Professional Documents

Culture Documents

Treatment of Distillery Spent Wash by Anaerobic

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Treatment of Distillery Spent Wash by Anaerobic

Copyright:

Available Formats

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

IC-RICE Conference Issue | Nov-2013, Available @ http://www.ijret.org 310

TREATMENT OF DISTILLERY SPENT WASH BY ANAEROBIC

DIGESTION PROCESS

Shashikant.R.Mise

1

, Rajani.Saranadgoudar

2

, Rajendra.Lamkhade

3

1

Professor, Department of Civil Engineering,

2

M.Tech, Scholar, Department of Environmental Engineering,

PDA College of Engineering, Gulbarga

3

Associate Professor, Department of Civil Engineering, Pravara Rural College of Engineering, Ahmednagar

srmise45@yahoo.com, rrajani.pda@gmail.com, rklamkhade@yahoo.com

Abstract

In this study, experiments were conducted to investigate the production of biogas from distillery spent wash by using anaerobic

digestion process. A laboratory scale digester with working volume of 8.0L was used. The experimental protocol was defined to

examine the effect of the change in the organic loading rate on the efficiency of the production of biogas. The digester was operated at

different organic feeding rates of 0.5, 1.0 and 1.5 kg COD/m

3

.d. The reactor showed stable performance with highest biogas yield of

1150ml with percent COD reduction of around 63.04% during loading rate of 1.5 kg COD/m

3

.d. As the time increased, percent

COD removal and gas production increased and attained optimum value for each OLR. The maximum COD removal

efficiency and gas produced on 30

th

, 60

th

and 88

th

day were 79.72%, 71.29%, 63.04% and 451mL, 815mL, 1150mL. Based on

data from this study, implementation of anaerobic digestion as the method of waste treatment leads to the regional

utilization of renewable energy resources, energy requirements and costs.

Keywords: Anaerobic Digestion, BOD, COD, Organic Loading Rate (OLR), distillery spent washes, Reactors.

--------------------------------------------------------------------***----------------------------------------------------------------------

1. INTRODUCTION

There is a growing interest in alternate energy sources as a

result of increased demand for energy coupled with a rise in

the cost of available fuels. Rapid industrialization has resulted

in the generation of a large quantity of effluents with high

organic contents, which if treated suitably, can result in a

perpetual source of energy. In spite of the fact that there is a

negative environmental impact associated with

industrialization, the effect can be minimized and energy can

be tapped by means of anaerobic digestion of the wastewater.

In recent years, considerable attention has been paid towards

the development of reactors for anaerobic treatment of wastes

leading to the conversion of organic molecules into biogas.

The Anaerobic reactors, known as second generation reactors

or high rate digesters, can handle wastes at a high organic

loading rate of 24 kg COD/m

3

day and high up-flow velocity

of 23 m/h at a low hydraulic retention time

[1]

. However, the

treatment efficiencies of these reactors are sensitive to

parameters like wastewater composition, especially the

concentration of various ions

[3]

and presence of toxic

compounds such as phenol

[4]

. The temperature and pH are

also known to affect the performance of the reactor by

affecting the degree of acidification of the effluent and the

product formation

[5]

. An improvement in the efficiency of

anaerobic digestion can be brought about by either suitably

modifying the existing digester design or by incorporating

appropriate advanced operating techniques. Thus, a anaerobic

digester is found to be superior to the conventional processes

and stable reactor performance

[4]

. The main objective of this

study is to treat the Distillery spent wash using anaerobic

process and to characterize the Distillery spent wash for

various parameters such as pH, BOD, COD, alkalinity, etc. To

study the effect of organic loading on the performance of

anaerobic digestion process and to find the amount of biogas

produced.

1.1 Anaerobic Digestion (Stages):

Biogas Production through anaerobic digestion is a

biochemical process involving microbial flora of bacteria

adapted to oxygen free environment to convert complex

biological and organic wastes in sequential stages into

Methane, the major energy fuel.

Stage 1: The Hydrolytic Bacteria primarily are involved in the

breakdown of complex organic waste streams into simple

sugars, fats and oils, and amino acids. This stage involves

splitting of the complex organic biological molecules into

simpler forms, the process is known as Hydrolysis or

Liquefaction.

Stage 2: The Fermentative Acidogenic Bacteria convert the

hydrolyzed portion into Organic acids.

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

IC-RICE Conference Issue | Nov-2013, Available @ http://www.ijret.org 311

Stage 3: The Fermentative Acetogenic Bacteria then convert

the Organic acids into Hydrogen, Acetate and CO2 (g).

Stage 4: Finally, the Methane producing Bacteria, the

Methanogens simultaneously produce Biogas from the

Acetate, or from Hydrogen and Carbon dioxide.

1.2 Sources of Wastewater:

Process waste streams: Spent wash from the analyser

column, Fermented sludge, Spent lees from the rectifier.

Non-process waste streams: Cooling water, Waste wash

water, Water treatment plant wastewater, Boiler blow

down, Bottling plant wash wastewater, other wastes.

2. MATERIALS AND METHODOLOGY

2.1 Fabrication and Setting up of Experimental

Setup:

The schematic diagram of the experimental setup used for

the present study is shown in Figure 1. Aspirator bottle of

10 L (bottle no.1) capacity was used as digester with

working volume of 8L. The digester was connected to 5 L

capacity bottle (bottle no.2), which contains the brine

solution. The liquid displaced by generated gas is

collected in the bottle no 3. The organic loading rate was

calculated based upon the working volume of the

digester. The organic loading on the digester were 0.5 Kg

COD/m

3

.d, 1.0 Kg COD/m

3

.d, 1.5 Kg COD/m

3

.d

Bottle No.1 Bottle No.2 Bottle No.3

Fig 1: Experimental Setup of anaerobic reactor

2.2 Start up of Reactor:

During the start-up of the reactor, the reactor was loaded with

7.0 L of cow-dung slurry & 1.0 L of distillery spent wash with

a COD concentration of 40,100 mg/L, this mixture gave a

composite COD of 14,800mg/L. Daily the reactor was loaded

with wastewater of volume 100mL with a COD concentration

of 40,100 mg/L. After 4

days lapse of time the Gas collection

started & by adjusting the reactor pH every-day the reactor

was operated for 30 days for achieving stabilization. During

various organic loading, 150ml of effluent sample was

collected for analysis of various physico-chemical

parameters such as pH, BOD, COD, alkalinity, total

solids, etc. and the analysis were carried out as per the

standard methods for the examination of water and

wastewater (AWWA) 20

th

edition.

2.3 General Characteristics of Distillery Spent Wash:

The fresh wastewater samples were brought from

"Padmashree Dr. Vittalrao Viakhe Patil co-operative

sugar factory" to P.D.A Engg. College laboratory and

preserved in deep freeze, to analyse the typical

characteristics. The key pollutants in the spent wash from

distilleries are organic compounds and solids.

Biodegradability may be estimated on the basis of BOD /

COD ratio. This ratio ranges between 0.42-0.64, which

indicates that the part of the organic compounds in the waste

water is not easily biodegradable. The BOD

5

is 30,000mg/L,

COD is 40,100mg/L & Total Solids in wastewater was found

to be 8600 mg/L. The pH value in this case varies from 3.8 -

4.4. When wastewater contains high concentration of organic

matter, dissolved oxygen depletes because of the breakdown

of organic matter, in absence of oxygen, sulphate acts as an

electron acceptor to produce H

2

s and odour.

3. RESULTS AND DISCUSSION

The results of alkalinity, percentage COD removal and

Gas production are shown in Figure 2, Figure 3 & Figure

4 for varying Organic Loading Rate.

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

IC-RICE Conference Issue | Nov-2013, Available @ http://www.ijret.org 312

Fig 2: Graph of Total Alkalinity, percent COD removal and Gas production for OLR=0.5 kg COD/m

3

.d

Fig 3: Graph of Total Alkalinity, percent COD removal and Gas production for OLR=1.0 kg COD/m

3

.d

Fig 4: Graph of Total Alkalinity, percent COD removal and Gas production for OLR=1.5 kg COD/m

3

.d

0

71.62 73.91 75.66 77.36 79.04 79.72

0 5

72

183

295

406

451

1070 1080

1450

1900

2610

2900

2980

-500

0

500

1000

1500

2000

2500

3000

3500

1 5 10 15 20 25 30

Experimental period in days

%COD reduction

gas production (!"

#ota! $!%a!init&

64.39 65.57 67.33 69.27 70.94 71.29

450

516

589

669

760

815 810

950

1249

1600

1886

1945

0

500

1000

1500

2000

2500

35 40 45 50 55 60

Experimental period in days

%COD reduction

gas production (!"

#ota! $!%a!init&

56.95 57.37 59.15 61.47 62.83 63.04

812

860

956

1062

1138

1150

690

739

851

980

1089

1110

0

200

400

600

800

1000

1200

1400

65 70 75 80 85 88

Experimental period in days

%COD reduction

gas production (!"

#ota! $!%a!init&

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

IC-RICE Conference Issue | Nov-2013, Available @ http://www.ijret.org 313

The reactor was started with an OLR of 0.5 kg COD/m

3

.d and

operated for a period of 30days till it attains stabilization.

During this period the pH is maintained from 7.02-7.04. The

alkalinity increased from 1080-2980 mg/L & and COD

reduced from 4200-3000 mg/L, refer Figure 2. On 30

th

day the

maximum COD removal efficiency obtained is 79.72 %

& gas produced is 451mL. As the time increased, %COD

removal increased & attained optimum value on 30

th

day.

When the OLR was increased from 0.5 to 1.0 kg COD/m

3

.d

(35-60

th

day) & operated for a period of 25days till it attains

stabilization. Throughout the study period the pH is

maintained from 7.10-7.03, the alkalinity increased from 810-

1945 mg/L & COD reduced from 5270-4248 mg/L, refer

Figure 3. On 60

th

day the maximum COD removal

efficiency obtained is 71.29 % & gas produced is 815mL.

As the time increased, %COD removal increased &

attained optimum value on 60

th

day.

When the OLR was increased from 1.0 to 1.5 kg COD/m

3

.d

(60-88

th

day) & operated for a period of 28days till the reactor

stabilises. Throughout the study period the pH is maintained

from 7.02-7.08, the alkalinity increased from 690-1110 mg/L

& COD reduced from 6370-5470 mg/L refer Figure 4. On 88

th

day the maximum COD removal efficiency obtained is

63.04 % & gas produced is 1150mL. As the time

increased, %COD removal increased & attained optimum

value on 88

th

day.

CONCLUSIONS

Based on the experimental study it can be concluded that

the spent wash is highly organic in nature having high

value of COD (41,100mg/L). The maximum COD removal

efficiency is 79.72 % achieved after 30

th

day (optimizing

time) at an organic loading rate of 0.5 kg COD/ m

3

.d. The

maximum biogas produced is 1150mL after 88

th

day of the

start of reactor at an OLR of 1.5 kg/m

3

.d. It was noticed

that the percent COD removal was increased and attained

optimum value on 88

th

day from the start up. As the OLR

was increased from 0.5 to 1.5 kg COD/m

3

.d, the volume of gas

produced increased form 5-451mL, 451-815mL and 812-

1150mL respectively, percent COD removal decreased from

71.62-79.72%, 64.39-71.29%, 56.95-63.04% and total

alkalinity was decreased from 1080-2980mg/L, 810-

1945mg/L and 690-1110mg/L respectively.

REFERENCES

[1] Blonskaja, V., Molder, H., Sokk, O., Vaalu, T.,

1999. Investi- gation of anaerobic treatment of

extremely high concentrated waste in the cheese

industry. Heleco 99, Environmental Technology

for 21st Century, Third International Exhibition and

Conference, 36 June 1999, Thessaloniki, Greece,

pp. 5762.

[2] Lawrence, A.W. and McCarty, P.L. (1969),

Methane formation in anaerobic treatment, J.

Wat. Pollut. Control Fed., Vol. 41, pp. R1-R7.

[3] Dague. R.R. (1968). Application of digestion

theory of digestion control J. Wat. Pollut. Control

Fed., Vol. 40. pp. 2021-2132.

[4] K. Sundar Kumar et al, International Journal of

Engineering and Science and Technology, Volume

2(12), 2010, pp. 7785 7796.

[5] Gujer, W. and Zehnder. A.J.B. (1983), Review

paper-anaerobic treatment of wastewater in fixed

film reactors, Water Science and Technology, Vol.

15, pp. 1-120.

You might also like

- Treatment of Sugar Industry Wastewater UsingDocument4 pagesTreatment of Sugar Industry Wastewater UsingInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Dewats - Water Quality AssessmentDocument4 pagesDewats - Water Quality Assessmentkarthik_g4uNo ratings yet

- Reduction of Cod and Bod by Oxidation: A Cetp Case Study: Prashant K. Lalwani, Malu D. DevadasanDocument5 pagesReduction of Cod and Bod by Oxidation: A Cetp Case Study: Prashant K. Lalwani, Malu D. Devadasanjmrozo3No ratings yet

- Parametric Study of Brewery Wastewater Effluent Treatment Using Chlorella Vulgaris MicroalgaeDocument8 pagesParametric Study of Brewery Wastewater Effluent Treatment Using Chlorella Vulgaris MicroalgaeAA0809No ratings yet

- Application of The Technique of Biosorption by A Plant Sorbent in Thetreatment of Chemical Releases From A Hospital LaboDocument6 pagesApplication of The Technique of Biosorption by A Plant Sorbent in Thetreatment of Chemical Releases From A Hospital LaboAnonymous 4MPMBROaNo ratings yet

- Process Biochemistry: SciencedirectDocument7 pagesProcess Biochemistry: Sciencedirectmorillas.ainoNo ratings yet

- Removal of CO From Biogas Plant Using Chemical Absorption ColumnDocument7 pagesRemoval of CO From Biogas Plant Using Chemical Absorption ColumnanirudhNo ratings yet

- III - A - 3 - D - 2022 Jurnal IPA Vol8 No6Document8 pagesIII - A - 3 - D - 2022 Jurnal IPA Vol8 No6Dr. Kuswandi ST.,MTNo ratings yet

- Kotra WTPDocument5 pagesKotra WTPrinkyNo ratings yet

- Physicochemical Treatment of Textile Industry Waste Water: Salman Mo Tabani, and Omprakash SahuDocument3 pagesPhysicochemical Treatment of Textile Industry Waste Water: Salman Mo Tabani, and Omprakash SahuCarlos Manuel RamosNo ratings yet

- Industrial Waste Water Treatment Using An Attached MediaDocument5 pagesIndustrial Waste Water Treatment Using An Attached Mediabahjath euNo ratings yet

- 10 1 1 261 2208Document4 pages10 1 1 261 2208Hirma Naufal RahmawatiNo ratings yet

- Effects of Different Parameters On Photocatalytic Oxidation of Slaughterhouse Wastewater Using Tio and Silver-Doped Tio NanoparticlesDocument10 pagesEffects of Different Parameters On Photocatalytic Oxidation of Slaughterhouse Wastewater Using Tio and Silver-Doped Tio NanoparticlesNicholas YeohNo ratings yet

- Anaerobic wastewater treatment processes explained in 38 charactersDocument12 pagesAnaerobic wastewater treatment processes explained in 38 charactersSabhari NatarajanNo ratings yet

- Biodegradability of Diesel Using Specific Oxygen Uptake RateDocument5 pagesBiodegradability of Diesel Using Specific Oxygen Uptake RatetheijesNo ratings yet

- Extended Aeration Activated Sludge Proce PDFDocument4 pagesExtended Aeration Activated Sludge Proce PDFEnrique MartinezNo ratings yet

- Produccion de Hidrogeno Por FermentacionDocument11 pagesProduccion de Hidrogeno Por FermentacionSanchez JorgeNo ratings yet

- E3sconf Asee2017 00015Document9 pagesE3sconf Asee2017 00015An BuiNo ratings yet

- Indonesia Workshop Symposium Bioenergy BiomassDocument4 pagesIndonesia Workshop Symposium Bioenergy BiomassMmediong UdofiaNo ratings yet

- Internal Circulation Reactor Pushing The LimitsDocument9 pagesInternal Circulation Reactor Pushing The LimitsAbhishek TripathiNo ratings yet

- Preliminary Study On Optimization of PH, Oxidant and Catalyst Dose For High COD Content: Solar Parabolic Trough CollectorDocument10 pagesPreliminary Study On Optimization of PH, Oxidant and Catalyst Dose For High COD Content: Solar Parabolic Trough Collectormemo_gh89No ratings yet

- 5508 Et EtDocument12 pages5508 Et Etmadhu guptaNo ratings yet

- Full Length Article: Contents Lists Available atDocument8 pagesFull Length Article: Contents Lists Available atDome VelardeNo ratings yet

- Project Report On Waste Water TreatmentDocument35 pagesProject Report On Waste Water TreatmentSami Zama100% (1)

- Anaerobic TolueneDocument11 pagesAnaerobic TolueneEmiliano Rodriguez TellezNo ratings yet

- Enhancement of Production and Upgradation of Biogas Using Different Techniques-A ReviewDocument17 pagesEnhancement of Production and Upgradation of Biogas Using Different Techniques-A ReviewZainul Fikri TampengNo ratings yet

- Jurnal AmamiDocument12 pagesJurnal AmamiSany FathinurNo ratings yet

- Improvement of Biogas Quality Product From Dairy CDocument6 pagesImprovement of Biogas Quality Product From Dairy CDieu Donné OUTCHINo ratings yet

- Oxygen Demand SlidesDocument8 pagesOxygen Demand SlidesShakir MohyuddinNo ratings yet

- Industrial Waste SurweyDocument34 pagesIndustrial Waste SurweyOmaya TariqNo ratings yet

- Biohydrogen production by dark fermentation in large lab scale reactorsDocument8 pagesBiohydrogen production by dark fermentation in large lab scale reactorsAlejandro Duvan Lopez RojasNo ratings yet

- Optimizing Organic Waste Treatment for Soft Drink FactoriesDocument7 pagesOptimizing Organic Waste Treatment for Soft Drink FactoriesJoni Hariadi SNo ratings yet

- Angeles Et Al., 2020Document9 pagesAngeles Et Al., 2020Hus KolNo ratings yet

- علي غانم خضير PDFDocument29 pagesعلي غانم خضير PDFAli AlibrahimiNo ratings yet

- Full-Scale Biodrying Process of Municipal Solid WaDocument6 pagesFull-Scale Biodrying Process of Municipal Solid WaHAMZA ZAKINo ratings yet

- Envirmonement Source ReportDocument19 pagesEnvirmonement Source Reportمهيمن الابراهيميNo ratings yet

- Application of Uasbr in Treatment of Dairy Waste Water: 1, PG Student, 2, Assistant ProfessorDocument9 pagesApplication of Uasbr in Treatment of Dairy Waste Water: 1, PG Student, 2, Assistant Professorvk100No ratings yet

- Wastewater 12Document27 pagesWastewater 12egorceacovaNo ratings yet

- Pyrolysis of Municipal Sewage Sludge For Bio Oil Production and Characterization of Bio-OilDocument6 pagesPyrolysis of Municipal Sewage Sludge For Bio Oil Production and Characterization of Bio-OilSMIT CHRISTIANNo ratings yet

- Removal of Nitrogen and Phosphorus From Waste WaterDocument6 pagesRemoval of Nitrogen and Phosphorus From Waste WaterShahbaz ShafiNo ratings yet

- SBR Manual For TreatmentDocument11 pagesSBR Manual For TreatmentDave DamalerioNo ratings yet

- BIOCHEMICAL OXYGEN DEMAND TESTDocument7 pagesBIOCHEMICAL OXYGEN DEMAND TESTJavier D. SolisNo ratings yet

- Case Study For Soap Waste WaterDocument6 pagesCase Study For Soap Waste WaterKari ConwayNo ratings yet

- Principles of Water Treatment and Wastewater EngineeringDocument12 pagesPrinciples of Water Treatment and Wastewater EngineeringRefisa JiruNo ratings yet

- Two-Phases Anaerobic Digestion of Fruit and Vegetable Wastes: Bioreactors PerformanceDocument5 pagesTwo-Phases Anaerobic Digestion of Fruit and Vegetable Wastes: Bioreactors PerformanceElizabeth CochranNo ratings yet

- Cavitation Process A New Tool For Waste Water TreatmentDocument3 pagesCavitation Process A New Tool For Waste Water TreatmentIJSTE100% (1)

- Research ArticleDocument12 pagesResearch ArticlePranavNo ratings yet

- Chapter#2Document29 pagesChapter#2Yousef SailiniNo ratings yet

- Anaerobic Treatment of Wastewater From Sugar Cane IndustryDocument12 pagesAnaerobic Treatment of Wastewater From Sugar Cane IndustryVaishnavi SrivastavaNo ratings yet

- Electrochemical Treatment of Slaughterhouse and Dairy Wastewater: Toward Making A Sustainable ProcessDocument13 pagesElectrochemical Treatment of Slaughterhouse and Dairy Wastewater: Toward Making A Sustainable ProcesskaltoumNo ratings yet

- IJEAS0301048Document2 pagesIJEAS0301048erpublicationNo ratings yet

- Ijisrt20may964 PDFDocument6 pagesIjisrt20may964 PDFUna Isma100% (23)

- 120C Waktu 12 JamDocument13 pages120C Waktu 12 JamcherinesakinahNo ratings yet

- C. C. C. C. S S S S.... Okoli Okoli Okoli Okoli and and and and P. C. P. C. P. C. P. C. Okonkwo Okonkwo Okonkwo OkonkwoDocument6 pagesC. C. C. C. S S S S.... Okoli Okoli Okoli Okoli and and and and P. C. P. C. P. C. P. C. Okonkwo Okonkwo Okonkwo OkonkwoHemaNo ratings yet

- Jurnal Rekayasa Proses: Journal Homepage: Http://journal - Ugm.ac - Id/jrekprosDocument7 pagesJurnal Rekayasa Proses: Journal Homepage: Http://journal - Ugm.ac - Id/jrekprosDewi SukmawatiNo ratings yet

- Performance of Continuous Stirred Tank Reactor CSTDocument7 pagesPerformance of Continuous Stirred Tank Reactor CSTانجینئر بلاول شمیرNo ratings yet

- Mathematical Model and System Identification To Optimize Inputs Conditions For Plant Design of CyclohexaneDocument28 pagesMathematical Model and System Identification To Optimize Inputs Conditions For Plant Design of CyclohexaneBüşraNo ratings yet

- 3-COD LABSHEET WORD Tim & PikaDocument22 pages3-COD LABSHEET WORD Tim & PikadanielseleyNo ratings yet

- Renewable Hydrogen Technologies: Production, Purification, Storage, Applications and SafetyFrom EverandRenewable Hydrogen Technologies: Production, Purification, Storage, Applications and SafetyLuis M GandiaRating: 3 out of 5 stars3/5 (2)

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- Wind Damage To Trees in The Gitam University Campus at Visakhapatnam by Cyclone HudhudDocument11 pagesWind Damage To Trees in The Gitam University Campus at Visakhapatnam by Cyclone HudhudInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Flood Related Disasters Concerned To Urban Flooding in Bangalore, IndiaDocument8 pagesFlood Related Disasters Concerned To Urban Flooding in Bangalore, IndiaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Enhancing Post Disaster Recovery by Optimal Infrastructure Capacity BuildingDocument8 pagesEnhancing Post Disaster Recovery by Optimal Infrastructure Capacity BuildingInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Groundwater Investigation Using Geophysical Methods - A Case Study of Pydibhimavaram Industrial AreaDocument5 pagesGroundwater Investigation Using Geophysical Methods - A Case Study of Pydibhimavaram Industrial AreaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Review Study On Performance of Seismically Tested Repaired Shear WallsDocument7 pagesReview Study On Performance of Seismically Tested Repaired Shear WallsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Role of Voluntary Teams of Professional Engineers in Dissater Management - Experiences From Gujarat EarthquakeDocument6 pagesRole of Voluntary Teams of Professional Engineers in Dissater Management - Experiences From Gujarat EarthquakeInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Likely Impacts of Hudhud On The Environment of VisakhapatnamDocument3 pagesLikely Impacts of Hudhud On The Environment of VisakhapatnamInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Impact of Flood Disaster in A Drought Prone Area - Case Study of Alampur Village of Mahabub Nagar DistrictDocument5 pagesImpact of Flood Disaster in A Drought Prone Area - Case Study of Alampur Village of Mahabub Nagar DistrictInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Effect of Lintel and Lintel Band On The Global Performance of Reinforced Concrete Masonry In-Filled FramesDocument9 pagesEffect of Lintel and Lintel Band On The Global Performance of Reinforced Concrete Masonry In-Filled FramesInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Shear Strength of RC Deep Beam Panels - A ReviewDocument15 pagesShear Strength of RC Deep Beam Panels - A ReviewInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Hudhud Cyclone - A Severe Disaster in VisakhapatnamDocument8 pagesHudhud Cyclone - A Severe Disaster in VisakhapatnamInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Wind Damage To Buildings, Infrastrucuture and Landscape Elements Along The Beach Road at VisakhapatnamDocument10 pagesWind Damage To Buildings, Infrastrucuture and Landscape Elements Along The Beach Road at VisakhapatnamInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Monitoring and Assessment of Air Quality With Reference To Dust Particles (Pm10 and Pm2.5) in Urban EnvironmentDocument3 pagesMonitoring and Assessment of Air Quality With Reference To Dust Particles (Pm10 and Pm2.5) in Urban EnvironmentInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Low Cost Wireless Sensor Networks and Smartphone Applications For Disaster Management and Improving Quality of LifeDocument5 pagesLow Cost Wireless Sensor Networks and Smartphone Applications For Disaster Management and Improving Quality of LifeInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Cyclone Disaster On Housing and Coastal AreaDocument7 pagesCyclone Disaster On Housing and Coastal AreaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Assessment of Seismic Susceptibility of RC BuildingsDocument4 pagesAssessment of Seismic Susceptibility of RC BuildingsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- A Geophysical Insight of Earthquake Occurred On 21st May 2014 Off Paradip, Bay of BengalDocument5 pagesA Geophysical Insight of Earthquake Occurred On 21st May 2014 Off Paradip, Bay of BengalInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Detection of Hazard Prone Areas in The Upper Himalayan Region in Gis EnvironmentDocument9 pagesDetection of Hazard Prone Areas in The Upper Himalayan Region in Gis EnvironmentInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Disaster Recovery Sustainable HousingDocument4 pagesDisaster Recovery Sustainable HousingInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Effect of Hudhud Cyclone On The Development of Visakhapatnam As Smart and Green City - A Case StudyDocument4 pagesEffect of Hudhud Cyclone On The Development of Visakhapatnam As Smart and Green City - A Case StudyInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Can Fracture Mechanics Predict Damage Due Disaster of StructuresDocument6 pagesCan Fracture Mechanics Predict Damage Due Disaster of StructuresInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Coastal Zones - Seismic Vulnerability An Analysis From East Coast of IndiaDocument4 pagesCoastal Zones - Seismic Vulnerability An Analysis From East Coast of IndiaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Comparative Study of The Forces in G+5 and G+10 Multi Storied Buildings Subjected To Different Wind SpeedsDocument10 pagesComparative Study of The Forces in G+5 and G+10 Multi Storied Buildings Subjected To Different Wind SpeedsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Brain Tumor Segmentation Using Asymmetry Based Histogram Thresholding and K-Means ClusteringDocument4 pagesBrain Tumor Segmentation Using Asymmetry Based Histogram Thresholding and K-Means ClusteringInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Developing of Decision Support System For Budget Allocation of An R&D OrganizationDocument6 pagesDeveloping of Decision Support System For Budget Allocation of An R&D OrganizationInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Challenges in Oil and Gas Industry For Major Fire and Gas Leaks - Risk Reduction MethodsDocument4 pagesChallenges in Oil and Gas Industry For Major Fire and Gas Leaks - Risk Reduction MethodsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Cpw-Fed Uwb Antenna With Wimax Band-Notched CharacteristicsDocument5 pagesCpw-Fed Uwb Antenna With Wimax Band-Notched CharacteristicsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Analytical Solutions For Square Shape PressureDocument4 pagesAnalytical Solutions For Square Shape PressureInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Rate Adaptive Resource Allocation in Ofdma Using Bees AlgorithmDocument5 pagesRate Adaptive Resource Allocation in Ofdma Using Bees AlgorithmInternational Journal of Research in Engineering and TechnologyNo ratings yet

- RWS PDFDocument6 pagesRWS PDFAnand NanduNo ratings yet

- Chemical Waste Management GuidelinesDocument5 pagesChemical Waste Management GuidelinesSolomon SundayNo ratings yet

- 40Document4 pages40Muhammad Umer ArshadNo ratings yet

- Port City Project ECBADocument61 pagesPort City Project ECBAVijaykanth ViveNo ratings yet

- Manual Equipos Culligan Hi FloDocument2 pagesManual Equipos Culligan Hi FloEdwin LaraNo ratings yet

- DPT Well S & ADocument57 pagesDPT Well S & ABrahim Letaief100% (2)

- Ecw331 Chapter 01 Final PDFDocument31 pagesEcw331 Chapter 01 Final PDFMuhd MuqhreyNo ratings yet

- Cell and Molecular BiologyDocument4 pagesCell and Molecular BiologyRea Joyce AldefollaNo ratings yet

- RAL 1018 Matt Safety SheetDocument13 pagesRAL 1018 Matt Safety SheetGustavo MendonçaNo ratings yet

- 2710 Tests On Sludges : 1. General DiscussionDocument8 pages2710 Tests On Sludges : 1. General Discussionpollux23No ratings yet

- PureWaterCooler Service ManualDocument38 pagesPureWaterCooler Service ManualAzhar HassanNo ratings yet

- The Messy Magpie Fact CardsDocument4 pagesThe Messy Magpie Fact CardsSam EspinosaNo ratings yet

- 105.a.0 - RO-DM Plant Chain Sizing CalcDocument7 pages105.a.0 - RO-DM Plant Chain Sizing Calcmkchy12No ratings yet

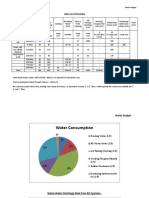

- Water consumption and waste analysisDocument6 pagesWater consumption and waste analysisNaveen MathurNo ratings yet

- Polarization Methods for Measuring Corrosion RatesDocument25 pagesPolarization Methods for Measuring Corrosion RatesPanji Aji WibowoNo ratings yet

- Hydronic Buffer Tank Install Manual 090811Document6 pagesHydronic Buffer Tank Install Manual 090811Andres CarrascoNo ratings yet

- BiogasDocument12 pagesBiogasAna AnawatiNo ratings yet

- Goosen 2000 ThermodynamicsDocument27 pagesGoosen 2000 ThermodynamicsUttam KarNo ratings yet

- Ch1 - Steam Power PlantsDocument44 pagesCh1 - Steam Power Plantsaminjoe93100% (1)

- Wendland RetainingWallsDocument30 pagesWendland RetainingWallsMahn NguyenNo ratings yet

- Test - 64 - Physical Geography - Test-4Document15 pagesTest - 64 - Physical Geography - Test-4Palak JioNo ratings yet

- US20120103906 Closed Circuit Desalination Retrofit For Improved Performance of Common Reverse Osmosis SystemsDocument11 pagesUS20120103906 Closed Circuit Desalination Retrofit For Improved Performance of Common Reverse Osmosis SystemsWendyNo ratings yet

- Project Data Sheet PDS 2Document86 pagesProject Data Sheet PDS 2Munir HussainNo ratings yet

- Good Phrases That Describe EmotionsDocument9 pagesGood Phrases That Describe EmotionsKevin LimNo ratings yet

- Bedzed Monitoring Report 2007Document39 pagesBedzed Monitoring Report 2007JCNo ratings yet

- Catálogo Vontron - CompletoDocument57 pagesCatálogo Vontron - CompletomarianaNo ratings yet

- Mineral Resources PDFDocument28 pagesMineral Resources PDFannayaNo ratings yet

- Waste Water Treatment TechDocument23 pagesWaste Water Treatment TechArchit Gupta100% (1)

- Indice Curso de Vapor Spirax SarcoDocument20 pagesIndice Curso de Vapor Spirax SarcoDavidNo ratings yet

- Control Water Levels with RAF 10 Float ValveDocument2 pagesControl Water Levels with RAF 10 Float Valvevelikimag87No ratings yet