composite drive shaft.

-----------------------------------------------------------------------***----------------------------------------------------------------------

1. INTRODUCTION

Composite materials have been widely used to improve the

performance of various types of structures. Compared to

conventional materials, the main advantages of composites are

their superior stiffness to mass ratio as well as high strength to

weight ratio. Because of these advantages, composites have been

increasingly incorporated in structural components in various

industrial fields. Some examples are helicopter rotor blades,

aircraft wings in aerospace engineering, and bridge structures in

civil engineering applications. Some of the basic concepts of

composite materials are discussed in the following section to

better acquaint ourselves with the behaviour of composites.

1.1 Basic Concepts of Composite Materials

Composite materials are basically hybrid materials formed of

multiple materials in order to utilize their individual structural

advantages in a single structural material. The constituents are

combined at a macroscopic level and are not soluble in each

other. The key is the macroscopic examination of a material

wherein the components can be identified by the naked eye.

Different materials can be combined on a microscopic scale, such

as in alloying of metals, but the resulting material is, for all

practical purposes, macroscopically homogeneous, i.e. the

components cannot be distinguished by the naked eye and

essentially acts together. The advantage of composite materials is

that, if well designed, they usually exhibit the best qualities of

their components or constituents and often some qualities that

neither constituent possesses. Some of the properties that can be

improved by forming a composite material are strength, fatigue

life, stiffness, temperature-dependent behaviour, corrosion

resistance, thermal insulation, wear resistance, thermal

conductivity, attractiveness, acoustical insulation and weight.

Naturally, not all of these properties are improved at the same

time nor is there usually any requirement to do so. In fact, some

of the properties are in conflict with one another, e.g., thermal

insulation versus thermal conductivity. The objective is merely to

create a material that has only the characteristics needed to

perform the designed task.

There are two building blocks that constitute the structure of

composite materials. One constituent is called the reinforcing

phase and the one in which it is embedded is called the matrix.

The reinforcing phase material may be in the form of fibres,

particulates, flakes. The matrix phase materials are generally

continuous. Examples of composite systems include concrete

reinforced with steel, epoxy reinforced with graphite fibres, etc

1.2 Fibres

Fibres are the principal constituent in a fibre-reinforced

composite material. They occupy the largest volume fraction in a

composite laminate and share the major portion of the load acting

on a composite structure. Proper selection of the type, amount

and orientation of fibres is very important, because it influences

the following characteristics of a composite laminate.

a. Specific gravity

b. Tensile strength and modulus

c. Compressive strength and modulus

d. Fatigue strength and fatigue failure

mechanisms

e. Electric and thermal conductivities

f. Cost

The various types of fibres currently in use are

a. Glass Fibres

b. Carbon Fibres

c. Aramid Fibres

d. Boron Fibres

e. Silicon Carbide Fibres

1.3 Matrix

In a composite material the fibres are surrounded by a thin layer

of matrix material that holds the fibres permanently in the desired

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 03 | May-2014 | NCRIET-2014, Available @ http://www.ijret.org 739

orientation and distributes an applied load among all the fibres.

The matrix also plays a strong role in determining the

environmental stability of the composite article as well as

mechanical factors such as toughness and shear strength.

The matrix binds the fibres together, holding them aligned in the

important stressed directions. The matrix must also isolate the

fibres from each other so that they can act as separate entities.

The matrix should protect the reinforcing filaments from

mechanical damage (e.g. abrasion) and from environmental

attack. A ductile matrix will provide a means of slowing down or

stopping cracks that might have originated at broken fibres;

conversely, a brittle matrix may depend upon the fibres to act as

matrix crack stoppers. Through the quality of its grip on the

fibres (the interfacial bond strength), the matrix can also be an

important means of increasing the toughness of the composite.

Because the reinforcing fibres can be oriented during fabrication

of item, composites can be tailored to meet increased load

demands in specific directions. The combined fibre-matrix

system is an engineered material designed to maximize

mechanical and environmental performance.

1.4 Classification of Composites

Composite materials in general are categorised based on the kind

of reinforcements or the surrounding matrix. There are four

commonly accepted types of composite materials based on

reinforcements-

a. Fibrous composite materials that consist of fibres in

a matrix.

b. Laminated composite materials that consist of

layers of various materials.

c. Particulate composite materials that are composed

of particles in a matrix.

d. Combinations of some or all of the first three types.

And the major composite classes based on structural composition

of the matrix are-

a. Polymer-Matrix Composites

b. Metal- Matrix Composites

c. Ceramic- Matrix Composites

d. Carbon- Carbon Composites

e. Hybrid Composites

1.5 Applications of Composite Materials

The common applications of composites are extending day by

day. Nowadays they are used in medical applications too. Some

other fields of applications are,

Automotive : Drive shafts, clutch plates, fibre

Glass/Epoxy leaf springs for heavy trucks and trailers,

rocker arm covers, suspension arms and bearings for

steering system, bumpers, body panels and doors.

Aerospace: Drive shafts, rudders, elevators, bearings,

landing gear doors, panels and floorings of airplanes,

payload bay doors, remote manipulator arm, high gain

antenna, antenna ribs and struts etc.

Marine: Propeller vanes, fans & blowers, gear cases,

valves &strainers, condenser shells.

Chemical Industries: Composite vessels for liquid

natural gas for alternative fuel vehicle, racked bottles for

fire service, mountain climbing, underground storage

tanks, ducts and stacks etc.

Electrical & Electronics: Structures for overhead

transmission lines for railways, Power line insulators,

Lighting poles, Fibre optics tensile members etc.

1.6 Drive Shaft

As mentioned above, recent developments in the applications of

composite materials have shown that a composite material

structural member used in power transmission can be of a great

assistance in overcoming a few of the problems faced with

conventional drive shafts. The assessment of the extent of this

fact is the essence of this work. Therefore a good understanding

of the drive shaft would be a prerequisite and is discussed in the

following section.

A drive shaft, propeller shaft (prop shaft), or Cardan shaft is a

mechanical component for transmitting torque and rotation,

usually used to connect other components of a drive train that

cannot be connected directly because of distance or the need to

allow for relative movement between them. Drive shafts are

carriers of torque. They are subject to torsion and shear stress,

equivalent to the difference between the input torque and the

load. They must therefore be strong enough to bear the stress,

whilst avoiding too much additional weight as that would in turn

increase their inertia. Therefore a drive shaft is expected to

function, as follows.

a. It must transmit torque from the transmission to the

differential gear box.

b. The drive shaft must also be capable of rotating at

very high speeds as required by the vehicle.

c. The drive shaft must also operate through constantly

changing angles between the transmission, the

differential and the axels.

d. The length of the drive shaft must also be capable of

changing while transmitting torque.

Thus the design of a drive shaft presents itself as a case of torsion

problem. Further, with regard to the conventional drive shafts

following shortcomings were observed some of which could be

addressed better with a composite shaft.

1. They have less specific modulus and strength

2. Increased weight

3. Conventional steel drive shafts are usually

manufactured in two pieces to increase the

fundamental bending natural frequency because the

bending natural frequency of a shaft is inversely

proportional to the square of beam length and

proportional to the square root of specific modulus.

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 03 | May-2014 | NCRIET-2014, Available @ http://www.ijret.org 740

Therefore the steel drive shaft is made in two sections

connected by a support structure, bearings and U-

joints and hence overall weight of assembly will be

more.

4. Its corrosion resistance is less as compared with

composite materials.

5. Steel drive shafts have less damping capacity.

Since a drive shaft is a case of torsion problem an understanding

of the methodology of solving such a problem in structural

mechanics is necessary.

1.7 Torsion Problem in Structural Mechanics

Torsion of cylindrical shafts has long been a subject of interest in

power transmission problems. To this end the stiffness of a

cylindrical shaft under torsional loading is considered. The axial

displacement field of the cross-section is assumed not to vary

along the axial direction away from the ends of the shaft. Under

this assumption, the torsional rigidity is only dependent on the

shape of the cross-section. The governing equations of this

boundary value problem can be formulated in terms of a Laplace

or Poisson Equation. Within the former one, one uses the

warping function as dependent variable, while in the latter the

Prandtls stress function is used. The solutions for the warping

and Prandtls stress function have been obtained exactly for

simple cross-sectional shapes such as a circle, annulus, ellipse,

rectangle, and triangle. For more complicated shapes, numerical

methods are usually employed, such as, the finite difference

method, finite element method and boundary element method.

Some authors use the approach of combination of experimental

and analytical methods to predict the effective in-plane and out-

of-plane shear moduli of structural composite laminates. Due to

the extensive use of composite materials, the study of compound

bars under torsion has become a point of focus in the recent days.

1.8 Torsion of Composite Shafts

Compared to homogeneous cylindrical shafts, the torsional

behaviour of composite shafts is considerably more complicated.

The torsional rigidity not only depends on the global cross-

sectional geometry, but also on the properties and configurations

of each constituent. The analytical solution of compound bars

under torsion was first obtained by Muskhelishvili (1963), where

the solution was expressed in terms of eigen functions.

Packhamand Shail (1978) used linear combinations of solutions

of a homogeneous shaft to solve the problem in which the cross

section is symmetric with respect to the common boundary. The

elastic properties of non-homogeneous anisotropic beams are

usually of engineering interest. Torsional rigidities of

multilayered composite beams are especially needed when

structures are under torsional loading. Savoia and Tullini (1993)

analyzed the torsional response of composite beams of arbitrary

cross section. The boundary value problem was formulated in

terms of both warping and Prandtls stress function. Using the

eigen function expansion method, the exact solution of

rectangular multilayered orthotropic beams under uniform

torsion was derived. Swanson (1998) extended the existing

solutions of torsion of orthotropic laminated rectangular beams to

the high aspect ratio case. Based on the membrane analogy, an

approximate solution of general, thin, laminated, open cross

sections was derived.

In this study, an analytical approach is proposed to solve the

torsion problem of laminated composite shafts that consist of

orthotropic sublaminates. The present approach uses the concept

of elastic constants (Chou, et al., 1972), in which the three-

dimensional nonhomogeneous orthotropic laminate is replaced

by an equivalent homogeneous orthotropic material. A small

element consisting of n layers from the composite material,

[assumed to represent the behaviour of the overall composite

laminate] is considered to be under a uniform state of stress when

the composite laminate is under arbitrary loading. Two

assumptions have been made in this regard: first, the normal

strains and shear strains parallel to the plane of layers are

uniform and the same for each constituent and the corresponding

stresses are averaged. Second, the normal stresses and shear

stresses perpendicular to the plane of layers are uniform and

equal for each constituent and the corresponding strains are

averaged. Under these two assumptions, the equilibrium at each

sublaminate interface and compatibility conditions of materials

are satisfied automatically. As the thickness of each layer

approaches zero, the overall effective elastic constants are

developed. The effective shear moduli of the composite

laminates are used to calculate the overall torsional rigidity of the

orthotropic laminated shaft.

Having convinced ourselves about the nature of the problem and

the possible solution to it, we now move on to develop a better

understanding of the fundamentals necessary for the present

work. A qualitative literature survey would greatly help us

achieve it and is presented in the following chapter.

1.9 Analysis of Composite Drive Shaft

A good design solution can be delivered only when the function

of the component being designed, is known before hand with

proper working condition specifications. Ability of different

methodologies in solving for these conditions can be appreciated

based on the complexity of the problem, though. Presently, the

specifications of the composite shaft to be designed are

considered to be same as that of an optimally designed steel

shaft. Comparison is made between the composite and the

conventional steel shaft for maximum shear stress induced in the

shafts and maximum deflections in the shafts. Finally modal

analysis is carried out to study the variation in natural frequency

by changing the fibre angle orientation of different layer of the

composite shaft.

1.9.1 Specification of Composite Shaft

In the present analysis hollow composite shaft is modelled in

ANSYS by using shell element and having following

specifications-

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 03 | May-2014 | NCRIET-2014, Available @ http://www.ijret.org 741

a) Length of shaft L = 1 m

b) Outer radius of the shaft R

o

= 50 mm with 5 mm thickness.

c) Torque applied at free end of shaft

1.9.2 Assumptions

In the analysis of the composite drive shaft following

assumptions are made.

1. The shaft rotates at a constant speed about its longitudinal

axis.

2. The shaft has a uniform, circular cross section.

3. The shaft is perfectly balanced, i.e., at every cross

section, the mass centre coincides with the geometric

centre.

4. All damping and nonlinear effects are excluded.

5. The stresses-strain relationship for composite material

is linear and elastic, i.e., Hookes law is applicable for

composite materials.

6. Acoustical fluid interactions are neglected, i.e., the shaft

is assumed to be acting in a vacuum.

7. Since lamina is thin and no out-of-plane loads are

applied, it is considered to be in plane stress condition.

1.9.3 Selection of Cross-Section

The shaft can be solid circular or hollow circular. Here hollow

circular cross-section was chosen because:

i. The hollow circular shafts are stronger in per kg weight

than solid circular shafts.

ii. The stress distribution in case of solid shaft is zero at the

centre and maximum at the outer surface while in hollow

shaft stress variation is smaller. In solid shafts the

material close to the centre are not fully utilized.

1.9.4 Selection of Reinforcement Fibre

Fibres are available with widely differing properties. Review of

the design and performance requirements usually dictate the fibre

to be used. So in our analysis we will consider the Carbon fibres

because its advantages include high specific strength and

modulus, low coefficient of thermal expansion, and high fatigue

strength which is ideal fibre for torque transmitting shaft.

1.9.5 Selection of Resin System

The important considerations in selecting resin are cost,

temperature capability, elongation to failure and resistance to

impact (a function of modulus of elongation). The resins selected

for most of the drive shafts are either epoxies or vinyl esters.

Here, epoxy resin was selected due to its high strength, good

wetting of fibres, lower curing shrinkage, and better dimensional

stability.

1.9.6 Why Carbon Epoxy Composite?

Following are the features of carbon epoxy composite, the reason

for which it is chosen.

1. Carbon epoxy composite gives high tensile strength,

high modulus of rigidity as compared to other

composites.

2. Carbon epoxy composite has unique damping

characteristic.

3. Carbon epoxy composite has positive coefficient of

thermal expansion i.e. tensile strength of this composite

increases with temperature.

4. Carbon epoxy composite is fatigue, wear and corrosion

resistant.

1.9.7 Selection of Material

Based on the advantages discussed above, the high strength and

high modulus Carbon/Epoxy materials are selected for composite

drive shaft. The Table 5.1 shows the properties of the

Carbon/Epoxy material used for composite drive shaft.

1.9.8 Modal Analysis of Composite Shaft

Modal analysis is used to determine the vibration characteristics

such as natural frequencies and mode shapes of a structure or a

machine component while it is being designed. A modal analysis

can be performed using the ANSYS. The vibration problem is

described by a set of equations, and there is a natural vibration

mode for every equation that can be extracted by using an Eigen

value extraction analysis. The displacement behaviour

dominating any structure subject to vibration is global; therefore,

modal analysis is utilized in these types of problems. In modal

analysis, the model of the composite shaft does not need a fine

mesh because the stress output is not required.

Additionally, there is no requirement to input an applied load,

because the natural frequency is only a function of mass and

stiffness. The ends of the composite shaft model were modelled

as simply-supported, and the boundary condition was varied until

the value of the natural frequency became nearly coincident with

that presented by a reliable example. It was recognized that the

end support conditions must also be applied to the edges of the

composite shaft. The rotational speed is limited by lateral

stability considerations. Most designs are sub critical, i.e.

rotational speed must be lower than the first natural bending

frequency of the shaft. The natural frequency depends on the

diameter of the shaft, thickness of the hollow shaft, specific

stiffness and the length. Boundary conditions for the modal

analysis are shown in Fig 5.3 below

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 03 | May-2014 | NCRIET-2014, Available @ http://www.ijret.org 742

1.9.9 Modelling of Conventional Steel Shaft

Conventional drive shaft is made up of steel for most of the

automobile, but sometimes aluminium is also used. To compare

the capability of composite material, steel shaft strength is

compared with composite.

In present analysis conventional shaft is modelled in ANSYS and

its length is considered as 1 m and diameter of the shaft as 50

mm with 2.032 mm thickness. Similar dimensions are used in

composite shaft analysis. Steel material has youngs modulus of

Ex = 210 GPa and Poisson ratio equal to 0.3. Comparison is

carried out based on maximum deformation, maximum stresses

induced in the shaft. Table 5.2 below shows the properties of

steel.

Table 2 Properties of steel

Steel

E = 207 e 9 N/m2

= 0.3

G = 80 e 9 N/m2

Density = 7600 Kg/m3

Max. Torque Tmax= 3000 N-m

Now for the steel shaft the maximum stresses and maximum

deflections are found out first and then modal analysis is done.

Analysis procedure for steel shaft is the same as that for

composite shaft. The only exception being the homogeneous,

isotropic nature input, meaning the same value input for all

directions.

In the chapter that follows are presented the discussions about the

results obtained from the above analysis, for various orientations

and different layers of the composite shaft and for the steel shaft.

2. RESULTS AND DISCUSSIONS

2.1 Static Analysis

The maximum shear stress and maximum deflection for each

layer are obtained using ANSYS by varying the orientation of

fibre in that layer by 10

0

and keeping the orientation of other

layers constant i.e. 0

0

.

2.2 Variation of Stresses with Fibre Angle Orientation

of Different Layers

2.2.1 Layer 1

Table 3 Variations in stresses by changing fibre angle orientation

of layer 1

Configuration Layer 1 Layer 2 Layer 3 Layer 4

10/0/0/0 4.79E+06 2.98E+06 6.49E+06 3.25E+06

20/0/0/0 7.39E+06 2.86E+06 6.29E+06 3.20E+06

30/0/0/0 9.18E+06 2.74E+06 6.07E+06 3.16E+06

40/0/0/0 9.84E+06 2.68E+06 6.00E+06 3.13E+06

50/0/0/0 9.42E+06 2.71E+06 6.08E+06 3.19E+06

60/0/0/0 8.11E+06 2.80E+06 6.24E+06 3.23E+06

70/0/0/0 6.20E+06 2.91E+06 6.41E+06 3.26E+06

80/0/0/0 4.13E+06 2.99E+06 6.54E+06 3.27E+06

90/0/0/0 3.01E+06 3.02E+06 6.58E+06 3.28E+06

Fig 2 Variations in stresses by changing fibre angle orientation of

layer 1

Fig. 1 Boundary conditions for the

modal analysis for composite shaft

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 03 | May-2014 | NCRIET-2014, Available @ http://www.ijret.org 743

2.2.2 Layer 2

Table 4 Variations in stresses by changing fibre angle orientation

of layer

Configuration Layer1 Layer2 Layer3 Layer4

0/10/0/0 2.97E+06 4.80E+06 6.48E+06 3.24E+06

0/20/0/0 2.85E+06 7.37E+06 6.29E+06 3.17E+06

0/30/0/0 2.73E+06 9.12E+06 6.04E+06 3.11E+06

0/40/0/0 2.67E+06 9.74E+06 5.95E+06 3.10E+06

0/50/0/0 2.70E+06 9.30E+06 6.02E+06 3.13E+06

0/60/0/0 2.79E+06 8.01E+06 6.19E+06 3.18E+06

0/70/0/0 2.90E+06 6.13E+06 6.38E+06 3.23E+06

0/80/0/0 2.98E+06 4.11E+06 6.53E+06 3.26E+06

0/90/0/0 3.01E+06 3.02E+06 6.58E+06 3.27E+06

Fig 3 Variations in stresses by changing fibre angle orientation of

layer 2

2.2.3 Layer 3

Table 5 Variations in stresses by changing fibre angle orientation

of layer 3

Fig 4 Variations in stresses by changing fibre angle orientation of

layer 3

2.2.4 Layer 4

Table 6 Variations in stresses by changing fibre angle orientation

of layer 4

Configurat

ion deflection1

Deflection

2 Deflection3 Deflection4

10/0/0/0 2.82E-04 2.82E-04 2.82E-04 2.82E-04

20/0/0/0 2.71E-04 2.71E-04 2.71E-04 2.71E-04

30/0/0/0 2.60E-04 2.60E-04 2.60E-04 2.60E-04

40/0/0/0 2.54E-04 2.54E-04 2.54E-04 2.54E-04

50/0/0/0 2.57E-04 2.57E-04 2.57E-04 2.57E-04

60/0/0/0 2.66E-04 2.66E-04 2.66E-04 2.66E-04

70/0/0/0 2.76E-04 2.76E-04 2.76E-04 2.76E-04

80/0/0/0 2.84E-04 2.84E-04 2.84E-04 2.84E-04

90/0/0/0 2.87E-04 2.87E-04 2.87E-04 2.87E-04

Configuration LAYER1 LAYER2 LAYER3 LAYER4

0/0/0/10 2.91E+06 2.91E+06 7.05E+06 4.30E+06

0/0/0/20 2.65E+06 2.63E+06 7.42E+06 5.70E+06

0/0/0/30 2.37E+06 2.39E+06 7.69E+06 6.21E+06

0/0/0/40 2.29E+06 2.35E+06 7.73E+06 6.19E+06

0/0/0/50 2.36E+06 2.42E+06 7.60E+06 5.91E+06

0/0/0/60 2.58E+06 2.57E+06 7.36E+06 5.30E+06

0/0/0/70 2.80E+06 2.80E+06 7.03E+06 4.42E+06

0/0/0/80 2.96E+06 2.96E+06 6.72E+06 3.50E+06

0/0/0/90 3.01E+06 3.02E+06 6.58E+06 3.25E+06

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 03 | May-2014 | NCRIET-2014, Available @ http://www.ijret.org 744

2.3 Variation of Deflection with Fibre Angle

Orientation of Different Layers

2.3.1 Layer 1

Variations in deflection by changing fibre angle orientation of

layer 1

2.3.2 Layer 2

Figure 6.5 Variations in deflection by changing fibre angle

orientation of layer 1

Table 7 Variations in deflection by changing fibre angle

orientation of layer 2

2.3.3 Layer 3

Table 8 Variations in deflection by changing fibre angle

orientation of layer 3

Configur

ation

Deflectio

n1

Deflectio

n2

Deflectio

n3

Deflectio

n4

0/10/0/0 2.82E-04 2.82E-04 2.82E-04 2.82E-04

0/20/0/0 2.71E-04 2.71E-04 2.71E-04 2.71E-04

0/30/0/0 2.59E-04 2.59E-04 2.59E-04 2.59E-04

0/40/0/0 2.54E-04 2.54E-04 2.54E-04 2.54E-04

0/50/0/0 2.57E-04 2.57E-04 2.57E-04 2.57E-04

0/60/0/0 2.65E-04 2.65E-04 2.65E-04 2.65E-04

0/70/0/0 2.76E-04 2.76E-04 2.76E-04 2.76E-04

0/80/0/0 2.84E-04 2.84E-04 2.84E-04 2.84E-04

0/90/0/0 2.87E-04 2.87E-04 2.87E-04 2.87E-04

Configu

ration

Deflection

1

Deflectio

n2

Deflection

3

Deflectio

n4

0/0/10/0 2.60E-04 2.60E-04 2.60E-04 2.60E-04

0/0/20/0 2.11E-04 2.11E-04 2.11E-04 2.11E-04

0/0/30/0 1.85E-04 1.85E-04 1.85E-04 1.85E-04

0/0/40/0 1.88E-04 1.88E-04 1.88E-04 1.88E-04

0/0/50/0 2.09E-04 2.09E-04 2.09E-04 2.09E-04

0/0/60/0 2.36E-04 2.36E-04 2.36E-04 2.36E-04

0/0/70/0 2.62E-04 2.62E-04 2.62E-04 2.62E-04

0/0/80/0 2.81E-04 2.81E-04 2.81E-04 2.81E-04

0/0/90/0 2.87E-04 2.87E-04 2.87E-04 2.87E-04

Configurati

on

Deflectio

n1

Deflectio

n2

Deflectio

n3

Deflectio

n4

0/0/0/10 2.66E-04 2.66E-04 2.66E-04 2.66E-04

0/0/0/20 2.25E-04 2.25E-04 2.25E-04 2.25E-04

0/0/0/30 1.99E-04 1.99E-04 1.99E-04 1.99E-04

0/0/0/40 1.99E-04 1.99E-04 1.99E-04 1.99E-04

0/0/0/50 2.16E-04 2.16E-04 2.16E-04 2.16E-04

0/0/0/60 2.40E-04 2.40E-04 2.40E-04 2.40E-04

0/0/0/70 2.64E-04 2.64E-04 2.64E-04 2.64E-04

0/0/0/80 2.81E-04 2.81E-04 2.81E-04 2.81E-04

0/0/0/90 2.87E-04 2.87E-04 2.87E-04 2.87E-04

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 03 | May-2014 | NCRIET-2014, Available @ http://www.ijret.org 745

Fig 5 Variations in deflection by changing fibre angle orientation

of layer 3

2.3.4 Layer 4

Variations in deflection by changing fibre angle orientation of

layer 4

Fig 6 Variations in deflection by changing fibre angle orientation

of layer 4

10.3 Comparison of Composite Shaft with Shaft made

up of Steel

Conventional drive shaft is made up of steel for most of the

automobile, but sometimes aluminium is also used. To

understand the effect of composite material in design, strength of

the steel shaft is compared with that of the composite shaft. In

the present analysis conventional shaft was modelled with its

length as 1 m, diameter 0.05 m and thickness 0.002032 m. The

same dimensions are used for the analysis of composite shaft.

Comparison is carried out based on maximum deformation and

maximum stresses induced in the shaft.

3. CONCLUSIONS

Following conclusions are drawn from the results obtained from

these analyses-

1. The High Strength Carbon/Epoxy and High Modulus

Carbon/Epoxy Composite drive shafts have been

designed to replace the steel drive shaft of an

automobile

2. The weight savings of the High strength carbon/epoxy

and high modulus carbon/epoxy shafts were equal to 50

% approximately of the steel shaft

3. Optimum fibre angle orientation will play important

role in composite shaft which depends on requirement

of composite shaft

4. The design procedure is studied and along with finite

element analysis some important parameter are

obtained. The composite drive shaft made up of HM

carbon / epoxy multilayered composites has been

designed. The results reveal that the orientation of

fibres has great influence on the static characteristics of

the composite shafts and offers advantages such as

a. Lower weight

b. Higher strength

c. Progressive failure mechanism (offers warning

before failure)

d. Lower power consumption

5. The present finite element analysis of the design

variables provide an insight of their effects on the drive

shafts critical mechanical characteristics and fatigue

resistance. A model of hybridized layers was generated

incorporating carbon-epoxy. The buckling, which

dominates the failure mode, have a value which not

increases regularly with increasing the winding angle.

6. Regression Analysis was done to obtain relations

between fibre angle orientation and parameters like

stresses induced in each layer, deflection in each layer

and natural frequencies of the composite shaft.

7. This relation helps in finding the above mentioned

parameters at any fibre orientation; which will help to

optimize the design of a composite shaft and hence will

reduce the cost of manufacturing.

REFERENCES

[1] T. Rangaswamy, et al., Optimal design and analysis of

automotive composite drive shaft, 2004.

[2] M. A. Badie, et al., Automotive composite driveshafts:

investigation of the design variables effects 2006, pp.

227-237.

[3] Y. A. Khalid, et al, Bending fatigue behavior of hybrid

aluminum/composite drive shafts, 2005.

[4] A. R. Abu Talib, et al., Developing a hybrid,

carbon/glass fiber-reinforced, epoxy composite

automotive drive shaft, 2010, pp. 514-521.

[5] A. Gebresilassie, Design and analysis of composite drive

shaft for rear-wheel drive engine, Volume 3, Issue 5,

May-2012.D. Jebakani, T. Paul Robert, Particle swarm

optimization for RBDO of composite drive shaft,

European Journal of Scientific Research,

Steel Composite

Max stresses 0.897e+07 0.424e+07

Deflection 0.249e-03 0.152e-04

You might also like

- Design and Analysis of Drive Shaft For Heavy Duty TruckDocument6 pagesDesign and Analysis of Drive Shaft For Heavy Duty TruckesatjournalsNo ratings yet

- TidongDocument162 pagesTidongSandeep AggarwalNo ratings yet

- Design and Analysis of Composite Drive ShaftDocument8 pagesDesign and Analysis of Composite Drive Shaftmesfin DemiseNo ratings yet

- On Pelton Efficiency and CavitationDocument10 pagesOn Pelton Efficiency and CavitationJohn RobinsonNo ratings yet

- Design and Analysis of Drum Brake: Dr. Kodathalapalli SudheerDocument15 pagesDesign and Analysis of Drum Brake: Dr. Kodathalapalli SudheerThalari VijayarajNo ratings yet

- Effect of Alkali Treatment On The Mechanical Properties of Raffia Palm Fibres/Oil Bean Pod Shell Reinforced Epoxy Hybrid CompositeDocument6 pagesEffect of Alkali Treatment On The Mechanical Properties of Raffia Palm Fibres/Oil Bean Pod Shell Reinforced Epoxy Hybrid CompositePremier PublishersNo ratings yet

- A Review of Structural and Thermal Analysis of Traction MotorsDocument11 pagesA Review of Structural and Thermal Analysis of Traction MotorsGari PastranaNo ratings yet

- Development of CNG Injection EngineDocument8 pagesDevelopment of CNG Injection EngineShasahank JoshiNo ratings yet

- Leaf Spring PDFDocument14 pagesLeaf Spring PDFSharanu Reshmi0% (1)

- Jntuk 3-1 R13 Q.P May 2018 DYNAMICS OF MACHINERY PDFDocument2 pagesJntuk 3-1 R13 Q.P May 2018 DYNAMICS OF MACHINERY PDFBv Rajesh Rëäl100% (1)

- Failure Analysis of Brake Shoe in Indian Railway WagonDocument5 pagesFailure Analysis of Brake Shoe in Indian Railway WagonInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Bearing ReliabilityDocument3 pagesBearing ReliabilityWayu100% (1)

- Automobile Brake Failure Indicator and Auxiliary Braking SystemDocument20 pagesAutomobile Brake Failure Indicator and Auxiliary Braking SystemPiyush PatilNo ratings yet

- AT 1 Fluid Flywheel and Torque Convertor NC PDFDocument14 pagesAT 1 Fluid Flywheel and Torque Convertor NC PDFERISON FARINo ratings yet

- New Microsoft Office Word DocumentDocument55 pagesNew Microsoft Office Word Documentkarnabalu100% (2)

- Study For Design of Magneto Rheological DamperDocument8 pagesStudy For Design of Magneto Rheological DamperAnonymous lPvvgiQjRNo ratings yet

- Design and Development of Mechanical Power AmplifierDocument4 pagesDesign and Development of Mechanical Power AmplifieresatjournalsNo ratings yet

- Classification of CompositesDocument4 pagesClassification of CompositeshijzainNo ratings yet

- NPTEL - Electrical Engineering - Introduction To Hybrid and Electric VehiclesDocument1 pageNPTEL - Electrical Engineering - Introduction To Hybrid and Electric VehiclesAshutosh TrivediNo ratings yet

- 1 Useful LifeDocument12 pages1 Useful LifeDon HaffisNo ratings yet

- ProposalDocument4 pagesProposalOlawale John AdeotiNo ratings yet

- Design and Analysis of Disc Brake and Caliper of Four WheelerDocument5 pagesDesign and Analysis of Disc Brake and Caliper of Four WheelerIJSTENo ratings yet

- A Review On Revolution of Flat Plate Collector For Solar Water HeaterDocument17 pagesA Review On Revolution of Flat Plate Collector For Solar Water HeaterIJRASETPublications100% (1)

- Modeling and Nonlinear Analysis of A Low-Power Gas Turbine - PsDocument25 pagesModeling and Nonlinear Analysis of A Low-Power Gas Turbine - PszanjebooreNo ratings yet

- Finite Element Analysis of Fatigue Life of Suspension Coil SpringDocument6 pagesFinite Element Analysis of Fatigue Life of Suspension Coil SpringSameer SinghNo ratings yet

- Process Planning and Cost Estimation - Unit1Document2 pagesProcess Planning and Cost Estimation - Unit1Parameswara RajaNo ratings yet

- Heavy Duty Chain Link DrawingDocument1 pageHeavy Duty Chain Link DrawingasotozuazuaNo ratings yet

- Eddy Current BrakesDocument18 pagesEddy Current BrakesAjoy RsNo ratings yet

- Ppa PDFDocument15 pagesPpa PDFravindraNo ratings yet

- 2009 - Todorov, Dobrev, Massouh - Analysis of Torsional Oscillation of The Drive Train in Horizontal-Axis Wind TurbineDocument7 pages2009 - Todorov, Dobrev, Massouh - Analysis of Torsional Oscillation of The Drive Train in Horizontal-Axis Wind TurbineLivrosScrNo ratings yet

- Mechanics of Machinery 2 - Balancing of Rotating MassesDocument11 pagesMechanics of Machinery 2 - Balancing of Rotating MassesAhmed Zawad ShovonNo ratings yet

- Design and Analysis of Connecting Rod For Reduction of Weight and Cost ReportDocument52 pagesDesign and Analysis of Connecting Rod For Reduction of Weight and Cost Reporthemtheboss100% (1)

- Hybrid Electric Vehicle: Presented By: Nikhil V Dhote Guided By: Prof C. R. Patil SirDocument24 pagesHybrid Electric Vehicle: Presented By: Nikhil V Dhote Guided By: Prof C. R. Patil SirRushikesh TajneNo ratings yet

- Analysis of Bolted Joints in Composite Laminates Strains and Bearing Stiffness PredictionsDocument9 pagesAnalysis of Bolted Joints in Composite Laminates Strains and Bearing Stiffness Predictionskhudhayer1970No ratings yet

- Numerical Analysis of Carbon Fibre Reinforced Aircraft WinDocument4 pagesNumerical Analysis of Carbon Fibre Reinforced Aircraft WinSiva BhaskarNo ratings yet

- IJREI - Vibration Analysis and Response Characteristics of A Half Car Model Subjected To Different Sinusoidal Road ExcitationDocument6 pagesIJREI - Vibration Analysis and Response Characteristics of A Half Car Model Subjected To Different Sinusoidal Road ExcitationIjrei JournalNo ratings yet

- Fatigue Failure of A Composite Wind Turbine Blade at Its Root EndDocument8 pagesFatigue Failure of A Composite Wind Turbine Blade at Its Root EndKendra KaiserNo ratings yet

- Maint Instructions For Ferrule FittingsDocument13 pagesMaint Instructions For Ferrule FittingsLakhwant Singh KhalsaNo ratings yet

- Spring-Supported Thrust BearingsDocument4 pagesSpring-Supported Thrust BearingsZoebairNo ratings yet

- Design and Analysis of Connecting RodDocument3 pagesDesign and Analysis of Connecting RodChandra Sekar50% (2)

- 0011 Structural Design of A Composite Wind Turbine Blade Using FiniteDocument8 pages0011 Structural Design of A Composite Wind Turbine Blade Using FiniteKhalil DeghoumNo ratings yet

- Unit 1. Fundamentals of Design Master b5Document20 pagesUnit 1. Fundamentals of Design Master b5S VNo ratings yet

- UntitledDocument3 pagesUntitledashish RautNo ratings yet

- Basic Components of Power TrainDocument24 pagesBasic Components of Power TrainAbdul Shukur100% (8)

- Governing of IC EnginesDocument1 pageGoverning of IC EnginesAbinash DasNo ratings yet

- Series Hybrid Car Doc - 3Document137 pagesSeries Hybrid Car Doc - 3mekkararameshNo ratings yet

- Flywheel AtzDocument5 pagesFlywheel AtzRakesh Bhaktha RNo ratings yet

- A-313 - 98Document7 pagesA-313 - 98José Ramón GutierrezNo ratings yet

- Bearing Stiffness DeterminationDocument11 pagesBearing Stiffness DeterminationSoumya ChatterjeeNo ratings yet

- Wheelhub Integration of Electric Motor in FSEDocument35 pagesWheelhub Integration of Electric Motor in FSEShivam WankhedeNo ratings yet

- Performance: East Technical University Ankara, 1994Document29 pagesPerformance: East Technical University Ankara, 1994MaRCoS8666100% (1)

- Leaf SpringDocument15 pagesLeaf SpringAjay SengarNo ratings yet

- 01 BOOST Release NotesDocument17 pages01 BOOST Release NoteshenevilNo ratings yet

- Electric Vehicle Modelling and SimulationDocument25 pagesElectric Vehicle Modelling and SimulationLakshmanan subas chandra bose100% (1)

- Summer Training Diesel Locomotive WorksDocument27 pagesSummer Training Diesel Locomotive WorksPankaj Sahu100% (2)

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987From EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNo ratings yet

- Structural Health MonitoringFrom EverandStructural Health MonitoringDaniel BalageasNo ratings yet

- Flood Related Disasters Concerned To Urban Flooding in Bangalore, IndiaDocument8 pagesFlood Related Disasters Concerned To Urban Flooding in Bangalore, IndiaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Effect of Lintel and Lintel Band On The Global Performance of Reinforced Concrete Masonry In-Filled FramesDocument9 pagesEffect of Lintel and Lintel Band On The Global Performance of Reinforced Concrete Masonry In-Filled FramesInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Impact of Flood Disaster in A Drought Prone Area - Case Study of Alampur Village of Mahabub Nagar DistrictDocument5 pagesImpact of Flood Disaster in A Drought Prone Area - Case Study of Alampur Village of Mahabub Nagar DistrictInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Wind Damage To Trees in The Gitam University Campus at Visakhapatnam by Cyclone HudhudDocument11 pagesWind Damage To Trees in The Gitam University Campus at Visakhapatnam by Cyclone HudhudInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Enhancing Post Disaster Recovery by Optimal Infrastructure Capacity BuildingDocument8 pagesEnhancing Post Disaster Recovery by Optimal Infrastructure Capacity BuildingInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Groundwater Investigation Using Geophysical Methods - A Case Study of Pydibhimavaram Industrial AreaDocument5 pagesGroundwater Investigation Using Geophysical Methods - A Case Study of Pydibhimavaram Industrial AreaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Shear Strength of RC Deep Beam Panels - A ReviewDocument15 pagesShear Strength of RC Deep Beam Panels - A ReviewInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Wind Damage To Buildings, Infrastrucuture and Landscape Elements Along The Beach Road at VisakhapatnamDocument10 pagesWind Damage To Buildings, Infrastrucuture and Landscape Elements Along The Beach Road at VisakhapatnamInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Role of Voluntary Teams of Professional Engineers in Dissater Management - Experiences From Gujarat EarthquakeDocument6 pagesRole of Voluntary Teams of Professional Engineers in Dissater Management - Experiences From Gujarat EarthquakeInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Low Cost Wireless Sensor Networks and Smartphone Applications For Disaster Management and Improving Quality of LifeDocument5 pagesLow Cost Wireless Sensor Networks and Smartphone Applications For Disaster Management and Improving Quality of LifeInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Monitoring and Assessment of Air Quality With Reference To Dust Particles (Pm10 and Pm2.5) in Urban EnvironmentDocument3 pagesMonitoring and Assessment of Air Quality With Reference To Dust Particles (Pm10 and Pm2.5) in Urban EnvironmentInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Likely Impacts of Hudhud On The Environment of VisakhapatnamDocument3 pagesLikely Impacts of Hudhud On The Environment of VisakhapatnamInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Review Study On Performance of Seismically Tested Repaired Shear WallsDocument7 pagesReview Study On Performance of Seismically Tested Repaired Shear WallsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Hudhud Cyclone - A Severe Disaster in VisakhapatnamDocument8 pagesHudhud Cyclone - A Severe Disaster in VisakhapatnamInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Effect of Hudhud Cyclone On The Development of Visakhapatnam As Smart and Green City - A Case StudyDocument4 pagesEffect of Hudhud Cyclone On The Development of Visakhapatnam As Smart and Green City - A Case StudyInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Cyclone Disaster On Housing and Coastal AreaDocument7 pagesCyclone Disaster On Housing and Coastal AreaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Can Fracture Mechanics Predict Damage Due Disaster of StructuresDocument6 pagesCan Fracture Mechanics Predict Damage Due Disaster of StructuresInternational Journal of Research in Engineering and TechnologyNo ratings yet

- A Geophysical Insight of Earthquake Occurred On 21st May 2014 Off Paradip, Bay of BengalDocument5 pagesA Geophysical Insight of Earthquake Occurred On 21st May 2014 Off Paradip, Bay of BengalInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Assessment of Seismic Susceptibility of RC BuildingsDocument4 pagesAssessment of Seismic Susceptibility of RC BuildingsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Detection of Hazard Prone Areas in The Upper Himalayan Region in Gis EnvironmentDocument9 pagesDetection of Hazard Prone Areas in The Upper Himalayan Region in Gis EnvironmentInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Comparative Study of The Forces in G+5 and G+10 Multi Storied Buildings Subjected To Different Wind SpeedsDocument10 pagesComparative Study of The Forces in G+5 and G+10 Multi Storied Buildings Subjected To Different Wind SpeedsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Cpw-Fed Uwb Antenna With Wimax Band-Notched CharacteristicsDocument5 pagesCpw-Fed Uwb Antenna With Wimax Band-Notched CharacteristicsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Disaster Recovery Sustainable HousingDocument4 pagesDisaster Recovery Sustainable HousingInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Coastal Zones - Seismic Vulnerability An Analysis From East Coast of IndiaDocument4 pagesCoastal Zones - Seismic Vulnerability An Analysis From East Coast of IndiaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Challenges in Oil and Gas Industry For Major Fire and Gas Leaks - Risk Reduction MethodsDocument4 pagesChallenges in Oil and Gas Industry For Major Fire and Gas Leaks - Risk Reduction MethodsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Rate Adaptive Resource Allocation in Ofdma Using Bees AlgorithmDocument5 pagesRate Adaptive Resource Allocation in Ofdma Using Bees AlgorithmInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Brain Tumor Segmentation Using Asymmetry Based Histogram Thresholding and K-Means ClusteringDocument4 pagesBrain Tumor Segmentation Using Asymmetry Based Histogram Thresholding and K-Means ClusteringInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Developing of Decision Support System For Budget Allocation of An R&D OrganizationDocument6 pagesDeveloping of Decision Support System For Budget Allocation of An R&D OrganizationInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Analytical Solutions For Square Shape PressureDocument4 pagesAnalytical Solutions For Square Shape PressureInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Evapco Maintenance Checklist Coolers & Condensers OM Bulletin 116-E - 0417Document3 pagesEvapco Maintenance Checklist Coolers & Condensers OM Bulletin 116-E - 0417Rudy HerreraNo ratings yet

- To Study On Behavior of Corbel Wrapped With FRP Sheet Under Monotonic LoadingDocument4 pagesTo Study On Behavior of Corbel Wrapped With FRP Sheet Under Monotonic LoadingAnonymous kw8Yrp0R5rNo ratings yet

- WW Review HandoutsDocument2 pagesWW Review HandoutsMoriel PradoNo ratings yet

- Egyptian Code 203 2006 EnglishDocument433 pagesEgyptian Code 203 2006 EnglishMahmoud El-Kateb75% (44)

- Tekeze Dam Water Power and Dam Construction 2009 04 AprilDocument5 pagesTekeze Dam Water Power and Dam Construction 2009 04 Aprilmivos4No ratings yet

- Chapter - 9 Mechanical Properties of SolidsDocument19 pagesChapter - 9 Mechanical Properties of SolidsTilahun ArfichoNo ratings yet

- AWC-DCA3-Fire-Resistance-Rated Wood-Frame Wall, Floor and Ceiling Assemblies-20210209Document28 pagesAWC-DCA3-Fire-Resistance-Rated Wood-Frame Wall, Floor and Ceiling Assemblies-20210209LarryHNo ratings yet

- Pavement Manual: Revised October 2019Document480 pagesPavement Manual: Revised October 2019emeterioNo ratings yet

- Intze Tank - Seismic Behaviour - SAP2000 PDFDocument7 pagesIntze Tank - Seismic Behaviour - SAP2000 PDFAnonymous fQLEF2tQpqNo ratings yet

- Feet Meter: Saudi Arabian Oil CompanyDocument1 pageFeet Meter: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Lecture - 2-1 - COEM 6012 - Geotechnics in ConstructionDocument20 pagesLecture - 2-1 - COEM 6012 - Geotechnics in ConstructionAJR365No ratings yet

- DLS 11 14 18 27 36 60 TOUCH Parts ManualDocument35 pagesDLS 11 14 18 27 36 60 TOUCH Parts ManualJose Manuel Castro50% (2)

- MOS Diaphragm WallDocument45 pagesMOS Diaphragm WallJasmine SmithNo ratings yet

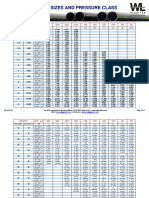

- WL102-0118 Ips Size Chart Pe4710Document2 pagesWL102-0118 Ips Size Chart Pe4710MarcoiNo ratings yet

- Metric - A. Volume and Height Between Tubing and Hole, and Casing and HoleDocument78 pagesMetric - A. Volume and Height Between Tubing and Hole, and Casing and HoleNorfolkingNo ratings yet

- Ec 167561Document2 pagesEc 167561efac7100% (1)

- Hydrogeology PDFDocument16 pagesHydrogeology PDFJenyy JenyyNo ratings yet

- Building Construction and Technology IV: Forth Semester, B.ArchDocument14 pagesBuilding Construction and Technology IV: Forth Semester, B.ArchRAVATNo ratings yet

- Design of An INTZE TankDocument78 pagesDesign of An INTZE TankSTAR PRINTING100% (1)

- Army TM 5-813-1 Navy Air Force Afm 88 10, Vol. 1Document53 pagesArmy TM 5-813-1 Navy Air Force Afm 88 10, Vol. 1Jinho LeeNo ratings yet

- Salient Features of Deras M.I.P. (Reservoir) : 1 LocationDocument3 pagesSalient Features of Deras M.I.P. (Reservoir) : 1 LocationAntariksha NayakNo ratings yet

- Ae 2254Document20 pagesAe 2254Inzamamul AlniyasNo ratings yet

- BS 5268 - 7.5 Structural Use of Timber PDFDocument28 pagesBS 5268 - 7.5 Structural Use of Timber PDFTom YeeNo ratings yet

- NMBS Castellated Beams CourseDocument62 pagesNMBS Castellated Beams CourseSeifeldin Ali MarzoukNo ratings yet

- Inspection and Maintenance of Steel Girders-12Document10 pagesInspection and Maintenance of Steel Girders-12vpmohammedNo ratings yet

- Dr. Majd Albana Design of Stairs-2Document26 pagesDr. Majd Albana Design of Stairs-2محمد محمدNo ratings yet

- Briefing: Water Surface Profile Over Side Weir in A Trapezoidal ChannelDocument7 pagesBriefing: Water Surface Profile Over Side Weir in A Trapezoidal ChannelRobert MacalanaoNo ratings yet

- 2018 MHG-R410a SpecDocument2 pages2018 MHG-R410a SpecEmilio MatarNo ratings yet

- Assignment & Project For Hydropwer EngineeringDocument3 pagesAssignment & Project For Hydropwer Engineeringashenafi negusNo ratings yet

- Microsoft Word - Design and Detailing of Flat SlabDocument22 pagesMicrosoft Word - Design and Detailing of Flat Slabanjana susan john100% (1)