Professional Documents

Culture Documents

Air Flow Control

Uploaded by

Pavle PerovicOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Flow Control

Uploaded by

Pavle PerovicCopyright:

Available Formats

08

Mechanical ow rate

controllers

Throttling, shut-o and

non-return dampers

Volume control

dampers

Overpressure

dampers

292

Air fow control units

Overpressure dampers are used to equalize the

pressures between adjacent rooms and for automatic

interruption of air supply or air exhaust.

Volume control dampers regulate the air fow volume in

ventilating ducts and air conditioning devices.

Throttling, shut-off and non-return dampers and fow rate

controllers are used for control the air fow volume in

ventilating ducts.

Air fow control units

293

V

E

N

T

I

L

A

T

I

N

G

G

R

I

L

L

E

S

,

V

E

N

T

I

L

A

T

I

N

G

V

A

L

V

E

S

C

I

R

C

U

L

A

R

D

I

F

F

U

S

E

R

S

,

S

Q

U

A

R

E

D

I

F

F

U

S

E

R

S

S

W

I

R

L

D

I

F

F

U

S

E

R

S

,

V

A

R

I

A

B

L

E

S

W

I

R

L

D

I

F

F

U

S

E

R

S

S

L

O

T

D

I

F

F

U

S

E

R

S

,

R

O

U

N

D

D

U

C

T

D

I

F

F

U

S

E

R

S

A

I

R

D

I

S

P

L

A

C

E

M

E

N

T

U

N

I

T

S

S

U

P

P

L

Y

A

I

R

N

O

Z

Z

L

E

S

E

X

T

E

R

N

A

L

E

L

E

M

E

N

T

S

A

I

R

F

L

O

W

C

O

N

T

R

O

L

U

N

I

T

S

S

O

U

N

D

A

T

T

E

N

U

A

T

O

R

S

,

S

O

U

N

D

A

T

T

E

N

U

A

T

I

N

G

L

O

U

V

R

E

S

Air fow control units

Overpressure dampers

Overpressure dampers are used to

equalize the pressures between adjacent

rooms and for automatic interruption of

air supply or air exhaust. Steel (Types JN)

or aluminium (Types AN) overpressure

dampers can be produced.

Volume control dampers

Volume control dampers regulate the air

fow volume in ventilating ducts and air

conditioning devices. We produce several

construction types with manual, motor or

pneumatic regulation.

Throttling, shut off and non

return dampers, fow rate

controllers

They are used to control the air fow volu-

me in ventilating ducts.

Overview

Volume control dampers

R-1 R-2 R-3 R-1/G

R-7

JN-6 AN-3, AN-4 JN-6W

Throttling, shut off and non return dampers

Mechanical fow rate controllers

Overpressure dampers

DL RSK DL-2 ZL-2

MRP-2 MRP-1 MRP-3 MRP-4

294

Air fow control units

Content

Page

OVERPRESSURE DAMPERS 296

Overpressure dampers JN-6, AN-3, AN-4 296

Louvre for maintaining the preset pressure difference JN-6W 299

VOLUME CONTROL DAMPERS 301

Volume control dampers R-1, R-2, R-3 301

Volume control dampers R-7 308

COMBINATIONS 311

Combination of Protection louvres JZR-6 and AZR-4 with Overpressure

damper JN-6 311

Combination of Protection louvres JZR-6 and AZR-4 with Volume control

damper R-1 311

THROTTLING, SHUT-OFF AND NON-RETURN DAMPERS 312

Throttling dampers DL 312

Throttling dampers DL-1, DL-2 314

Shut-off dampers ZL-1, ZL-2 316

Non-return damper RSK 318

MECHANICAL FLOW RATE CONTROLLERS 319

Mechanical fow-rate controller MRP-1 (Circular) 319

Mechanical fow-rate controller MRP-2 (Rectangular) 321

Mechanical fow-rate controller MRP-3 (Circular) 323

Mechanical fow-rate controller MRP-4 (Square) 328

MOTOR ACTUATORS BELIMO AND JOVENTA 333

Motor actuators 333

295

V

E

N

T

I

L

A

T

I

N

G

G

R

I

L

L

E

S

,

V

E

N

T

I

L

A

T

I

N

G

V

A

L

V

E

S

C

I

R

C

U

L

A

R

D

I

F

F

U

S

E

R

S

,

S

Q

U

A

R

E

D

I

F

F

U

S

E

R

S

S

W

I

R

L

D

I

F

F

U

S

E

R

S

,

V

A

R

I

A

B

L

E

S

W

I

R

L

D

I

F

F

U

S

E

R

S

S

L

O

T

D

I

F

F

U

S

E

R

S

,

R

O

U

N

D

D

U

C

T

D

I

F

F

U

S

E

R

S

A

I

R

D

I

S

P

L

A

C

E

M

E

N

T

U

N

I

T

S

S

U

P

P

L

Y

A

I

R

N

O

Z

Z

L

E

S

E

X

T

E

R

N

A

L

E

L

E

M

E

N

T

S

A

I

R

F

L

O

W

C

O

N

T

R

O

L

U

N

I

T

S

S

O

U

N

D

A

T

T

E

N

U

A

T

O

R

S

,

S

O

U

N

D

A

T

T

E

N

U

A

T

I

N

G

L

O

U

V

R

E

S

Air fow control units

JN-6 AN-3, AN-4

H

/

B

H

/

B

7

B = B1+28

H = H1+28

B2 = B1+23

H2 = H1+23

H

1

/

B

1

H

/

B

H

2

/

B

2

35

8

2

.

5

2

8

H

1

/

B

1

H

1

/

B

1

H

1

+

1

5

/

B

1

+

1

5

120

8

2

.

5

3

8

H

1

/

B

1

3

8

8

2

.

5

JN-6 AN-3 AN-4

Overpressure dampers

JN-6, AN-3, AN-4

Application

Overpressure dampers are used in all

kinds of low pressure air conditioning,

air heating ind ventilation, where it

is necesary to equalise the pressure

between adjacent rooms. They can be

applied where the automatic break of

the supply and exhaust air is required

after conditioning-, heating- or ventilation

device has been turned off.

Description

Overpressure dampers consist of

supporting frame made of galvanized

sheet steel (steel overpressure dampers

JN-6) or aluminium section anodised

in natural aluminium colour (aluminium

overpressure dampers AN-3 and

AN-4) and horizontal swinging vanes

of sheet aluminium. The horizontal

vanes are inserted into plastic bearings,

temperature resistant to 80 C. Sealing

stripe, attached on lower part of vanes

reduces noise.

Caution

In the cases of effective velocities

exceeding the values provided in the

diagram of the determination of the

total pressure drop on page 14, or in the

cases of a likely exposure of the louvres

to strong wind gusts, we recommend the

installation of a constraint crossbar.

Sizes:

All combinations of B1 and H1 according

to the table of dimensions are possible.

Non-standard dimensions are available on

request.

Sizes JN-6, AN-3, AN-4

H1 (mm) 100 150 200 250 300 400 500 600 700 800 900 1000 1100 1200

B1 (mm) 200 250 300 400 500 600 700 800 900 1000 1100 1200

n 1 1 2 3 3 5 6 7 8 10 11 12 13 14

n number of vanes

Overpressure dampers

296

Air fow control units

Overpressure dampers

H

/

B

H

/

B

7

B = B1+28

H = H1+28

B2 = B1+23

H2 = H1+23

H

1

/

B

1

H

/

B

H

2

/

B

2

35

8

2

.

5

2

8

H

1

/

B

1

H

1

/

B

1

H

1

+

1

5

/

B

1

+

1

5

120

8

2

.

5

3

8

H

1

/

B

1

3

8

8

2

.

5

H

/

B

H

/

B

7

B = B1+28

H = H1+28

B2 = B1+23

H2 = H1+23

H

1

/

B

1

H

/

B

H

2

/

B

2

35

8

2

.

5

2

8

H

1

/

B

1

H

1

/

B

1

H

1

+

1

5

/

B

1

+

1

5

120

8

2

.

5

3

8

H

1

/

B

1

3

8

8

2

.

5

H

/

B

H

/

B

7

B = B1+28

H = H1+28

B2 = B1+23

H2 = H1+23

H

1

/

B

1

H

/

B

H

2

/

B

2

35

8

2

.

5

2

8

H

1

/

B

1

H

1

/

B

1

H

1

+

1

5

/

B

1

+

1

5

120

8

2

.

5

3

8

H

1

/

B

1

3

8

8

2

.

5

H

1

H

1

H

3

H

/

B

B1

B / H

B1 B1

B3

H

1

1 2 3 4 5 6 0.5

5

20

30

40

50

80

10

100

Hitrost zraka v (m/s) v efektivnem preseku A

ef

P

a

d

e

c

t

l

a

k

a

p

c

e

l

(

P

a

)

H

1

H

1

H

3

H

/

B

B1

B / H

B1 B1

B3

H

1

1 2 3 4 5 6 0.5

5

20

30

40

50

80

10

100

Hitrost zraka v (m/s) v efektivnem preseku A

ef

P

a

d

e

c

t

l

a

k

a

p

c

e

l

(

P

a

)

Overpressure damper is fastened in

built-in frame of angle steel.

Designation: JN-6/3

Overpressure damper is fastened

on duct. Connection accessories

are not supplied.

Designation: JN-6

Overpressure damper is

fastened in built-in frame

Designation:

AN-3/2, AN-4/2

H3=(2xH1)+56 B3=(2xB1)+56

Combinations of larger overpressure dampers JN-6, AN-3, AN-4:

Installation

297

V

E

N

T

I

L

A

T

I

N

G

G

R

I

L

L

E

S

,

V

E

N

T

I

L

A

T

I

N

G

V

A

L

V

E

S

C

I

R

C

U

L

A

R

D

I

F

F

U

S

E

R

S

,

S

Q

U

A

R

E

D

I

F

F

U

S

E

R

S

S

W

I

R

L

D

I

F

F

U

S

E

R

S

,

V

A

R

I

A

B

L

E

S

W

I

R

L

D

I

F

F

U

S

E

R

S

S

L

O

T

D

I

F

F

U

S

E

R

S

,

R

O

U

N

D

D

U

C

T

D

I

F

F

U

S

E

R

S

A

I

R

D

I

S

P

L

A

C

E

M

E

N

T

U

N

I

T

S

S

U

P

P

L

Y

A

I

R

N

O

Z

Z

L

E

S

E

X

T

E

R

N

A

L

E

L

E

M

E

N

T

S

A

I

R

F

L

O

W

C

O

N

T

R

O

L

U

N

I

T

S

S

O

U

N

D

A

T

T

E

N

U

A

T

O

R

S

,

S

O

U

N

D

A

T

T

E

N

U

A

T

I

N

G

L

O

U

V

R

E

S

Air fow control units

Overpressure dampers

H

1

H

1

H

3

H

/

B

B1

B / H

B1 B1

B3

H

1

1 2 3 4 5 6 0.5

5

20

30

40

50

80

10

100

Air velocity v (m/s) at the effective area Aef

P

r

e

s

s

u

r

e

d

r

o

p

p

c

e

l

(

P

a

)

Example of calculation for

JN-6, AN-3, AN-4

A

ef

= B1 x (H1-10-(13 x n)) in m where n is a number of vanes.

B1 = 500 mm, H1 = 400 mm, n = 5

Q = 2000 m/h

A

ef

= 500 x (400 -10-(13 x 5)) = 162500 mm 0.16 m

v = (Q / 3600) / A

ef

= (2000 / 3600) / 0.16 = 3.47 m/s

p

cel

(Pa) Pressure drop

Ordering example

Steel overpressure damper

with installation frame: JN-6/3 B1xH1

Size: B1=500 H1=428

Pcs: 4

Aluminium overpressure damper

with installation frame:

AN-4/2 B1xH1

Size: B1=500 H1=428

Pcs: 4

Pressure drop diagram

Use the diagram to determine the total pressure drop in

respect of air velocity at the free sectional area.

298

Air fow control units

Overpressure dampers

B1

B1+76

H

1

H

1

+

7

6

B1

B1+76

1

2

0

H

1

H

1

+

7

6

120

Vgradnje:

Standardne dimenzije:

Mo`ne so vse kombinacije {irin B1 in vi{in H1 po

tabeli dimenzij.

Po `elji izdelujemo nadtla~ne `aluzije poljubnih

vmesnih dimenzij.

n ... {tevilo lamel

H

1

/

B

1

H

1

+

1

5

/

B

1

+

1

5

120

8

2

.

5

3

8

H

1

/

B

1

3

8

8

2

.

5

n... number of vanes

100 150 200 250 300 400 500 600 700 800 900 1000

200 250 300 400 500 600 700 800 900 1000

1 1 2 3 3 5 6 7 8 10 11 12

H1(mm)

B1(mm)

n

Size JN @-6W

Louvre for maintaining the preset pressure

difference JN-6W

Application

The JN-6W louvre for maintaining the preset pressure difference

is designed for maintaining the preset pressure difference between

two rooms or between indoors and outdoors. Depending on its

orientation, the louvre can support overpressure or underpressure.

It is a rapid-response precisely adjustable passive element for

maintaining the pressure difference and is not airtight. Standard

dimensions: from 200x100 to 1000x1000 with 50 mm steps. Other

dimensions available upon request.

It can be used as

an underpressure louvre to prevent the egress of

substances (chemicals, smoke, etc.);

an overpressure louvre for rooms where preventing the

ingress of polluted air is desired;

an overpressure valve to prevent the ingress of gases

into smokeless areas.

Description

The blades are interconnected using connecting rods.

Precise adjustments are performed on-site.

Easy to set up: weights are placed on the threaded rods

and secured against unscrewing using nuts.

Size JN-6W

H1 (mm) 100 150 200 250 300 400 500 600 700 800 900 1000

B1 (mm) 200 250 300 400 500 600 700 800 900 1000

n 1 1 2 3 3 5 6 7 8 10 11 12

n number of vanes

Sizes

All combinations of B1 and H1 according to the table of

dimensions are possible. Non-standard dimensions are

available on request.

Installation

299

V

E

N

T

I

L

A

T

I

N

G

G

R

I

L

L

E

S

,

V

E

N

T

I

L

A

T

I

N

G

V

A

L

V

E

S

C

I

R

C

U

L

A

R

D

I

F

F

U

S

E

R

S

,

S

Q

U

A

R

E

D

I

F

F

U

S

E

R

S

S

W

I

R

L

D

I

F

F

U

S

E

R

S

,

V

A

R

I

A

B

L

E

S

W

I

R

L

D

I

F

F

U

S

E

R

S

S

L

O

T

D

I

F

F

U

S

E

R

S

,

R

O

U

N

D

D

U

C

T

D

I

F

F

U

S

E

R

S

A

I

R

D

I

S

P

L

A

C

E

M

E

N

T

U

N

I

T

S

S

U

P

P

L

Y

A

I

R

N

O

Z

Z

L

E

S

E

X

T

E

R

N

A

L

E

L

E

M

E

N

T

S

A

I

R

F

L

O

W

C

O

N

T

R

O

L

U

N

I

T

S

S

O

U

N

D

A

T

T

E

N

U

A

T

O

R

S

,

S

O

U

N

D

A

T

T

E

N

U

A

T

I

N

G

L

O

U

V

R

E

S

Air fow control units

Overpressure dampers

JN@-6W/DP B1xH1

JN@-6W/3 B1xH1

B1=500 H1=428

4

Diagram za doloitev celotnega padca tlaka:

Air velocity (m/s) at the effective area A

ef

1 2 3 4 5 6 0.5

5

20

30

40

50

80

10

100

Iz diagrama dobimo celotni padec tlaka v odvisnosti od hitrosti zra~nega curka

B1 = 500 mm, H1 = 400mm, n = 5

Q = 2000 m

3

/h

A

ef

= 500 x (400 -10 -(13x5)) = 162500 mm

2

=> 0,16 m

2

v = (Q / 3600) / A

ef

= (2000 / 3600) / 0,16 = 3,47 m/s

na prostem preseku.

Primer naro~ila:

aluzija za vzdrevanje

nastavljene tlane razlike JN-6W:

aluzija za vzdrevanje

nastavljene tlane razlike

z vgradnim okvirjem JN-6W/3:

Dimenzije:

[tevilo kosov:

DP: Nastavljena tlana razlika

Opomba: Vrednost elene nastavljene tlane razlike mora biti nastavljena

posebej pri naroilu.

B1 x (H1-10-(13 x n)) izra`en v m

2

pri ~emer je n {tevilo lamel. A =

ef

Primer izrauna za JN-6W

P

r

e

s

s

u

r

e

d

r

o

p

p

c

e

l

(

P

a

)

Example of calculation for

JN-6W

B1 = 500 mm, H1 = 400mm, n = 5

Q = 2000 m/h

A

ef

= 500 x (400 -10 -(13 x 5)) = 162500 mm 0.16 m

v = (Q / 3600) / A

ef

= (2000 / 3600) / 0.16 = 3.47 m/s

p

cel pressure drop

Ordering example

Louvre for maintaining the preset

pressure dierence JN-6W: JN-6W/DP B1xH1

Louvre for maintaining the preset

pressure dierence with

installation frame JN-6W/3: JN-6W/3 B1xH1

Dimensions: B1=500 H1=428

Pcs: 4

DP: Preset pressure dierence

Note:

Value of the desired preset pressure dierence must be

determined extra by the order.

Use the diagram to determine the total pressure drop in respect

of air velocity at the free sectional area.

A

ef

= B1 x (H1-10-(13 x n)) in m

where n is a number of vanes.

Pressure drop diagram:

300

Air fow control units

Overpressure dampers

B1

B1+76

H

1

H

1

+

7

6

1

6

200

3

8

10

180

B1

B1+76

3

8

10

180

200

H

1

H

1

+

7

6

1

6

180 B1

B1+76

H

1

+

7

6

H

1

R-1 R-2

R-3 R-1/G

Volume control dampers

R-1, R-2 and R-3

Application

Volume control dampers are designed

for regulation of air fow and pressure

in ventilating ducts and air handling

units. They are installed as independent

devices or combined with protection- or

overpressure louvers.

Description

They are made of galvanised sheet

steel. Volume control dampers consist

of supporting frame and interconnected

blades. Blades are inserted into

PVC bearings. When operating by

temperatures, higher then 70 C bearings

are made of brass. Blades can be moved

manually or by the means of the electric

actuator. Pneumatic control is also

possible.

Type R-1A

Parallel blades

Bearings made of PVC or brass (higher operating

temperatures)

Galvanised supporting frame R-1A/3

Control handle is attached to the blade which is

closer to the centre (from the top side)

Volume control dampers

301

V

E

N

T

I

L

A

T

I

N

G

G

R

I

L

L

E

S

,

V

E

N

T

I

L

A

T

I

N

G

V

A

L

V

E

S

C

I

R

C

U

L

A

R

D

I

F

F

U

S

E

R

S

,

S

Q

U

A

R

E

D

I

F

F

U

S

E

R

S

S

W

I

R

L

D

I

F

F

U

S

E

R

S

,

V

A

R

I

A

B

L

E

S

W

I

R

L

D

I

F

F

U

S

E

R

S

S

L

O

T

D

I

F

F

U

S

E

R

S

,

R

O

U

N

D

D

U

C

T

D

I

F

F

U

S

E

R

S

A

I

R

D

I

S

P

L

A

C

E

M

E

N

T

U

N

I

T

S

S

U

P

P

L

Y

A

I

R

N

O

Z

Z

L

E

S

E

X

T

E

R

N

A

L

E

L

E

M

E

N

T

S

A

I

R

F

L

O

W

C

O

N

T

R

O

L

U

N

I

T

S

S

O

U

N

D

A

T

T

E

N

U

A

T

O

R

S

,

S

O

U

N

D

A

T

T

E

N

U

A

T

I

N

G

L

O

U

V

R

E

S

Air fow control units

Volume control dampers

B1

B1+76

H

1

H

1

+

7

6

1

6

200

3

8

10

180

B1

B1+76

3

8

10

180

200

H

1

H

1

+

7

6

1

6

180 B1

B1+76

H

1

+

7

6

H

1

B1

B1+76

H

1

H

1

+

7

6

1

6

200

3

8

10

180

B1

B1+76

3

8

10

180

200

H

1

H

1

+

7

6

1

6

180 B1

B1+76

H

1

+

7

6

H

1

1

2

55

H

1

H

1

+

8

0

B1

B1+80

8

250

4

0

4

0

130 130

2

0

B1

B1+76

H

1

H

1

+

7

6

3

8

10

180

200

1

6

Type R-1B

The same construction as R-1A

Counterdirectional blades

Type R-1A, B/G

Same design as R-1A or R-1B

Heaters built in blades

Operation thermostat 0-40 C

Temperature limitter 85 C

Manual or motor control

Heater capacity depending on the dimension

Type R-2

The same construction as R-1A

Special sealing stripe between blades as well as between

Blades and frame

Air-tight construction

302

Air fow control units

Volume control dampers

1

2

55

H

1

H

1

+

8

0

B1

B1+80

8

250

4

0

4

0

130 130

2

0

B1

B1+76

H

1

H

1

+

7

6

3

8

10

180

200

1

6

Type R-3A, B

Type A parallel blades

Type B counterdirectional blades

Blade made of sectional sheet steel

Bearings made of PVC or brass (higher

operating temperatures)

All combinations ob B1 and H1 according to the

table of dimensions are possible.

Volume control dampers R-1/A and R-1/B are

available in all sizes.

Table of dimensions:

Sizes R-1

H1 (mm) 100 150 200 250 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000

B1 (mm) 200 250 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000

n 1 1 2 2 2 3 3 4 4 5 5 6 7 7 8 9 9 10 10 11 12 13

n number of vanes

Sizes R-2

H1 (mm) 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600

B1 (mm) 200 250 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600

n 2 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

n number of vanes

Sizes R-3

H1 (mm) 100 150 200 250 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000

B1 (mm) 200 250 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000

n 1 1 2 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

n number of vanes

303

V

E

N

T

I

L

A

T

I

N

G

G

R

I

L

L

E

S

,

V

E

N

T

I

L

A

T

I

N

G

V

A

L

V

E

S

C

I

R

C

U

L

A

R

D

I

F

F

U

S

E

R

S

,

S

Q

U

A

R

E

D

I

F

F

U

S

E

R

S

S

W

I

R

L

D

I

F

F

U

S

E

R

S

,

V

A

R

I

A

B

L

E

S

W

I

R

L

D

I

F

F

U

S

E

R

S

S

L

O

T

D

I

F

F

U

S

E

R

S

,

R

O

U

N

D

D

U

C

T

D

I

F

F

U

S

E

R

S

A

I

R

D

I

S

P

L

A

C

E

M

E

N

T

U

N

I

T

S

S

U

P

P

L

Y

A

I

R

N

O

Z

Z

L

E

S

E

X

T

E

R

N

A

L

E

L

E

M

E

N

T

S

A

I

R

F

L

O

W

C

O

N

T

R

O

L

U

N

I

T

S

S

O

U

N

D

A

T

T

E

N

U

A

T

O

R

S

,

S

O

U

N

D

A

T

T

E

N

U

A

T

I

N

G

L

O

U

V

R

E

S

Air fow control units

Volume control dampers

75

H

/

B

3

8

180

H

+

6

/

B

+

6

H

/

B

75

H

/

B

3

8

180

H

+

6

/

B

+

6

H

/

B

75

H

/

B

3

8

180

H

+

6

/

B

+

6

H

/

B

75

H

/

B

3

8

180

H

+

6

/

B

+

6

H

/

B

75

H

/

B

3

8

180

H

+

6

/

B

+

6

H

/

B

Manual control with handle

Mechanism for locking selected

position

Type R-1/R

Pneumatic control with cylinder

Operating pressure 1.2 or 6 bar

Type R-1/P

Motor control with electric actuator

Control via the electric actuator accor-

ding to the table of motor actuators on

page 333

Regulation types

Pneumatic control

One-way pneumatic cylinder with

return spring

Output power over 18 Nm

Type R-2/P

Installation

Direct installation in duct.

Fastening accessories are not

supplied.

Installation in built-in frame

(fastened with screws).

Built-in frame is made of galvanised

sheet steel with point-welded

mounting anchors.

Designation: R-1, 2/3

304

Air fow control units

Volume control dampers

125 125

9.5

B

H

2

0

20

asymetrical

9.5

125 125

symetrical

250 250

8

B

H

2

0

20

asymetrical

8

250 250

symetrical

125 125

9.5

B

H

2

0

20

asymetrical

9.5

125 125

symetrical

250 250

8

B

H

2

0

20

asymetrical

8

250 250

symetrical

35/35/4 75/35/2

B2

B1 150 B1

35/35/4

H

1

7

6

H

1

H

2

B1

Asymetrical

Asymetrical

Symetrical

Symetrical

Hole arrangement on dampers R-1A, B and R-2:

Hole arrangement on dampers R-3:

Ordering example

Volume control

damper: R-1A divided acc. to B

Sizes: B2=4150 H1=840

Connection frame: H1=840

Pcs: 3, 6

Installation of volume control dampers of larger dimensions:

Combinations according to the width:

Connection frame supplied as per order.

Dimension upon customers request.

B2 = (2xB1) + 150

305

V

E

N

T

I

L

A

T

I

N

G

G

R

I

L

L

E

S

,

V

E

N

T

I

L

A

T

I

N

G

V

A

L

V

E

S

C

I

R

C

U

L

A

R

D

I

F

F

U

S

E

R

S

,

S

Q

U

A

R

E

D

I

F

F

U

S

E

R

S

S

W

I

R

L

D

I

F

F

U

S

E

R

S

,

V

A

R

I

A

B

L

E

S

W

I

R

L

D

I

F

F

U

S

E

R

S

S

L

O

T

D

I

F

F

U

S

E

R

S

,

R

O

U

N

D

D

U

C

T

D

I

F

F

U

S

E

R

S

A

I

R

D

I

S

P

L

A

C

E

M

E

N

T

U

N

I

T

S

S

U

P

P

L

Y

A

I

R

N

O

Z

Z

L

E

S

E

X

T

E

R

N

A

L

E

L

E

M

E

N

T

S

A

I

R

F

L

O

W

C

O

N

T

R

O

L

U

N

I

T

S

S

O

U

N

D

A

T

T

E

N

U

A

T

O

R

S

,

S

O

U

N

D

A

T

T

E

N

U

A

T

I

N

G

L

O

U

V

R

E

S

Air fow control units

Volume control dampers

35/35/4 75/35/2

B2

B1 150 B1

35/35/4

H

1

7

6

H

1

H

2

B1

Ordering key

R Manual control

B Power driven but without actuator

B1/J1 Actuator LM24A / DAN 1.N

B2/J2 Actuator LM230A / DAN 2.N

B3/J3 Actuator LM 24A SR / DMN 1.2N

B4/J4 Actuator NM 24A / DAS 1.N

B5/J5 Actuator NM 230A / DAS 2.N

B6/J6 Actuator NM 24A-SR / DMS 1

B7/J7 Actuator SM 24A / DA 1

B8/J8 Actuator SM 230A / DA 2

B9/J9 Actuator SM 24A SR (continuous regulation) / DM 1.1

B10/J10 Actuator SM 230A SR (continuous regulation) / DM 2.2

B11/J11 Actuator GM 24A / DAG 1

B12/J12 Actuator GM 230A / DAG 2

B13/J13 Actuator GM 24A SR (continuous regulation) / DMG 1.1

P Pneumatic control

3 Installation frame

/ Without installation frame

G Heaters built in blades

A Parallel blades

B Counterdirectional blades

1, 2, 3 Type of the volume control damper R

Ordering example

Volume control

damper: R-1A divided acc. to H

Sizes: B1=400 H2=4066

Pcs: H2=4066

No. of pieces: 3

Combinations according to the height:

Connection frame supplied as per order.

Dimension upon customers request.

H2 = (2xH1) + 76

R-1 A / G / 3 / R B1 x H1

Note:

The range of applicability of individual actuators see table on page 333.

306

Air fow control units

Volume control dampers

V

H

/

B

p

R-1A R-1B

L

W

A

(

d

B

(

A

)

)

R-2

0 0.5 1 2 3 4 5 10 15

1500

1000

500

300

200

100

50

20

10

5

80 70

60

50

40

30

20

10

5

0

6

0

7

0

8

0

9

0

4

0

0 0.5 1 2 3 4 5 10 15

1500

1000

500

300

200

100

50

10

10

5

80

20

5

0

6

0

7

0

8

0

9

0

20

30

40

50 60 70

0 0.5 1 2 3 4 5 10 15

1500

1000

500

300

200

100

50

10

10

5

80 70 50 40

20

30

20

60

4

0

5

0

6

0

7

0

8

0

9

0

L

W

A

(

d

B

(

A

)

)

L W

A

(

d

B

(

A

)

)

Hitrost zraka v (m/s) ) s / m ( v a k a r z t s o r t i H ) s / m ( v a k a r z t s o r t i H

e l e m a l t o k e l e m a l t o k e l e m a l t o k

P

a

d

e

c

t

l

a

k

a

p

(

P

a

)

P

a

d

e

c

t

l

a

k

a

p

(

P

a

)

P

a

d

e

c

t

l

a

k

a

p

(

P

a

)

R-3A

0 0.5 1 2 3 4 5 10 15

1500

1000

500

300

200

100

50

20

10

5

80 70 60 50

40

10

20

30

5

0

4

0

6

0

7

0

8

0

9

0

L

W

A

(

d

B

(

A

)

)

kot lamele

Hitrost zraka v (m/s)

P

a

d

e

c

t

l

a

k

a

p

(

P

a

)

R-3B

0 0.5 1 2 3 4 5 10 15

1500

1000

500

300

200

100

50

20

10

5

80 60 50

10

20

40 30

9

0

8

0

7

0

6

0

5

0

4

0

L

W

A

(

d

B

(

A

)

)

kot lamele

Hitrost zraka v (m/s)

P

a

d

e

c

t

l

a

k

a

p

(

P

a

)

V

H

/

B

p

R-1A R-1B

L

W

A

(

d

B

(

A

)

)

R-2

0 0.5 1 2 3 4 5 10 15

1500

1000

500

300

200

100

50

20

10

5

80 70

60

50

40

30

20

10

5

0

6

0

7

0

8

0

9

0

4

0

0 0.5 1 2 3 4 5 10 15

1500

1000

500

300

200

100

50

10

10

5

80

20

5

0

6

0

7

0

8

0

9

0

20

30

40

50 60 70

0 0.5 1 2 3 4 5 10 15

1500

1000

500

300

200

100

50

10

10

5

80 70 50 40

20

30

20

60

4

0

5

0

6

0

7

0

8

0

9

0

L

W

A

(

d

B

(

A

)

)

L W

A

(

d

B

(

A

)

)

Hitrost zraka v (m/s) ) s / m ( v a k a r z t s o r t i H ) s / m ( v a k a r z t s o r t i H

e l e m a l t o k e l e m a l t o k e l e m a l t o k

P

a

d

e

c

t

l

a

k

a

p

(

P

a

)

P

a

d

e

c

t

l

a

k

a

p

(

P

a

)

P

a

d

e

c

t

l

a

k

a

p

(

P

a

)

R-3A

0 0.5 1 2 3 4 5 10 15

1500

1000

500

300

200

100

50

20

10

5

80 70 60 50

40

10

20

30

5

0

4

0

6

0

7

0

8

0

9

0

L

W

A

(

d

B

(

A

)

)

kot lamele

Hitrost zraka v (m/s)

P

a

d

e

c

t

l

a

k

a

p

(

P

a

)

R-3B

0 0.5 1 2 3 4 5 10 15

1500

1000

500

300

200

100

50

20

10

5

80 60 50

10

20

40 30

9

0

8

0

7

0

6

0

5

0

4

0

L

W

A

(

d

B

(

A

)

)

kot lamele

Hitrost zraka v (m/s)

P

a

d

e

c

t

l

a

k

a

p

(

P

a

)

V

H

/

B

p

R-1A R-1B

L

W

A

(

d

B

(

A

)

)

R-2

0 0.5 1 2 3 4 5 10 15

1500

1000

500

300

200

100

50

20

10

5

80 70

60

50

40

30

20

10

5

0

6

0

7

0

8

0

9

0

4

0

0 0.5 1 2 3 4 5 10 15

1500

1000

500

300

200

100

50

10

10

5

80

20

5

0

6

0

7

0

8

0

9

0

20

30

40

50 60 70

0 0.5 1 2 3 4 5 10 15

1500

1000

500

300

200

100

50

10

10

5

80 70 50 40

20

30

20

60

4

0

5

0

6

0

7

0

8

0

9

0

L

W

A

(

d

B

(

A

)

)

L W

A

(

d

B

(

A

)

)

Hitrost zraka v (m/s) ) s / m ( v a k a r z t s o r t i H ) s / m ( v a k a r z t s o r t i H

e l e m a l t o k e l e m a l t o k e l e m a l t o k

P

a

d

e

c

t

l

a

k

a

p

(

P

a

)

P

a

d

e

c

t

l

a

k

a

p

(

P

a

)

P

a

d

e

c

t

l

a

k

a

p

(

P

a

)

R-3A

0 0.5 1 2 3 4 5 10 15

1500

1000

500

300

200

100

50

20

10

5

80 70 60 50

40

10

20

30

5

0

4

0

6

0

7

0

8

0

9

0

L

W

A

(

d

B

(

A

)

)

kot lamele

Hitrost zraka v (m/s)

P

a

d

e

c

t

l

a

k

a

p

(

P

a

)

R-3B

0 0.5 1 2 3 4 5 10 15

1500

1000

500

300

200

100

50

20

10

5

80 60 50

10

20

40 30

9

0

8

0

7

0

6

0

5

0

4

0

L

W

A

(

d

B

(

A

)

)

kot lamele

Hitrost zraka v (m/s)

P

a

d

e

c

t

l

a

k

a

p

(

P

a

)

V

H

/

B

p

R-1A R-1B

L

W

A

(

d

B

(

A

)

)

R-2

0 0.5 1 2 3 4 5 10 15

1500

1000

500

300

200

100

50

20

10

5

80 70

60

50

40

30

20

10

5

0

6

0

7

0

8

0

9

0

4

0

0 0.5 1 2 3 4 5 10 15

1500

1000

500

300

200

100

50

10

10

5

80

20

5

0

6

0

7

0

8

0

9

0

20

30

40

50 60 70

0 0.5 1 2 3 4 5 10 15

1500

1000

500

300

200

100

50

10

10

5

80 70 50 40

20

30

20

60

4

0

5

0

6

0

7

0

8

0

9

0

L

W

A

(

d

B

(

A

)

)

L W

A

(

d

B

(

A

)

)

Hitrost zraka v (m/s) ) s / m ( v a k a r z t s o r t i H ) s / m ( v a k a r z t s o r t i H

e l e m a l t o k e l e m a l t o k e l e m a l t o k

P

a

d

e

c

t

l

a

k

a

p

(

P

a

)

P

a

d

e

c

t

l

a

k

a

p

(

P

a

)

P

a

d

e

c

t

l

a

k

a

p

(

P

a

)

R-3A

0 0.5 1 2 3 4 5 10 15

1500

1000

500

300

200

100

50

20

10

5

80 70 60 50

40

10

20

30

5

0

4

0

6

0

7

0

8

0

9

0

L

W

A

(

d

B

(

A

)

)

kot lamele

Hitrost zraka v (m/s)

P

a

d

e

c

t

l

a

k

a

p

(

P

a

)

R-3B

0 0.5 1 2 3 4 5 10 15

1500

1000

500

300

200

100

50

20

10

5

80 60 50

10

20

40 30

9

0

8

0

7

0

6

0

5

0

4

0

L

W

A

(

d

B

(

A

)

)

kot lamele

Hitrost zraka v (m/s)

P

a

d

e

c

t

l

a

k

a

p

(

P

a

)

Pressure drop and sound power level diagrams

Defnition of symbols

Q (m/h) Air ow volume

() Blade inclination

p

cel

(Pa) Pressure drop

L

WA

(dB(A)) Sound power level

v (m/s) Air velocity at the sectional

area B x H

Technical data

P

r

e

s

s

u

r

e

d

r

o

p

P

r

e

s

s

u

r

e

d

r

o

p

P

r

e

s

s

u

r

e

d

r

o

p

P

r

e

s

s

u

r

e

d

r

o

p

P

r

e

s

s

u

r

e

d

r

o

p

Air velocity

Air velocity

Air velocity

Blade angle

Blade angle

Blade angle Blade angle

Blade angle

Air velocity

Air velocity

307

V

E

N

T

I

L

A

T

I

N

G

G

R

I

L

L

E

S

,

V

E

N

T

I

L

A

T

I

N

G

V

A

L

V

E

S

C

I

R

C

U

L

A

R

D

I

F

F

U

S

E

R

S

,

S

Q

U

A

R

E

D

I

F

F

U

S

E

R

S

S

W

I

R

L

D

I

F

F

U

S

E

R

S

,

V

A

R

I

A

B

L

E

S

W

I

R

L

D

I

F

F

U

S

E

R

S

S

L

O

T

D

I

F

F

U

S

E

R

S

,

R

O

U

N

D

D

U

C

T

D

I

F

F

U

S

E

R

S

A

I

R

D

I

S

P

L

A

C

E

M

E

N

T

U

N

I

T

S

S

U

P

P

L

Y

A

I

R

N

O

Z

Z

L

E

S

E

X

T

E

R

N

A

L

E

L

E

M

E

N

T

S

A

I

R

F

L

O

W

C

O

N

T

R

O

L

U

N

I

T

S

S

O

U

N

D

A

T

T

E

N

U

A

T

O

R

S

,

S

O

U

N

D

A

T

T

E

N

U

A

T

I

N

G

L

O

U

V

R

E

S

Air fow control units

Volume control dampers

1. Frame of extruded aluminium

sections.

2. Bar of aluminium sections

(installed by B>1200 mm).

3. Blade made of extruded

aluminium sections.

4. Plastic gear wheel.

5. Handle for manual control and

locking made of aluminium alloy.

6. Rubber sealant.

Volume control damper R-7

Application

Volume control dampers are designed

for regulation of air fow and pressure in

ventilating ducts and air handling units.

Description

Frame and blades are made of extruded

aluminium sections. Blades are inserted

in plastic bearings. They are driven via

the plastic gear wheels, fxed in the frame

section with plastic holders. Mechanism

is encased in separate housing and

therefore protected from dust ant other

infuences. A rubber strip attached on

blades provides better sealing. Blades

open in opposed direction only. The

dampers can be regulated manually

(standard version) or power operated by

pneumatic or electric actuator. Volume

control damper is temperature resistant

to 70 C.

Construction and dimensions

Sizes R-7

H1 (mm) 110 210 310 410 510 610 710 810 910 1010 1110 1210 1310 1410 1510 1610 1710 1810 1910 2010

B1 (mm) 100 150 200 300 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000

n 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

n number of vanes

308

Air fow control units

Volume control dampers

1

4

5

1

2

0

3

0

2

1

4

75

45

1

2

.

L(+)220V / 50Hz (24V-)

L+

PE

N(-)

stikalo

pnevmatski

cilinder magnetni ventil 3/2 duilka

tlani vod

SM 24 SM 220

C A V 0 2 2 C A V 4 2

2 3 2 1 1 3

N L1 (-) (+)

SGS,SGR

SM 220-SR

1 2 3

220 V-

N L1 a b

1 2 3 4 N L1

+ Y -

Kontrola kon ne lege

a - odprto ODPRTO

b - odprto ZAPRTO

24 VAC

SM 24-SR

1 2 3 4 5

U Y Y

1 2

Y 0...10 V-

1

Y 0...20 V-

2

U 2...10 V-

1

4

5

1

2

0

3

0

2

1

4

75

45

1

2

.

L(+)220V / 50Hz (24V-)

L+

PE

N(-)

switch

pnevmatski

cylinde solenoid 3/2 damper

pressure line

SM 24 SM 220

C A V 0 2 2 C A V 4 2

2 3 2 1 1 3

N L1 (-) (+)

SGS,SGR

SM 220-SR

1 2 3

220 V-

N L1 a b

1 2 3 4 N L1

+ Y -

Kontrola kon ne lege

a - odprto ODPRTO

b - odprto ZAPRTO

24 VAC

SM 24-SR

1 2 3 4 5

U Y Y

1 2

Y 0...10 V-

1

Y 0...20 V-

2

U 2...10 V-

1

4

5

1

2

0

3

0

2

1

4

75

45

1

2

.

L(+)220V / 50Hz (24V-)

L+

PE

N(-)

stikalo

pnevmatski

cilinder magnetni ventil 3/2 duilka

tlani vod

SM 24 SM 220

C A V 0 2 2 C A V 4 2

2 3 2 1 1 3

N L1 (-) (+)

SGS,SGR

SM 220-SR

1 2 3

220 V-

N L1 a b

1 2 3 4 N L1

+ Y -

Kontrola kon ne lege

a - odprto ODPRTO

b - odprto ZAPRTO

24 VAC

SM 24-SR

1 2 3 4 5

U Y Y

1 2

Y 0...10 V-

1

Y 0...20 V-

2

U 2...10 V-

Manual control with handle and locking

mechanism

Pneumatic actuator (1, 2 bar) Wiring scheme

Regulation types:

Power driven by electric

actuator BELIMO

Wiring scheme

Two position control requires actuators

type SM 24 or SM 220 with 15 Nm. of

output power (see page 46) Continuous

control and blades position of 0 90

is achieved with actuators SM 24-SR or

SM 220-SR.

End position control

a opened OPEN

b opened CLOSED

309

V

E

N

T

I

L

A

T

I

N

G

G

R

I

L

L

E

S

,

V

E

N

T

I

L

A

T

I

N

G

V

A

L

V

E

S

C

I

R

C

U

L

A

R

D

I

F

F

U

S

E

R

S

,

S

Q

U

A

R

E

D

I

F

F

U

S

E

R

S

S

W

I

R

L

D

I

F

F

U

S

E

R

S

,

V

A

R

I

A

B

L

E

S

W

I

R

L

D

I

F

F

U

S

E

R

S

S

L

O

T

D

I

F

F

U

S

E

R

S

,

R

O

U

N

D

D

U

C

T

D

I

F

F

U

S

E

R

S

A

I

R

D

I

S

P

L

A

C

E

M

E

N

T

U

N

I

T

S

S

U

P

P

L

Y

A

I

R

N

O

Z

Z

L

E

S

E

X

T

E

R

N

A

L

E

L

E

M

E

N

T

S

A

I

R

F

L

O

W

C

O

N

T

R

O

L

U

N

I

T

S

S

O

U

N

D

A

T

T

E

N

U

A

T

O

R

S

,

S

O

U

N

D

A

T

T

E

N

U

A

T

I

N

G

L

O

U

V

R

E

S

Air fow control units

Volume control dampers

V

p

cel

H

/

B

L

d

B

(

A

)

75

45

30

15 a=

a=

a=

a=

60 a=

0.1 0.2 0.4 0.6 0.8 1 2 4 6 8 10 20

1

2

4

6

10

20

40

60

100

200

400

600

1000

2000

W

A

50

60

70

80

90

P

a

d

e

c

t

l

a

k

a

p

c

e

l

(

P

a

)

Hitrost zraka v (m/s)

V

p

cel

H

/

B

L

d

B

(

A

)

75

45

30

15 a=

a=

a=

a=

60 a=

0.1 0.2 0.4 0.6 0.8 1 2 4 6 8 10 20

1

2

4

6

10

20

40

60

100

200

400

600

1000

2000

W

A

50

60

70

80

90

P

a

d

e

c

t

l

a

k

a

p

c

e

l

(

P

a

)

Hitrost zraka v (m/s)

Defnition of symbols

Blade angle

p

cel

(Pa) Pressure drop

dierence

v (m/s) Velocity in duct

Q (m/h) Air ow

L

WA

(dB(A)) Sound power level

Volume control damper sealing:

Closed volume control damper of 1 m

area has a leakage of approx. 50 m/h at

the pressure of 100 Pa.

(Standard DIN 1946 permits leakage of

10 m/h at equal conditions).

Pressure drop and sound power level diagram

v = Q(m/h) / (H(m) x B(m) x 3600(s/h))

Ordering key

R Manual control

B Power driven but without actuator

B1/J1 Actuator LM24A / DAN 1.N

B2/J2 Actuator LM230A / DAN 2.N

B3/J3 Actuator LM 24A SR / DMN 1.2N

B4/J4 Actuator NM 24A / DAS 1.N

B5/J5 Actuator NM 230A / DAS 2.N

B6/J6 Actuator NM 24A-SR / DMS 1

B7/J7 Actuator SM 24A / DA 1

B8/J8 Actuator SM 230A / DA 2

B9/J9 Actuator SM 24A SR (continuous regulation)

/ DM 1.1

B10/J10 Actuator SM 230A SR/DM 2.2

P Pneumatic control

R-7 / R B1 x H1

Note: The range of applicability of individual actuators see table on page 333.

Air velocity

P

r

e

s

s

u

r

e

d

r

o

p

310

Air fow control units

Volume control dampers

4

0

H

1

+

1

0

5

/

B

1

+

1

0

5

H

1

+

9

5

/

B

1

+

9

5

H

1

/

B

1

H

1

+

8

0

/

B

1

+

8

0

8

2

.

5

3

8

215

4

0

215

8

2

.

5

H

1

+

8

0

/

B

1

+

8

0

H

1

+

1

0

5

/

B

1

+

1

0

5

H

1

+

9

5

/

B

1

+

9

5

H

1

/

B

1

3

8

H

1

+

8

0

/

B

1

+

8

0

H

1

/

B

1

H

1

+

9

5

/

B

1

+

9

5

H

1

+

1

0

5

/

B

1

+

1

0

5

min 280

8

2

.

5

4

0

H

1

+

1

0

5

/

B

1

+

1

0

5

H

1

+

9

5

/

B

1

+

9

5

H

1

/

B

1

H

1

+

8

0

/

B

1

+

8

0

8

2

.

5

3

8

215

4

0

215

8

2

.

5

H

1

+

8

0

/

B

1

+

8

0

H

1

+

1

0

5

/

B

1

+

1

0

5

H

1

+

9

5

/

B

1

+

9

5

H

1

/

B

1

3

8

H

1

+

8

0

/

B

1

+

8

0

H

1

/

B

1

H

1

+

9

5

/

B

1

+

9

5

H

1

+

1

0

5

/

B

1

+

1

0

5

min 280

8

2

.

5

4

0

H

1

+

1

0

5

/

B

1

+

1

0

5

H

1

+

9

5

/

B

1

+

9

5

H

1

/

B

1

H

1

+

8

0

/

B

1

+

8

0

8

2

.

5

3

8

215

4

0

215

8

2

.

5

H

1

+

8

0

/

B

1

+

8

0

H

1

+

1

0

5

/

B

1

+

1

0

5

H

1

+

9

5

/

B

1

+

9

5

H

1

/

B

1

3

8

H

1

+

8

0

/

B

1

+

8

0

H

1

/

B

1

H

1

+

9

5

/

B

1

+

9

5

H

1

+

1

0

5

/

B

1

+

1

0

5

min 280

8

2

.

5

Combinations

If after the end of the operation we want to prevent the invasion

of external air into the system, the combination of an overpres-

sure damper with steel or aluminium protection louvres can be

used. The A variant is used for the outtake of air, whereas the B

variant is intended for its supply. The starting point can be the

dimension of the overpressure damper or the dimension of the

protection louvre. It is important for the dimensions to be in the

same proportion, which is evident from the draft.

Louvres and dampers are available separately or combined, as

desired.

Combination of Protection louvres JZR-6 and

AZR-4 with Overpressure damper JN-6

Type A

Exhaust air

Type B

Supply air

Designations:

JN-6 + AZR-4/3 Type A

JN-6 + JZR-6/3 Type A

Designations:

JN-6 + AZR-4/3 Type B

JN-6 + JZR-6/3 Type B

Combination of Protection louvres JZR-6 and

AZR-4 with Volume control damper R-1

Designations:

R-1 + AZR-4/3

R-1 + JZR-6/3

Ordering example

Combination: R-1 + AZR-4/3

Sizes: B1xH1

B1=1200 H1=510

Pcs: 4

311

V

E

N

T

I

L

A

T

I

N

G

G

R

I

L

L

E

S

,

V

E

N

T

I

L

A

T

I

N

G

V

A

L

V

E

S

C

I

R

C

U

L

A

R

D

I

F

F

U

S

E

R

S

,

S

Q

U

A

R

E

D

I

F

F

U

S

E

R

S

S

W

I

R

L

D

I

F

F

U

S

E

R

S

,

V

A

R

I

A

B

L

E

S

W

I

R

L

D

I

F

F

U

S

E

R

S

S

L

O

T

D

I

F

F

U

S

E

R

S

,

R

O

U

N

D

D

U

C

T

D

I

F

F

U

S

E

R

S

A

I

R

D

I

S

P

L

A

C

E

M

E

N

T

U

N

I

T

S

S

U

P

P

L

Y

A

I

R

N

O

Z

Z

L

E

S

E

X

T

E

R

N

A

L

E

L

E

M

E

N

T

S

A

I

R

F

L

O

W

C

O

N

T

R

O

L

U

N

I

T

S

S

O

U

N

D

A

T

T

E

N

U

A

T

O

R

S

,

S

O

U

N

D

A

T

T

E

N

U

A

T

I

N

G

L

O

U

V

R

E

S

Air fow control units

Combinations

200

H

2

/

B

2

H

/

B

Designations of motors:

B1 (LM 24A)

B2 (LM 220A)

B3 (LM 24A SR) continous regulation

Throttling dampers DL

Application

Throttling damper is designed for

regulation of air fow volume. It is

constructed to ft square ducts.

Description

Damper consists of housing and blade,

both made of galvanised sheet steel and

mechanism for altering the blade angel.

All dampers can be outside insulated.

Dimensions:

B H B2 H2

125 125 185 190

160

125

220

190

160 225

200

125

260

190

160 225

200 265

250

125

310

190

160 225

200 265

250 315

315

125

375

190

160 225

200 265

250 315

315 380

400

125

460

190

160 225

200 265

250 315

315 380

400 465

500

125

560

190

160 225

200 265

250 315

315 380

400 465

500 565

630

125

690

190

160 225

200 265

250 315

315 380

400 465

500 565

600 665

Throttling, shut-off and

non-return dampers

312

Air fow control units

Throttling, shut-off and non return dampers

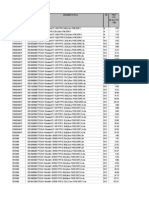

100 200 300 400 500 1000 2000 3000 5000 10000 15000

B

=

1

2

5

H

=

1

2

5 1

6

0

1

6

0

2

0

0

2

0

0

2

5

0

2

5

0

3

1

5

3

1

5

4

0

0

4

0

0

5

0

0

5

0

0

6

3

0

6

3

0

Q(m

3

/h)

500

400

300

200

100

50

40

30

20

2 3 4 5 10 15

v(m/s)

P

a

d

e

c

t

l

a

k

p

t

(

P

a

)

K

o

t

l

a

m

e

l

=

9

0

7

8

7

2

6

6

6

0

5

4

4

8

4

2

3

6

Pri kotu lamel 0 je padec tlaka zanemarljiv.

P

r

e

s

s

u

r

e

d

r

o

p

Pressure drop diagram

Ordering key

R Manual control

B Power driven but without actuator

B1 Actuator LM 24A

B2 ActuatorLM 230A

B3 Actuator LM 24A SR (continous regulation)

DL / R B1 x H1

Defnition of symbols

Q (m/h) Air ow

v (m/s) Air velocity in the duct

p

cel

(Pa) pressure drop dierence

Pressure drop with 0 blade angle is negligible.

313

V

E

N

T

I

L

A

T

I

N

G

G

R

I

L

L

E

S

,

V

E

N

T

I

L

A

T

I

N

G

V

A

L

V

E

S

C

I

R

C

U

L

A

R

D

I

F

F

U

S

E

R

S

,

S

Q

U

A

R

E

D

I

F

F

U

S

E

R

S

S

W

I

R

L

D

I

F

F

U

S

E

R

S

,

V

A

R

I

A

B

L

E

S

W

I

R

L

D

I

F

F

U

S

E

R

S

S

L

O

T

D

I

F

F

U

S

E

R

S

,

R

O

U

N

D

D

U

C

T

D

I

F

F

U

S

E

R

S

A

I

R

D

I

S

P

L

A

C

E

M

E

N

T

U

N

I

T

S

S

U

P

P

L

Y

A

I

R

N

O

Z

Z

L

E

S

E

X

T

E

R

N

A

L

E

L

E

M

E

N

T

S

A

I

R

F

L

O

W

C

O

N

T

R

O

L

U

N

I

T

S

S

O

U

N

D

A

T

T

E

N

U

A

T

O

R

S

,

S

O

U

N

D

A

T

T

E

N

U

A

T

I

N

G

L

O

U

V

R

E

S

Air fow control units

Throttling, shut-off and non return dampers

D

1

O

1

2

3

4

5

C A C

L

D

2

E

D

1

L C C

B

A

DL-1

DL-1

DL-2

DL-2

Dimensions for DL-1

Size 100 125 160 200 250 315 400 500 630

D1 98 123 158 198 248 312 397 496 626

D2 104 129 164 204 254 318 403 502 632

A 100 105 170

C 40 50 80

L 180 230 270 330

E 147 173 207 247 297 362 449 548 678

Dimensions for DL-2

Size 80 100 125 140 150 160 180 200 225 250 280 315 400 500 630

D1 78 98 123 138 148 158 178 198 223 248 278 313 398 498 628

A 105 115 125 135 140 145 155 165 175 190 205 220 295 345 410

B 55 65 75 85 90 95 105 115 125 140 155 170 215 265 330

C 40 65

L 100 130 130

Throttling dampers

DL-1, DL-2

Application

Throttling damper is designed for regula-

tion of air fow volume. It is constructed to

ft round and spiro ducts.

Description

Throttling damper consists of housing and

blade, both made of galvanised sheet ste-

el and mechanism for altering the blade

angel. All dampers can be insulated.

On the outer side, DL-2 is ftted with a

rubber seal.

Ordering key

DL-1 / R Size 200

R Manual control

B Power driven but without actuator

B1 Actuator LM 24A

B2 Actuator LM 230A

B3 Actuator LM 24A SR (continuous regulation)

J1 Actuator DAN 1.N (24 V)

J2 Actuator DAN 2.N (230 V)

J3 Actuator DMN 1.2N (24 V continuous

regulation)

1, 2 Throttling damper type

314

Air fow control units

Throttling, shut-off and non return dampers

1

0

0

1

2

5

1

6

0

2

0

0

2

5

0

3

1

5

4

0

0

5

0

0

6

3

0

1

2

3

4

6

8

10

15

v

(

m

/

s

)

10 20 50 100 200 500 20 40 100 200 400 1000 2000 4000 10000 10 20 50 100 200

15

30

45

60

75

15

30

45

60

75

p (Pa) p (Pa) Q (m /h)

3

Dimenzije 5 1 3 - 0 0 1 Dimenzije Dimenzije 400 - 630

-30

-20

-10

0

+10

+20

+30

5 10 15

v (m/s)

L

2

(

d

B

)

1

0

0

1

2

5