Professional Documents

Culture Documents

How To Troubleshoot Motor and Drives

Uploaded by

Yared Tuemay0 ratings0% found this document useful (0 votes)

104 views4 pagesa quick reference(leaflet( to troubleshooting

Original Title

How to Troubleshoot Motor and Drives

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenta quick reference(leaflet( to troubleshooting

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

104 views4 pagesHow To Troubleshoot Motor and Drives

Uploaded by

Yared Tuemaya quick reference(leaflet( to troubleshooting

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

HOW TO TROUBLESHOOT

MOTORS & DRIVES

>>

Taking measurements, starting at the inputs, can ensure a motor and

drive system is getting the high-quality power it needs, and that its not

adversely affecting power quality upstream.

Its important to look closely at the rst segment in a three-phase motor and

drive system from the mains supply at the drive input to the drive itself. Tese

measurements will help identify common problems. Also, knowing what tools to

use for a given situation and how to apply them will enable more quick and accurate

troubleshooting.

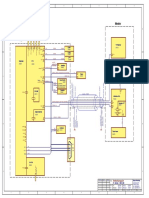

Te test points in a typical three-phase motor drive system (see Figure 1) include:

Te drive input where AC power enters the drive from the mains.

Te drive and its output, where the AC to DC converter, the DC nlter, and the

DC to AC inverter provide the three-phase power to the motor.

Te motor and drive train itself.

Follow these steps to learn about troubleshooting tools and

how to use them for problems in a typical three-phase motor

and drive system, from the inputs to the drive.

By Hilton Hammond, Product Manager, Fluke Corp.

33 WWW.ROCKWELLAUTOMATION.COM/THEJOURNAL DECEMBER 2012 | THE JOURNAL

AC to DC

Conversion

Mains

Supply

Mechanical

Output

Motor (Load) Cable

Interface

DC to AC Converter DC Filter

and Buffer

bus

voltage

L1

T3

PWM Output

L2

T2

L3

Gnd

T1

+Vdc

-Vdc

T3

T2

T1

DRIVE

INPUT MOTOR AND DRIVE TRAIN DRIVE AND DRIVE OUTPUT

PROBLEMS

Nominal Supply

Voltage

Voltage Unbalance

Transients

Harmonic

Power Factor

Voltage Unbalance

Current Unbalence

Sigma Current and PE Current

Control Signal

Output Transients

Distrurbances

Harmonics

Volt to Hertz Radtio

Diagnostic Shutdown

Motor Overload

Single Phasing

Bearing Failures

Misalignment

Imbalance

Looseness

Insulation Breakdown

Shaft Voltage and

Bearing Current

Figure 1. This graph illustrates a three-phase motor and drive system and common problems.

34 THE JOURNAL | DECEMBER 2012 WWW.ROCKWELLAUTOMATION.COM/THEJOURNAL

Introduction to Input Measurements

When troubleshooting a motor and drive system, checking

the supply voltage, current and frequency rst can rule out

problems that might aect performance. Tis saves time and

leads to faster problem resolution. In addition, identifying

over- or under-voltage conditions can avoid nuisance tripping

of drive fault circuits and eventual motor-drive damage.

Input measurements can be taken at a number of loca-

tions. Figure 2 shows dierent input points going from the

main service entrance to subpanel or disconnect switch to the

power input at the drive.

Potentially, each of these points could provide dierent

results if theyre aected by other loads on the circuits.

Input measurements should be taken to:

Determine if there's enough capacity to power the motor

and drive system.

Establish power quality.

Make sure the drive load isn't adversely anecting power

quality in the system, such as a motor drive generating

harmonics or creating dips that could disrupt operations.

Te voltage, current and frequency of the electricity power-

ing a variable speed motor system can aect both its short-

term and long-term operation, so its best to start diagnostics

at the input side.

Three Primary Measurements

Nominal supply voltage, current and frequency are the

primary measurements for voltage supplied to the drive under

normal operating conditions. Nominal voltage is the named

(or rated) voltage at which the device is designed to operate.

Nominal values provide a basis to compare measurements.

Starting at the input of the motor drive, measure voltage,

current and frequency, then compare your measurements

with nominal values.

You can take measurements with a digital multimeter

and a current clamp, just as you would on a single-phase

circuit, but a three-phase power quality analyzer makes

the job easier (see Figure 3). Measuring three phases

simultaneously can reveal interactions between phases that

cant be seen with single-phase measurements. When mea-

suring, be sure the power quality analyzer is connected to

the correct circuit type.

Te amount of deviation from nominal thats considered

acceptable varies by locale, but as a rule:

Voltage should be within 10% of nominal.

Current should never exceed the load's nameplate rating.

Frequency should be within 0.5 Hz of nominal.

Evaluating Measurements

A measurement of more than 10% out of range means there's

potentially a supply voltage problem. For long-term trouble-

shooting, attach a power quality analyzer. If the voltage is

consistently too high, consult with the electric utility.

If voltage is too low, check whether the local circuit is over-

loaded by comparing current measurements with the circuit

breaker rating. If the measured current is within the range of

the breaker, check the size of the cable that supplies the drive

to make sure it conforms to National Electric Code (NEC)

requirements.

If voltage measurements are within an acceptable range

and the circuit appears to be correctly congured, but there

are still problems (such as the motor drive resetting or circuit

breakers opening), intermittent power supply problems might

be present. To detect problems happening over a longer time

Main Switchgear

Disconnect

Switch

Motor Drive

Motor Load

L1

L2

L3

T1

T2

T3

L1

L2

L3

Figure 2. Input points go from the main service entrance, to subpanel or disconnect switch, to the power input at the drive.

35 WWW.ROCKWELLAUTOMATION.COM/THEJOURNAL DECEMBER 2012 | THE JOURNAL

or until the next fault occurs, use a power quality analyzer or

power quality recorder to log any disturbances on the circuit.

If all voltage, current and frequency measurements are within

an acceptable range, check for voltage and current unbalance.

Voltage and Current Unbalance

Ideally, voltage and current measured in each phase of a three-

phase system should be the same. Because voltage or current

unbalance can cause downtime or damage to a motor drive,

its important to know how to interpret these measurements.

Expressing the amount of voltage or current unbalance as

a percentage helps determine the size of the problem quickly

with a single number. To get the percentage of unbalance,

divide the biggest deviation measured on one phase by the

average of three phases and multiply by 100.

For example, if you measured 480V, 485V and 490V,

the average voltage is 485 and the biggest deviation is 5V.

Five volts divided by 485V is .01, which gives a 1% voltage

unbalance when multiplied by 100.

480V+485V+490V

3 = 485 average voltage

5V maximum

deviation from average

485V average *100 = 1% voltage unbalance

As little as a 2% voltage unbalance can cause voltage

notching and excessive current ow in one or more phases

going to the motor. Voltage unbalance can also cause tripping

of the motor drives current overload fault protection.

Current unbalance is a measure of dierence in current

drawn on each leg of a three-phase system. It can cause over-

heating and deterioration of motor-winding insulation.

Te draw on each leg should be equal or close to equal.

Voltage unbalance can cause current unbalance far out of

proportion to the voltage unbalance itself. When current un-

balance occurs in the absence of voltage unbalance, look for

another cause of the unbalance; for example, faulty insulation

or a phase shorted to ground.

Just like voltage unbalance, current unbalance is calculated

as 100 times the maximum current variation from average,

divided by the average current of the three phases. So, if mea-

sured current is 30A, 35A and 30A, the average is 31.7A, and

the current unbalance is: [(35 31.7) 100] 31.7 = 10.4%.

Current unbalance for three-phase motors shouldnt

exceed 10%. High neutral current can indicate unbalance.

Unbalance current will ow in neutral conductors in three-

phase wye systems.

Harmonics

Te 50 or 60 Hz frequency of the voltage supplied is called

the fundamental frequency. In a perfect world, the funda-

mental frequency is the only one present. Unfortunately,

some electrical loads (such as computers, controls, drives and

energy-saving lighting systems) can cause other frequencies,

called harmonics, to appear in measurements.

Most harmonic-generating devices can be found inside a

facility. Although motor drives can be aected by harmonics,

often theyre the source of harmonics aecting other devices.

If signicant levels of harmonics appear in drive measure-

ments, consider adding ltering to block those harmonics.

Transients

Transients are brief events (less than one half cycle, so less

than 1/120th of a second in a 60 Hz system) on the AC line.

Main Switchgear

Disconnect

Switch

Motor Drive

L1

L2

L3

T1

T2

T3

L1

L2

L3

L1 L2 L3

L1

L2

L3

Figure 3. Use a power quality analyzer connected to the drive input to measure the input side of the drive. Then, if needed, measure at the service entrance.

36 THE JOURNAL | DECEMBER 2012 WWW.ROCKWELLAUTOMATION.COM/THEJOURNAL

Many people associate transients with external events, such

as lightning surges, but transients can also originate within a

system or building. Detecting, troubleshooting and address-

ing transients is important because they can damage motors

and its circuitry.

Troubleshooting transients typically requires using a test

tool with a fault capture rate, such as a power quality ana-

lyzer or a portable oscilloscope.

Diagnostic Benets

Checking the primary measurements rst often can rule out

issues that might aect the motor drive or breaker circuits.

Diagnosing from the inputs can save time, lead to faster prob-

lem resolution and help prevent damage to the drive itself.

Editors Note: Testing from the inputs is one of many ways to

troubleshoot motors and drives. To learn more on testing from

the outputs, please see How to Measure Output Voltage from a

VFD to a Motor, in our April edition at http://bit.ly/H7iyEW.

Fluke Corp. is a participating Encompass Product Partner

in the Rockwell Automation PartnerNetwork. Based in Ever-

ett, Wash., Fluke Corp. manufactures, distributes and services

electronic test tools.

Fluke Corp.

www.rockwellautomation.com/go/p-uke

>> Review of the Fundamentals

Voltage: The amount of electromotive force being

applied to the system. Voltage is often compared to the

water pressure in a pipe.

Current: The amount of electrons flowing through

the wires. Electric current is often compared to the

volume of water flowing through a pipe.

Frequency: The number of times alternating current

(AC) changes direction. This frequency is determined

by the movement of magnets in the generator. Different

countries use electricity with different frequencies. In

the U.S. and Canada, the frequency is nominally 60

cycles per second (60 Hz). In most other countries the

frequency is 50 Hz.

You might also like

- Intro To Basic Fire Alarm TechnologyDocument37 pagesIntro To Basic Fire Alarm TechnologyAnonymous bcsvK289QNo ratings yet

- Abb MaterialDocument64 pagesAbb Materialvijayakanthc100% (1)

- Bourns Ip Class CodesDocument2 pagesBourns Ip Class Codesnmatic1No ratings yet

- Training Basic HydraulicsDocument50 pagesTraining Basic Hydraulicssalicurri88% (8)

- Success Proj MGTDocument134 pagesSuccess Proj MGTRupesh SawantNo ratings yet

- A Second Course in ProbabilityDocument213 pagesA Second Course in ProbabilityYared Tuemay100% (3)

- CNC PresentationDocument37 pagesCNC PresentationMarvin BelenNo ratings yet

- 865109Document298 pages865109vinaybabaNo ratings yet

- A Philosophy of Technology From Technical Artefacts To Sociotechnical Systems Synthesis Lectures On Engineers Technology and SocietyDocument134 pagesA Philosophy of Technology From Technical Artefacts To Sociotechnical Systems Synthesis Lectures On Engineers Technology and SocietyDhananjay Kumar100% (1)

- Fundamentals of Applied Probability TheoryDocument152 pagesFundamentals of Applied Probability TheoryYared Tuemay100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ECE521 Presentation Evaluation Form Sept 2015Document3 pagesECE521 Presentation Evaluation Form Sept 2015ÎQbãl HãikãmNo ratings yet

- Product Sheet: Nibp100D Noninvasive Blood Pressure Monitoring SystemDocument3 pagesProduct Sheet: Nibp100D Noninvasive Blood Pressure Monitoring SystemSadegh ShebaniNo ratings yet

- Option M14 IO Extension Card 4 Relay Outputs 4189340682 UKDocument8 pagesOption M14 IO Extension Card 4 Relay Outputs 4189340682 UKAung MhNo ratings yet

- RF Integrated Circuits Mid-Term ExamDocument1 pageRF Integrated Circuits Mid-Term Examsreekanth2728No ratings yet

- 03 Rig InstrumentationDocument34 pages03 Rig InstrumentationArkhatTompakovNo ratings yet

- 1176 PDFDocument169 pages1176 PDFJoshua PalizaNo ratings yet

- eNB-MCE Functions, Parameters & Statistics - 20140626 PDFDocument64 pageseNB-MCE Functions, Parameters & Statistics - 20140626 PDFanupwadhwaniNo ratings yet

- Model G PressDocument2 pagesModel G Pressbeach_lover_1970No ratings yet

- Engineering Physics II Question BankDocument58 pagesEngineering Physics II Question Bankjj012586100% (2)

- Catalogo EmersonDocument102 pagesCatalogo EmersonCarlos Palma100% (1)

- Id210 SpecsDocument8 pagesId210 Specsrose HNo ratings yet

- IITH ranked 8th in NIRF Engineering & 10th in ARIIADocument43 pagesIITH ranked 8th in NIRF Engineering & 10th in ARIIAYoo HooNo ratings yet

- SiGe RF Front-End PerformanceDocument6 pagesSiGe RF Front-End PerformancekimvirusNo ratings yet

- White Paper Distribution Network ProtectionDocument5 pagesWhite Paper Distribution Network ProtectionAhmed Hamzeh100% (1)

- ST Link UtilityDocument11 pagesST Link UtilityAleixLNo ratings yet

- Pro Ar12 4 Gs N.en GBDocument1 pagePro Ar12 4 Gs N.en GBBao Quoc MaiNo ratings yet

- Sigma-Amelung Trintity PC AMAX200 - Circuit DiagramDocument5 pagesSigma-Amelung Trintity PC AMAX200 - Circuit DiagramSoporte CicomerxNo ratings yet

- ELECTRONIC ENGINEERING LTD. Outdoor PIR ManualDocument18 pagesELECTRONIC ENGINEERING LTD. Outdoor PIR Manualtadeo.hdzNo ratings yet

- Unix Interview Questions and AnswersDocument9 pagesUnix Interview Questions and AnswersKarthikReNo ratings yet

- EmtlDocument707 pagesEmtlLaxmiSahithi100% (1)

- Questions 6Document3 pagesQuestions 6Bobeth TubigNo ratings yet

- Production Sound Essentials PDFDocument6 pagesProduction Sound Essentials PDFAlex HavranNo ratings yet

- High-Efficiency Pure Sine Wave InverterDocument5 pagesHigh-Efficiency Pure Sine Wave Invertermariojrm74No ratings yet

- TDA7442Document16 pagesTDA7442gaston30-3@No ratings yet

- Nglide ReadmeDocument9 pagesNglide ReadmeBooz A Gomez FNo ratings yet

- Parts IR5000-IR6000Document264 pagesParts IR5000-IR6000Bhoopesh Saraswat AligarhianNo ratings yet

- 8KV 500mA Ultra Fast Recovery High Voltage DiodeDocument1 page8KV 500mA Ultra Fast Recovery High Voltage Diodeedilbertos_4No ratings yet

- Admissibility of Electronic Evidence in CourtsDocument22 pagesAdmissibility of Electronic Evidence in CourtsNasir ZamanNo ratings yet

- NEC SpectraView II Users GuideDocument455 pagesNEC SpectraView II Users Guidelistro0No ratings yet

- XT5042 - Datasheet PDFDocument2 pagesXT5042 - Datasheet PDFlabbasatyamNo ratings yet