Professional Documents

Culture Documents

C 932 - 03 QZKZMG

Uploaded by

Humberto Gutierrez0 ratings0% found this document useful (0 votes)

89 views5 pagesThis standard has been approved for use by agencies of the Department of Defense. It covers minimum requirements for exterior Surface-Applied Bonding Compounds. This standard does not purport to address all of the safety concerns associated with its use.

Original Description:

Original Title

C 932 – 03 ;QZKZMG__

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis standard has been approved for use by agencies of the Department of Defense. It covers minimum requirements for exterior Surface-Applied Bonding Compounds. This standard does not purport to address all of the safety concerns associated with its use.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

89 views5 pagesC 932 - 03 QZKZMG

Uploaded by

Humberto GutierrezThis standard has been approved for use by agencies of the Department of Defense. It covers minimum requirements for exterior Surface-Applied Bonding Compounds. This standard does not purport to address all of the safety concerns associated with its use.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

Designation: C 932 03

Standard Specication for

Surface-Applied Bonding Compounds for Exterior

Plastering

1

This standard is issued under the xed designation C 932; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specication covers minimum requirements for

exterior surface-applied bonding compounds for improving the

adhesion of cementitious material to concrete or other masonry

surfaces or any structurally sound surfaces.

1.2 This specication also covers test methods for determin-

ing performance requirements and physical properties.

1.3 The values stated in inch-pound units are to be regarded

as the standard. The SI metric values given in parentheses are

approximate and are provided for information purposes only.

1.4 The following safety hazards caveat pertains only to the

test methods described in Sections 9, 10, 11, and 12 in this

specication: This standard does not purport to address all of

the safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C 11 Terminology Relating to Gypsum and Related Build-

ing Materials and Systems

2

C 109/C 109M Test Method for Compressive Strength of

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

Specimens

2

C 150 Specication for Portland Cement

2

C 305 Practice for Mechanical Mixing of Hydraulic Cement

Pastes and Mortars of Plastic Consistency

2

C 511 Specication for Moist Cabinets, Moist Rooms, and

Water Storage Tanks Used in the Testing of Hydraulic

Cements and Concretes

2

C 778 Specication for Standard Sand

2

3. Terminology

3.1 Denitions used in this specication shall be in accor-

dance with Terminology C 11.

4. Physical Properties

4.1 Surface Applied Bonding CompoundA freeze-thaw

stable composition, suitable for brush, roller, or spray applica-

tion. It shall be tinted to show by visual inspection where it has

been applied. The tint shall not bleed through the material

being bonded.

4.2 ConsistencyThe bonding compound shall be free of

foreign matter as determined by visual inspection and shall be

of such uniform consistency that when applied in accordance

with the producers directions by brush, roller, or spray to

concrete, masonry, or other structurally sound surface, the

bonding compound shall ow on evenly and dry uniformly.

4.3 Film CharacteristicsThe lm-forming property shall

be determined by visual inspection to determine the presence

of a continuous lm not broken by sheyes, cracking, pull-

back, or any other discontinuity in the lm surface. It shall not

be noticeably affected by alkaline surfaces or weak acids.

5. Performance Requirements

5.1 Bonding CapabilityThe bonding compound shall be

capable of bonding cementitious materials when applied in

accordance with the producers directions and tested as speci-

ed in Section 12.

5.2 DegradationBonding compound which separates

shall be able to be re-mixed to a uniform consistency when

tested as specied in Section 10.

5.3 High Temperature TestThe bond strength shall be not

less than 150 psi (1034 kPa) when tested as specied in Section

9.

5.4 Freeze-Thaw StabilityThe bond strength shall be not

less than 150 psi (1034 kPa) and 100 psi (690kPa) when tested

under the dry and wet conditions, respectively, as specied in

Section 11.

5.5 Tensile Bond StrengthBond strength of a fresh sample

or a 6-month old sample of bonding compound shall have an

average tensile strength of not less than 150 psi (1034 kPa) and

1

This specication is under the jurisdiction of ASTM Committee C11 on

Gypsum and Related Building Materials and Systems and is the direct responsibility

of Subcommittee C11.02 on Specications and Test Methods for Accessories and

Related Products.

Current edition approved June 10, 2003. Published August 2003. Originally

approved in 1980. Last previous edition approved in 1998 as C 932 98a.

2

Annual Book of ASTM Standards, Vol 04.01.

1

*A Summary of Changes section appears at the end of this standard.

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

100 psi (690 kPa) when tested under the dry and wet

conditions, respectively, as specied in Section 12.

6. Sampling

6.1 Take a sample of not less than 2.2 lb (1000 g) from each

shipment or consignment for analysis and tests. Except in

special cases, take the sample from not less than three separate

containers, chosen at random. In addition, take samples from

containers that appear to be nonrepresentative, and test sepa-

rately. Place the samples immediately in airtight glass contain-

ers and transport to the testing laboratory in these containers.

Take precautions to reduce evaporation or drying to a mini-

mum. Thoroughly mix the bonding compound in the container

if there is a tendency for liquid phase separation.

7. Apparatus

7.1 Moist CabinetSpecication C 511.

7.2 OvenA forced draft type oven, having a temperature

controlled at 140 6 5F (60 6 3C) for high temperature tests.

7.3 FreezerA freezer having a controlled temperature of

10 6 2F (23 6 1C).

7.4 BalanceA balance capable of weighing not less than

5.5 lb (2500 g) at a precision of 0.0002 lb (0.1 g).

7.5 Timing DeviceAn instrument capable of reading to the

nearest second.

7.6 TamperA tamper made up of a nonabsorptive, non-

abrasive, non-brittle material and having a cross section of

1

2

in. by 1 in. (13 3 25 mm) and approximately 5 to 6 in. (130 to

150 mm) long. The tamping face shall be at and at right

angles to the length of the tamper.

7.7 Straight EdgeA steel straight edge not less than 4 in.

(100 mm) long and not less than

1

16 in. (1.6 mm) nor more than

1

8 in. (3.2 mm) in thickness.

7.8 SpatulaAspatula with a metal blade 6 in. (150 mm) in

length and

1

2 in. (13 mm) in width, with straight edges.

7.9 Paint BrushA standard 1 in. (25 mm) wide brush,

with synthetic bristles.

7.10 Testing MachineAny type that is of sufficient capac-

ity and that is capable of applying the load continuously and

without shock at the rate of 0.05 in. (1.27 mm) per minute, with

provision for adjustment of the rate of loading.

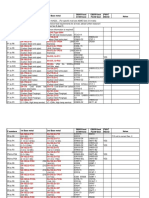

7.11 Briquet MoldsThe molds for making test specimens

shall be made of metal not attacked by the mortar and shall

have sufficient material in the sides to prevent spreading during

molding. Gang molds, when used, shall be of the type shown

in Fig. 1. The dimensions of the briquet molds shall conform to

the following requirements: width of mold, between inside

faces, at waist line of the briquet, 1 in. (25.4 mm) with

permissible variations of 60.01 in. (0.25 mm) for molds in use

and 60.005 in. (0.13 mm) for new molds; thickness of molds

measured at the point of greatest thickness on either side of the

mold at the waist line, 1 in. (25.4 mm) with permissible

variations of +0.004 in. (0.10 mm) and 0.002 in. (0.05 mm)

for new molds and 0.02 in. (0.5 mm) for molds in use. The

briquet specimens shall conform to the dimensional require-

ments shown in Fig. 2.

7.12 SawA table saw equipped with an abrasive cutting

blade or other blade suitable for cutting cementitious materials.

7.13 Clips for Briquet Testing MachineThe clips for

holding the tension test specimen shall be in accordance with

Fig. 3.

8. Conditioning

8.1 Room Temperature and HumidityMaintain the air

temperature in the vicinity of the mixing and testing area at 70

65F (21 63C). Maintain the relative humidity at 50 62 %.

8.2 Temperature of the Mixing Water72 6 2F (22 6

1C).

9. High Temperature Test

9.1 Signicance and UseThis test method provides pro-

cedures for evaluating the adhesive strength of bonding com-

pounds after being exposed to accelerated aging at high

temperature.

9.2 Specimen PreparationFor each test specimen, transfer

the bonding compound, taken from the sample obtained, into a

standard 1 pt. (500 mL) glass container.

9.3 ProcedurePlace the specimen in the oven for 30 days.

Remove the container, allow the compound to cool to room

temperature, mix the compound to a uniform consistency, and

test as specied in Section 12.

9.4 Tests and RetestsTest six briquets and report the

average of the test results. If the result of any one of the six

tests varies more than 15 % from the average, reject it and

report the average of the other ve tests. If the results from

more than two tests vary more than 15 % from the average,

reject the series and retest.

9.5 Precision and BiasThe precision and bias of the high

temperature test for determining bond strength after exposure

to high temperature are essentially the same as specied in the

test method for bond strength, paragraph 12.7.

10. Degradation Test

10.1 Signicance and UseThis test method simulates the

effects of high temperature storage on the physical properties

of bonding compound.

FIG. 1 Briquet Gang Mold

C 932 03

2

10.2 Specimen PreparationFor each test, transfer the

bonding compound, from the sample obtained, into a standard

1 pt. (500 mL) glass container.

10.3 ProcedurePlace the specimen in the oven for 15

days. Remove the container from the oven and examine the

contents for settling and separation. Place the container back in

the oven for an additional 15 days. Remove the container and

examine the contents again for settling and separation. Allow

the compound to come to room temperature, and mix to a

uniform consistency. Mix by hand stirring with a wood, metal,

or plastic paddle for not more than ve minutes.

10.4 Tests and RetestsBonding compound that fails to be

remixed to a uniform consistency shall be considered to have

failed the test.

10.5 ReportDetermine the extent of settling and separa-

tion by measuring and report as a percentage of the height of

the specimen in the clear glass container, represented by the

location of the liquid/solid interface.

10.6 Precision and BiasNo information is presented

about either the precision or bias of the Degradation test for

measuring settling, separation, or the ability to be mixed to a

uniform consistency since the test result is non-quantitative.

11. Freeze-Thaw Cycle Test

11.1 Signicance and UseThis test method provides pro-

cedures for determining the bond strength of bonding com-

pounds after being exposed to accelerated storage conditions of

alternate freezing and thawing.

11.2 Specimen PreparationFor each test specimen, trans-

fer the bonding compound, taken from the sample obtained,

into a standard 1 pt. (500 mL) glass container having a screw

on or friction t cover.

11.3 ProcedurePlace a covered specimen in the freezer

for 16 h. Remove the specimen and allow to thaw at room

temperature for 8 h. Repeat this procedure for 5 cycles. After

the fth cycle, allow the compound to come to room tempera-

ture, then test as specied in Section 12.

11.4 Tests and RetestsTest six briquets and report the

average of the test results. If the result of any one of the six

tests varies more than 15 % from the average, reject it and

report the average of the other ve tests. If the results from

more than two tests vary more than 15 % from the average,

reject the series and retest.

11.5 Precision and BiasThe precision and bias of the

freeze-thaw cycle test for determining bond strength after

exposure to alternate freezing and thawing are essentially the

same as specied in the test method for bond strength,

paragraph 12.7.

12. Bond Strength Test

12.1 Signicance and UseThis test method provides a

method for determining the ability of bonding compound, after

being subject to various simulated conditions of aging and

exposure to temperature extremes, to adhere cementitious

materials to a properly prepared substrate.

12.2 Materials:

12.2.1 CementSpecication C 150.

12.2.2 Graded Standard SandSpecication C 778.

12.3 Preparation of Briquets:

12.3.1 Prepare not less than six briquets for each series of

tests.

12.3.2 Prepare the proportions of the standard mortar in

accordance with the procedure given in Test Method C 109/

C 109M.

12.3.3 Mechanically mix the mortar in accordance with the

procedure given in Practice C 305.

12.3.4 Prepare molds by coating the molds with a thin lm

of mineral oil. Support the molds on a lightly oiled glass or

metal plate.

12.3.5 Cast the briquets immediately after completely mix-

ing the mortar, half ll the molds and puddle the mortar

uniformly with the tamper, taking care not to displace the

divider. Slightly over ll the molds with additional mortar and

repeat the puddling. After the mortar has set, cut off the excess

to a plane surface ush with the top of the mold, using a broad

knife or similar implement.

12.3.6 Immediately after molding, place the molds, on the

base plate, into the moist cabinet for 48 h.

12.3.7 Remove the briquets from the mold and store them at

room temperature and humidity for not less than 48 h.

12.3.8 Examine the specimens, discard any that have air

holes or excessively rough surfaces.

12.3.9 Saw the specimens in half at the mid-point of the

waist line, aligning the saw blade so that the entire saw kerf is

taken out of one side of the briquet, and the remaining side

maintains a 1 in. cross section. Discard the smaller portion of

the briquet.

NOTE 11 in. = 25.4 mm.

FIG. 2 Briquet Specimen for Tensile Strength Test

C 932 03

3

12.4 Procedure:

12.4.1 Thoroughly clean dust and loose particles from the

at waist surface of the specimen. Apply the bonding com-

pound, in accordance with the producers directions, to the at

waist surface of the briquet by means of a paint brush.

12.4.2 Place the half briquet, coated with bonding com-

pound, into the mold. Fill the remaining space in the mold with

mortar, mixed and molded as specied in 12.3.

12.4.3 The time between coating the briquet with compound

and casting the mortar against it shall be immediately after the

compound has dried, or as recommended by the manufacturer,

except when otherwise specied for a ten day waiting period.

12.4.4 Place the lled briquet mold in the moist cabinet for

24 h, then remove the briquets from the molds.

12.5 Test Method:

12.5.1 Test the briquets at the following intervals:

12.5.1.1 Dry ConditionAir cure three briquets for 14 days

and test.

12.5.1.2 Wet ConditionAir cure three briquets for 7 days,

soak in water for 7 days, and test.

12.5.2 Remove any loose particles or ash from the surfaces

that will be in contact with the clips of the testing machine.

Make sure the bearing surfaces of the clips are clean and free

of sand, and the roller bearings are lubricated and maintained

to ensure freedom of turning. Keep the stirrups supporting the

clips free of accumulations. Keep the pivots in proper adjust-

ment so that the clips swing freely on the pivots without

binding the stirrups. Carefully center the briquets in the clips

and apply the load continuously at the rate of 0.05 in. (1.27

mm)/min.

12.6 Tests and RetestsTest each group of three briquets

for bond strength and report the average of the test results. If

the result of any one of the six tests varies more than 15 %

from the average, reject it and report the average of the other

ve tests. If the results from more than two tests vary more

than 15 % from the average, reject the series and retest.

12.7 Precision and BiasPrecision and bias have not been

determined for the test method specied.

13. Inspection

13.1 Inspection of the bonding compound shall be agreed

upon between the producer or purchaser and the supplier as

part of the purchase agreement.

14. Rejection

14.1 Rejection of bonding compound that fails to conform

to the requirements of this specication shall be reported to the

producer or supplier promptly and in writing. The notice of

rejection shall contain a statement documenting how the

product has failed to conform to the requirements of this

specication.

15. Certication

15.1 When specied in the purchase agreement, the pro-

ducer or supplier shall furnish a report certifying that, at the

time of shipment, the bonding compound is in compliance with

the requirements of this specication.

16. Package and Package Marking

16.1 PackagingThe bonding compound shall be packed

in standard commercial containers. The containers shall be so

NOTE 11 in. = 25.4 mm.

FIG. 3 Clips for Briquet Testing Machine

C 932 03

4

constructed as to ensure acceptance by common or other

carriers for safe transportation at the lowest rate to the point of

delivery, unless otherwise specied in the purchase order.

16.2 MarkingShipping containers shall be marked with

the name of the bonding compound, the quantity contained

therein, the name, brand, or trade mark of the producer or

supplier, the shelf life, the batch number, and the ASTM

designation.

17. Keywords

17.1 bond; bonding compound; mortar; surface-applied

bonding compound

SUMMARY OF CHANGES

Committee C11 has identied the location of selected changes to this standard since the last issue

(C 932 98a) that may impact the use of this standard. (Approved June 10, 2003.)

(1) Revised paragraph 5.4.

(2) Revised paragraph 5.5.

(3) Revised paragraph 12.5.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every ve years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

C 932 03

5

You might also like

- C 932 - 03 PDFDocument5 pagesC 932 - 03 PDFTarek FennicheNo ratings yet

- Unconfined Compressive Strength Index of Chemical-Grouted SoilsDocument3 pagesUnconfined Compressive Strength Index of Chemical-Grouted SoilsninaNo ratings yet

- Bonding Compounds For Interior Gypsum PlasteringDocument5 pagesBonding Compounds For Interior Gypsum PlasteringSgjsevenpNo ratings yet

- C 587 - 97 Qzu4ny05nwDocument2 pagesC 587 - 97 Qzu4ny05nwHumberto GutierrezNo ratings yet

- C 1497 - 04 Qze0otcDocument4 pagesC 1497 - 04 Qze0otcRufo CascoNo ratings yet

- C367Document5 pagesC367dinhtung2210No ratings yet

- ASTMDocument6 pagesASTMcarmin79100% (2)

- Norma Astm Dd1338Document3 pagesNorma Astm Dd1338Manuel ContrerasNo ratings yet

- 672CDocument3 pages672CJGD123No ratings yet

- Astm D 2583Document4 pagesAstm D 2583Mohammad Rawoof100% (4)

- C 1135 - 00 QzexmzuDocument4 pagesC 1135 - 00 QzexmzuRufo CascoNo ratings yet

- ASTM-3574-11 Flexible Cellular Materials-Slab, Bonded, and Molded Urethane FoamDocument29 pagesASTM-3574-11 Flexible Cellular Materials-Slab, Bonded, and Molded Urethane FoamheobukonNo ratings yet

- High Solids Content, Cold Liquid-Applied Elastomeric Waterproofing Membrane For Use With Separate Wearing CourseDocument3 pagesHigh Solids Content, Cold Liquid-Applied Elastomeric Waterproofing Membrane For Use With Separate Wearing CourseSatya kaliprasad vangara100% (1)

- D 926 - 98 Rdkyni1sruqDocument5 pagesD 926 - 98 Rdkyni1sruqfadjarNo ratings yet

- ASTM D1171 - 15 - Rubber Deterioration-Surface Ozone Cracking Outdoors or Chamber (Triangular Specimens)Document3 pagesASTM D1171 - 15 - Rubber Deterioration-Surface Ozone Cracking Outdoors or Chamber (Triangular Specimens)Thảo Nhân NguyễnNo ratings yet

- C535 - 16 - Standard Test Method For Resistance To Degradatio of Large-Size Coarse Aggregate ByAbrasion Impact in The Los Angeles MachineDocument3 pagesC535 - 16 - Standard Test Method For Resistance To Degradatio of Large-Size Coarse Aggregate ByAbrasion Impact in The Los Angeles MachineTomás Venegas Pardo100% (1)

- ASTM D 3574 08 Standard Test Methods For Flexible Cellular MaterialsDocument27 pagesASTM D 3574 08 Standard Test Methods For Flexible Cellular MaterialsMiguel Angel Lupaca BernalesNo ratings yet

- Astm D 3164 - 03Document4 pagesAstm D 3164 - 03phaindikaNo ratings yet

- C 509 - 00 - QzuwoqDocument5 pagesC 509 - 00 - Qzuwoqmercab150% (1)

- Astm D1667-97Document6 pagesAstm D1667-97Lin Shenghuai CalvinNo ratings yet

- C 712 - 93 R97 Qzcxmi05m1i5nwDocument2 pagesC 712 - 93 R97 Qzcxmi05m1i5nwRufo CascoNo ratings yet

- C 907 - 98 Qzkwny05oaDocument3 pagesC 907 - 98 Qzkwny05oaRufo CascoNo ratings yet

- Astm C1262-10Document5 pagesAstm C1262-10Miguelina NR100% (1)

- Adhesion-in-Peel of Elastomeric Joint Sealants: Standard Test Method ForDocument4 pagesAdhesion-in-Peel of Elastomeric Joint Sealants: Standard Test Method ForRufo Casco100% (1)

- D 6768 - 03Document3 pagesD 6768 - 03luis-12No ratings yet

- Norma Astm 2412Document7 pagesNorma Astm 2412Jluis IpnNo ratings yet

- D4832 NormaDocument5 pagesD4832 NormaMike LemusNo ratings yet

- Joint Treatment Materials For Gypsum Board Construction: Standard Test Methods ForDocument14 pagesJoint Treatment Materials For Gypsum Board Construction: Standard Test Methods ForJoseph Marriott AndersonNo ratings yet

- Astm C 882Document4 pagesAstm C 882Nikolay Drumev33% (3)

- Adhesion-in-Peel of Elastomeric Joint Sealants: Standard Test Method ForDocument4 pagesAdhesion-in-Peel of Elastomeric Joint Sealants: Standard Test Method Forמשה אביסדריסNo ratings yet

- C672-12 Scalling Resistance of Concrete Surfaces Exposed To Deicing Chemicals.13104Document3 pagesC672-12 Scalling Resistance of Concrete Surfaces Exposed To Deicing Chemicals.13104Kartika Setia RiniNo ratings yet

- ASTM D3163 For Determining Strength of Adhesively Bonded Rigid Plastic Lap-Shear Joints in Shear by Tension LoadingDocument3 pagesASTM D3163 For Determining Strength of Adhesively Bonded Rigid Plastic Lap-Shear Joints in Shear by Tension LoadingSaavedra Aurel MarcNo ratings yet

- C1403 15Document5 pagesC1403 15Lorena JimenezNo ratings yet

- Thermal Compatibility Between Concrete and An Epoxy-Resin OverlayDocument2 pagesThermal Compatibility Between Concrete and An Epoxy-Resin Overlaysmanoj354No ratings yet

- Astm C-1231Document5 pagesAstm C-1231Sebastian TobonNo ratings yet

- Adhesion-in-Peel of Elastomeric Joint Sealants: Standard Test Method ForDocument4 pagesAdhesion-in-Peel of Elastomeric Joint Sealants: Standard Test Method Forquality staffordNo ratings yet

- Astm C267 - 01 (2012)Document6 pagesAstm C267 - 01 (2012)minhhuan0101No ratings yet

- C 1173 - 97 Qzexnzmtotc - PDFDocument4 pagesC 1173 - 97 Qzexnzmtotc - PDFMung Duong XuanNo ratings yet

- C882Document4 pagesC882Jorge Luis Arevalo LopezNo ratings yet

- Astm C143Document4 pagesAstm C143Audrey Schwartz100% (2)

- Compressive Strength of Bituminous Mixtures: Standard Test Method ForDocument6 pagesCompressive Strength of Bituminous Mixtures: Standard Test Method ForHany ElsayedNo ratings yet

- Lap Shear Strength of Hot-Applied Sealants: Standard Test Method ForDocument4 pagesLap Shear Strength of Hot-Applied Sealants: Standard Test Method ForRufo CascoNo ratings yet

- C 712 - 03 - QZCXMGDocument2 pagesC 712 - 03 - QZCXMGmercab15No ratings yet

- 2ASTM C794 - Adhesion-in-Peel of Elastomeric Joint SealantsDocument4 pages2ASTM C794 - Adhesion-in-Peel of Elastomeric Joint SealantsRajeshNo ratings yet

- ASTM Designation: C 1305 - 08Document3 pagesASTM Designation: C 1305 - 08Lupita RamirezNo ratings yet

- C672C672M 12 Scaling Resistance of Concrete Surfaces Exposed ToDocument3 pagesC672C672M 12 Scaling Resistance of Concrete Surfaces Exposed ToJamman Shahid ShiblyNo ratings yet

- E736Document3 pagesE736Rufo CascoNo ratings yet

- Acid ResistanceDocument6 pagesAcid ResistanceSARAH ABRAHAMNo ratings yet

- D2919 PDFDocument4 pagesD2919 PDFengahmed22281No ratings yet

- D7530D7530M-10 Standard Specification For Self-Adhesive Glass Fiber Fabric Reinforced Polymer Modified Asphalt Steep Slope Roll Roofing Surfaced With Mineral GranulesDocument5 pagesD7530D7530M-10 Standard Specification For Self-Adhesive Glass Fiber Fabric Reinforced Polymer Modified Asphalt Steep Slope Roll Roofing Surfaced With Mineral GranulesSatya kaliprasad vangaraNo ratings yet

- Crack Bridging Ability of Liquid-Applied Waterproofing MembraneDocument3 pagesCrack Bridging Ability of Liquid-Applied Waterproofing Membranesabaris ksNo ratings yet

- ASTM C1019 GroutingDocument5 pagesASTM C1019 Groutingalexago75% (4)

- C535 12Document3 pagesC535 12Pedro VenturaNo ratings yet

- Astm C932Document5 pagesAstm C932adolfo camayoNo ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- F 409 - 99 Rjqwos05oueDocument16 pagesF 409 - 99 Rjqwos05oueHumberto GutierrezNo ratings yet

- F 477 - 02 RJQ3NWDocument4 pagesF 477 - 02 RJQ3NWHumberto GutierrezNo ratings yet

- Jesús Rubí M.: Fórmulas de Cálculo Diferencial e IntegralDocument0 pagesJesús Rubí M.: Fórmulas de Cálculo Diferencial e IntegralSergio1218No ratings yet

- F 438 - 99 Rjqzoc05oqDocument5 pagesF 438 - 99 Rjqzoc05oqHumberto GutierrezNo ratings yet

- D 5319 - 97 R01 RduzmtkDocument4 pagesD 5319 - 97 R01 RduzmtkHumberto GutierrezNo ratings yet

- D 4726 - 02 Rdq3mjyDocument11 pagesD 4726 - 02 Rdq3mjyHumberto GutierrezNo ratings yet

- D 5926 - 96 Rdu5mjytukveDocument5 pagesD 5926 - 96 Rdu5mjytukveHumberto GutierrezNo ratings yet

- D 2729 - 96 Rdi3mjktukveDocument6 pagesD 2729 - 96 Rdi3mjktukveHumberto GutierrezNo ratings yet

- D 2105 - 01 - RdixmduDocument6 pagesD 2105 - 01 - RdixmduSwapnil CallaNo ratings yet

- D 3840 - 99 Rdm4ndatotkDocument9 pagesD 3840 - 99 Rdm4ndatotkHumberto GutierrezNo ratings yet

- D 3309 - 96a R02 RDMZMDKDocument11 pagesD 3309 - 96a R02 RDMZMDKHumberto GutierrezNo ratings yet

- D 3517 - 03 Rdm1mtctukveDocument14 pagesD 3517 - 03 Rdm1mtctukveHumberto GutierrezNo ratings yet

- D 4495 - 98 Rdq0otutukveDocument7 pagesD 4495 - 98 Rdq0otutukveHumberto GutierrezNo ratings yet

- Type PSM Poly (Vinyl Chloride) (PVC) Sewer Pipe and Fittings: Standard Specification ForDocument12 pagesType PSM Poly (Vinyl Chloride) (PVC) Sewer Pipe and Fittings: Standard Specification ForHumberto GutierrezNo ratings yet

- D 3035 - 03 RdmwmzutukveDocument8 pagesD 3035 - 03 RdmwmzutukveHumberto GutierrezNo ratings yet

- D 2657 - 03 Rdi2ntcDocument7 pagesD 2657 - 03 Rdi2ntcHumberto GutierrezNo ratings yet

- D 2680 - 95 Rdi2odatotvbDocument8 pagesD 2680 - 95 Rdi2odatotvbHumberto GutierrezNo ratings yet

- D 2235 - 96 RdiymzutukveDocument7 pagesD 2235 - 96 RdiymzutukveHumberto GutierrezNo ratings yet

- D 2467 - 02 Rdi0njctmdiDocument8 pagesD 2467 - 02 Rdi0njctmdiHumberto GutierrezNo ratings yet

- D 1527 - 99 Rde1mjctukveDocument11 pagesD 1527 - 99 Rde1mjctukveHumberto GutierrezNo ratings yet

- D 2122 - 98 RdixmjitotgDocument5 pagesD 2122 - 98 RdixmjitotgHumberto GutierrezNo ratings yet

- D 2444 - 99 Rdi0ndqDocument8 pagesD 2444 - 99 Rdi0ndqHumberto GutierrezNo ratings yet

- D 1694 - 95 R00 Rde2otqDocument4 pagesD 1694 - 95 R00 Rde2otqHumberto GutierrezNo ratings yet

- D 1608 - 98 R03 Rde2mdgDocument6 pagesD 1608 - 98 R03 Rde2mdgHumberto GutierrezNo ratings yet

- D 542 - 95 Rdu0mi1sruqDocument5 pagesD 542 - 95 Rdu0mi1sruqHumberto GutierrezNo ratings yet

- D 6216 - 03 RdyymtyDocument32 pagesD 6216 - 03 RdyymtyHumberto GutierrezNo ratings yet

- D 6246 - 01 RdyyndytmdeDocument10 pagesD 6246 - 01 RdyyndytmdeHumberto GutierrezNo ratings yet

- D 4947 - 00 RDQ5NDCDocument8 pagesD 4947 - 00 RDQ5NDCHumberto GutierrezNo ratings yet

- D 2914 - 01 Rdi5mtqDocument14 pagesD 2914 - 01 Rdi5mtqHumberto GutierrezNo ratings yet

- D 6941 - 03 Rdy5ndetukveDocument5 pagesD 6941 - 03 Rdy5ndetukveHumberto GutierrezNo ratings yet

- Elements Compounds Mixtures WKSTDocument5 pagesElements Compounds Mixtures WKSTAmanda ClayNo ratings yet

- Manual HECHT 650 GB PDFDocument14 pagesManual HECHT 650 GB PDFEmaNo ratings yet

- Types and Design of The Towers TraysDocument12 pagesTypes and Design of The Towers TraysoluninjaaNo ratings yet

- Flange Gasket Basics GFDocument8 pagesFlange Gasket Basics GFSri DharNo ratings yet

- Chapter - 7 Materials HandlingDocument14 pagesChapter - 7 Materials HandlingTanaya KambliNo ratings yet

- Refrigeration Practical 1Document6 pagesRefrigeration Practical 1SamNo ratings yet

- LNG Tank Oerlikon PDFDocument32 pagesLNG Tank Oerlikon PDFElias Kapa100% (1)

- Caleb Catalogue DiscspringDocument5 pagesCaleb Catalogue DiscspringsantoshNo ratings yet

- Innoplus 1100J PDFDocument1 pageInnoplus 1100J PDFindahNo ratings yet

- Design & Analysis Project BY INDIAN STUDENT (ANSYS CATIA MATLAB)Document58 pagesDesign & Analysis Project BY INDIAN STUDENT (ANSYS CATIA MATLAB)Vaibhav Soni100% (1)

- Product Design SpecificationDocument2 pagesProduct Design SpecificationCharlie100% (1)

- Clase 10 Pruebas Hidráulicas en Perforaciones y PiezómetrosDocument32 pagesClase 10 Pruebas Hidráulicas en Perforaciones y Piezómetrosyaku1618No ratings yet

- DesaltingDocument25 pagesDesaltingOmar GamalNo ratings yet

- Basalt FiberDocument19 pagesBasalt FiberHitesh Shah100% (1)

- Boozhound Laboratories JFETPhono PreampDocument3 pagesBoozhound Laboratories JFETPhono Preampvali29No ratings yet

- Air Conditioning SystemsDocument14 pagesAir Conditioning Systemsarslan KhanNo ratings yet

- Welding Electrodes SelectionDocument19 pagesWelding Electrodes SelectionjerickNo ratings yet

- Solid - Liquid ExtractionDocument20 pagesSolid - Liquid ExtractionFikriyatul KhaeriyahNo ratings yet

- Fisher Y690 ValveDocument16 pagesFisher Y690 ValvemadithakNo ratings yet

- Caracksil Acrylic PasteDocument3 pagesCaracksil Acrylic PasteHaradhon DattaNo ratings yet

- Example Problems For Tension Members SteelDocument5 pagesExample Problems For Tension Members SteelEyoel Ashagre81% (32)

- WWWT 1111 Pt2 Water Distribution 3.3 - (Water Distribution Foundations - 3Document11 pagesWWWT 1111 Pt2 Water Distribution 3.3 - (Water Distribution Foundations - 3marioNo ratings yet

- Hub AppletonDocument2 pagesHub AppletonDavid JuyarNo ratings yet

- 21-09 Machine Drawing (ME - in.MN - MT) (97-03)Document2 pages21-09 Machine Drawing (ME - in.MN - MT) (97-03)rkarthick27No ratings yet

- 01 Integrity Management of CRA Pipelines - 20 December 2015 PDFDocument24 pages01 Integrity Management of CRA Pipelines - 20 December 2015 PDFIndunil Prasanna Bandara WarnasooriyaNo ratings yet

- Launie "Kris" Hansen: Work ExperienceDocument3 pagesLaunie "Kris" Hansen: Work ExperienceKris HansenNo ratings yet

- John Deere 7830Document5 pagesJohn Deere 7830Ramiro GonzálezNo ratings yet

- DLL - Science 5 - Q1 - W5Document9 pagesDLL - Science 5 - Q1 - W5HEVER TORRESNo ratings yet

- MPI Report 009 Sub Structure B668Document1 pageMPI Report 009 Sub Structure B668John DolanNo ratings yet