Professional Documents

Culture Documents

2010 Bridges AnalysisandModelling LDavaine

Uploaded by

Cesar AlexisCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2010 Bridges AnalysisandModelling LDavaine

Uploaded by

Cesar AlexisCopyright:

Available Formats

1

Composite bridge design (EN1994-2)

Bridge modelling and structural analysis

Laurence DAVAINE

French Railways (SNCF) y ( )

Bridge Engineering Department (IGOA)

Dissemination of information for training Vienna, 4-6 October 2010 2

Contents

1. Bridge modelling

Geometry

Effective width (shear lag effect)

Modular ratios (concrete creep)

}

Cross-sectional

Modular ratios (concrete creep)

Transversal distribution

}

mechanical properties

2. The global cracked analysis according to EN 1994-2

Determination of the cracked zones on internal supports Determination of the cracked zones on internal supports

Results from the global analysis

Dissemination of information for training Vienna, 4-6 October 2010 3

Twin-girder bridge modelling

C3

G

P2

z

P1

x

z

y

simply supported bar model (dz=0 for every support)

half-bridge cross-section represented by its centre of gravity G

(neutral fibre)

C0

structural steel alone, or composite, mechanical properties

according to the construction phases of the bridge slab

Dissemination of information for training Vienna, 4-6 October 2010 4

Concrete slab thickness

Actual slab

Computed slab

S

actual

= S

computed

(same area)

actual

=

computed

(same location of the slab gravity centre G

c

)

Dissemination of information for training Vienna, 4-6 October 2010 5

Shear lag in the concrete slab according to EN 1994-2

eff

b

,max xx

o

xx

o

Non-uniform transverse

distribution of the

longitudinal stresses

0

750 mm b =

1 1 e

b |

2 2 e

b |

1

3.125 m b =

2

2.125 m b = 0

b

0

0 eff i ei

i

b b b | = +

min ;

8

e

ei i

L

b b

| |

=

|

\ .

1

i

| = except for end supports where 1

i

| except for end supports where

0.55 0.025 1.0

e

i

ei

L

b

| = + s

Dissemination of information for training Vienna, 4-6 October 2010 6

Shear lag in the concrete slab according to EN 1994-2

Equivalent span length L

e

Global analysis (calculation of internal forces and moments) : constant

along each span (equal to the value at mid-span)

Section analysis (calculation of stresses) : linearly variable along L

i

/4

surrounding the internal supports

Dissemination of information for training Vienna, 4-6 October 2010 7

Application to the twin-girder bridge example

C0

P1 C3

P2

60 m 80 m 60 m

L

e

(m)

0.85x60 = 51 0.7x80 = 56 0.85x60 = 51

e

( )

0.25 x (60+80) = 35 0.25 x (60+80) = 35

L (m) b

1

(m) b

2

(m) | | b

ff

(m) L

e

(m) b

e1

(m) b

e2

(m) |

1

|

2

b

eff

(m)

In-span 1 and 3 48 3.125 2.125 1 1 6.0

In-span 2 56 3.125 2.125 1 1 6.0

Internal supports P1 and P2 35 3 125 2 125 1 1 6 0 Internal supports P1 and P2 35 3.125 2.125 1 1 6.0

End supports C0 and C3 48 3.125 2.125 0.958 1.15 but < 1.0 5.869 < 6.0

Dissemination of information for training Vienna, 4-6 October 2010 8

Application to the twin-girder bridge example

3

P1

P2

C3

C0

2

3

L /2

L /2

L /2

0

1

0 20 40 60 80 100 120 140 160 180 200

L

1

/2

L

1

/2

L

2

/2

L

2

/4 L

2

/4 L

1

/4

L

1

/4

L

1

/4

L

1

/4

-2

-1

0 20 40 60 80 100 120 140 160 180 200

-3

-4

Dissemination of information for training Vienna, 4-6 October 2010 9

Composite cross-sections mechanical properties

eff

b

G

Un-cracked behaviour (mid-span regions, M

c,Ed

> 0)

R i f t l t d (i i )

c

a

A A

n

A

= +

elastic

neutral axis

c

G

G

G

y

Gc

y

Reinforcement neglected (in compression)

c

G a Ga Gc

A

Ay A y

n

y = +

( )

2

2

1

( )

a a G Ga c c G Gc

I I A y y I A y

n

y

(

= + + +

a

G

Ga

y

Cracked behaviour (support regions, M

c,Ed

< 0)

eff

b

G

E

a

= E

s

= 210 000 N/mm (n= 1)

elastic

neutral axis

s

G

G

G

y

Gs

y

a s

A A A = +

G a Ga s Gs

Ay A y A y = +

( )

2

2

a

G

Ga

y

G

y

( )

2

2

( )

a a G Ga s s G Gs

I I A y y I A y y = + + +

( )

0

s

I

Dissemination of information for training Vienna, 4-6 October 2010 10

Modular ratios (creep effect)

a

0

cm

E

n

E

= Short-term modular ratio:

L t d l ti

0.3

cm

cm

f

E 22000

10

| |

=

|

\ .

( )

L 0 L t

n n . 1 = + |

( )

t 0

t t | = |

Long-term modular ratio:

Creep coefficient according to EN 1992-1-1 with :

t = age of concrete at the considered time during the bridge life

t

0

= age of concrete when the considered loading is applied to the bridge

{

t

0

= 1 day for shrinkage

t

0

= mean value of age of concrete segments, in case of composites structures

cast in several stages (permanent load) g (p )

L

depends on the

load case :

Permanent loads

Shrinkage

1.1

0.55 Shrinkage

Imposed deformations

0.55

1.5

Dissemination of information for training Vienna, 4-6 October 2010 11

Creep coefficient according to Annex B in EN 1992-1-1

( )

0

0

0

0.3

t 0 c 0 0

H

t

t

. t .

t

t

t

t

+

| |

| = | | = | |

|

| +

\ .

(end of bridge life)

0 H \ .

( )

18

H 0 3 3

1.5. 1 0.012 RH .h 250. 1500.

(

| = + + o s o

(

( ) ( )

0

0

0 RH cm 1 2

0.2

3

0 cm

RH

1

16.8 1

100

. f . 1 . . . .

0.1

1

t

f

t

0. 0 h

(

(

( (

| = | | | = + o o

(

( (

+

(

(

with : RH = 80 % (relative humidity in the bridge area)

2A

c

0

2A

h

u

=

notional size (u is the concrete slab

perimeter exposed to drying)

0.7

1

cm

35

0.8658

f

| |

o = =

|

\ .

0.2

2

cm

35

0.9597

f

| |

o = =

|

\ .

0.5

3

cm

35

0.9022

f

| |

o = =

|

\ .

Dissemination of information for training Vienna, 4-6 October 2010 12

Application to the twin-girder bridge example

1 16

t =0

... ...

time (in day)

t=66 t=80 t=110

Slab segments

Beginning of concreting

Composite behaviour or

not, according to the

segment concreting order

End of

concreting

Meanvalue of concrete age :

J acking

Bridge equipments

Mean value of concrete age :

t

0

= 35.25 days

14 days

For shrinkage :

( )

1 0

,t | = |

t

0

= 49.25 days

30 days

t

0

= 1 day

n

L,1

( )

2 0

,t | = |

t

0

= 79.25 days

n

L 2

( )

3 0

,t | = |

0

y

( )

4 0

,t | = |

n

L,2

n

L,3

n

L,4

Dissemination of information for training Vienna, 4-6 October 2010 13

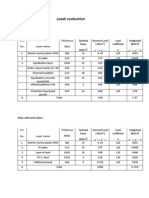

Application to the twin-girder bridge example

Short-term modular ratio

For all load cases :

a

6

E

n 1625 = =

Long-term modular ratio

For all load cases :

0

cm

6. n

E

1625 = =

Load case

L

t

0

(days) |

t

= |

0

n

L

Concrete slab segment (selfweight)

Settlement

Shrinkage

1.10

1.50

0.55

35.25

49.25

1

1.394

1.291

2.677

15.61

18.09

15.24 g

Bridge equipments 1.10 79.25 1.179 14.15

Dissemination of information for training Vienna, 4-6 October 2010 14

Transversal distribution between the two girders

1

F

a e a

Influence line

of the support

reaction on

i d 1

0

girder no. 1

Bridge axle

girder no. 2 Girder no.1

(modeled)

e / 2 e / 2

Bridge axle

| |

|

1

a

R F

e / 2 e / 2

a

R F

| |

=

|

\ .

1

1 R F

e

=

2

R F

e

Dissemination of information for training Vienna, 4-6 October 2010 15

Application to the traffic load model LM1

1. Conventional traffic lanes positioning

Lane no 1 Lane no 2 Lane no 3 Remaining area

0.5 m 1 m

3 m 3 m 3 m 2 m

Lane no.1 Lane no.2 Lane no.3 Remaining area

Bridge axle

girder no. 2 Girder no.1

(modeled)

3.5 m 3.5 m

Dissemination of information for training Vienna, 4-6 October 2010 16

Application to the traffic load model LM1

2. Tandem TS

Bridge axle

TS 1 per axle :

1 0 x 300 =300 kN

TS 2 per axle :

1.0 x 200 = 200 kN

TS 3 per axle :

1

R1

1.0 x 300 300 kN

1.0 x 100 = 100 kN

0

R2 R1

Influence line of the

support reaction on

girder no. 1

0.5 m

R2

1 m 2 m

Support reaction on each main girder : R

1

= 471.4 kN

128 6 R

2

= 128.6 kN

Dissemination of information for training Vienna, 4-6 October 2010 17

Application to the traffic load model LM1

3. Uniform Design Load UDL

Bridge axle

Load on lane no.1 :

1.0 x 9 x 3 = 27 kN/ml

Load on lane no.2 :

1.0 x 2.5 x 3 = 7.5 kN/ml

1

Load on lane no.3 :

1.0 x 2.5 x 3 = 7.5 kN/ml

LANE 1

LANE 2 LANE 3

R1

0

Influence Line

R2

0.5 m 1 m 2 m

Support reaction for each main girder : R

1

= 35.36 kN/ml

R

2

= 6.64 kN/ml

Dissemination of information for training Vienna, 4-6 October 2010 18

Application to the traffic load model LM1

4. Bending Moment (MN.m) for UDL and TS

Dissemination of information for training Vienna, 4-6 October 2010 19

Contents

1. Bridge modelling

Geometry

Effective width (shear lag effect)

Modular ratios (concrete creep)

}

Cross-sectional

Modular ratios (concrete creep)

Transversal distribution

}

mechanical properties

2. The global cracked analysis according to EN 1994-2

Determination of the cracked zones on internal supports Determination of the cracked zones on internal supports

Results from the global analysis

Dissemination of information for training Vienna, 4-6 October 2010 20

Structural analysis of a composite bridge girder

Uniform load q (N/m)

Concrete cracking

Static system

P

u

1

Deformed shape

Steel yielding

M

2

M

M

pl,Rd

M at mid-span with P

increasing

Class 1

Linear elastic global analysis (except for accidental

loads)

No bending redistribution is allowed

M

el,Rd

u

Class 1

Concrete cracking near internal support and steel

yielding near mid-span are taken into account through

simplified methods

Plate bucklingis neglected in the global analysis except u Plate buckling is neglected in the global analysis except

if the effective

p

area of one of the panel is lower than half

its gross area (A

eff

< 0.5 A

gross

)

Dissemination of information for training Vienna, 4-6 October 2010 21

1 Global cracked analysis

Stress distribution o

c

in the concrete slab for the characteristic SLS

combination of actions assuming the concrete resists in every cross

section (EI ) section (EI

1

)

In the zones where o

c

< - 2 f

ctm

, the concrete is assumed to be cracked

(and then neglected) for the bending stiffness distribution (EI

2

)

EI

EI

1

EI

1

EI

2

1

EI

1

= un-cracked composite second moment of area

(structural steel + concrete slab in compression) (structural steel + concrete slab in compression)

EI

2

= cracked composite second moment of area

(structural steel + reinforcement in tension)

This approach is not iterative (the cracked zones are

determined only once).

!

Dissemination of information for training Vienna, 4-6 October 2010 22

Global cracked analysis 1

Simplified method is possible if :

- no pre-stress

A

EI

2

0.15 (L

1

+ L

2

)

p

- L

min

/L

max

> 0.6

A

s

EI

1

L

1

L

2

A

c

=0

In the stiffness zones EI

2

: In the stiffness zones EI

2

:

concrete in tension is neglected

reinforcement are included

Dissemination of information for training Vienna, 4-6 October 2010 23

In-span steel yielding 2

Mid-span eventual yielding is taken into account if :

Class 1 or 2 at mid span (and M

Ed

> M

el,Rd

)

Class 3 or 4 on internal support Class 3 or 4 on internal support

L

min

/L

max

< 0.6

L L L

max

L

min

Class 1 or 2 Class 3 or 4

As L

min

/L

max

> 0.6 in the example, the redistribution due to

yielding near mid-span is not taken into account.

Dissemination of information for training Vienna, 4-6 October 2010 24

Application to the twin-girder bridge example

10

1 2 3 16 15 14 4 5 6 7 13 12 11 10 9 8

Concreting phases, Slab segments order:

5

10

(

N

/

m

m

)

i

n

a

t

i

o

n

0

0 20 40 60 80 100 120 140 160 180 200

o

n

c

r

e

t

e

s

l

a

b

(

i

c

S

L

S

c

o

m

b

-10

-5

2

ctm

2f 6.4 N/mm =

S

t

r

e

s

s

e

s

i

n

c

o

C

h

a

r

a

c

t

e

r

i

s

t

i

-15

x = 35.0 m x = 76.0 m

x = 124.0 m x = 152.0 m

S

Cracked zone for P1

41.0 % 19.5 %

Cracked zone for P2

19.5 % 20.0 %

Dissemination of information for training Vienna, 4-6 October 2010 25

Application to the twin-girder bridge example

80

100

Characteristic SLS

SLS and ULS bending moment distribution M

Ed

(= M

a,Ed

+ M

c,Ed

)

42.58 41.01

47.18

57.59

55.42

63.90

40

60

80

Fundamental ULS

0

20

0 20 40 60 80 100 120 140 160 180 200 m

e

n

t

(

M

N

.

m

)

-40

-20

0 20 40 60 80 100 120 140 160 180 200

B

e

n

d

i

n

g

m

o

m

-84.56

-81.67

-80

-60

-112.72

-109.35

-120

-100

Dissemination of information for training Vienna, 4-6 October 2010 26

Application to the twin-girder bridge example

SLS and ULS shear force distribution V

Ed

8 12 7 47

10

6.02

5.98

8.12

4.83

7.47

6

8

Characteristic SLS

Fundamental ULS

2.78

2

4

e

s

(

M

N

)

-1.90

-2

0

0 20 40 60 80 100 120 140 160 180 200

S

h

e

a

r

f

o

r

c

e

-6.04

-5.74

8

-6

-4

-8.14

-8.01

-10

-8

Dissemination of information for training Vienna, 4-6 October 2010 27

Application to the twin-girder bridge example

400

ULS stresses (N/mm) along the steel flanges, calculated without concrete resistance

272.6

277.5

200

300

100

-100

0

0 20 40 60 80 100 120 140 160 180 200

-287.1

292 6

-300

-200

-292.6

-400

Dissemination of information for training Vienna, 4-6 October 2010 28

Thank you for your kind attention !

You might also like

- 747Document12 pages747GurdevBaines100% (3)

- Erich Segal Doctors PDFDocument2 pagesErich Segal Doctors PDFAlicia13% (8)

- Example Elastic Analysis of A Single Bay Portal FrameDocument29 pagesExample Elastic Analysis of A Single Bay Portal FrameYam BalaoingNo ratings yet

- Detailed Calculation For Box Girder DesignDocument109 pagesDetailed Calculation For Box Girder Designleodegarioporral100% (8)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- 25m Single Lane Bridge Design Calculations LatestDocument16 pages25m Single Lane Bridge Design Calculations Latestntah84100% (4)

- Rigid and Flexible Pavemment FormulasDocument13 pagesRigid and Flexible Pavemment FormulasRonald Costales100% (2)

- Puddle FlangeDocument15 pagesPuddle FlangeKumar KoteNo ratings yet

- Example Beam Simply Supported With Lateral RestraintDocument11 pagesExample Beam Simply Supported With Lateral RestraintjplezpNo ratings yet

- Workshop On EC4 - CompositeDocument53 pagesWorkshop On EC4 - CompositePeyman MznNo ratings yet

- ES - 02 - Courbon & Engesser MethodsDocument47 pagesES - 02 - Courbon & Engesser MethodsNalvaPaulinoNo ratings yet

- Composite Construction Design (ULS Only)Document93 pagesComposite Construction Design (ULS Only)CawanNeroMiranio100% (1)

- Cloud Computing 101 TutorialDocument203 pagesCloud Computing 101 TutorialYunis Iklil100% (1)

- Position, Velocity and AccelerationDocument12 pagesPosition, Velocity and Accelerationpeter vuNo ratings yet

- 2010 Bridges AnalysisandModelling LDavaineDocument28 pages2010 Bridges AnalysisandModelling LDavainebaciu_cristian8412No ratings yet

- Guidance Ec Eng3Document10 pagesGuidance Ec Eng3iseekhNo ratings yet

- 2010 EN1998 Bridges BKoliasDocument110 pages2010 EN1998 Bridges BKoliasÜstün Onur BaktırNo ratings yet

- Action On BridgesDocument162 pagesAction On Bridgesbaciu_cristian8412No ratings yet

- Pushover Example LargeDocument39 pagesPushover Example LargeCapt Reza100% (6)

- Strut - and - Tie Model For Analysis of Piles CapDocument8 pagesStrut - and - Tie Model For Analysis of Piles CapselvarajselvaaNo ratings yet

- Design of Composite Beams Using Allowable Stress Design: Presented By: Dr. Sherine SwelemDocument70 pagesDesign of Composite Beams Using Allowable Stress Design: Presented By: Dr. Sherine Swelemabdelrahman emadNo ratings yet

- Extracts From Ec3 For Students 2012Document6 pagesExtracts From Ec3 For Students 2012Alexandru MarincuNo ratings yet

- EN1994 5 Hicks Composite SlabDocument42 pagesEN1994 5 Hicks Composite SlaberleosNo ratings yet

- ACI - Rectangular Tanks 2010Document18 pagesACI - Rectangular Tanks 2010Yulian Jesús100% (1)

- Loads Evaluation: TerraceDocument9 pagesLoads Evaluation: TerracemayanekitaNo ratings yet

- 02 EC2WS BiasioliMancini DurabilityMaterialsActionsConceptualDesign PDFDocument96 pages02 EC2WS BiasioliMancini DurabilityMaterialsActionsConceptualDesign PDFLuigiForgeroneNo ratings yet

- 03 1 Weynand Moment Resistant JointsDocument71 pages03 1 Weynand Moment Resistant Jointsdeepak_dce_meNo ratings yet

- Structural Design For Low Rise BuildingDocument42 pagesStructural Design For Low Rise BuildingMohammed SumerNo ratings yet

- Chapter 24 WexDocument7 pagesChapter 24 WexCiprian VarlanNo ratings yet

- RC2009 University of HongKong Reinforced Concrete DesignDocument29 pagesRC2009 University of HongKong Reinforced Concrete DesignApril IngramNo ratings yet

- 25m Single Lane Bridge Design Calculations LatestDocument23 pages25m Single Lane Bridge Design Calculations Latestdravinonares100% (1)

- Proiectare Poduri GlulamDocument12 pagesProiectare Poduri Glulamdragos_militaru5067No ratings yet

- Graduation Project: Three Dimensional Analysis and Design of Al-Arab HospitalDocument52 pagesGraduation Project: Three Dimensional Analysis and Design of Al-Arab HospitalkusumchitikaNo ratings yet

- Servicability LimitsDocument51 pagesServicability LimitsjadlouisNo ratings yet

- 8 CHS Joints 2011Document25 pages8 CHS Joints 2011hherfstNo ratings yet

- DeflectionDocument31 pagesDeflectionAnonymous nQ9RqmNo ratings yet

- Nonlinear GuideDocument17 pagesNonlinear Guidepiv0ter_betterNo ratings yet

- PF2Document4 pagesPF2nhulugallaNo ratings yet

- Design of Long-Span TrussDocument51 pagesDesign of Long-Span TrussFeigyl Miro100% (4)

- Special Topics H.W 1:: Design An Interior Panel of A Span Continuous Slab For H20-44 LoadingDocument7 pagesSpecial Topics H.W 1:: Design An Interior Panel of A Span Continuous Slab For H20-44 LoadingHAKAM AL ABBASNo ratings yet

- Lecture 4 (EC4 Version)Document67 pagesLecture 4 (EC4 Version)ikanyu79100% (1)

- Fibre Beam ElementDocument55 pagesFibre Beam Elementmakkusa100% (1)

- Composite Bridge Design PDFDocument50 pagesComposite Bridge Design PDFAminNo ratings yet

- Influence of Steel Fibres in Steel Fibre Reinforced Concrete On ULS and SLSDocument7 pagesInfluence of Steel Fibres in Steel Fibre Reinforced Concrete On ULS and SLSErick Martinez OrunaNo ratings yet

- Einforced Oncrete: Bridge Design Manual - 2002 Reinforced ConcreteDocument24 pagesEinforced Oncrete: Bridge Design Manual - 2002 Reinforced ConcretemuradNo ratings yet

- Einforced Oncrete: Bridge Design Manual - 2002 Reinforced ConcreteDocument24 pagesEinforced Oncrete: Bridge Design Manual - 2002 Reinforced Concretetonying86No ratings yet

- FINAL - SKILLS - Design of Built-Up Columns - V3Document41 pagesFINAL - SKILLS - Design of Built-Up Columns - V3johnautodidacteNo ratings yet

- Yield Line Theory: Prepared byDocument22 pagesYield Line Theory: Prepared byKartikMandaniNo ratings yet

- Analysis of Straight and Skewed Box Girder Bridge by Finite Strip MethodDocument8 pagesAnalysis of Straight and Skewed Box Girder Bridge by Finite Strip MethodBharat SharmaNo ratings yet

- 2 Dp2 Prestress Losses FullDocument12 pages2 Dp2 Prestress Losses FullChandeshwor ShahNo ratings yet

- Final Yield LineDocument21 pagesFinal Yield LineKartikMandaniNo ratings yet

- Spreadsheet - Steel Design (Common Section)Document54 pagesSpreadsheet - Steel Design (Common Section)Vincent WongNo ratings yet

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- MOS Integrated Circuit DesignFrom EverandMOS Integrated Circuit DesignE. WolfendaleNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- O level Physics Questions And Answer Practice Papers 2From EverandO level Physics Questions And Answer Practice Papers 2Rating: 5 out of 5 stars5/5 (1)

- Chart and Compass (London Zetetic Society)Document8 pagesChart and Compass (London Zetetic Society)tjmigoto@hotmail.comNo ratings yet

- Getting Good Grades in School Is What Kids Are Supposed To Be Doing.Document6 pagesGetting Good Grades in School Is What Kids Are Supposed To Be Doing.The QUEENNo ratings yet

- Post Covid StrategyDocument12 pagesPost Covid Strategyadei667062No ratings yet

- An Introduction To Formal Language and Automata Solution Manual PDFDocument4 pagesAn Introduction To Formal Language and Automata Solution Manual PDFAsad IkramNo ratings yet

- ISMR B-School BrochureDocument28 pagesISMR B-School Brochurerahul kantNo ratings yet

- Experimental Psychology & The Scientific MethodDocument73 pagesExperimental Psychology & The Scientific MethodRuru LavariasNo ratings yet

- Digital Album On Prominent Social ScientistsDocument10 pagesDigital Album On Prominent Social ScientistsOliver Antony ThomasNo ratings yet

- METR3210 Clausius ClapeyronDocument28 pagesMETR3210 Clausius Clapeyronshubhang2392No ratings yet

- Wind Tunnel Technique Notes For Aeronautical Engineers TP 2Document6 pagesWind Tunnel Technique Notes For Aeronautical Engineers TP 2Ramji VeerappanNo ratings yet

- Approaches To Curriculum DesigningDocument20 pagesApproaches To Curriculum DesigningCristel CatapangNo ratings yet

- Wartsila O Env Multi Stage Flash EvaporatorsDocument2 pagesWartsila O Env Multi Stage Flash EvaporatorsRichard Periyanayagam0% (1)

- Solutions Tutorial 6Document9 pagesSolutions Tutorial 6Nur Aqilah Abdullah HashimNo ratings yet

- FWD Week 47 Learning Material For Alaric YeoDocument7 pagesFWD Week 47 Learning Material For Alaric YeoarielNo ratings yet

- Bistable Relays RXMVB 2, RXMVB 4: FeaturesDocument4 pagesBistable Relays RXMVB 2, RXMVB 4: FeaturesGabriel Maxo PapagalloNo ratings yet

- Understanding Terrorism and Political Violence PDFDocument304 pagesUnderstanding Terrorism and Political Violence PDFmihaela buzatuNo ratings yet

- 48 Sociology: B.A./B.Sc.: Elective and OptionalDocument4 pages48 Sociology: B.A./B.Sc.: Elective and OptionalMNo ratings yet

- Toyota Motor Manufacturing (TMM)Document20 pagesToyota Motor Manufacturing (TMM)Lekha ShahNo ratings yet

- Astro-Spiri Camp - Chinmaya Vibhooti - Shankar Kumaran PDFDocument10 pagesAstro-Spiri Camp - Chinmaya Vibhooti - Shankar Kumaran PDFShankar KumaranNo ratings yet

- Links of XII Physics Investigatory Project Allowtment 2Document3 pagesLinks of XII Physics Investigatory Project Allowtment 2yashtomarsoop07No ratings yet

- ISO IEC 11801-5 - IT - Generic Cabling For Data CentreDocument63 pagesISO IEC 11801-5 - IT - Generic Cabling For Data Centreshazwanshaiful1No ratings yet

- Roman Helmet From SivacDocument33 pagesRoman Helmet From SivacArachne DreamweaverNo ratings yet

- List Katalog Fire Hydrant (Box)Document3 pagesList Katalog Fire Hydrant (Box)Sales1 mpicaNo ratings yet

- Yuasa Technical Data Sheet: The World's Leading Battery ManufacturerDocument1 pageYuasa Technical Data Sheet: The World's Leading Battery ManufacturerAshraf Sayed ShabaanNo ratings yet

- Jurnal Ari Maulana Ullum Sasmi 1801038Document12 pagesJurnal Ari Maulana Ullum Sasmi 180103803. Ari Maulana Ullum Sasmi / TD 2.10No ratings yet

- 1 Ha Cabbages - May 2018 PDFDocument1 page1 Ha Cabbages - May 2018 PDFMwai EstherNo ratings yet

- h2s Naoh Equilibrium CurveDocument22 pagesh2s Naoh Equilibrium Curvesmartleo_waloNo ratings yet