Professional Documents

Culture Documents

Design Fundamentals DPWH

Uploaded by

Jerome Angelo B. BaybayCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Fundamentals DPWH

Uploaded by

Jerome Angelo B. BaybayCopyright:

Available Formats

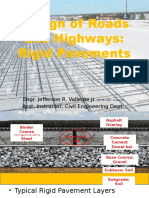

Basics of Concrete Pavement

Thickness Design

Concrete Pavement Design

Geometrics

Thickness(es)

Joints

Materials

Concrete Pavement Design

Geometrics

Thickness(es)

Joints

Materials

Most Often Influence Cost

& Selection of Projects

C

O

S

T

Concrete Pavement Design

Geometrics

Thickness(es)

Joints

Materials

Most Often Influence

Real-world Performance

PERFORMANCE

Concrete Pavement Design

Performance Factor Design Area

Blow-ups

Random cracking

Faulting

Pumping

Spalls

Jointing & Subbase

Materials Selection &

Proportioning

ASR

D-cracking

Freeze-Thaw

Scaling

Skid Resistance

Thickness (Slab)

Fatigue Cracking

Principles of Design

Load stresses

Volume change stresses

Curling/Warping stresses

Jointing or

Reinforcing

Thickness

Thickness Design Procedures

Empirical Design Procedures

Based on observed performance

AASHO Road Test

Mechanistic Design Procedures

Based on mathematically calculated pavement

responses

PCA Design Procedure (PCAPAV)

PAVEMENT DESIGN

NCHRP 1-26 Phase II Final Report

Pavement design is an a priori process.

The new pavement will be built in the future, on

subgrades often not yet exposed or accessible;

using materials not yet manufactured from sources

not yet identified; by a contractor who submitted the

successful "low dollar" bid, employing unidentified

personnel and procedures under climatic conditions

that are frequently less than ideal.

Thickness Design Considerations:

Traffic Loads and Traffic Growth

Subgrade and Subbases

Drainage

Concrete Properties

Load Transfer

Reliability

Design of Concrete Pavements

AASHTO Design Procedures

AASHTO Guide for

Design of Pavement

Structures - 1993

AASHO Road Test

(1958-1960)

Third Large Scale Road Test

Maryland Road Test (1950-51)

Rigid Pavements Only

WASHO Road Test (1952-54)

Flexible Pavements only

Include both Rigid and

Flexible Designs

Include a wide range of axle

loads and pavement cross-

sections

AASHO Test Layout

AASHO Test Layout

368 rigid test sections 468 flexible test sections

Max Single Axle

Max Tandem Axle

AASHO Test Traffic

AASHO Road Test Performance

Surviving Sections

Loop 3

1.0

2.0

3.0

4.0

5.0

0 250 500 750 1000 1250

S

e

r

v

i

c

e

a

b

i

l

i

t

y

Concrete (36 Sect)

Asphalt (4 Sect)

Loop 4

1.0

2.0

3.0

4.0

5.0

0

250 500 750 1000 1250

Load Applications

S

e

r

v

i

c

e

a

b

i

l

i

t

y

Loop 5

1.0

2.0

3.0

4.0

5.0

0 250 500 750 1000 1250

S

e

r

v

i

c

e

a

b

i

l

i

t

y

Loop 6

1.0

2.0

3.0

4.0

5.0

0 250 500 750 1000 1250

Load Applications

S

e

r

v

i

c

e

a

b

i

l

i

t

y

Concrete (38 Sect)

Asphalt (10 Sect)

Concrete (39 Sect)

Asphalt (11 Sect)

Concrete (47 Sect)

Asphalt (17 Sect)

AASHTO Design

Procedures & Changes

1961-62 AASHO Interim Guide for the Design of

Rigid and Flexible Pavements

1972 AASHTO Interim Guide for the Design of

Pavement Structures - 1972

1981 Revised Chapter III on Portland Cement Concrete

Pavement Design

1986 Guide for the Design of Pavement Structures

1993 Revised Overlay Design Procedures

1998 Revised Portland Cement Concrete Pavement Design

Log(ESALs) Z * s +7.35*Log(D+1) - 0.06

R o

=

( )

+

Log

PSI

4.5- 1.5

1+

1.624*10

D

7

1

8 46 .

Standard

Normal Deviate

Overall

Standard Deviation

Depth

( )

+ 4.22- 0.32p

t

*

[ ]

( )

Log

S' C D 1.132

215.63* J * D -

18.42

E / k

c d

0.75

0.75

c

0 25 .

* *

Change in Serviceability

Terminal

Serviceability

Drainage

Coefficient

Load

Transfer

Modulus of

Rupture

Modulus

of Elasticity

Modulus of

Subgrade Reaction

1986-93 Rigid Pavement

Design Equation

AASHTO DESIGN

Traffic

ESALs or E-18s

The number and weight of all axle loads

from the anticipated vehicles expected

during the pavement design life - expressed

in 18-kip (80 kN) Equivalent Single Axle

Loads for each type of pavement.

Rigid ESALs or E-18s

Flexible ESALs or E-18s

AASHTO DESIGN

Traffic - ESALs

Equivalent Number of 18k Single Axle Loads

ESALs GENERATED BY

DIFFERENT VEHICLES/DAY

VEHICLE NUMBER

RIGID

ESALs

FLEXIBLE

ESALs

Single Units 2 Axle 20 6.38 6.11

Busses 5 13.55 8.73

Panel Trucks 10 10.89 11.11

Semi-tractor Trailer 3 Axles 10 20.06 13.41

Semi-tractor Trailer 4 Axles 15 39.43 29.88

Semi-tractor Trailer 5 Axles 15 57.33 36.87

Automobile, Pickup, Van 425 1.88 2.25

Total 500 149.52 108.36

AASHTO DESIGN

Traffic

Load Equivalence Factor (LEF)

The Ratio of the Effect (Damage) of a Specific

Axle Load on Pavement Serviceability to the

Effect Produced by an 18-kip Axle Load at the

AASHO Road Test.

Change for each:

Pavement Type

Thickness

Terminal Serviceability.

AASHTO DESIGN

Traffic

Load Equivalence Factor (LEF)

No. of repetitions of 18-k SAL Load causing given PSI

No. of repetitions of X-k Y-Axle Load for a same PSI

Change for each:

Pavement Type

Thickness

Terminal Serviceability.

For a Given Stress or Strain:

LOAD EQUIVALENCY FACTORS

FOR A GIVEN PAVEMENT STRUCTURE

Stress or Strain of X-kip Load on Axle Type Y

Stress or Strain of 18-kip Load on a Single Axle

For a Given Serviceability Loss:

LOAD EQUIVALENCY FACTORS

FOR A GIVEN PAVEMENT STRUCTURE

# of Repetitions of X-kip Load on Axle Type Y

# of Repetitions of 18-kip Load on a Single Axle

PSI PSI

Concrete

Response

Asphalt

Response

Since pavement responses are different, the equivalency

factors (LEFs) are different. When multiplying the traffic by

the different equivalencies, you get different ESALs

AASHTO DESIGN

Traffic

Subgrade and Subbases

Subbase

Layer of material

directly below the

concrete pavement.

Subgrade

Natural ground, graded,

and compacted on

which the pavement is

built.

Subbase

Subgrade

Concrete Section

Subgrade / Subbase Strength

Modulus of Subgrade Reaction, k

Reaction

Stacked Plates

Hydraulic Jack

Pressure Gauge

Deflection Dial at 1/3 Points

k (psi/in) = unit load on plate / plate deflection

Subgrade and Subbases

Design

Subgrade strength is not a critical element in the

thickness design.

Has little impact on thickness.

Need to know if pavement is on:

Subgrade (k 100 psi/in.),

Granular subbase (k 150 psi/in.),

Asphalt treated subbase (k 300 psi/in.)

Cement treated/lean concrete subbase (k 500 psi/in.).

AASHTO DESIGN

Subgrade Strength

Typical Soil Relationships

Soil Type Strength k-value

(psi / in.)

Mr (psi) CBR

Silts / Clays Very Low 50-100 1000-1900 <3

Fine grained Low 100-150 1900-2900 3-5.5

Sands Medium 150-220 2900-4300 5.5-12

Gravely soils High 220-250 4300-4850 >12

Bitumin.Treat. High 350-450 100,000+ >12

Cement.Treat./LCB High 400-600 500,000+ >12

Subgrade and Subbases

Performance

Proper design and construction are absolutely

necessary if the pavement is to perform.

Must be uniform throughout pavements life.

Poor subgrade/subbase preparation can not be

overcome with thickness.

Any concrete pavement, built of any thickness, will

have problems on a poorly designed and

constructed subgrade or subbase.

UNIFORMITY:

The Key To

GOOD

PAVEMENT

PERFORMANCE

Design for Uniform Support

Expansive soils

Frost susceptible soils

Pumping (loss of Support)

Cut-fill transitions

Poorly compacted excavations

Utility work

Culverts

Sources of Non-Uniform Support

PAVEMENT DESIGN

Subbase Effects

The current Design does not

model the contribution of bases

accurately.

At the AASHO Road Test, it was

found that the concrete

pavements with granular bases

could carry about 30% more

traffic.

The current design procedures

allows concrete pavements built

with granular bases to carry

about 5 - 8% more traffic.

Flexural Strength (Sc) Determination

Head of Testing Machine

L/3

Span Length = L

d=L/3

Span Length = L

L/2

Third-point Loading Center-point Loading

Concrete Properties

Concrete Properties

f

c

= Compressive Strength (psi)

S

c

= Flexural Strength (psi)

S

c

= 8-10 f

c

Head of Testing

Machine

Cylinder

Depth

Compressive Strength f

c

Concrete Properties

Use average, in-field

strength for design

(not minimum specified)

If specify minimum flexural

strength at 28-day of 550 psi &

allow 10% of beams to fall

below minimum:

STEP 1

Estimate SDEV:

9% for typical ready mix.

SDEV = 550 * 0.09 = 50 psi

STEP 2

Sc design = Sc minimum + z * SDEV

Sc design = 550 + 1.282 * 50

Sc design = 614 psi

Drainage

Conditions for Pumping

Subgrade Soil that will go

into Suspension

Free water between Slab

and Subgrade

Frequent Heavy wheels

loads / Large Deflections

Drainage

Major Conclusions

For Doweled PCC

Pavements, Drainage has

little affect on Faulting

Does reduce D-cracking

Drainage significantly

reduces fatigue cracking

and rutting in AC

Pavements

Day lighted drainage works

best with permeable bases

NCHRP 1-34: Subsurface Drainage for Pavements

Load Transfer

A slabs ability to share its

load with neighboring

slabs

Dowels

Aggregate Interlock

Concrete Shoulders

Tied Concrete, curb & gutter,

and extended lane have

same effect.

L

= x

U

= 0

Poor Load Transfer

Load Transfer

Good Load Transfer

L

= x/2

U

= x/2

Aggregate Interlock

Shear between aggregate particles

below the initial saw cut

Aggregate Interlock

Dowel bars

Lengths from 15-18 in.

6.0 in. min. embedment

length

Diameter

1.25 - 1.50 in. for roads

1.5 - 2.0 in. for airports

Epoxy or other coating

used in harsher climates

for corrosion protection

Deflections in Concrete Pavement

12 ft Lanes

Outside Pavement Edge (free edge)

Longitudinal Centerline

(acts as tied concrete shoulder)

Undoweled transverse Joint Doweled transverse Joint

2 D

i

~2.5 D

i

5 D

i

~3.5 D

i

D

i

D

i

Load Transfer

AASHTO DESIGN

Effect of Dowels and Shoulders

0.0E+00

1.0E+07

2.0E+07

3.0E+07

4.0E+07

7 8 9 10 11 12

Thickness

A

l

l

o

w

a

b

l

e

E

S

A

L

s

Dowels &

Shoulders

Dowels &

No Shoulders

No Dowels &

Shoulders

No Dowels &

No Shoulders

Concrete Pavement Design

Exclude dowels if:

Slab thickness < 7.0 in

Include dowels if:

Slab thickness > 8.0 in.

Trucks

Control

Thickness

To Dowel or Not to Dowel?

AASHTO DESIGN

Reliability

The statistical factors that influence pavement

performance are:

RELIABILITY, R

The statistical probability that a pavement will meet

its design life.

STANDARD DEVIATION, so

The amount of statistical error present in the design

equations resulting from variability in materials,

construction, traffic, etc.

AASHTO DESIGN

Reliability

Log ESALs

S

E

R

V

I

C

E

A

B

I

L

I

T

Y

p

t

p

o

Design Curve

Performance

Curve

Z

R

* s

o

WinPAS

PCAPAV Design Procedure

Mechanistic stress

analysis

Calibrated to field tests,

test roads

Control criteria can be

either:

Fatigue (cracking)

Erosion (pumping)

Available computer

program (PCAPAV)

Design Basics

Fatigue

Midslab loading away

from transverse joint

produces critical edge

stresses

Erosion

Corner loading

produces critical

pavement deflections

Transverse joint

Transverse joint

Critical Loading Positions

Differences Between Design

Procedures

Traffic Classification:

AASHTO - uses 18-kip ESALs

PCA - uses axle load distribution

Reliability

AASHTO - Reliability

PCA - Load Safety Factors

Drainage

PCAPAV Design

Fatigue

Keeps pavement stresses due to repeated loads within

safe limits

Erosion

Limits the effects of pavement deflections at edges,

joints and corners.

Two design criteria:

PCAPAV Design Procedure

Concrete Properties

Flexural strength (modulus of rupture)

Subgrade Strength, or subgrade-subbase combination

modulus of subgrade reaction, k-value

Weights, frequencies, and types of truck axle loads

Load Transfer

Load Safety Factor

Design Period

Design Factors

PCAPAV Design

Traffic

Numbers & weights of heavy axle loads

expected during the design life

ADT (average daily traffic in both directions)

ADTT (average daily truck traffic in both directions)

Includes only trucks with six tires or more

Does not include panel and pickup trucks and other four-tire

vehicles.

Axle loads of trucks

PCAPAV Design

Traffic

Axle loads Distribution

The number of single

and tandem axles over

the design period

Expressed as Axles per

1000 trucks

Does not include panel

and pickup trucks and

other four-tire vehicles.

Axle load

Kips

Single Axles

28-30

26-28

24-26

22-24

20-22

18-20

16-18

14-16

12-14

10-12

Tandem Axles

48-52

44-48

40-44

36-40

32-36

28-32

24-28

20-24

16-20

12-16

Axles/1000

Trucks

0.58

1.35

2.77

5.92

9.83

21.67

28.24

38.83

53.94

168.85

1.96

3.94

11.48

34.27

81.42

85.54

152.23

90.52

112.81

124.69

Axles in

design period

6,310

14,690

30,140

64,410

106,900

235,800

307,200

422,500

586,900

1,837,000

21,320

42,870

124,900

372,900

885,800

930,700

1,656,000

984,900

1,227,000

1,356,000

PCAPAV Design

Traffic

Light Residential

Residential

Rural & secondary rds.

Collector streets

Rural & secondary rds.

(heavy trucks)

Minor Arterial Sts.

Primary roads

Major Arterial Sts.

3

10 - 30

50 - 500

300 - 600

700 - 1500

LR

1

2

2

3

1.0

1.0

1.1

1.2

1.2

Two-way ADTT Category LSF

Traffic Categories

PCAPAV Design

Load Safety Factors

Interstate, interprovincial, multilane projects

LSF = 1.2.

Highways and arterial streets

LSF = 1.1

Roads, residential streets, and other streets

that carry small volumes of truck traffic

LSF = 1.0

Recommended values

PCAPAV

PCAPAV Design

Simplified Procedure

Designs presented in Tabular Form

Traffic

Type of road

Axle-load category (for the road type)

Avg. daily truck traffic

Probable maximum truck weights

Subgrade and Subbase

Dowels & slab edge support

Concrete strength

PCAPAV Design

Simplified Procedure

Foundation Support, k, MPa/m

Flexural Strength, MPa

Light Resident.

ADTT = 50

100

500

ADTT = 300

600

ADTT = 10

20

50

3.8 4.1 4.5 4.1 4.5 3.8

165

165

175

150

150

165

190

200

215

190

190

215

215

225

200

215

140

150

150

175

175

190

200

200

150

150

150

175

175

190

200

200

140

140

150

140

140

140

165

175

175

165

165

175

190

190

175

190

No Dowels - No edge support

40 80

Residential

Rural & Sec. Rd.

Collector

Rural & sec. Rd.

Minor Arterial

2-way ADTT = 3 150 mm 140 140 140 125 125

PCAPAV Design

Simplified Procedure

Foundation Support, k, MPa/m

Flexural Strength, MPa

Light Resident.

ADTT = 50

100

500

ADTT = 300

600

ADTT = 10

20

50

3.8 4.1 4.5 4.1 4.5 3.8

140

140

150

125

140

140

165

175

175

150

165

175

190

190

175

190

125

125

125

160

160

160

165

175

125

125

140

150

150

165

175

175

125

125

125

125

125

125

140

150

150

140

140

150

165

165

150

165

No Dowels - With Edge Support

40 80

Residential

Rural & Sec. Rd.

Collector

Rural & sec. Rd.

Minor Arterial

2-way ADTT = 3 125 mm 125 125 125 125 125

Typical Concrete Pavement

Thickness

Depends on traffic load, subgrade, and

climate.

City streets, secondary roads, and small

airports

100 to 175 mm (4 to 7 in.)

Primary roads and interstate highways

175 to 280 mm (7 to 12 in.)

Large airports

200 to 460 mm (8 to 18 in.)

1986-93 RIGID PAVEMENT

DESIGN

Factors Affecting Rigid Pavements

Thickness

Serviceability (p

o

, p

t

)

Traffic (ESALs, E-18s)

Load Transfer (J)

Concrete Properties (S

c

, E

c

)

Subgrade Strength (k, LS)

Drainage (C

d

)

Reliability (R, S

o

)

AASHTO DESIGN

Serviceability

Serviceability -

the pavements ability

to serve the type of

traffic (automobiles

and trucks) that use

the facility

Very Good

Good

Fair

Poor

Very Poor

5.0

4.0

3.0

2.0

1.0

0.0

Present Serviceability

Index (PSI)

P

r

e

s

e

n

t

S

e

r

v

i

c

e

a

b

i

l

i

t

y

I

n

d

e

x

Accumulated Traffic

p

o

Rehabilitation Required

p

t

PSI

AASHTO DESIGN

Concrete Properties

There are two concrete properties that influence

pavement performance

Flexural Strength (Modulus of Rupture), S

c

Average 28-day strength

3rd-Point Loading

Modulus of Elasticity, E

c

AASHTO DESIGN

Concrete Properties

Flexural Strength (S

c

) Determination

Head of Testing Machine

L/3

Span Length = L

d=L/3

Span Length = L

L/2

Third-point Loading Center-point Loading

AASHTO DESIGN

Concrete Properties

Use average, in-field

strength for design

(not minimum specified)

If specify minimum flexural

strength at 28-day of 550 psi &

allow 10% of beams to fall

below minimum:

STEP 1

Estimate SDEV:

9% for typical ready mix.

SDEV = 550 * 0.09 = 50 psi

STEP 2

Sc design = Sc minimum + z * SDEV

Sc design = 550 + 1.282 * 50

Sc design = 614 psi

AASHTO DESIGN

Concrete Properties

Modulus of Elasticity

E

c

= 6750 S

c

E

c

= 57,000 (f

c

)

0.5

Flexural Strength Modulus of Elasticity

600 psi 3,900,000 psi

650 psi 4,200,000 psi

700 psi 4,600,000 psi

Avenues for water entry

WATER-TABLE

Water-Table Rise

Capillary

Suction from

Water-Table

Natural Drainage

from High-Ground

From Edge

Vapor

Movement

Surface

Entry

2

4

1

3

1

5

PAVEMENT

BASE

AASHTO DESIGN

Drainage , C

d

AASHTO DESIGN

Reliability

The statistical factors that influence

pavement performance are:

RELIABILITY, R - The statistical probability that a

pavement will meet its design life.

STANDARD DEVIATION, s

o

-The amount of

statistical error present in the design equations

resulting from variability in materials,

construction, traffic, etc.

AASHTO DESIGN

Reliability

Log ESALs

S

E

R

V

I

C

E

A

B

I

L

I

T

Y

p

t

p

o

Design Curve

Performance

Curve

Z

R

* s

o

WinPAS

PCAPAV Design Procedure

Mechanistic stress analysis

Calibrated to field tests,

test roads

Control criteria can be

either:

Fatigue (cracking)

Erosion (pumping)

Available computer

program (PCAPAV)

Design Basics

Differences Between Design

Procedures

Traffic Classification:

AASHTO - uses 18-kip ESALs

PCA - uses axle load distribution

Reliability

AASHTO - Reliability

PCA - Load Safety Factors

Drainage

PCA does not include

PCAPAV Design

Fatigue

Keeps pavement stresses due to repeated loads within

safe limits

Erosion

Limits the effects of pavement deflections at edges,

joints and corners.

Two design criteria:

Fatigue Analysis

Performed for edge

stresses (critical stresses)

Based on stress ratio

Fatigue not consumed by

repetitions of one load is

available for repetitions of

other loads.

Equivalent Flexural Stress

28-Day Modulus of Rupture

SR =

Fatigue Analysis

Allowable number of load

repetitions for each axle

group is determined from

nomographs

% Fatigue is calculated for

each axle group

Total fatigue consumed

should not exceed 100%.

Expected repetitions

Allowable repetitions

% Fatigue =

Erosion Analysis

Repetitions of heavy axle loads cause:

pumping; erosion of subgrade, subbase and shoulder

materials; voids under and adjacent to the slab; and

faulting of pavement joints.

Erosion is a function of Power, or rate of work.

Power = corner deflection (w) * pressure (p) * area

duration of deflection.

A thin pavement with its shorter deflection basin

receives a faster load punch than a thicker slab.

Erosion Analysis

Performed for corner deflections (critical deflections)

Erosion factor is determined from tables

Allowable number of load repetitions for each axle

group is determined from nomographs

Erosion Damage is calculated for each axle group

% Erosion Damage = Expected repetitions

Allowable repetitions

Total erosion damage from all axle groups should be

less than 100%

PCAPAV Design

Fatigue usually controls design of light-traffic

pavements

Single-axles usually cause more fatigue damage

Erosion usually controls design of undoweled

medium- and heavy-traffic pavements

Tandem-axles usually cause more erosion damage

Design controlled by:

PCAPAV Design Procedure

Selection of an adequate thickness is

dependent upon the choice of other design

features:

Jointing system

Shoulder type

Subbase type

PCAPAV Design Procedure

Concrete Properties

Flexural Strength

(Modulus of Rupture),

Avg. 28-day strength in

3rd-point loading

Other Factors

Fatigue Properties

Concrete Strength

Gain with Age

L/3

Span Length = L

d=L/3

Third-point Loading

PCAPAV Design

Concrete Properties

Comparison of f

c

, MR, and Required Thickness

Compressive

Strength

3000 psi

4000 psi

5000 psi

Third Point

Flexural Strength

450 - 550 psi

510 - 630 psi

570 - 710 psi

Effect on

Slab Thickness

7.0 in

6.5 in.

6.0 in.

PCAPAV Design

Subgrade Properties

Modulus of Subgrade

Reaction, k-value

Plate load on subgrade

Plate deflection on subgrade

k =

5.0 psi

0.5 in

k =

= 100 psi / in.

Reaction

Stacked Plates

Pressure Gauge

Subgrade

Plate-Load Test

PCAPAV Design

Subgrade Properties

Plate-load test is rarely performed

time consuming & expensive

Estimate k-value by correlation to other tests

e.g. California Bearing Ratio (CBR) or R-value tests.

Lean concrete subbases increases k-value.

PCAPAV Design

Subgrade Properties

Comparison of Soil Types and k-value

k-value

100 psi/in.

200 psi/in.

300 psi/in.

Type of Soil

Silts and clays

Sandy soils

Sand-gravels

Remarks

Satisfactory

Good

Excellent

Effect of Untreated Subbase on k-value

Subbase k-value

4 in.

85

165

235

320

Subgrade

k-value (psi/in)

75

150

225

300

6 in.

96

180

242

330

9 in.

117

210

280

367

12 in.

140

243

330

430

Effect of Cement-treated Subbase on k-value

Subbase k-value

4 in.

220

367

514

Subgrade

k-value (psi/in)

75

150

225

6 in.

294

477

698

9 in.

386

680

900

12 in.

496

845

--

Effect of Untreated Subbase on k-value

Subbase k-value

4 in.

85

165

235

320

Subgrade

k-value (psi/in)

75

150

225

300

6 in.

96

180

242

330

9 in.

117

210

280

367

12 in.

140

243

330

430

PCAPAV Design

Subgrade Properties

PCAPAV Design

Subgrade Properties

Effect of Cement-treated Subbase on k-value

Subbase k-value

4 in.

220

367

514

Subgrade

k-value (psi/in)

75

150

225

6 in.

294

477

698

9 in.

386

680

900

12 in.

496

845

--

PCAPAV Design

Design Period

20 to 35 years is commonly used

Shorter or longer design period may be

economically justified in some cases

A special haul road to be used for only a few years.

PCAPAV Design

Traffic

Numbers & weights of heavy axle loads

expected during the design life

ADT (average daily traffic in both directions)

ADTT (average daily truck traffic in both directions)

Includes only trucks with six tires or more

Does not include panel and pickup trucks and other four-tire

vehicles.

Axle loads of trucks

PCAPAV Design

Traffic

Axle loads Distribution

The number of single

and tandem axles over

the design period

Expressed as Axles per

1000 trucks

Does not include panel

and pickup trucks and

other four-tire vehicles.

Axle load

kN

Axles/1000

Trucks

Axles in

design period

Single Axles

125-133

115-125

107-115

97.8-107

88.8-97.8

80.0-88.8

71.1-80.0

62.2-71.1

53.3-72.2

44.4-53.3

0.58

1.35

2.77

5.92

9.83

21.67

28.24

38.83

53.94

168.85

6,310

14,690

30,140

64,410

106,900

235,800

307,200

422,500

586,900

1,837,000

Tandem Axles

213-231

195-213

178-195

160-178

142-160

125-142

107-125

88.8-107

71.1-88.8

53.3-71.1

1.96

3.94

11.48

34.27

81.42

85.54

152.23

90.52

112.81

124.69

21,320

42,870

124,900

372,900

885,800

930,700

1,656,000

984,900

1,227,000

1,356,000

PCAPAV Design

Traffic

Light Residential

Residential

Rural & secondary rds.

Collector streets

Rural & secondary rds.

(heavy trucks)

Minor Arterial Sts.

Primary roads

Major Arterial Sts.

3

10 - 30

50 - 500

300 - 600

700 - 1500

LR

1

2

2

3

1.0

1.0

1.1

1.2

1.2

Two-way ADTT Category LSF

Traffic Categories

PCAPAV Design

Load Safety Factors

Interstate, interprovincial, multilane projects

LSF = 1.2.

Highways and arterial streets

LSF = 1.1

Roads, residential streets, and other streets

that carry small volumes of truck traffic

LSF = 1.0

Recommended values

PCAPAV Design

Other Loads

Warping - moisture variations.

Creates compressive restraint stresses in the slab bottom.

Curling - temperature variations.

During the day, the top surface is warmer than the bottom

and stresses develop at the slab bottom.

During the night, the top is colder and stresses develop at

the slab surface.

Assumed to cancel each other out.

Warping and Curling of Concrete

PCAPAV Design

Design Procedures

Rigorous

Detailed axle-load-distribution data is available

Simplified

Axle-Load Data Not Available

Designer does not directly use the axle-load

data

Tabular form

PCAPAV Design

Rigorous Procedure

Requires the following design factors:

Type of joint and shoulder

Concrete flexural strength (MR) at 28 days

k-value of subgrade or subgrade-subbase combination

Load safety factor (LSF)

Axle-load distribution

Expected number of axle-load repetitions

Use PCAPAV Computer Program

PCAPAV

Design Tip

Dont Drink

and Design

You might also like

- 5.1 AASHTO and DPWH Design of Rigid PavementsDocument32 pages5.1 AASHTO and DPWH Design of Rigid PavementsJefferson R. Vallente Jr.100% (2)

- Dowel Bars For PCCPDocument2 pagesDowel Bars For PCCPKristelle Ramos100% (2)

- PCCP Minimum StandardDocument3 pagesPCCP Minimum StandardJanssen Gerardo Valbuena100% (4)

- Seismic Design of Bridges in PhilippinesDocument80 pagesSeismic Design of Bridges in PhilippinesMike2322No ratings yet

- DPWH Standard Specifications On Prime Coat, TackDocument8 pagesDPWH Standard Specifications On Prime Coat, TackChesterMercado100% (2)

- DPWH Standard Specification For Chevron Signs Item 620Document9 pagesDPWH Standard Specification For Chevron Signs Item 620Son GokouNo ratings yet

- DPWH 2004 BluebookDocument452 pagesDPWH 2004 BluebookRoel Briones100% (4)

- Highway Planning Manual Volume 8 PDFDocument72 pagesHighway Planning Manual Volume 8 PDFHanz Maca-ayanNo ratings yet

- DPWH Curb and Gutter PDFDocument6 pagesDPWH Curb and Gutter PDFRyan AntipordaNo ratings yet

- Bridge PapasaDocument59 pagesBridge PapasaCamille Garcia100% (1)

- DO - 063 - S2014 - Item 522A Slope ProtectionDocument5 pagesDO - 063 - S2014 - Item 522A Slope ProtectionRay RamiloNo ratings yet

- Project Scheduling: Precedence Diagram MethodDocument78 pagesProject Scheduling: Precedence Diagram MethodMN Bayalas ConstructionNo ratings yet

- Design and Analysis of RCBCDocument9 pagesDesign and Analysis of RCBCTejay Tolibas100% (1)

- Pavement DesignDocument88 pagesPavement DesignNiraj Bohara100% (1)

- Pavement Design DPWHDocument8 pagesPavement Design DPWHSwerthson Wasawas83% (6)

- DPWH PavementDocument3 pagesDPWH PavementDanny Ferrer100% (1)

- 02 DILG General Provisions and Other Limit StatesDocument99 pages02 DILG General Provisions and Other Limit StatesHarry Basada100% (1)

- DPWH Design Criteria and GuidelinesDocument228 pagesDPWH Design Criteria and GuidelinesJonas de Silva100% (2)

- DPWH General Notes For ROADSDocument7 pagesDPWH General Notes For ROADSFerdie Tolosa100% (1)

- DPWH Min. Design Standard For Industry ROADSDocument2 pagesDPWH Min. Design Standard For Industry ROADSRandy Cerna75% (4)

- DPWH Road Design StandardsDocument1 pageDPWH Road Design StandardsBenson James Chan100% (4)

- 6 Foundation DesignDocument72 pages6 Foundation DesignKenneth AustriaNo ratings yet

- Drainage and Slope ProtectionDocument84 pagesDrainage and Slope ProtectionJMSoriano100% (6)

- DPWH Blue Book Volume 3Document178 pagesDPWH Blue Book Volume 3Kevin John MaximoNo ratings yet

- Department Orders SummaryDocument15 pagesDepartment Orders SummaryLowie Torres TonioNo ratings yet

- DPWH Geotextile StandardsDocument12 pagesDPWH Geotextile StandardsFatima Jade Castillo Ang100% (1)

- Pocketbook On Routine MaintenanceDocument94 pagesPocketbook On Routine MaintenanceKevinNeilPe-il100% (3)

- DPWH Matrix of TrucksDocument4 pagesDPWH Matrix of TrucksJerome Angelo B. BaybayNo ratings yet

- Summary of DPWH Standard Specs and Min Test RequirmentDocument34 pagesSummary of DPWH Standard Specs and Min Test Requirmentcharlee_05No ratings yet

- DPWH Concrete SPECIFICATIONSDocument6 pagesDPWH Concrete SPECIFICATIONSShe Timbancaya100% (1)

- DPWHDocument92 pagesDPWHLem Lemlem67% (3)

- DPWH Standard SpecificationsDocument6 pagesDPWH Standard SpecificationsNiño Donayre Wariza100% (1)

- DPWH Road & Gutter Details PDFDocument10 pagesDPWH Road & Gutter Details PDFRandy Cerna100% (1)

- Design ComputationDocument61 pagesDesign ComputationRheyJun Paguinto AnchetaNo ratings yet

- Design Guidelines, Criteria and Standards of Bridge Design DPWH DgcsDocument13 pagesDesign Guidelines, Criteria and Standards of Bridge Design DPWH DgcsHarvey Bautista100% (1)

- DPWH Cost AnalysisDocument4 pagesDPWH Cost AnalysisDivina Teja Rebanal-Glino100% (1)

- DPWH Road & Gutter DetailsDocument10 pagesDPWH Road & Gutter DetailsRandy CernaNo ratings yet

- PCCP Construction MethodDocument11 pagesPCCP Construction Methodknight kingNo ratings yet

- STAAD Seismic Analysis 81915Document16 pagesSTAAD Seismic Analysis 81915Harry BasadaNo ratings yet

- 2014 Acel Rates: (Minimum Operation 8 Hrs. Per Day)Document4 pages2014 Acel Rates: (Minimum Operation 8 Hrs. Per Day)Shielagil CailoNo ratings yet

- Materials Engineer Reviewer Min Req - 2Document88 pagesMaterials Engineer Reviewer Min Req - 2Zner NivlekNo ratings yet

- 02 AM Road DrainageDocument67 pages02 AM Road Drainagerolandtrojas100% (1)

- DPWH Blue BookDocument548 pagesDPWH Blue Bookjulesjusayan100% (5)

- PDF DPWH Cost Estimation Manual For Low Rise Buildings DLDocument260 pagesPDF DPWH Cost Estimation Manual For Low Rise Buildings DLMichael Angelo Ballon100% (1)

- Dpwh-Jica Pasig River Estimate Ref.Document385 pagesDpwh-Jica Pasig River Estimate Ref.Alfred Panugao100% (2)

- DPWH Min. Pavement Thickness & Width of Nat'l. Road With DESIGN COMPUTATION PDFDocument8 pagesDPWH Min. Pavement Thickness & Width of Nat'l. Road With DESIGN COMPUTATION PDFRandy CernaNo ratings yet

- DPWH 3dr QTR Price Canvass PDFDocument34 pagesDPWH 3dr QTR Price Canvass PDFCDRRMO ValenciaNo ratings yet

- Supervising Highway Engineer: Passbooks Study GuideFrom EverandSupervising Highway Engineer: Passbooks Study GuideNo ratings yet

- DPWH ReviewerDocument597 pagesDPWH Reviewercharles sedigoNo ratings yet

- Design Fundamentals of PavementDocument96 pagesDesign Fundamentals of Pavement류태하100% (1)

- Presentacion - WinPAS - AASHTO 93Document9 pagesPresentacion - WinPAS - AASHTO 93Fabricio OrtegaNo ratings yet

- PCCP Design PDFDocument61 pagesPCCP Design PDFKeeperNo ratings yet

- Design of Rigid PavementDocument35 pagesDesign of Rigid PavementAzman Samer0% (1)

- Unit 2.1Document40 pagesUnit 2.1naren0143No ratings yet

- 6 - RPDDocument92 pages6 - RPDArpit GondaliyaNo ratings yet

- 7.2 Design of Rigid PavementsDocument53 pages7.2 Design of Rigid PavementsJeffjr Vallente100% (2)

- PavementsDocument67 pagesPavementscblerNo ratings yet

- 1 - Analysis & Design of PCCP - ShirazDocument25 pages1 - Analysis & Design of PCCP - ShirazMA Ing Francisco Leal GarciaNo ratings yet

- CEP-1 Project 1 Group 9Document31 pagesCEP-1 Project 1 Group 9Mk ModiNo ratings yet

- Lect No. 11Document23 pagesLect No. 11kamran KhanNo ratings yet

- DPWH Material EngineeringDocument11 pagesDPWH Material EngineeringDonald Pereyra33% (3)

- DPWH Matrix of TrucksDocument4 pagesDPWH Matrix of TrucksJerome Angelo B. BaybayNo ratings yet

- DPWH, Cavite II District, August 29, 2013Document20 pagesDPWH, Cavite II District, August 29, 2013Jerome Angelo B. BaybayNo ratings yet

- Design of Rec FootingDocument20 pagesDesign of Rec FootingBhanu VadlamaniNo ratings yet

- Business Guide For Reducing Solid WasteDocument82 pagesBusiness Guide For Reducing Solid WasteJerome Angelo B. BaybayNo ratings yet

- Opmbcs 2013 2017Document42 pagesOpmbcs 2013 2017Jerome Angelo B. BaybayNo ratings yet

- PDM Mns ArchiveDocument24 pagesPDM Mns ArchiveJerome Angelo B. BaybayNo ratings yet

- 13 Perrie Concrete Construction ManualDocument15 pages13 Perrie Concrete Construction ManualdraganugNo ratings yet

- Research All AboutDocument40 pagesResearch All AboutJerome Angelo B. Baybay100% (1)

- Design of Tension Member LRFDDocument57 pagesDesign of Tension Member LRFDJerome Angelo B. Baybay100% (1)

- My Maid Invest1Document28 pagesMy Maid Invest1api-200319437No ratings yet

- Irr P.D. 1586Document14 pagesIrr P.D. 1586Hannah Tolentino-Domantay0% (1)

- Safety of Offshore Structures PDFDocument46 pagesSafety of Offshore Structures PDFAnonymous IwqK1NlNo ratings yet

- Intro To Dynamics of Structures Washington University 23pDocument23 pagesIntro To Dynamics of Structures Washington University 23pcgingenierosNo ratings yet

- Ra 9003 Compliance Options For Lgu Part 1Document59 pagesRa 9003 Compliance Options For Lgu Part 1Jerome Angelo B. Baybay100% (2)

- Environmental Planners Board ExamDocument7 pagesEnvironmental Planners Board ExamAngelu Via Claridades64% (11)

- Manila Bay ClassificationDocument10 pagesManila Bay ClassificationJerome Angelo B. BaybayNo ratings yet

- Paving Method StatementDocument7 pagesPaving Method StatementOfentse LedwabaNo ratings yet

- Supplemental Specs For Ag RoadsDocument42 pagesSupplemental Specs For Ag Roadsluismarcial01No ratings yet

- Pavement Design: Flexible Pavement Design (JKR Method)Document16 pagesPavement Design: Flexible Pavement Design (JKR Method)Khairul AnuarNo ratings yet

- CHAPTER 3. PAVEMENT DESIGN 150 - 5320 - 6d - Part3 PDFDocument30 pagesCHAPTER 3. PAVEMENT DESIGN 150 - 5320 - 6d - Part3 PDFHenra HalimNo ratings yet

- Cons Method 122Document2 pagesCons Method 122Top FiveNo ratings yet

- Swa 2Document13 pagesSwa 2mj macaspacNo ratings yet

- Design Fundamentals DPWHDocument96 pagesDesign Fundamentals DPWHJerome Angelo B. Baybay100% (1)

- Development of RStO-01 For Designing The Asphalt Pavements in USA and Compare With AASHTO 1993Document14 pagesDevelopment of RStO-01 For Designing The Asphalt Pavements in USA and Compare With AASHTO 1993pghasaeiNo ratings yet

- Bcrp-1 CP 1-b - BoqDocument16 pagesBcrp-1 CP 1-b - BoqRafael AbedesNo ratings yet

- 1) LSM Pavement LayersThickness DesignDocument1 page1) LSM Pavement LayersThickness DesignMahar Qasim LaliNo ratings yet

- 400 MtrsDocument79 pages400 MtrsCarl Malone TolentinoNo ratings yet

- Pavement DesignDocument45 pagesPavement Designjologscresencia100% (4)

- Site Grading, Subgrade Excavate (Cut & Fill) Excavation (Cut) & Backfilling Compacted To 90% MDDDocument13 pagesSite Grading, Subgrade Excavate (Cut & Fill) Excavation (Cut) & Backfilling Compacted To 90% MDDEdgar QuinonesNo ratings yet

- Concrete Pavement Design: 1. Wheel Loads On To PavementDocument3 pagesConcrete Pavement Design: 1. Wheel Loads On To PavementKakara SrikanthNo ratings yet

- Pavement Manual DOHDocument84 pagesPavement Manual DOHChia Wai Livingston100% (1)

- Bandara - 13 - 14 - Airport Pavement Design - FAA - RigidDocument20 pagesBandara - 13 - 14 - Airport Pavement Design - FAA - RigidAbillNo ratings yet

- Description and Application of Dual Mass Dynamic Cone Penetrometer by Webster Et AlDocument52 pagesDescription and Application of Dual Mass Dynamic Cone Penetrometer by Webster Et AlIvan MasubaNo ratings yet

- RMS Specs 3051 Ed6Document37 pagesRMS Specs 3051 Ed6Luke DigginsNo ratings yet

- 21dj0111 Re-Ad PowDocument54 pages21dj0111 Re-Ad PowRic Anthony GenetianNo ratings yet

- Pavement and Materials Design Manual 1999 - CHAPTER 8Document12 pagesPavement and Materials Design Manual 1999 - CHAPTER 8Kisali Sarakikya100% (2)

- PWA-IAN 101 Rev 1 - Amendments To QHDMDocument35 pagesPWA-IAN 101 Rev 1 - Amendments To QHDMMahmoud AlsuradiNo ratings yet

- Bandara - 11 - 12 - Airport Pavement Design - FAA - Flexible PDFDocument29 pagesBandara - 11 - 12 - Airport Pavement Design - FAA - Flexible PDFfebriantoNo ratings yet

- Isbn 0-626-07197-6Document6 pagesIsbn 0-626-07197-6Michael MatshonaNo ratings yet

- 007JTG D40-2011-EnDocument80 pages007JTG D40-2011-Enziming li100% (1)

- Lecture 7 - Flexible PavementDocument12 pagesLecture 7 - Flexible PavementAtina Tungga DewiNo ratings yet

- Advisory Circular: U.S. Department of TransportationDocument12 pagesAdvisory Circular: U.S. Department of Transportationrol NowaNo ratings yet

- Uniform Support in Concrete Pavement StructuresDocument2 pagesUniform Support in Concrete Pavement StructuresCarolina MaestreNo ratings yet

- 800 Series Highways Vol 2Document18 pages800 Series Highways Vol 2Temur LomidzeNo ratings yet

- HD25-26 NRA Pavement & Foundation DesignDocument44 pagesHD25-26 NRA Pavement & Foundation DesignMelissa GrahamNo ratings yet