Professional Documents

Culture Documents

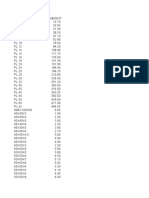

Vice President Distribution Supply Chain Logistics in Houston TX Resume Herbert Jahn

Uploaded by

HerbertJahn0 ratings0% found this document useful (0 votes)

167 views3 pagesHerbert Jahn is a Supply Chain / Logistics leader who has consistently contributed to the success of large, complex organizations in diverse industries.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHerbert Jahn is a Supply Chain / Logistics leader who has consistently contributed to the success of large, complex organizations in diverse industries.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

167 views3 pagesVice President Distribution Supply Chain Logistics in Houston TX Resume Herbert Jahn

Uploaded by

HerbertJahnHerbert Jahn is a Supply Chain / Logistics leader who has consistently contributed to the success of large, complex organizations in diverse industries.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

1 | P a g e

Herbert (Herb) C. Jahn

herbjahn1@gmail.com

(361)-463-6811

Professional Summary

Supply Chain/Logistics leader who has consistently contributed to the success of large, complex organizations in diverse

industries by quickly evaluating current business operations and re-engineering the processes necessary to achieve short

and long term financial goals, designing and integrating appropriate technology to support key business processes; and,

providing change management/leadership to advance the organization to the new can be position in the marketplace-

all to the benefit of the customer, workforce, and the entire organization.

Areas of Strengths and Expertise

Supply Chain Management Logistics Operations Distribution Operations

Distribution Network Design P&L Management Process Re-engineering

Warehouse design/re-engineering New Construction/Retro-fits ROI Analysis

Change Management Performance Optimization Labor Standards Design

Multi-Site Distribution Management WMS Re-design /Implementation Labor Standards Implementation

Merger/Acquisition Integration Third Party Contracts (3PL) E-commerce Distribution

Continuous Improvement Business Re-engineering Reverse Logistics

Team Training/Development Vendor Management Business/Client Development

Union/Non-Union Workforces Automated/Non-Automated Systems Risk Management

Inventory Mgmt./optimization Customer Service Optimization Labor Maximization

Familiar w/SAP, ORACLE, IBM, JDA, Manhattan Assoc. and Videx software/interface

Professional Experience

Synergistics Group, Inc. 2006-Present

Signature Logistics, Inc. 1996-2013

Texas based consulting L.L.C organizations that provide services to Fortune 100 and other large, complex

organizations in the Distribution arena in a variety of industries including: Retail Food /Foodservice, Manufacturing

(food/beverage, equipment, textile, IS hardware), Telecommunications, E-Commerce Distribution (pharmaceutical

and hardware), Utilities (Power Plant, T&D), and third party logistics (3PL).

President

Provided re-engineered distribution network designs for transportation and warehouse operations to reduce

costs and improve customer service including new software designs needed to bridge operational gaps in in-

house mainframe systems (Oracle, SAP, and IBM) created by the new designs (including PC based bolt on

modules where necessary); plus, also supplied the change management resources to ensure the successful

adoption of all planned improvements by the workforce with minimal disruption to the business and customer.

Project Highlights

Implemented 15 major business re-engineering projects using proven process evaluation and

enhancement methodology and software to provide clients with an as is evaluation and an achievable

can be solution where all results had an ROI of less than 32 months and saving a total of $5.5 million

annualized.

Created over 20 distribution network designs for transportation and warehousing operations resulting in

reduced operating costs to clients of over $23 million/year and achieved customer service levels

exceeding 99.0% while achieving ROI in less than 32 months in each situation.

Created shared central parts distribution (CDC) for a six-state nuclear consortium, which reduced the

individual customers on-hand inventories from $110MM to less than $30MM. Negotiated a tax-free

designation for the CDC within the respective state for up to five years saving an additional $6.0MM per

year.

2 | P a g e

Project Highlights-Continued

Retained by an Integrated Logistics client to design enterprise distribution networks for 3PL warehousing

and transportation operations for their client companies. Efficiencies and related benefits to the client

companies overall performance resulted in contracts totaling $180 million being awarded to our

Integrated Logistics client. All three contracts were renewed after the initial 3 and 5 year terms

Designed bolt-on E-commerce systems solution for a Hardware client that interfaced with new internet

web site and IBM mainframe for order fulfillment of Web sales which increased overall store sales by 5%

in the first 12 months while E-commerce items experienced a net profit increase of 10% resulting in

bottom-line profit increase of $525,000.

Provided PC based distribution module for a Retail Textile Manufacturing client, which improved

production performance by 14%, operations performance by 38% and reduced inventory shrinkage from

8% to 1%. Total annualized savings $325,000.

Created PC based electronic data interface (EDI) in order to conduct wall-to-wall physical inventory for a

pharmaceutical E-commerce client and created a data file needed for their Oracle implementation. This

project reduced FTE count by 15% and increased productivity by 20%.

Designed bolt on distribution module that interfaced with Oracle mainframe and performed receiving,

put-away, letdown, order refill, replenishment, and inventory control for a pharmaceutical E-commerce

distribution client reducing FTE count by 18%, improving inventory integrity from 64.8% to 99.2% and

order fill accuracy from 98.2% to 99.8%.

Kraft Foodservice 1988-1996

Windsor, CT

Kraft Foodservice is a division of Kraft Foods Group, Inc. (NASDAQ: KRFT), North America's fourth largest consumer

packaged food and beverage company. Kraft Foodservice provides a diverse portfolio of brands, marketing and sales

expertise and resources to the U.S. and Canadian foodservice industry.

Branch President 1994-1996

National Sales & Operations Manager 1991-1994

Regional Operations Manager-Southern Region 1988-1991

After consistently exceeding expectations in the National and Regional positions, was promoted to President for the New

England distribution facility with full P&L responsibilities for sales, marketing, purchasing and distribution.

Highlights

Reversed 3 year loss of over $3 million to a $925k profit in less than 12 months and $2.8 million turn-

around in 24 months.

Increased sales by 15% in less than 24 months.

Increased gross profit per case by 13% and net profit by 22%.

Implemented preferred vendor programs, which reduced cost of goods by 6.3% in the first 12 months.

Decreased operational cost by 17% in the first 12 months.

Successfully implemented integration of $600 million foodservice acquisition into existing distribution

network in a 6 month period versus the Wall Street schedule of 2.5 years

Improved overall customer service levels from an average of 87% to 98.7% in 14 districts in a 24 month

period.

Implemented the merger of 5 districts into the remaining 37 districts thus reducing annual fixed costs by

$2.5 million and annual variable costs by $1.5 million.

Successfully integrated more than $300 million of new chain account business into several districts with

no drop in customer service rating of 98.7%.

3 | P a g e

H.E. B. Grocery Company 1980-1988

San Antonio, Texas

HEB Grocery Company, also known as H-E-B Grocery Stores, is a privately held supermarket chain based in San Antonio,

Texas, with more than 350 stores throughout the U.S. state of Texas, as well as in northern Mexico.

Director, Distribution Maintenance 1986-1988

Director, Frozen Food Distribution 1985-1986

Manager, MIS Distribution Operations 1983-1985

Manager, General Merchandise Distribution 1982-1983

Manager, Grocery Distribution 1980-1982

Held multiple manager and director level positions in distribution with responsibility for warehouse operations and

systems integration (including automated order systems and sort/pick/pack systems) at facilities that ranged in size

from 400 thousand square feet of warehouse space to 1.25 million square feet of warehouse space with sales volume of

$600 million to $1.2 billion.

Highlights

Successfully managed the construction of 300,000 square feet of distribution space, completing the

respective projects on time and on budget with no disruption in service levels.

Designated General Manager of the first ever in-house, third party, Material Handling distributorship

ever granted by Barrett Industries with first year revenue exceeding projection by 28% and company

savings of 33% for equipment purchases that previously were retail cost.

Achieved a high level of workforce engagement, which allowed successful implementation of

Engineered Labor Standards at assigned facilities while maintaining non-union status and the highest

employee satisfaction rating of any department since tracking was instituted (83% vs. next closest at

67%).

Successfully implemented the reengineering and reset of over 1 million sq. ft. of warehousing (Dry and

Refrigerated) in an 24 month period, which not only facilitated the roll-out of ELS but also deferred a

projected $3.7MM in capital expenditures, and improved the overall cost of operations by a combined

25.5% (12% for layout and 13.5% for ELS - $1.6 MM labor savings).

Converted 300,000 sq. ft. of leased warehousing space into a Forward Buy warehouse environment with

projected annual savings of $500K after expenses.

Achieved aggressive budgeted goals for each assigned department. Selected to train supervisory personnel

for the division in the K/T problem solving techniques and also trained more than two dozen

intern/supervisory candidates of which six were trained and promoted to shift manager and later four were

eventually promoted to department heads.

Education

Bachelor of Arts, Industrial Management/Engineering

Our Lady of the Lake University

San Antonio, Texas

You might also like

- Brenda Banks SAP/Manhattan/Oracle Analyst: Experience SummaryDocument4 pagesBrenda Banks SAP/Manhattan/Oracle Analyst: Experience Summarylbanks3318No ratings yet

- Power Point GENCO MISDocument12 pagesPower Point GENCO MISapi-19740871No ratings yet

- Warehouse Management Systems and EquipmentDocument18 pagesWarehouse Management Systems and Equipmentvictor18576184No ratings yet

- Gartner WMS Report 2019Document50 pagesGartner WMS Report 2019Fernando MartinezNo ratings yet

- SAM System Automation Manager - Traffic ControlDocument4 pagesSAM System Automation Manager - Traffic ControlWallie BillingsleyNo ratings yet

- 10 Technology Best PracticesDocument8 pages10 Technology Best Practicesदीपक सैनीNo ratings yet

- Supply Chain Management An Overview PDFDocument39 pagesSupply Chain Management An Overview PDFRamadhania SismiNo ratings yet

- Manh Warehouse Management Brochure enDocument8 pagesManh Warehouse Management Brochure enTanweer AlamNo ratings yet

- Arco Elaez: Logistics & Fulfillment ExecutiveDocument2 pagesArco Elaez: Logistics & Fulfillment ExecutiveChristina TrigoNo ratings yet

- Supply Chain Management PPT 2Document65 pagesSupply Chain Management PPT 2Harris LodhiNo ratings yet

- Omnichannel Order MGTDocument22 pagesOmnichannel Order MGTRajat RoyNo ratings yet

- WmsDocument6 pagesWmsStevoIlicNo ratings yet

- Supply Chain Management IntroductionDocument75 pagesSupply Chain Management IntroductionVishnu RajNo ratings yet

- Best Practices For WarehousesDocument44 pagesBest Practices For WarehousesAbraham Siju CherianNo ratings yet

- Building Warehousing CompetitivenessDocument40 pagesBuilding Warehousing CompetitivenessTejaswini ChauhanNo ratings yet

- Director Supply Chain Management in Waldwick NJ Resume Joseph CervinoDocument2 pagesDirector Supply Chain Management in Waldwick NJ Resume Joseph CervinoJosephCervinoNo ratings yet

- Manh Manhattan Active Warehouse Management Mawm Level 1 en PDFDocument2 pagesManh Manhattan Active Warehouse Management Mawm Level 1 en PDFpunitha_pNo ratings yet

- Manh Supply Chain Solutions enDocument32 pagesManh Supply Chain Solutions enPrasanna VenkatesanNo ratings yet

- Data Science & AI Master's Program OverviewDocument47 pagesData Science & AI Master's Program Overviewabhishek sumanNo ratings yet

- Director Supply Chain in Washington DC Resume Steven BoemermanDocument2 pagesDirector Supply Chain in Washington DC Resume Steven BoemermanStevenBoemermanNo ratings yet

- F1009, Ganga Vertica, Neeladri Road, Electronic City Phase 1, Bangalore-560100Document3 pagesF1009, Ganga Vertica, Neeladri Road, Electronic City Phase 1, Bangalore-560100AkashSinghNo ratings yet

- Inbound Cross DockDocument135 pagesInbound Cross Docklakshmanan84100% (1)

- Manh Supply Chain Solutions enDocument32 pagesManh Supply Chain Solutions enpeter50% (2)

- Gartner Magic Quadrant Wms 2884695Document23 pagesGartner Magic Quadrant Wms 2884695kuto2005No ratings yet

- Manhattan WMS Training MaxMunusDocument7 pagesManhattan WMS Training MaxMunuspaul muchemi0% (1)

- Resume-Roberta Strange 2014Document3 pagesResume-Roberta Strange 2014Jamie RobertsNo ratings yet

- WMS FundamentalsDocument35 pagesWMS FundamentalsKapil KarwalNo ratings yet

- Cross-Docking DC Advantages TitleDocument19 pagesCross-Docking DC Advantages TitleKhosro NoshadNo ratings yet

- Manhattan Strategies - AnalysisDocument32 pagesManhattan Strategies - Analysisalok26sinhaNo ratings yet

- Grey OrangeDocument18 pagesGrey Orangesaimanobhiram100% (1)

- Automated Warehouse Robots, Goods-To-Man AutomationDocument7 pagesAutomated Warehouse Robots, Goods-To-Man AutomationronalddragoNo ratings yet

- Excel Template Saves Time Configuring RedPrairie WMS ReplenishmentsDocument9 pagesExcel Template Saves Time Configuring RedPrairie WMS ReplenishmentsChristian RNNo ratings yet

- S&OP: What Great S&OP Feels LikeDocument3 pagesS&OP: What Great S&OP Feels LikeCyrus NyoriNo ratings yet

- Applying analytics to improve supply chain managementDocument1 pageApplying analytics to improve supply chain managementTushar PrasadNo ratings yet

- Activity ProfilingDocument9 pagesActivity ProfilingSafijo AlphonsNo ratings yet

- Top Supply Chain Companies Focus on Customer ValueDocument62 pagesTop Supply Chain Companies Focus on Customer ValueSyed Tauseef ChowdhuryNo ratings yet

- Hype Cycle For Suppl 771081 NDXDocument92 pagesHype Cycle For Suppl 771081 NDXAndrea MorunoNo ratings yet

- Warehouse Management SystemDocument3 pagesWarehouse Management SystemSoumitra Chakraborty100% (1)

- GreyOrange Product - Supply Chain Automation CompanyDocument12 pagesGreyOrange Product - Supply Chain Automation CompanyronalddragoNo ratings yet

- Lecture 20 - Supply Chain Management PDFDocument32 pagesLecture 20 - Supply Chain Management PDFBhaumik JainNo ratings yet

- GreyOrange Job DescriptionDocument3 pagesGreyOrange Job DescriptionAnanya BhardwajNo ratings yet

- KIVA SYSTEMS Revolutionizes Warehousing with Intelligent RobotsDocument2 pagesKIVA SYSTEMS Revolutionizes Warehousing with Intelligent RobotsElena JelerNo ratings yet

- Senior Operations Lean Manager in Dallas Fort Worth TX Resume James BirdDocument2 pagesSenior Operations Lean Manager in Dallas Fort Worth TX Resume James BirdJames BirdNo ratings yet

- Process Mapping ChecklistDocument2 pagesProcess Mapping ChecklistCK EspanolNo ratings yet

- Profiling vs. SlottingDocument5 pagesProfiling vs. Slottingbanshy1100% (1)

- Forecasting Methods and Techniques for Business DecisionsDocument116 pagesForecasting Methods and Techniques for Business DecisionsJohn Philip ReyesNo ratings yet

- Calculate your warehouse ROI with this free toolDocument11 pagesCalculate your warehouse ROI with this free toolJose De LeonNo ratings yet

- Multiechelon Inventory Optimization White Paper en UsDocument13 pagesMultiechelon Inventory Optimization White Paper en UsGerson Cordon0% (1)

- Inbound Cross DockDocument135 pagesInbound Cross DockSonaliNo ratings yet

- Warehousing Decisions & TypesDocument11 pagesWarehousing Decisions & Typespuneetgaur9744100% (1)

- POV - Flow Path Design - An Alternative Approach To Distribution Network DesignDocument5 pagesPOV - Flow Path Design - An Alternative Approach To Distribution Network DesigntltiedeNo ratings yet

- Inventory Management NotesDocument9 pagesInventory Management NotesArpandeep KaurNo ratings yet

- Warehouse Automation EnglishDocument5 pagesWarehouse Automation EnglishAnish BabuNo ratings yet

- Help Wanted For Secret City Recruiting Workers For The ManhattanDocument19 pagesHelp Wanted For Secret City Recruiting Workers For The ManhattanzazghbkbaevequwjitNo ratings yet

- Supply Chain TerminologyDocument5 pagesSupply Chain TerminologyMehroz KhanNo ratings yet

- Warehouse Management Systems A Complete Guide - 2019 EditionFrom EverandWarehouse Management Systems A Complete Guide - 2019 EditionNo ratings yet

- SCM Implementation Challenges and BenefitsDocument1 pageSCM Implementation Challenges and BenefitsAzaan KaulNo ratings yet

- Value Chains, Concepts and Supply Chain: Strategic Management Lesson Number: 8Document15 pagesValue Chains, Concepts and Supply Chain: Strategic Management Lesson Number: 8si touloseNo ratings yet

- A Process Improvement Project: GSK Case StudyDocument14 pagesA Process Improvement Project: GSK Case StudyMuhammad Sajid SaeedNo ratings yet

- Effect of B2B Supply Chain on Small FirmsDocument5 pagesEffect of B2B Supply Chain on Small FirmsAngelo SaayoNo ratings yet

- Create Material Master MRP Views and Assign MRP TypesDocument12 pagesCreate Material Master MRP Views and Assign MRP Typesdudhmogre23No ratings yet

- 132kV NB-A BOM (1.2 MTR BASE)Document32 pages132kV NB-A BOM (1.2 MTR BASE)ramudureddyNo ratings yet

- Modern Marketing ConceptDocument4 pagesModern Marketing ConceptLianalene MiguelNo ratings yet

- Supply Chain ManagementDocument254 pagesSupply Chain ManagementHarish MasandNo ratings yet

- Alok Deo SMBD Rflective NotesDocument6 pagesAlok Deo SMBD Rflective NotesMegha KushwahNo ratings yet

- Business Forms-Abm 12Document18 pagesBusiness Forms-Abm 12Raymundo Claridad JrNo ratings yet

- CV - Himanshu Mishra - OpsDocument3 pagesCV - Himanshu Mishra - Opsshivamarchit1234No ratings yet

- To Pull or Not To Pull - What Is The QuestionDocument17 pagesTo Pull or Not To Pull - What Is The QuestionSunil KambojNo ratings yet

- Logistics Role in FirmsDocument18 pagesLogistics Role in FirmsGh LimNo ratings yet

- Histustan Case Study SolDocument7 pagesHistustan Case Study SolYuvi ChauhanNo ratings yet

- TPS and Lean ProductionDocument18 pagesTPS and Lean ProductionMikey ChuaNo ratings yet

- Notice: Ocean Transportation Intermediary Licenses: Fastpak Express Corp., Et Al.Document1 pageNotice: Ocean Transportation Intermediary Licenses: Fastpak Express Corp., Et Al.Justia.comNo ratings yet

- Chapter 10 - Inventory Decision MakingDocument84 pagesChapter 10 - Inventory Decision MakingArman100% (1)

- SCM - Lessius Chapter 4 - Supply ContractsDocument42 pagesSCM - Lessius Chapter 4 - Supply ContractsRoel Leus100% (1)

- Store LayoutDocument20 pagesStore LayoutkrishnavnNo ratings yet

- Procurement Department PROCUREMENT POLICY SummaryDocument18 pagesProcurement Department PROCUREMENT POLICY SummaryheminsleyNo ratings yet

- 21-22 - Assignment - FOH - Part 2Document4 pages21-22 - Assignment - FOH - Part 2Oliviane Theodora WennoNo ratings yet

- SCM For Business ImpactDocument2 pagesSCM For Business ImpactKARTHIYAENI VNo ratings yet

- SCM AssignmentDocument37 pagesSCM AssignmentAaradhya DixitNo ratings yet

- Supply Chain Logistics Management 4th Edition Browersox Test BankDocument4 pagesSupply Chain Logistics Management 4th Edition Browersox Test Bankkathleenroweeoyzgdatxk100% (13)

- Supply Chain Management in Hospitality Industry: An OverviewDocument13 pagesSupply Chain Management in Hospitality Industry: An Overviewjune dela cernaNo ratings yet

- Inward OutwardDocument6 pagesInward Outwardikm27marchNo ratings yet

- SNJB's Late Sau. Kantabai Bhavarlalji Jain College of Engineering, ChandwadDocument10 pagesSNJB's Late Sau. Kantabai Bhavarlalji Jain College of Engineering, ChandwadAkash JadhavNo ratings yet

- BSCM Quiz Session 1 PDFDocument3 pagesBSCM Quiz Session 1 PDFmenagesNo ratings yet

- Retail Management (Bajaj, Tuli, Srivastava) 2nd Ed.Document53 pagesRetail Management (Bajaj, Tuli, Srivastava) 2nd Ed.Learner's LicenseNo ratings yet

- Ias 02 InventoryDocument20 pagesIas 02 Inventorydương nguyễn vũ thùyNo ratings yet