Professional Documents

Culture Documents

Sika Powerfix 1

Uploaded by

Hakiki SaputraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sika Powerfix 1

Uploaded by

Hakiki SaputraCopyright:

Available Formats

Technical Data Sheet

Edition 1, 2003

Identification no. 20.005

Version no. 0010

Sika Powerfix 1

1/3

Sika Powerfix 1 1

C

o

n

s

t

r

u

c

t

i

o

n

Sika Powerfix

1

Fast Curing Anchoring Adhesive

Description Solvent and styrene free polyester-based two-component anchoring adhesive for

fixing anchor and rein stacker bars into a wide range of materials.

Uses As a fast curing anchoring adhesive for all grades of

rebars

threaded rods

bolts

and special fastening systems into the following base material

concrete

hard natural stone

solid rock

hollow and solid masonry

Advantages supplied in ready to use cartridge

low sensitivity to mixing errors

excellent adhesion

non sag properties

fast curing

styrene free

low odour

low waste

standard sealant cartridge guns can be used

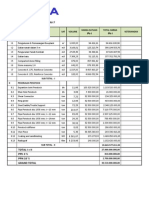

Load Capacity For all threaded rods

Stud

diamet

er

d(mm)

Hole

diamet

er

d

o

(mm)

Hole

dept

h

h

o

(mm)

Require

d edge

distanc

e

C

cr

(mm)

Require

d

anchor

spacing

S

cr

(mm)

Min

concret

e

thicknes

s

h

min

(mm)

Characteri

stic

load in min

25N/mm

concrete

N

RK

(kN)

Recommen

ded

load in min

25N/mm

concrete

N

rec

(kN)

8 10 80 120 80 110 14.9 5.0

10 12 90 135 90 120 24.6 8.2

12 14 110 165 110 140 31.3 10.4

18 18 125 190 125 165 44.0 14.7

20 24 170 255 170 220 63.2 21.6

24 26 210 315 210 270 80.3 26.8

Load capacity data for reinforcing bar anchors:

Minimum hole diameter:

Bar diameter, d (mm) 6 8 10 12 14 16 20 25

Hole diameter, do (mm) 8 10 12 14 18 20 25 32

Minimum anchor embedment, hmin (mm) 60 80 90 100 115 130 140 150

Back

2/3

2 Sika Powerfix 1

Characteristic ultimate tensile load NRK = hef - 50

2.5

Characteristic ultimate shear load VRK = 0.5 hef.do.fcm

1000

Reduction factors for close edge distances and anchor spacing:

Tension and shear load reduction factor for close hole spacing

Smin = 0.50 hef ( 16 mm), Smin = 0.25 hef ( > 16 mm), Smax = 1 hef

Rfs = 0.4 + [0.6 (S / hef)] < 1.0

Tension load reduction factor for close edge distance

Cmin = 0.5 hef, Cmax = 1.5 hef

RfcN = 0.4 + [0.4 (C / hef)] < 1.0

Shear load reduction factor for close edge distance

Cmin = 0.50 hef, Cmax = 1.5 hef

RfcV = 0.25 + [0.5 (C / hef)] < 1.0

Notes:

1. All data assumes sound 25 MPa concrete

2. All data assumes concrete is in a dry condition and holes are thoroughly

cleaned.

3. The characteristic failure loads do not have factors of safety applied. The

characteristic failure loads assume no close spacing and close edge

reduction factors. Factors of safety of 2 or 3 are typically applied to

calculated NRK and VRK loads for reinforcing bar.

4. This information has been provided to assist qualified structural engineers

or other suitably skilled persons to assess anchorage requirements when

using Sika PowerFix-1. The designer is responsible for ensuring compliance

with all relevant Standards, Codes of Practices, Building Regulations,

Statutes, etc. All information is given as a guide only and it is the

responsibility of the designer to ensure that the anchors are appropriate for

their intended usage.

Notation:

hef = effective anchorage depth (mm)

NRK = anchor characteristic load under tension (kN)

VRK = anchor characteristic load under shear (kN)

do = hole diameter (mm)

fcm = concrete compressive strength (N/mm)

S = distance between anchors (mm)

C = distance of anchor from free edge (mm)

Cleaning Clean tools immediately after use with colma cleaner. Hardened material can

only be mechanically re-moved.

Cautions May cause sensitization by skin contact. Wear suitable gloves and eye/face

protection.

Use only in well ventilated areas.

Comp.A : Non-hazardous

Comp.B : Non-hazardous

Limitations Sika PowerFix-1 has excellent adhesion on porous, dry surfaces. Do not use

Sika PowerFix-1 on non-porous surfaces. Do not apply Sika PowerFix-1 to

surfaces with standing water on them. Sika PowerFix-1 will adhere to damp

surface but the tensile and shear load capacities will be reduced.

When using compressed air to clean out drilled holes for starters and bolts it is

essential that the hose be pushed to the base of the hole. This will ensure that

any dust is blown up to the top and out of the hole. Check that the compressed

air is clean and oil free.

3/3

3 Sika Powerfix 1

Technical Data

Colour

Comp. A : white

Comp. B : black

Comp. A+B mixed : light grey

Consistency Comp. A+ B mixed : creamy paste

Density 1,6 kg/l (mixed)

Application

Temperature

Substrate and ambient : +5C to +30C

Tack Free and Curing

Times

Application temperature Gel time Curing time

(tgel) (tour)

30C 3 min 25 min

20C 7 min 50 min

10C 22 min 150 min

5C 30 min 200 min

Shelf Life 12 months when unopened and stored at cool conditions out of direct sunlight

Packaging 300 ml cartridge

Disclaimer

In Technical Data Sheets

The information, and, in particular the recommendations relating to the application and end-use of Sika products are given in good faith based on

Sikas current knowledge and experience of the product when properly stored, handled and applied under normal conditions. In practice, the

differences in materials, substrates and actual site conditions are such that no warranty in respect of merchantability or of fitness for a particular

purpose, nor any liability arising out of any legal relationship whatsoever, can be inferred either from this information, or from any written

recommendations, or from any other advice offered. The proprietary rights of third parties must be observed. All orders are accepted subject to our

current terms of sales and delivery. Users should always refer to the most recent issue of the Technical Data Sheet for the product concerned, copies

of which will be supplied on request.

PT. Sika Indonesia

Jl. Raya Cibinong- Bekasi km.

20

Limusnunggal - Cileungsi

BOGOR 16820 - Indonesia

Tel. +62 21 8230025

Fax. +62 21 8230026

www.sika.co. id

e-mail: marketing@sika.co.id

Branches

Surabaya,

Tel : 031-8420377

Fax : 031-8495018

Medan,

Tel : 061-4149224,

4552441

Fax : 061-4150805

Batam,

Tel : 0778-424928

Fax : 0778-426913

Sub Distributor

Bandung, Tel : 022-6018161, Fax : 022-6018272

Denpasar, Tel : 0361-235998,235973,237622, Fax:0361-237053

Makassar, Tel : 0411- 859147, 858527, Fax : 0411-858527

Balikpapan, Tel : 0542-411258, Fax : 0542-412230

Pekanbaru, Tel : 0761-46993,47677, Fax : 0761-45112

Duri/Dumai. Tel : 0765-595259, Fax : 0765-91135

Palembang, Tel : 0711-351523, Fax : 0711-369858

Palu, Tel : 0451-454855, 422122, Fax : 0451-454855

C

o

n

s

t

r

u

c

t

i

o

n

You might also like

- Sika Anchorfix - 1: Fast Curing Anchoring AdhesiveDocument6 pagesSika Anchorfix - 1: Fast Curing Anchoring Adhesiveeye4aneye1989No ratings yet

- Sikaflex 1ADocument4 pagesSikaflex 1Athe pilotNo ratings yet

- Sika CarbodurDocument3 pagesSika CarbodurHakiki SaputraNo ratings yet

- Sikaflex ProDocument4 pagesSikaflex ProAmr Adel HameedNo ratings yet

- Sikaflex® Construction AP: Product Data SheetDocument4 pagesSikaflex® Construction AP: Product Data Sheetneo2jatiNo ratings yet

- Sikaflex ConstructionapDocument4 pagesSikaflex ConstructionapYe Min AungNo ratings yet

- Sikaflex® Construction+: Product Data SheetDocument4 pagesSikaflex® Construction+: Product Data SheetM. KumaranNo ratings yet

- Sikaflex 11FCDocument3 pagesSikaflex 11FCthe pilotNo ratings yet

- Sikahyflex 140 Construction Pds enDocument4 pagesSikahyflex 140 Construction Pds enReno MaulanaNo ratings yet

- Sikaflex® PRO-3 WF: Product Data SheetDocument4 pagesSikaflex® PRO-3 WF: Product Data Sheetsugiarto budiNo ratings yet

- SikaflexPRO TdsDocument6 pagesSikaflexPRO TdsidontlikeebooksNo ratings yet

- Sikaflex Construction DDocument3 pagesSikaflex Construction Dthe pilotNo ratings yet

- PDS - Sikaflex®-11 FC+ PDFDocument5 pagesPDS - Sikaflex®-11 FC+ PDFblancogonzalosNo ratings yet

- Sikaflex - 11 FC+Document5 pagesSikaflex - 11 FC+emmanuel nwankwoNo ratings yet

- SikaMembran UniversalDocument2 pagesSikaMembran UniversalColégio MilitarNo ratings yet

- Sikaflex® Construction: Product Data SheetDocument4 pagesSikaflex® Construction: Product Data SheetFritz NatividadNo ratings yet

- Flex - 11fc+ - Icure 0211Document5 pagesFlex - 11fc+ - Icure 0211Gabz WilliamsNo ratings yet

- E - 9039 - Sika - Per - 3326 EG-HDocument4 pagesE - 9039 - Sika - Per - 3326 EG-HBogdan DavidescuNo ratings yet

- Sikaflex®-11 FC+: Product Data SheetDocument5 pagesSikaflex®-11 FC+: Product Data SheetYousef HalasehNo ratings yet

- Sika Construction Data SheetDocument4 pagesSika Construction Data SheetsathiyanNo ratings yet

- Sikahyflex®-140 Construction: Product Data SheetDocument4 pagesSikahyflex®-140 Construction: Product Data SheetNicholas WashingtonNo ratings yet

- Sikaflex 140construction en ID 02 2023 1 1 PDFDocument4 pagesSikaflex 140construction en ID 02 2023 1 1 PDFcahyo hutomoNo ratings yet

- Polymer Pin Insulator SpecificationDocument14 pagesPolymer Pin Insulator SpecificationdamlanNo ratings yet

- Sikaflex Construction (J) SealantDocument4 pagesSikaflex Construction (J) SealantFronica Litad SamionNo ratings yet

- Sikaflex® PRO-3: Product Data SheetDocument4 pagesSikaflex® PRO-3: Product Data SheetArrow LazarusNo ratings yet

- PDS - Sikaflex®-11 FC+Document4 pagesPDS - Sikaflex®-11 FC+Mahmoud MohamedNo ratings yet

- Sika PDS - E - Sikaflex Construction (NWE)Document4 pagesSika PDS - E - Sikaflex Construction (NWE)Pisut LeelalumlertNo ratings yet

- TDS SikaDocument4 pagesTDS SikaBara GailNo ratings yet

- Sika Top Seal 107 BRDocument2 pagesSika Top Seal 107 BRthe pilotNo ratings yet

- IsoTek Manual 8-18-14Document13 pagesIsoTek Manual 8-18-14usamazarifehNo ratings yet

- Sika Plan 14.6Document3 pagesSika Plan 14.6the pilotNo ratings yet

- Sikaflex® PRO-3: Product Data SheetDocument4 pagesSikaflex® PRO-3: Product Data SheetLovely BoutikNo ratings yet

- Sikadur - 42 HS: High Strength Pourable Epoxy GroutDocument4 pagesSikadur - 42 HS: High Strength Pourable Epoxy GroutMuhammad Azlan AhmadNo ratings yet

- Sikaflex® PRO-3: Product Data SheetDocument4 pagesSikaflex® PRO-3: Product Data Sheetislam mohamedNo ratings yet

- Sikaflex-Construction (D)Document4 pagesSikaflex-Construction (D)Akif MehmoodNo ratings yet

- Section-Viii: Composite Long Rod InsulatorDocument33 pagesSection-Viii: Composite Long Rod Insulatorsaravanan jNo ratings yet

- SikaWrap-231 C PDFDocument3 pagesSikaWrap-231 C PDFDarwin SyahputraNo ratings yet

- Sikaflex 252Document2 pagesSikaflex 252alexcus1539No ratings yet

- Method Statement For GroutingDocument43 pagesMethod Statement For GroutingMohd Syaril Mohd Ali100% (5)

- Sikadur 30Document3 pagesSikadur 30Hakiki SaputraNo ratings yet

- Sika AnchorFix 3001 (A B) EDocument4 pagesSika AnchorFix 3001 (A B) EfarooqNo ratings yet

- 08 - 1 Section VIII Composite Longrod Insulator, Rev-0 (July'2022) - 1Document27 pages08 - 1 Section VIII Composite Longrod Insulator, Rev-0 (July'2022) - 1Jash PancholiNo ratings yet

- Sikaflex® Precast: Product Data SheetDocument4 pagesSikaflex® Precast: Product Data SheetRoyce MarchaNo ratings yet

- Sikaflex® Construction PLUS - PDSDocument4 pagesSikaflex® Construction PLUS - PDSAzhar ShaikhNo ratings yet

- Sikadur 752Document2 pagesSikadur 752Gry ArdiansyahNo ratings yet

- My Con Pds Sikadur 31 LPDocument3 pagesMy Con Pds Sikadur 31 LPmcwong_98No ratings yet

- Particular Specifications For Expanssion Joint Waterproofing - Sikadur CombiflexDocument5 pagesParticular Specifications For Expanssion Joint Waterproofing - Sikadur CombiflexEIL DORCNo ratings yet

- Sikadur - 42: Epoxy Resin Castable GroutDocument2 pagesSikadur - 42: Epoxy Resin Castable Groutthe pilotNo ratings yet

- SikaWrap Hex - 430G - VPDocument3 pagesSikaWrap Hex - 430G - VPHakiki SaputraNo ratings yet

- Sikaflex PRO 3 WFDocument4 pagesSikaflex PRO 3 WFfrahliaNo ratings yet

- Sika PDS - E - Sikadur - 42 TH PDFDocument2 pagesSika PDS - E - Sikadur - 42 TH PDFlwin_oo2435100% (1)

- Sika Cavity Drainage SystemDocument2 pagesSika Cavity Drainage SystemtonjouqouqueNo ratings yet

- PDS - SikaSeal-402 Fillerboard MYDocument2 pagesPDS - SikaSeal-402 Fillerboard MYSiji OktoberNo ratings yet

- SikaDur 53Document2 pagesSikaDur 53pnNo ratings yet

- Sikasil PoolDocument3 pagesSikasil PoolA GlaumNo ratings yet

- Sika® Rokkon C-Id: Product Data SheetDocument2 pagesSika® Rokkon C-Id: Product Data Sheetal mukarramahNo ratings yet

- Strengthen Concrete and Masonry with High-Strength CFRPDocument8 pagesStrengthen Concrete and Masonry with High-Strength CFRPGoranPerovicNo ratings yet

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIFrom EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IITatsuki OhjiNo ratings yet

- IRCHRBJournal Jan Jun 13Document84 pagesIRCHRBJournal Jan Jun 13Himagiri Subramaniam100% (1)

- 03 Denah LT AtapDocument1 page03 Denah LT AtapHakiki SaputraNo ratings yet

- Medium Tensile Steel A Is I 1045Document2 pagesMedium Tensile Steel A Is I 1045Madhav RajpurohitNo ratings yet

- SikaWrap Hex - 230CDocument3 pagesSikaWrap Hex - 230CHakiki SaputraNo ratings yet

- Plastiment RTD-01: Water Reducing and Set RetardingDocument2 pagesPlastiment RTD-01: Water Reducing and Set RetardingBoby culiusNo ratings yet

- Justek, Approval Material HowsolpanDocument5 pagesJustek, Approval Material HowsolpanHakiki SaputraNo ratings yet

- Facade Curtain Wall, Alexindo - Asahi MasDocument10 pagesFacade Curtain Wall, Alexindo - Asahi MasHakiki SaputraNo ratings yet

- (New) Facade Curtain Wall, Asahi MasDocument16 pages(New) Facade Curtain Wall, Asahi MasHakiki SaputraNo ratings yet

- (New) Facade Curtain Wall, Asahi Mas PDFDocument16 pages(New) Facade Curtain Wall, Asahi Mas PDFHakiki SaputraNo ratings yet

- Sika AerDocument2 pagesSika AerBoby culiusNo ratings yet

- Plastiment RTD-01: Water Reducing and Set RetardingDocument2 pagesPlastiment RTD-01: Water Reducing and Set RetardingBoby culiusNo ratings yet

- 11final Pro - OucpredDocument44 pages11final Pro - OucpredHakiki SaputraNo ratings yet

- FM-LiftSpec by Imperial CollegeDocument182 pagesFM-LiftSpec by Imperial CollegeKelvin Chih-Yong LeeNo ratings yet

- SikaWrap Hex - 230CDocument3 pagesSikaWrap Hex - 230CHakiki SaputraNo ratings yet

- Sika Fume - PDSDocument3 pagesSika Fume - PDSHakiki SaputraNo ratings yet

- Larihan MatematikanvcncvncgmnDocument1 pageLarihan MatematikanvcncvncgmnHakiki SaputraNo ratings yet

- SikaWrap Hex - 430G - VPDocument3 pagesSikaWrap Hex - 430G - VPHakiki SaputraNo ratings yet

- Sikadur 30Document3 pagesSikadur 30Hakiki SaputraNo ratings yet

- Acacia Suites: - With Anti Bacterial GlazeDocument3 pagesAcacia Suites: - With Anti Bacterial GlazeHakiki SaputraNo ratings yet

- Spec2500 A8eDocument6 pagesSpec2500 A8eHakiki SaputraNo ratings yet

- BoQ Revisi 02 07Document1 pageBoQ Revisi 02 07Hakiki SaputraNo ratings yet

- Apophthegmata Patrum ArticleDocument3 pagesApophthegmata Patrum ArticleGeorge FaragNo ratings yet

- 2 Thessalonians 3:1-18 Dennis MockDocument3 pages2 Thessalonians 3:1-18 Dennis Mockapi-26206801No ratings yet

- Gajendra's PrayersDocument4 pagesGajendra's PrayersAnna NightingaleNo ratings yet

- Prada (Compatibility Mode)Document35 pagesPrada (Compatibility Mode)Tanvi MishraNo ratings yet

- Grade 7 Music Stage 3Document4 pagesGrade 7 Music Stage 3Farrah MacalinoNo ratings yet

- Constantinople's Vampiric Power StruggleDocument2 pagesConstantinople's Vampiric Power StruggleyrtalienNo ratings yet

- Maps Navigation BasicsDocument36 pagesMaps Navigation Basicsvergie andresNo ratings yet

- MMW Module 1 - Patterns, Transformation & FractalsDocument17 pagesMMW Module 1 - Patterns, Transformation & Fractalscai8viaNo ratings yet

- History of BalletDocument3 pagesHistory of BalletAaron ScottNo ratings yet

- Guide To SOP Image Layout Image Manipulation in PhotoshopDocument34 pagesGuide To SOP Image Layout Image Manipulation in PhotoshopUtpal YadulNo ratings yet

- BAB 1 - Analisis Perilaku BiayaDocument31 pagesBAB 1 - Analisis Perilaku BiayaKartika Wulandari IINo ratings yet

- Hamartia and Hubris in Oedipus RexDocument5 pagesHamartia and Hubris in Oedipus RexAR MalikNo ratings yet

- Intellectual Property Law Course OutlineDocument2 pagesIntellectual Property Law Course OutlineShivam SinghNo ratings yet

- DragonBall Z D10Document102 pagesDragonBall Z D10Aaron Puchalski100% (3)

- The Science Behind StorytellingDocument4 pagesThe Science Behind StorytellingKarloscedenoNo ratings yet

- My Drive - Google DriveDocument65 pagesMy Drive - Google DriveDraven WebbNo ratings yet

- Benefits of Gayatri Mantra, Chandi Homam, Dhanvanthri HomamDocument3 pagesBenefits of Gayatri Mantra, Chandi Homam, Dhanvanthri HomamVedic Folks0% (1)

- Pelli Choopulu - Breakdown Elements by SceneDocument132 pagesPelli Choopulu - Breakdown Elements by SceneNoble CreatureNo ratings yet

- Ricoh Error CodeDocument7 pagesRicoh Error CodeMarxe Ozil MurimiNo ratings yet

- The Susan B. Anthony Dollar Collector Checklist: Compliments of Littleton Coin Company, LLCDocument1 pageThe Susan B. Anthony Dollar Collector Checklist: Compliments of Littleton Coin Company, LLCosrulzNo ratings yet

- Mapeh-Arts: First Quarter - Week 8Document9 pagesMapeh-Arts: First Quarter - Week 8shang anneNo ratings yet

- Language Devices: Irony Onomatopoeia ImageryDocument1 pageLanguage Devices: Irony Onomatopoeia Imagerymonalisa samuddinNo ratings yet

- Reevaluatin The Compositional Process of Anton WebernDocument488 pagesReevaluatin The Compositional Process of Anton WebernSlobodan Marjanovic67% (3)

- Dphoto SyllabusDocument3 pagesDphoto Syllabusapi-262384001No ratings yet

- BT-BD 701 ManualDocument54 pagesBT-BD 701 ManualIvan BenginNo ratings yet

- Life in Coastal Plains and IslandsDocument8 pagesLife in Coastal Plains and IslandsRamani100% (1)

- English 200Document3 pagesEnglish 200Rhom Lloyd OduyanNo ratings yet

- Christian Marclay Discography DocumentDocument41 pagesChristian Marclay Discography DocumentMikelRNietoNo ratings yet

- Grimlores Grimoire v101Document54 pagesGrimlores Grimoire v101Nathan Jensen50% (4)

- Lif Co Books PDFDocument8 pagesLif Co Books PDFashokj1984100% (1)