Professional Documents

Culture Documents

Research Operation Report

Uploaded by

krovidiprasanna0 ratings0% found this document useful (0 votes)

25 views12 pagesResearch

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentResearch

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views12 pagesResearch Operation Report

Uploaded by

krovidiprasannaResearch

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 12

Research Operation Report

Supply chain management

In Wal-Mart Industry

Name: Liu Gen

Course: BMO6508 Operation Management

Tutor: Dr. Nick Billington

Due Date: 24/03/2014

Research Operation Report 2

2013 2nd semester

EXECUTIVE SUMMARY

This report analysis the very important issue of business management that WAL-MARTs supply

chain management. Takes WAL-MART as the object of study, Supply chain management is an

important element in the management of the company or industry. Supply chain management is a

new level service to customer, to meet certain conditions, in order to make sure minimum the whole

supply chain system cost. Supply chain management, including planning, procurement,

manufacturing, delivery and return. The huge pressure of modern business environment, not just

selling products to customers, but also to provide satisfactory service for them, to get enhance

customer satisfaction. Kotler said: "the customer is God, without them, all enterprises cannot survive

must focus on customer retention and customer satisfaction." In order to get more customers,

synergistic reaction in domestic and overseas market will unavoidable inevitably prompt and flexible

requirements of enterprises on the supply chain and customer needs. Changes in supply chain

environment and building a happy market becomes the development trend of modern enterprises in

supply chain. The case study as the following shows, a successful supply chain management strategy

may result in lower cost of product, improve competitive prices and provide low price for

consumers.

In the past decade, WAL-MART has grown into the worlds largest retails, WAL-MART

transformation from a regional retailer to global power is the effective management of change of its

supply chain.

WAL-MART will focus on the development of cost structure, so it can offer low prices of daily. The

main factor to achieve is to enable the company to add stocks and inventory strategy, which relies on

known as the core way cross docking logistics technology. The use of cross docking, the product is

routed from the supplier to WAL-MART's warehouse, that transported to the store does not take a

long time inventory. This method reduces the WAL-MART cost significantly. WAL-MART passes

Research Operation Report 3

2013 2nd semester

these savings on offer very competitive prices to their customers. WAL-MART has concentrate on

the development of a comprehensive structured and advanced supply chain management strategy, in

order to develop and strengthen the competitive advantage.

EXECUTIVE SUMMARY2

Research Operation Report 4

2013 2nd semester

TABLE OF CONTENTS..3

1.0 INTRODUCTION.4

2.0 WHY SUPPLY CHIAN MANAGEMENT IS IMPORTANT4

3.0 APPLICATION.5

3.1 BENEFITS OF EFFICIENT SUPPLY CHAIN MANAGEMENT...5

3.2 EMPHASIZES THE CORE COMPETITIVENESS OF ENTERPRISES..6

3.3 METHODS AND TECHNOLOGICAL ...7

4.0 CONCLUSION...8

REFERENCES.....9

1.0 INTRODUCTION

Research Operation Report 5

2013 2nd semester

In the development of technology and the world economy, transnational management is becoming

more and more common. In manufacturing, product design may be in Japan and procurement of raw

materials in the China or Brazil, parts and components production can be done at the same time, In

Taiwan or Indonesia, and then in the China assembly, finally sold all over the world. Before the

products enter the market, company manufacturing quite a number of related products, because of

the different position, the production level and management ability, so as to form a complex network

of supply chain production.

WAL-MART is the worlds largest retailer, more than 4000 stores, 6000 stores in American and

international. Key to the success of retailers is its "everyday low price" or "daily specials" strategy, in

which we provide products at the lowest prices on the market. Even so, the company has maintained

its gross margin at around 27% as an efficient supply chain and strong bargaining power by.

WAL-MART is the modern supply chain management has a strong focus on supplier partnerships,

pioneer distribution and inventory management. Retailers use a variety of strategies, such as cross

docking, vendor managed inventory and the RFID (radio frequency identification), in order to

maintain control over the company's purchase, transport and storage of goods. This allows it to buy

goods at low prices, reduce intermediate storage and inventory holding cost.

2.0 WHY SUPPLY CHAIN MANAGEMEN IS IMPORTANT

Research Operation Report 6

2013 2nd semester

Supply chain management is an important factor in operational efficiency. Supply chain management

can be applied to the customer's satisfaction and success of the company, in social situations,

including medical, disaster relief, all kinds of emergencies; evolution of culture, it can help people

improve their quality of life. As the supply chain management organization skills and knowledge to

take a key role in action, the employer and the employee of supply chain management. Supply chain

management is the core of company management and successful for the following reasons: Supply

chain management is essential in the range of global.

Basically, the world is a big supply chain. The main issues involved in supply chain management,

including the rapid development and strategic partnerships multinational, global expansion and

procurement; oil prices and environmental concerns wave, these problems greatly affect the business

strategy and the bottom line. As these trends come out, supply chain management becomes the

world's most important business principles.

3.0 HOW TO IMPROVE SUPPLY CHAIN MANAGEMENT

Wal-Mart has been become the market leader, because its efficient of suppliers, manufacturing,

warehousing, distribution to stores. The four main components of its supply chain strategy are

vendor partnerships, cross-docking and distribution management, technology, and integration.

Wal-Mart's supply chain strategic is looking for products from the vendor who is in a most favorable

price position; ensure that they are able to meet the demand. Wal-Mart to establish a partnership with

most of the manufacturers, giving them in exchange for the lowest possible price and a lot of buying

long-term potential .

Then suppliers of the product shipped to cross-docking, and then transported to the Wal-Mart stores.

Cross- docking, distribution and transportation management to maintain inventory well and reduce

Research Operation Report 7

2013 2nd semester

transportation costs, transit time and eliminate inefficiencies.

Technology makes the Wal-Mart's supply chain successful, is the foundation of its supply chain.

Wal-Mart has a private company that is the world's largest information technology infrastructure

service for management department. The most advanced of its technology and network information

to allow Wal-Mart to analysis the country's needs and forecasting stocks and inventory levels, then

establishment of efficient transport routes. Wal-Mart also has managed customer relationships and

service response logistics system.

3.1 SUCCESSFUL SUPPLY CHAIN MANAGEMENT BRING BENEFITS

Wal-Marts supply chain management strategy operate mature with the market and other department

has provided number of long-term competitive advantages for company, including makes product

costs and inventory holding costs, makes more choice and products for customer, and highly

competitive pricing for the consumer, makes customer use less money to buy more goods. This

strategy has helped Wal-Mart become leader strength in a competitive market of global. As

technology developing, Wal-Mart keeps going to concentrate on innovative processes and systems,

in order to improve its supply chain and makes greater efficiency.

3.2 EMPHASIZES THE CORE COMPETITIVENESS OF ENTERPRISES

In supply chain management, an important concept is that enterprise and core business

Research Operation Report 8

2013 2nd semester

competitiveness, and its position in the supply chain, the non-core business outsourcing. Because of

the limited resources, enterprises must in every kind of industries and fields to gain a competitive

advantage is very difficult, so it must focus resources on one of your area of expertise, namely the

core business. In this supply chain positioning, become an irreplaceable role in supply chain.

WAL-MART as a chain of retail enterprises, high level of service and based on customer network is

its core competitiveness. WAL-MART beyond its own "commercial retail enterprise identity set up

efficient supply chain. First of all, WAL-MART is not only a home waiting for the upstream

manufacturers supply, tissue distribution of purely commercial enterprises, but also directly involved

in the upstream manufacturers production plan, and the upstream manufacturers to discuss and

develop product plan, delivery cycle, and even help the upstream manufacturers in new product

development and quality control work. This means that WAL-MART can always the earliest and

most want to see the goods on the market, while other retailers are waiting for the supplier's product

catalo or negotiate the contract, WAL-MART has started selling this product on the shelf. Secondly,

WAL-MART customer service can timely customer feedback to the manufacturer, and help

companies improve the quality of products. In the past, commercial retail enterprises just as a

middleman, delivering the products from manufacturers to consumers, which in turn will consumer

advice by telephone or written feedback to suppliers. It seems that WAL-MART did not one's own

knack in, but the results are very different. The reason is that, WAL-MART will be able to participate

in the production planning and control of the upstream manufacturers to, thus the opinions of

consumers quickly reflected in the production, rather than simply as a setter or microphone.

The WAL-MART way is not complex, but most commercial enterprises is more of a "bridge" of

consumers and manufacturers, lack the ability to participate in and control of production. That is to

say, WAL-MART model has crossed the enterprise internal management and external

"communication" category, but formed with itself as the main chain, link manufacturers and

Research Operation Report 9

2013 2nd semester

customers of the global supply chain. A supply chain is guaranteed through advanced information

technology, which is a set of advanced supply chain management system. Leave the unified,

centralized, real-time dug in supply chain management system ", direct control of production" of

WAL-MART and a high standard of "customer service" will be impossible.

3.3 METHODS AND TECHNOLOGICAL

The overall goal of SCM is to optimize supply chains in an attempt to provide more accurate and

time sensitive information that can be used to improve process times and cut costs. Supply chains

have been around for decades and a constantly being improved. The newest opportunity for

improvement is the introduction of radio frequency identification (RFID) tags. RFID technology

will provide real-time information that will allow manufacturers to get better readings of customers

and markets thus further improving supply chains. RFID will help retailers provide the right

products at the right places at the right times. Ultimately, maximizing sales and profits

Wal-Mart has been leading the charge with RFID technology. Having the largest retailer adopt and

begin to use RFID technology has given strong backing to the technology and will only further and

quicken the expansion of RFID. They have begun requiring all their major suppliers to implement

RFID technology on all products supplied to Wal-Mart.

One example of what Wal-Mart has done with SCM and its suppliers is that of its relationship with

Proctor & Gamble. These two built a software system that hooked Proctor & Gamble up to

Wal-Marts distribution centers. This system would then monitor supply levels and when products

run low, automatic alerts are sent out to require the shipment of more products to that distribution

center. Wal-Mart has taken this as far as going to the individual store locations. The shelves are

Research Operation Report 10

2013 2nd semester

monitored in real time via satellite links that send inventory messages whenever Proctor & Gamble

products are scanned at a register. This allows Proctor & Gamble to be fully aware of up to the

minute product inventories at the actual store locations and ship additional products as necessary.

This concept is a huge step in making SCM as efficient as it can be.

4.0 CONCLUSION

In conclusion, today's market is a buyer's market; today's market competition is also increasingly

fierce global market. Enterprises want to survive in the market, in addition to efforts to improve the

quality of the products, but also for its activities in the market to take a more advanced, more

efficient management mode of operation. Supply chain management is to appear in this reality, many

scholars on the supply chain management gives the definition, but more in many definitions of

comprehensive should be this: supply chain management is to market and customer demand as the

guidance, the core enterprise under the coordination, and win-win principle, to improve

competitiveness, market share, customer satisfaction, profit maximization as the goal, to

collaborative commerce, collaborative competition for commercial operation mode, through the use

of modern enterprise management technology, information technology and integration technology, to

achieve the effective planning and control of the whole supply chain information flow, logistics,

capital flow, business flow and value flow, thus the customer, suppliers, manufacturers, vendors,

service providers and other partners to form a complete network structure, strategic alliance to form a

very competitive. Say simply, supply chain management is to optimize and improve the supply chain

activities, its object is between supply chain organizations and their "flow", the application of the

method is integrated and collaborative; goal is to meet customer needs, and ultimately improve the

Research Operation Report 11

2013 2nd semester

overall competitiveness of the supply chain. The essence of supply chain management is the

value-added supply chain deeply, the correct product customer required (Right Product) can be at the

right time (Right time), in the right quantities (Right Quantity), the right quality (Right Quality) and

the correct state (Right Status) to the right place (Right Place) - "6R", and the minimum total cost.

We also hope every company should do the supply chain management by sustainability ways.

Research Operation Report 12

2013 2nd semester

You might also like

- A Case Study Report On "Walmart: Supply Chain Management"Document8 pagesA Case Study Report On "Walmart: Supply Chain Management"Risha RoyNo ratings yet

- Independent University, Bangladesh School of Business: MBA ProgramDocument9 pagesIndependent University, Bangladesh School of Business: MBA ProgramRahi MunNo ratings yet

- Wal-Mart Stores, Inc., Global Retailer case study, the GUIDE editionFrom EverandWal-Mart Stores, Inc., Global Retailer case study, the GUIDE editionNo ratings yet

- Wal-Mart Company AnalysisDocument5 pagesWal-Mart Company AnalysisAnas Ahmad AllamNo ratings yet

- WalmartDocument10 pagesWalmartAnonymous 1RSbCRE7mJNo ratings yet

- Ome752 Supply Chain Management Unit - I IntroductionDocument21 pagesOme752 Supply Chain Management Unit - I Introductionjeeva santhiyaNo ratings yet

- A Literature Analysis of WalmartDocument11 pagesA Literature Analysis of WalmartharpreetNo ratings yet

- Retail Supply Chain ManagementDocument9 pagesRetail Supply Chain ManagementShivatiNo ratings yet

- Amazonvswalmart 111010133132 Phpapp01Document27 pagesAmazonvswalmart 111010133132 Phpapp01Harsha VardhanaNo ratings yet

- Why Supply Chain Management Is Important Management EssayDocument7 pagesWhy Supply Chain Management Is Important Management EssayHND Assignment Help100% (1)

- Supply Chain Management of Wal-MartDocument35 pagesSupply Chain Management of Wal-MartManik SahaNo ratings yet

- Aditonal Notes - 1Document8 pagesAditonal Notes - 1yeteday615No ratings yet

- Supply Study TvsDocument20 pagesSupply Study TvsSiva RatheeshNo ratings yet

- Supply Chain Management Is The Management of A Network of Interconnected Businesses Involved in The Ultimate Provision of SCMDocument8 pagesSupply Chain Management Is The Management of A Network of Interconnected Businesses Involved in The Ultimate Provision of SCMPankajNo ratings yet

- Topic I - Introduction To SCMDocument9 pagesTopic I - Introduction To SCMHobiNo ratings yet

- Supply Chain Business Startup Guide: Step-by-Step Tips for SuccessFrom EverandSupply Chain Business Startup Guide: Step-by-Step Tips for SuccessNo ratings yet

- Wal-Mart's Successfully Integrated Supply ChainDocument16 pagesWal-Mart's Successfully Integrated Supply ChainCarlos GirónNo ratings yet

- Supply Chain Guide by Quasar-MedDocument25 pagesSupply Chain Guide by Quasar-MedDiniy YusofNo ratings yet

- Strategy Management Balanced Scorecards Example - Wal-Mart: July 2020Document14 pagesStrategy Management Balanced Scorecards Example - Wal-Mart: July 2020Laleska OsorioNo ratings yet

- Supply Chain Unit 3 - CompressedDocument38 pagesSupply Chain Unit 3 - CompressedAmol KareNo ratings yet

- Strategic Sourcing: CIT End Term Project Report OnDocument21 pagesStrategic Sourcing: CIT End Term Project Report Onnavyapurwar100% (1)

- IIBA2014 MELTEMUYGUNp 478-485Document10 pagesIIBA2014 MELTEMUYGUNp 478-485annguyen.learningNo ratings yet

- Let's Know What Supply Chain IsDocument8 pagesLet's Know What Supply Chain IsRafia TasnimNo ratings yet

- A Project Report On Supply Cahin Management atDocument39 pagesA Project Report On Supply Cahin Management atjizozorNo ratings yet

- Group 3 - Walmart CaseDocument3 pagesGroup 3 - Walmart CasePrajapati BhavikMahendrabhaiNo ratings yet

- Rahul Final Project Final PDFDocument72 pagesRahul Final Project Final PDFNandan KesariNo ratings yet

- Group 1 - PCM 804 SSCMDocument20 pagesGroup 1 - PCM 804 SSCMPhilcas LiNo ratings yet

- Creating Supply Chains in Competitive AdvantageDocument2 pagesCreating Supply Chains in Competitive AdvantageMacayanan, Norlanie L.No ratings yet

- Walmart Supply ChainDocument11 pagesWalmart Supply Chainfatima afzalNo ratings yet

- Good HabitsDocument9 pagesGood HabitsAman Kumar ThakurNo ratings yet

- 8-DanitaDoxaWidiyanto FinalExamPaperDocument26 pages8-DanitaDoxaWidiyanto FinalExamPaperNguyễn Thị Kiều OanhNo ratings yet

- Supply Chain ManagementDocument6 pagesSupply Chain ManagementHarshith Kumar H RNo ratings yet

- Introduction of Store Operations: Chapter - 1Document13 pagesIntroduction of Store Operations: Chapter - 1Prakash BoroNo ratings yet

- SCM Notes 1 and 2 ModulesDocument30 pagesSCM Notes 1 and 2 ModuleskavitaNo ratings yet

- SCM PDFDocument4 pagesSCM PDFAbdul SattarNo ratings yet

- Supply Chain Management of Walmart: Submitted On: 23 October 2010Document4 pagesSupply Chain Management of Walmart: Submitted On: 23 October 2010anakhasmNo ratings yet

- A Study of Supply Chain of Wal-Mart: PDPM Iiitdm-JabalpurDocument15 pagesA Study of Supply Chain of Wal-Mart: PDPM Iiitdm-JabalpurjizozorNo ratings yet

- MGT330 2Document15 pagesMGT330 2Hasan AveeNo ratings yet

- Reliance SynopsisDocument7 pagesReliance Synopsistarungupta1986_66389No ratings yet

- GSCM-25-Challenges in Global ManufacturingDocument18 pagesGSCM-25-Challenges in Global Manufacturingabdul rehmanNo ratings yet

- Thi SCMDocument30 pagesThi SCMDương Xuân NamNo ratings yet

- Andiyappillai 2020 Ijais 451896Document5 pagesAndiyappillai 2020 Ijais 451896Christian CardiñoNo ratings yet

- Supply Chain Management: Submitted To: Sir Khalid HafeezDocument4 pagesSupply Chain Management: Submitted To: Sir Khalid HafeezanwarNo ratings yet

- Pom AsignmentDocument20 pagesPom AsignmentSEID WORKUNo ratings yet

- The Report Has Been Prepared OnDocument10 pagesThe Report Has Been Prepared OnSusan ArafatNo ratings yet

- SCM AssignmentDocument6 pagesSCM AssignmentMahantesh MamadapurNo ratings yet

- Project - Supply - Chain - Management - at - Wal - Mart Sukanya 20212MLS0040Document21 pagesProject - Supply - Chain - Management - at - Wal - Mart Sukanya 20212MLS0040Sukanya ChukkiNo ratings yet

- Bruce Constantine, Brian D. Ruwadi, and Joshua Wine, Management Practices That Drive Supply Chain, February 2009, Mckinsey QuaterlyDocument6 pagesBruce Constantine, Brian D. Ruwadi, and Joshua Wine, Management Practices That Drive Supply Chain, February 2009, Mckinsey QuaterlyChinmay MohapatraNo ratings yet

- SCM in GeneralDocument22 pagesSCM in GeneralMartin JohnNo ratings yet

- Case Study 1 Half A Century of Supply CHDocument3 pagesCase Study 1 Half A Century of Supply CHSamNo ratings yet

- How Integrated Supply Chain Increases TH@Document33 pagesHow Integrated Supply Chain Increases TH@Debasis NathNo ratings yet

- What Is Marketing?Document17 pagesWhat Is Marketing?zohaibmehfooz89No ratings yet

- Supply-Chain and Logistics Management FOR Creating A Competitive Edge Part OneDocument21 pagesSupply-Chain and Logistics Management FOR Creating A Competitive Edge Part OneNixon PatelNo ratings yet

- Wal-Marts Successfully Integrated Supply Chain AnDocument17 pagesWal-Marts Successfully Integrated Supply Chain AnThảo ĐoànNo ratings yet

- Ib Assignment CASE STUDYDocument5 pagesIb Assignment CASE STUDYSubham ChakrabortyNo ratings yet

- Unit 4Document2 pagesUnit 4akash agarwalNo ratings yet

- Arpita Sonawane Section CDocument11 pagesArpita Sonawane Section CVishal MishraNo ratings yet

- Project Management ProjectDocument21 pagesProject Management ProjectANAM AFTAB 22GSOB2010404No ratings yet

- Environmental Health - Immunisation Schedule 2015Document1 pageEnvironmental Health - Immunisation Schedule 2015krovidiprasannaNo ratings yet

- Wind Energy Fact Sheet 2 Wind Farms and Property PricesDocument2 pagesWind Energy Fact Sheet 2 Wind Farms and Property PriceskrovidiprasannaNo ratings yet

- Standard Mediation AgreementDocument9 pagesStandard Mediation AgreementkrovidiprasannaNo ratings yet

- Ecatt Tutorial Prasanna 4436147Document3 pagesEcatt Tutorial Prasanna 4436147krovidiprasannaNo ratings yet

- Beyond IY AlignmentDocument9 pagesBeyond IY AlignmentkrovidiprasannaNo ratings yet

- Support To Mutiny Communicating ChangeDocument32 pagesSupport To Mutiny Communicating ChangekrovidiprasannaNo ratings yet

- Accenture Postal Poste Italiane Next Generation Postal ServicesDocument4 pagesAccenture Postal Poste Italiane Next Generation Postal ServiceskrovidiprasannaNo ratings yet

- Teamster Wal-Mart/Mclane Distribution Center Research QuestionnaireDocument4 pagesTeamster Wal-Mart/Mclane Distribution Center Research QuestionnairekrovidiprasannaNo ratings yet

- Jeff Sly - Case Study Nagios at Nu SkinDocument58 pagesJeff Sly - Case Study Nagios at Nu Skinkrovidiprasanna0% (1)

- Accenture Techombank CRMDocument2 pagesAccenture Techombank CRMkrovidiprasannaNo ratings yet

- SAP GUI 730 Installation Guide (E20 and SCMTRN) 1Document9 pagesSAP GUI 730 Installation Guide (E20 and SCMTRN) 1krovidiprasannaNo ratings yet

- Profile Generator-Pfcg: Submitted by Prasanna Krovidi (4436147) Parvathy Ragajapan Nissa Nur Dilyani - SriramDocument2 pagesProfile Generator-Pfcg: Submitted by Prasanna Krovidi (4436147) Parvathy Ragajapan Nissa Nur Dilyani - SriramkrovidiprasannaNo ratings yet

- ECE Deptt 7th Sem Minor ProjectS LIST 2013 14Document9 pagesECE Deptt 7th Sem Minor ProjectS LIST 2013 14krovidiprasannaNo ratings yet

- Williams William-W Resume CurrentDocument10 pagesWilliams William-W Resume CurrentkrovidiprasannaNo ratings yet

- Sweta Panda TesterDocument4 pagesSweta Panda TesterkrovidiprasannaNo ratings yet

- 4IR Framework Presentation - FINALDocument56 pages4IR Framework Presentation - FINALNathanNo ratings yet

- Kennedy School BrochureDocument2 pagesKennedy School BrochureBrennan GamwellNo ratings yet

- Au 3Document138 pagesAu 3Alejandra CastilloNo ratings yet

- Poverty ResearchDocument9 pagesPoverty ResearchBravo,Jessy Anne G.No ratings yet

- CRediT Author StatementDocument2 pagesCRediT Author StatementCarlos MaroveNo ratings yet

- Sustainability, Creativity and Innovation in Project Management PDFDocument17 pagesSustainability, Creativity and Innovation in Project Management PDFDavico MartinezNo ratings yet

- Studiu de Caz - Lean SCM TescoDocument2 pagesStudiu de Caz - Lean SCM TescoMircea-Nesu CiprianNo ratings yet

- Socio-Anhtro Assessment 2Document2 pagesSocio-Anhtro Assessment 2Adrienne GamaNo ratings yet

- Entrepreneurship Development Institute of IndiaDocument7 pagesEntrepreneurship Development Institute of IndiaAnisha MarwahNo ratings yet

- Maximilien RobespierreDocument20 pagesMaximilien Robespierreapi-443978182No ratings yet

- Dale Carnige TTT RequirementsDocument4 pagesDale Carnige TTT RequirementskrishnachivukulaNo ratings yet

- CIVE 461 - IOEC Parking: Amil Kaba & Hadi SoueidanDocument4 pagesCIVE 461 - IOEC Parking: Amil Kaba & Hadi SoueidanEmil KabaNo ratings yet

- Eapp Quarter 2 Module 3 (Jenny Mae D. Otto Grade 12 Abm-Yen)Document12 pagesEapp Quarter 2 Module 3 (Jenny Mae D. Otto Grade 12 Abm-Yen)Jenny Mae OttoNo ratings yet

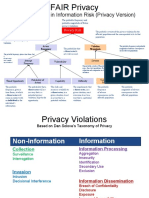

- Factor Analysis in Information Risk (Privacy Version)Document8 pagesFactor Analysis in Information Risk (Privacy Version)Otgonbayar TsengelNo ratings yet

- Exam Prep Guide Priya Rao: Taking Stock: 2 Weeks Before Study LeaveDocument2 pagesExam Prep Guide Priya Rao: Taking Stock: 2 Weeks Before Study LeavePriya RaoNo ratings yet

- 143 Narra ST., Mountview Subdivision, Tanauan City, Batangas Contact Nos.: (043) 778-6352 - (043) 778-6893Document2 pages143 Narra ST., Mountview Subdivision, Tanauan City, Batangas Contact Nos.: (043) 778-6352 - (043) 778-6893Alyssa MariNo ratings yet

- ADP-1project 120Document64 pagesADP-1project 120Koganti Naga Sai RamuNo ratings yet

- The Review of James Hartley's BookDocument3 pagesThe Review of James Hartley's BookAmir RashidNo ratings yet

- People v. Del RosarioDocument2 pagesPeople v. Del RosarioLyleThereseNo ratings yet

- Masters Degree Thesis For Educational ManagementDocument39 pagesMasters Degree Thesis For Educational ManagementJohn Bryan Aldovino100% (2)

- AT&T Case StudyDocument9 pagesAT&T Case StudyAdrian DsouzaNo ratings yet

- Enem Enem Enem: Me Deu Um Beijo e Virou PoesiaDocument34 pagesEnem Enem Enem: Me Deu Um Beijo e Virou PoesiaMaristella GalvãoNo ratings yet

- k12 QuestionnaireDocument3 pagesk12 QuestionnaireGiancarla Maria Lorenzo Dingle75% (4)

- RSN Referral FormDocument1 pageRSN Referral Formapi-315905321No ratings yet

- OJT Presentation For S and ADocument21 pagesOJT Presentation For S and AS.R.SAHANo ratings yet

- Website Planning Template ForDocument10 pagesWebsite Planning Template ForDeepak Veer100% (2)

- Boeing Case StudyDocument4 pagesBoeing Case Studyapi-541922465No ratings yet

- Michael Loadenthal - Criminology Seminar PDFDocument16 pagesMichael Loadenthal - Criminology Seminar PDFCristopherDebordNo ratings yet

- Care Routines ReferencesDocument2 pagesCare Routines Referencesapi-374587217No ratings yet

- Pass Format From Police StationDocument1 pagePass Format From Police StationThe Indian Express83% (6)