Professional Documents

Culture Documents

Load Studies and Effects of Load Variation

Uploaded by

Areeba Mushtaq Ahmed0 ratings0% found this document useful (0 votes)

261 views14 pages-

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document-

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

261 views14 pagesLoad Studies and Effects of Load Variation

Uploaded by

Areeba Mushtaq Ahmed-

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 14

1

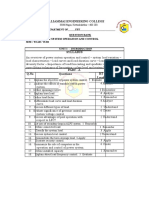

Load Study & Effects Of Load

Variation:

Subject: Power Generation Economics

Submitted By: Areeba Mushtaq Ahmed

2

Load Study & Effects of Load Variation

Introduction:

The function of a power station is to deliver power to a large number

of consumers. However, the power demands of different consumers vary in accordance with their

activities. The result of this variation in demand is that load on a power station is never constant;

rather it varies from time to time. Most of the complexities of modern power plant operation arise

from the inherent variability of the load demanded by the users. Unfortunately, electrical power

cannot be stored and, therefore, the power station must produce power as and when demanded to

meet the requirements of the consumers. On one hand, the power engineer would like that the

alternators in the power station should run at their rated capacity for maximum efficiency and on

the other hand, the demands of the consumers have wide variations. This makes the design of a

power station highly complex. We shall focus our attention on the problems of variable load on

power stations.

Important Terms and Factors

1. Connected load.

It is the sum of continuous ratings of all the equipment connected to supply system.

A power station supplies load to thousands of consumers. Each consumer has certain equipment

installed in his premises. The sum of the continuous ratings of all the equipment in

the consumers premises is the connected load of the consumer. For instance, if a consumer has

connections of five100-watt lamps and a power point of 500 watts, then connected load of the

consumer is 5100 + 500= 1000 watts. The sum of the connected loads of all the consumers is the

connected load to the power station

2. Maximum demand:

It is the greatest demand of load on the power station during a given period.

The load on the power station varies from time to time. The maximum of all the demands that

have occurred during a given period (say a day) is the maximum demand. The maximum demand

3

on the power station during the day is 6 MW and it occurs at 6 P.M. Maximum demand is

generally less than the connected load because all the consumers do not switch on their connected

load to the system at a time. The knowledge of maximum demand is very important as it helps in

determining the installed capacity of the station. The station must be capable of meeting the

maximum demand.

3. Demand factor.

It is the ratio of maximum demand on the power station to its connected load i.e.,

Demand factor=Maximum demand / Connected load

The value of demand factor is usually less than 1. It is expected because maximum demand on the

power station is generally less than the connected load. If the maximum demand on the power

station is 80 MW and the connected load is 100 MW, then demand factor = 80/100 = 0 8. The

knowledge of demand factor is vital in determining the capacity of the plant equipment.

4. Average load.

The average of loads occurring on the power station in a given period (day or month or year) is

known as average load or average demand.

Daily average load=No. of units (kWh) generated in a day / 24 hours

Monthly average load=No. of units (kWh) generated in a month / Number of hours in a month

Yearly average load=No. of units (kWh) generated in a year / 8760 hours

5. Load factor.

The ratio of average load to the maximum demand during a given period is known as load factor

i.e., Load factor=Average load / Max. demand

If the plant is in operation for T hours,

Load factor=Average load T / Max. Demand T

=Units generated in T hours / Max. Demand T hours

The load factor may be daily load factor, monthly load factor or annual load factor if the time

period considered is a day or month or year. Load factor is always less than 1 because average

4

load is smaller than the maximum demand. The load factor plays key role in determining the

overall cost per unit generated. Higher the load factor of the power station, lesser will be the cost

per unit generated.

6. Diversity factor.

The ratio of the sum of individual maximum demands to the maximum demand on power station

is known as diversity factor

i.e., Diversity factor=Sum of individual max. Demands / Max. demand on PowerStation

A power station supplies load to various types of consumers whose maximum demands generally

do not occur at the same time. Therefore, the maximum demand on the power station is always

less than the sum of individual maximum demands of the consumers. Obviously, diversity factor

will always be greater than 1. The greater the diversity factor, the lesser is the cost of generation

of power.

7. Plant capacity factor.

It is the ratio of actual energy produced to the maximum possible energy that could have

been produced during a given period i.e.,

Plant capacity factor=Actual energy produced / Max. energy that could have been produced

=Average demand T / Plant capacity T

=Average demand / Plant capacity

Thus if the considered period is one year,

Annual plant capacity factor= Annual kWh output / Plant capacity 8760

The plant capacity factor is an indication of the reserve capacity of the plant. A power station is

so designed that it has some reserve capacity for meeting the increased load demand in

future. Therefore, the installed capacity of the plant is always somewhat greater than the

maximum demand on the plant.

Reserve capacity=Plant capacityMax. Demand

It is interesting to note that difference between load factor and plant capacity factor is an

indication of reserve capacity. If the maximum demand on the plant is equal to the plant capacity,

5

then load factor and plant capacity factor will have the same value. In such a case, the plant will

have no reserve capacity.

8. Plant use factor.

It is ratio of kWh generated to the product of plant capacity and the number of hours for which

the plant was in operation i.e.

Plant use factor=Station output in kWh / Plant capacity Hours of use

Suppose a plant having installed capacity of 20 MW produces annual output of 7 3510 kWh

and remains in operation for 2190 hours in a year. Then,

Plant use factor=7.3510 / (2010) 2190

= 0 167 or 16 7%

Why is Load Study Conducted?

We should be able to analyze the performance of power systems both in normal operating

conditions and under fault (short-circuit) condition. The analysis in normal steady-state operation

is called a Load Study and it targets on determining the voltages, currents, and real and reactive

power flows in a system under a given load conditions.

The purpose of Load studies is to plan ahead and account for various hypothetical situations. For

instance, what if a transmission line within the power system properly supplying loads must be

taken off line for maintenance. Can the remaining lines in the system handle the required loads

without exceeding their rated parameters?

Basic Techniques for Conducting Load Study:

The equations used to update the estimates differ for different types of busses. Each bus in a

power system can be classified to one of three types:

1. Load bus (PQ bus)

A bus at which the real and reactive power are specified, and for which the bus voltage will

be calculated. Real and reactive powers supplied to a power system are defined to be positive,

6

while the powers consumed from the system are defined to be negative. All busses having no

generators are load busses.

2. Generator bus (PV bus)

A bus at which the magnitude of the voltage is kept constant by adjusting the field current of

a synchronous generator on the bus (as we learned, increasing the field current of the

generator increases both the reactive power supplied by the generator and the terminal

voltage of the system). We assume that the field current is adjusted to maintain a constant

terminal voltage V

T

. We also know that increasing the prime movers governor set points

increases the power that generator supplies to the power system. Therefore, we can control

and specify the magnitude of the bus voltage and real power supplied.

3. Slack bus (swing bus)

A special generator bus serving as the reference bus for the power system. Its voltage is

assumed to be fixed in both magnitude and phase (for instance, 10 p.u). The real and

reactive powers are uncontrolled: the bus supplies whatever real or reactive power is

necessary to make the power flows in the system balance.

In practice, a voltage on a load bus may change with changing loads. Therefore, load busses have

specified values of P and Q, while V varies with load conditions.

Real generators work most efficiently when running at full load. Therefore, it is desirable to keep

all but one (or a few) generators running at 100% capacity, while allowing the remaining (swing)

generator to handle increases and decreases in load demand. Most busses with generators will

supply a fixed amount of power and the magnitude of their voltages will be maintained constant

by field circuits of generators.

The controls on the swing generator will be set up to maintain a constant voltage and frequency,

allowing P and Q to increase or decrease as loads change.

Key Points for Load Study :

Load-flow studies are performed to determine the steady-state operation of an electric

power system. It calculates the voltage drop on each feeder, the voltage at each bus, and

the power flow in all branch and feeder circuits.

7

Determine if system voltages remain within specified limits under various contingency

conditions, and whether equipment such as transformers and conductors are overloaded.

Load-flow studies are often used to identify the need for additional generation,

capacitive, or inductive VAR support, or the placement of capacitors and/or reactors to

maintain system voltages within specified limits.

Losses in each branch and total system power losses are also calculated.

Necessary for planning, economic scheduling, and control of an existing system as well

as planning its future expansion

Pulse of the system

Different Methods in Practice for Conducting Load Study :

Classical methods

Gauss-Seidal method

Newton Raphson method

Fast Decoupled method

Other methods

Fuzzy Logic application

Genetic Algorithm application

Particle swarm method (PS0)

Effects of Load Variation :

Results in sustained frequency deviations

speed control and the subsequent responses of prime mover and energy supply

systems play a major role

8

often, situation compounded by high- or low-voltage conditions

Under generated condition:

frequency will decline

if sufficient spinning generation reserve is not available, frequency may reach

low levels at which thermal units are tripped by under frequency protection

therefore, under frequency load shedding used

Over generated condition:

speed governors respond to frequency rise

performance of island depends on the ability of power plants to sustain a "partial

load rejection"

Reactive power balance:

a significant mismatch could lead to high- or low-voltage conditions

generator under/over excitation, loss-of-excitation protections may be activated

Power plant auxiliaries:

decrease in power supply voltage and frequency can degrade performance of

induction motors

may lead to loss of condenser vacuum, high turbine-exhaust temperature,

insufficient condensate/feed water

many nuclear units are equipped with relays set to trip plant at low voltages (0.7

pu) and low frequency

Power system loads respond to variations in voltage and frequency

9

Frequency Instability Incidents due to Load Variation :

1. April 19, 1972 disturbances in Ontario

islanding of Eastern Ontario

Incident:

230 kV lines east of Toronto tripped due to communication malfunction; ties to New

York at St. Lawrence tripped

generation rich island formed in eastern Ontario

(G = 3900 MW, L = 3000 MW)

frequency rose to 62.5 Hz and then dropped to 59.0 Hz due to speed governor

under frequency load shedding

frequency rose to 62.6 Hz and dropped to 58.7 Hz

significant loss of generation and load

stabilized at 60.8 Hz with 1875 MW generation

Source of problem:

overspeed controls associated with prime-mover governors

2. January 20, 1974 disturbance

islanding of Toronto area

Incident:

severe ice storm caused separation of power system in Toronto area

island consisting of Lakeview GS supplying Manby and Cooksville TSs

generation rich island

(G = 1400 MW, L = 760 MW)

frequency rose to 63.4 Hz, dropped to 60.7 Hz, rose again to 62.3 Hz and oscillated for

several seconds

boiler trips occurred on 4 of the 5 units at Lakeview

frequency dropped to 59 Hz

under frequency load shedding restored frequency to 59.6 Hz

10

Source of problem:

Over speed controls associated with prime-mover governors

Objectives of a Power station:

The power station is constructed, commissioned and operated to supply required power to

consumer swith generators running at rated capacity for maximum efficiency.

Generation, transmission and distribution of electrical energy is the fact that electrical energy

cannot be stored. It must be generated, transmitted and distributed as and when needed.

Now looking at problems associated with variable loads on power stations, and let me briefly

discuss the complexities met in deciding the make, size and capacity of Generators (Generating

units) that must be installed in a power plant to successfully meet these varying energy demands

on a day to day basis.

How to Meet Variable Load (Load Variation):

The load on a power station varies from time to time due to uncertain demands of the consumers

and is known as variable load on the station.

A power station is designed to meet the load requirements of the consumers. An ideal load on the

station, from stand point of equipment needed and operating routine, would be one of constant

magnitude and steady duration. However, such a steady load on the station is never realized in

actual practice. The consumers require their small or large block of power in accordance with the

demands of their activities. Thus the load demand of one consumer at any time may be different

from that of the other consumer. The result is that load on the power station varies from time to

time.

Effects of variable load:

The variable load on a power station introduces many perplexities in its operation. Some of the

important effects of variable load on a power station are:

11

1. Need of additional equipment.

The variable load on a power station necessitates to have additional equipment. By way

of illustration, consider a steam power station. Air, coal and water are the raw materials for

this plant. In order to produce variable power, the supply of these materials will be required to be

varied correspondingly. For instance, if the power demand on the plant increases, it must be

followed by the increased flow of coal, air and water to the boiler in order to meet the increased

demand. Therefore, additional equipment has to be installed to accomplish this job. As a matter of

fact, in a modern power plant, there is much equipment devoted entirely to adjust the rates of

supply of raw materials in accordance with the power demand made on the plant.

2. Increase in production cost.

The variable load on the plant increases the cost of the production of electrical energy. An

alternator operates at maximum efficiency near its rated capacity. If a single alternator is used, it

will have poor efficiency during periods of light loads on the plant. Therefore, in actual practice,

a number of alternators of different capacities are installed so that most of the alternators can be

operated at nearly full load capacity. However, the use of a number of generating units increases

the initial cost per kW of the plant capacity as well as floor area required. This leads to the

increase in production cost of energy.

From above discussion, we conclude that the total demands on the power station to vary over a

given period of time and may necessitate the following:

Additional equipment/Generating units to meet demand

Increase in production cost to recuperate use of more material/equipment

In order to study the pattern and effect of the varying load, station engineers use load curves

Load Curves:

A load curve is a graph showing the variation of load on the power station with respect to time.

The following load curves are used in power stations:

Daily load curve: -- Load variations captured during the day (24Hrs ), recorded either

half-hourly or hourly.

12

Monthly load curve: -- Load variations captured during the month at different times of

the day plotted against No. of days.

Yearly load curve: -- Load variations captured during the Year, this is derived from

monthly load curves of a particular year.

Information obtained from load curves:

Area under load curve = Units generated

Highest point of the curve = Maximum Demand

(Area under curve) (by total hours) = Average load

(Area under load curve) (Area of rectangle containing load curve) = LF

Helps to select size & number of generating units.

Helps to create operating schedule of the power plant.

Selecting Generating Units for Meeting Variable Load :

Selecting generating units:

The following must be considered when selecting the number and size of Generating units

(Generators):

Number and size of units to approximately fit the annual load curve.

Units to be of different capacities to meet load requirements.

At least 15 - 20% of extra capacity for future expansion should be allowed for.

Spare generating capacity must be allowed for to cater for repairs and overhauling of

working units without affecting supply of minimum demand.

Avoid selecting smaller units to closely fit load curve.

13

Meeting Load:

The best method to meet load requirements on power station is to interconnect two different

power stations in parallel as follows:

More efficient Plant Carries Base load ( The unvarying load on the load curve ).

-- Generally thermal & nuclear power stations.

Less efficient Plant Carries Peak load (Various load peak demands on the load curve).

-- Generally Hydro Pumped Storage & Gas Turbine power stations.

Careful study of load curves must be undertaken before deciding which type of station will be

used for what purpose as this is greatly dependent on environmental issues and availability of fuel

used by a particular power station.

Power Grid for Meeting Variable Load

The power grid is constructed by connecting several generating stations together in parallel. This

method has helped solve most transmission and distribution problems facing power engineers.

Below are the advantages of using a power grid:

Economical operation:

Sharing of load among stations allows for more efficient stations to work constantly at high load

factors and less efficient stations to be used for peak supply only.

Increased diversity factor:

Different stations have different load curves thus the total maximum demand of the system is

decreased, thus effectively increasing the diversity factor of the system.

Reduces Plant Reserve Capacity:

The stand-by capacity required of individual plants is reduced when they are interconnected in a

grid.

Increased reliability:

If major breakdown occurs on one station, supply is maintained by other stations.

14

Exchange of peak loads:

Excess load can be shared from highly stressed plants to plant with lower peak loads ( Identified

from load curves ).

Older plants can still be used:

Older plants which are less efficient can still be used to carry peak loads of short.

Protection and Controls Necessary for Variable Load or

Load Variation:

Following protection/controls have significant influence:

Prime mover/energy supply system

turbine over speed control

turbine under frequency protection

power plant auxiliaries protection

Generator and excitation system

loss-of-excitation relay

under/over excitation limiter

volts/Hz limiter and protection

Electrical network

transmission and distribution system relays

under frequency and under voltage load shedding relays

You might also like

- PMP Formulae & Tips Cheat SheetDocument5 pagesPMP Formulae & Tips Cheat Sheetbhaveshkumar78100% (8)

- Concrete CoolingDocument19 pagesConcrete CoolingAbdulrahman AlnagarNo ratings yet

- Voltage and Reactive Power ControlDocument34 pagesVoltage and Reactive Power Controlpsmeee100% (1)

- Reactive PowerDocument177 pagesReactive PowerSalih Ahmed ObeidNo ratings yet

- Reactive Power ControlDocument183 pagesReactive Power ControlAmberMeerabNo ratings yet

- Electrical Power SystemsDocument14 pagesElectrical Power SystemsEternalOOOSunshine100% (1)

- PSP Notes For 5 QuestionsDocument115 pagesPSP Notes For 5 Questionspratik100% (3)

- Electricity Pricing and Generation Tariff - PMI - 21.11.2008Document46 pagesElectricity Pricing and Generation Tariff - PMI - 21.11.2008SamNo ratings yet

- F0358 CMM 010Document164 pagesF0358 CMM 010MJI EUWNo ratings yet

- Active Power Line Conditioners: Design, Simulation and Implementation for Improving Power QualityFrom EverandActive Power Line Conditioners: Design, Simulation and Implementation for Improving Power QualityRating: 5 out of 5 stars5/5 (1)

- Traveling WaveDocument59 pagesTraveling WaveMohit Kumar ChowdaryNo ratings yet

- Psoc PDFDocument130 pagesPsoc PDFshree_rs81No ratings yet

- Power System TransientsDocument11 pagesPower System TransientsKhairul AshrafNo ratings yet

- 007d Schneider Electric Reclosers Loop Automation Classic Intelligent 1 - 1Document31 pages007d Schneider Electric Reclosers Loop Automation Classic Intelligent 1 - 1César Bolaños QuirósNo ratings yet

- Eee-Viii-power System Operation and Control (06ee82) - NotesDocument138 pagesEee-Viii-power System Operation and Control (06ee82) - Noteskeerthanavijaya100% (3)

- HVDC Transmission SystemDocument77 pagesHVDC Transmission SystemSourin BisalNo ratings yet

- Internal Procedure For Operating State GridDocument71 pagesInternal Procedure For Operating State GridSiddharth Bhawsar100% (1)

- Effect of Load Shedding Strategy On Interconnected Power Systems Stability When A Blackout OccursDocument6 pagesEffect of Load Shedding Strategy On Interconnected Power Systems Stability When A Blackout OccursMoon3pellNo ratings yet

- Adaptive Relaying For Power System Protection: Department of Electrical and Electronics EngineeringDocument12 pagesAdaptive Relaying For Power System Protection: Department of Electrical and Electronics EngineeringJayanth BhargavNo ratings yet

- 100 QuestionsDocument3 pages100 QuestionsprashantshivanagiNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Protection Technologies of Ultra-High-Voltage AC Transmission SystemsFrom EverandProtection Technologies of Ultra-High-Voltage AC Transmission SystemsNo ratings yet

- Power System PlanningDocument13 pagesPower System PlanningAncy VargheseNo ratings yet

- Welcome To A Presentation On: "Transmission-An Over View" BY A.Sai Prasad Sarma Retd. Ce/AptranscoDocument189 pagesWelcome To A Presentation On: "Transmission-An Over View" BY A.Sai Prasad Sarma Retd. Ce/AptranscoElwasila100% (1)

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsFrom EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNo ratings yet

- Power System Operation and Control NotesDocument130 pagesPower System Operation and Control NotesParimal PatelNo ratings yet

- Power OscillationsDocument54 pagesPower OscillationsVijay RohillaNo ratings yet

- Cell Organelles - NotesDocument3 pagesCell Organelles - NotesJay R ChivaNo ratings yet

- EE1402 Power System Protection and SwitchgearDocument8 pagesEE1402 Power System Protection and Switchgearmoonsoon_j100% (1)

- Interconnected SystemDocument17 pagesInterconnected SystemChowdhury, A HasibNo ratings yet

- Power System Stability Question PaperDocument8 pagesPower System Stability Question PaperMousa Dhrgham100% (1)

- Voltage Collapse: M. H. SadeghiDocument31 pagesVoltage Collapse: M. H. Sadeghiken84hnNo ratings yet

- EHVAC NotesDocument36 pagesEHVAC NotesVenkatNo ratings yet

- STATCOM Review PDFDocument6 pagesSTATCOM Review PDFMoataz JabarNo ratings yet

- Wires and Cables PDFDocument14 pagesWires and Cables PDFRomel Panis88% (8)

- M.E.Electrical Power System - 2 PDFDocument32 pagesM.E.Electrical Power System - 2 PDFAnonymous 9VcxlFErfNo ratings yet

- Building Services AssignmentDocument19 pagesBuilding Services AssignmentRoushell KhanNo ratings yet

- Methods for Increasing the Quality and Reliability of Power System Using FACTS DevicesFrom EverandMethods for Increasing the Quality and Reliability of Power System Using FACTS DevicesNo ratings yet

- Power System Interview QuestionDocument10 pagesPower System Interview QuestionTanuja Singh100% (1)

- Integration of Green and Renewable Energy in Electric Power SystemsFrom EverandIntegration of Green and Renewable Energy in Electric Power SystemsNo ratings yet

- 590p Trips and Fault Finding Sds Quick GuidesDocument19 pages590p Trips and Fault Finding Sds Quick GuidesHitesh Panigrahi100% (1)

- 3.6-PSOC Optimized PDFDocument68 pages3.6-PSOC Optimized PDFN R SHEKARNo ratings yet

- Substation Switching SchemeDocument13 pagesSubstation Switching Schememehrbloor@gmail.comNo ratings yet

- Utilization of Electrical Energy (1-100) 11Document100 pagesUtilization of Electrical Energy (1-100) 11Gopala Krishna YadavNo ratings yet

- Selection of Power Rating of MotorDocument6 pagesSelection of Power Rating of MotorSEC ExamcellNo ratings yet

- Economic Operation of Power SystemsDocument45 pagesEconomic Operation of Power SystemsDogbey BrightNo ratings yet

- EE6603-Power System Operation and ControlDocument23 pagesEE6603-Power System Operation and ControlJegan8586100% (1)

- EE 442 642 IntroductionDocument14 pagesEE 442 642 IntroductionUSERNAME12340987No ratings yet

- Adaptive RelayingDocument9 pagesAdaptive RelayingDarshan RaghuNo ratings yet

- Automatic Generation ControlDocument5 pagesAutomatic Generation ControlMuhammad Nizamuddin100% (1)

- IDA - QuesbankDocument10 pagesIDA - QuesbankKavitha KaviNo ratings yet

- A Refined HVDC Control SystemDocument10 pagesA Refined HVDC Control Systemshawnr7376No ratings yet

- Switchgear and Protection: Seminar Adaptive RelayingDocument16 pagesSwitchgear and Protection: Seminar Adaptive RelayingrajumohandasNo ratings yet

- Basic Structure of A Power SystemDocument9 pagesBasic Structure of A Power Systembiruke6No ratings yet

- Symmetrical FaultsDocument11 pagesSymmetrical FaultsNeha RajputNo ratings yet

- PSOC Unit 3 Restructuring of Power System (Notes)Document11 pagesPSOC Unit 3 Restructuring of Power System (Notes)Tanmay GautamNo ratings yet

- Calculation of KvarDocument9 pagesCalculation of KvartwadintwadNo ratings yet

- O&M Substation Workshop BangaloreDocument2 pagesO&M Substation Workshop Bangalorejenopaul1No ratings yet

- NERC Balancing and Frequency Control 040520111Document53 pagesNERC Balancing and Frequency Control 040520111pongpumNo ratings yet

- EE2401 Power System Operation and ControlDocument93 pagesEE2401 Power System Operation and ControlPrasanth GovindarajNo ratings yet

- Power System Protection and Switchgear by B. S. Ravindranath Chander M. PhillipsDocument5 pagesPower System Protection and Switchgear by B. S. Ravindranath Chander M. PhillipsKiranNo ratings yet

- Theory of Arc Interruption in Circuit BreakersDocument128 pagesTheory of Arc Interruption in Circuit BreakersRahul MishraNo ratings yet

- PS7008 Smart GridDocument2 pagesPS7008 Smart GridLakshmi Zahara100% (1)

- Different Techniques of Reactive Power CompensationDocument2 pagesDifferent Techniques of Reactive Power CompensationJagdeep Singh0% (1)

- 228 Power System ProtectionDocument2 pages228 Power System ProtectionRamesh Prajapat100% (1)

- Advertisement PlanDocument3 pagesAdvertisement PlanAreeba Mushtaq AhmedNo ratings yet

- B2B Project Maersk Line (Things Assigned)Document2 pagesB2B Project Maersk Line (Things Assigned)Areeba Mushtaq AhmedNo ratings yet

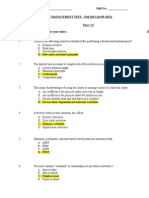

- Name: - Roll No.: - PROJECT MANAGEMENT TEST - Fall 2012 (24-09-2012) Part "A"Document8 pagesName: - Roll No.: - PROJECT MANAGEMENT TEST - Fall 2012 (24-09-2012) Part "A"Areeba Mushtaq AhmedNo ratings yet

- Booking Confirmation: Bed in 8 Bed Mixed Dormitory RoomDocument1 pageBooking Confirmation: Bed in 8 Bed Mixed Dormitory RoomAreeba Mushtaq AhmedNo ratings yet

- PMP Cheat SheetDocument2 pagesPMP Cheat SheetsaravaNo ratings yet

- Factor Analysis Using SPSS: ExampleDocument14 pagesFactor Analysis Using SPSS: ExampleGovindamal ThangiahNo ratings yet

- ConflictsDocument16 pagesConflictsAreeba Mushtaq AhmedNo ratings yet

- Chap 008Document43 pagesChap 008Areeba Mushtaq AhmedNo ratings yet

- ch15 PMPDocument41 pagesch15 PMPMohyuddin A MaroofNo ratings yet

- Faculty of Business and Accountancy University Malaya: CMGB 6103 Research Methods in BusinessDocument5 pagesFaculty of Business and Accountancy University Malaya: CMGB 6103 Research Methods in BusinessAreeba Mushtaq AhmedNo ratings yet

- Method StudyDocument23 pagesMethod StudyAreeba Mushtaq AhmedNo ratings yet

- University of Nebraska-Lincoln College of Business AdministrationDocument12 pagesUniversity of Nebraska-Lincoln College of Business AdministrationAreeba Mushtaq AhmedNo ratings yet

- EngroDocument73 pagesEngrogoldenguy90100% (3)

- Final Shan ProjectDocument36 pagesFinal Shan ProjectAreeba Mushtaq AhmedNo ratings yet

- Chapter Electric MotorsDocument24 pagesChapter Electric MotorsDenstar Ricardo SilalahiNo ratings yet

- Mem (Electrical) Spring 2013 Semester: Em-505: Operations Research Assignment I QUESTION 1 (B & D Only)Document1 pageMem (Electrical) Spring 2013 Semester: Em-505: Operations Research Assignment I QUESTION 1 (B & D Only)Areeba Mushtaq AhmedNo ratings yet

- Factors Influencing Word of Mouth in Malaysia-The Malaysian Airline SystemsDocument2 pagesFactors Influencing Word of Mouth in Malaysia-The Malaysian Airline SystemsAreeba Mushtaq AhmedNo ratings yet

- Project Menagement Frame Work & ToolsDocument27 pagesProject Menagement Frame Work & ToolsAreeba Mushtaq AhmedNo ratings yet

- Overdurf, Silverthorn, Beyond Words, Languaging Change Through The Quantum FieldDocument36 pagesOverdurf, Silverthorn, Beyond Words, Languaging Change Through The Quantum FieldOscar Federico Spada100% (6)

- Total Quality ManagementDocument23 pagesTotal Quality ManagementAreeba Mushtaq AhmedNo ratings yet

- Mem (Electrical) Spring 2013 Semester QUESTION 1 (A & C Only)Document1 pageMem (Electrical) Spring 2013 Semester QUESTION 1 (A & C Only)Areeba Mushtaq AhmedNo ratings yet

- Or Lecture06Document26 pagesOr Lecture06Areeba Mushtaq AhmedNo ratings yet

- Car PicDocument1 pageCar PicAreeba Mushtaq AhmedNo ratings yet

- Chapter Two Discussion QuestionsDocument4 pagesChapter Two Discussion QuestionsAreeba Mushtaq AhmedNo ratings yet

- Lect #3 A&fmDocument1 pageLect #3 A&fmAreeba Mushtaq AhmedNo ratings yet

- Boost Morale With An Injection of FunDocument37 pagesBoost Morale With An Injection of FunAreeba Mushtaq AhmedNo ratings yet

- Case Study Analysis SPDMDocument15 pagesCase Study Analysis SPDMAreeba Mushtaq AhmedNo ratings yet

- TQM9Document50 pagesTQM9Areeba Mushtaq AhmedNo ratings yet

- Bench MarkingDocument6 pagesBench MarkingAreeba Mushtaq AhmedNo ratings yet

- Cgb-2 K Cgw-2 Cgs-2 Csz-2 GBDocument24 pagesCgb-2 K Cgw-2 Cgs-2 Csz-2 GBFlorin StanciuNo ratings yet

- Unit 9 - Optical AmplifierDocument55 pagesUnit 9 - Optical Amplifiervidyasawant2012No ratings yet

- Molecular Orbital TutorialDocument28 pagesMolecular Orbital TutorialehmedNo ratings yet

- Operation and Service Everfresh Controlled Atmosphere: 69Nt40-489-100 SeriesDocument178 pagesOperation and Service Everfresh Controlled Atmosphere: 69Nt40-489-100 SeriesHéctor AraujoNo ratings yet

- Waste Materials Storage and Disposition Written Test 1Document4 pagesWaste Materials Storage and Disposition Written Test 1GENEBEI FAITH SAJOLANNo ratings yet

- Chemical Kinetics: Practice ExamplesDocument31 pagesChemical Kinetics: Practice ExamplesJudith Del Valle MorejonNo ratings yet

- Bachelor of Engineering (Hons) Chemical Course OutlineDocument2 pagesBachelor of Engineering (Hons) Chemical Course OutlineWan Mohammad Faris FahmiNo ratings yet

- Alabama Power Plant The Right Tree in The Right PlaceDocument4 pagesAlabama Power Plant The Right Tree in The Right PlaceAna GoodNo ratings yet

- User Manual: T6DBG721N T6DBG720NDocument26 pagesUser Manual: T6DBG721N T6DBG720NViorica TrohinNo ratings yet

- Pure Epoxy Primer (Zinc and Lead Free) 1 X 50 M Micaceous Iron Oxide 2 Pack Epoxy 2 X 100 M Polyurethane-Acrylic 1 X 50 M Total 300 MDocument2 pagesPure Epoxy Primer (Zinc and Lead Free) 1 X 50 M Micaceous Iron Oxide 2 Pack Epoxy 2 X 100 M Polyurethane-Acrylic 1 X 50 M Total 300 MTrịnh Đức HạnhNo ratings yet

- Bahrain World Trade Center Integrated Wind TurbinesDocument73 pagesBahrain World Trade Center Integrated Wind TurbinesMaisie SuyatNo ratings yet

- BLW29Document12 pagesBLW29glow4No ratings yet

- Methods in Environmental Analysis III - ElectrogravimetryDocument20 pagesMethods in Environmental Analysis III - ElectrogravimetryseyseaNo ratings yet

- TD-esc-02-De-En-16-010 Rev000 Morgan Rekofa Slip Ring Unit LabelDocument2 pagesTD-esc-02-De-En-16-010 Rev000 Morgan Rekofa Slip Ring Unit LabelFelipe SilvaNo ratings yet

- CT/PT Selection Chart: Applicable Standard (A) (V) CT's Qty PT PT's Part # PT's Qty Service Size CT CT's Part # PhaseDocument1 pageCT/PT Selection Chart: Applicable Standard (A) (V) CT's Qty PT PT's Part # PT's Qty Service Size CT CT's Part # PhasePrabakar PNo ratings yet

- Thermal Power Plant: " " NTPC (Dadri)Document17 pagesThermal Power Plant: " " NTPC (Dadri)Kulvinder SinghNo ratings yet

- O Level Physics 2018 Past PaperDocument20 pagesO Level Physics 2018 Past PaperfordalNo ratings yet

- Laydown Light Towers: LED/Metal Halide/LED BalloonDocument2 pagesLaydown Light Towers: LED/Metal Halide/LED BalloonAugusto BellezaNo ratings yet

- Shell Gadinia s3 40 PDFDocument2 pagesShell Gadinia s3 40 PDFNatália ValeriaNo ratings yet

- Downstream - Processing - Lecture 5rnjDocument8 pagesDownstream - Processing - Lecture 5rnjqwertyuNo ratings yet

- Ega125 gr05 Emsc SG 0001 20200925Document238 pagesEga125 gr05 Emsc SG 0001 20200925api-292325707No ratings yet

- ασκήσεις υδραυλικων λαδιουDocument160 pagesασκήσεις υδραυλικων λαδιουchristodoulos charalambousNo ratings yet

- BBBV3 ForegroundReading Solar UPS MarineDocument7 pagesBBBV3 ForegroundReading Solar UPS MarineSaibal BhattacharyyaNo ratings yet

- Mooring System Analysis of Multiple Wave Energy Converters in A Farm ConfigurationDocument10 pagesMooring System Analysis of Multiple Wave Energy Converters in A Farm ConfigurationAleix Jesus Maria ArenasNo ratings yet