Professional Documents

Culture Documents

Executive Summary: Phyco / Michigan State University / Dow Chemical 18 Month Full-Scale Bioreactor Test Plan

Uploaded by

carrmvOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Executive Summary: Phyco / Michigan State University / Dow Chemical 18 Month Full-Scale Bioreactor Test Plan

Uploaded by

carrmvCopyright:

Available Formats

MSU-Dow-Phyco2 Full-Scale Test Plan Executive Summary DRAFT 2-July-12 2:37p PT

1

Executive Summary

PHYCO

2

/ Michigan State University / Dow Chemical

18 Month Full-Scale Bioreactor Test Plan

The Opportunity

An innovative process (patent pending) for the accelerated production of algae biomass is

under development by PHYCO

2

LLC in conjunction with Michigan State University and Dow

Chemical Company. This summary identifies the necessary steps to build and operate two

full-scale Helix Algae Photobioreactors to demonstrate their ability to grow algae at an

accelerated rate while sequestering CO

2

.

Market demand for the use of algae biomass in the production of food, pharmaceuticals,

nutraceuticals and fuel oil is increasing. Simultaneously, global social and political

pressure is increasing to reduce levels of emitted CO

2

.

The Challenge

Current algae production is hamstrung by the use of natural sunlight, which limits the

time of exposure to daylight hours, and geography to warmer regions. PHYCO

2

holds the

rights to a potentially game changing technology that can grow algae of any type, any

time, anywhere. With the PHYCO

2

bioreactor design, Algae can now be grown 24/7 and

along side any power plant, capturing CO

2

emissions anywhere in the world.

Algae Biomass Product Opportunity

Algae based products are in the infancy stage of supplying the markets of fuel, bio-

chemicals, pharmaceuticals, nutraceuticals, food additives and animal feed. Globally, the

current total available markets (TAM) are $2,500B for fuel, and over $1,200B for the rest.

There is substantial social, political and market pressure to incorporate natural based

components into these production processes. Amongst the bio-alternatives, algal biomass

has the greatest promise of economic viability.

Market estimates widely vary, but all carry the same message of potentially large and

growing markets. For instance, just addressing biofuels:

The Algae 2020: market report forecasts algal based biofuels growing from 2018

to 2025 at a 30% clip globally from 1B to 6B gallons produced. This would be a

$20B market at todays prices.

MSU-Dow-Phyco2 Full-Scale Test Plan Executive Summary DRAFT 2-July-12 2:37p PT

2

A 2011 study by the US Department of Energy shows a potential by 2022 of

replacing 17% of all imported oil with algae based biofuels. This would represent a

$62B market in the US alone.

(Source: National microalgae biofuels production potential and resource demand. Mark S. Wigmosta, 2011)

Market Research Media estimates total biofuel production (algae and other bio

sources) production at 1.9B barrels globally in 2020, growing at a CAGR of 10%

from 2015-2020. This would yield a $240B annual market and growing. And it will

represent only about 6% of the of total global fuel production in 2020.

(Source: Market Research Media Global Biofuel Production Forecast 2015-2020)

Thus for algal based biofuels alone we have a market potential range of $20B - $240B in

about 10 years and growing at a double digit rates.

CO

2

Sequestration Opportunity

Over a ton of CO

2

is released for each MWh produced using coal as the energy source.

Natural gas produces about half that amount. The US produces over 2 trillion tons of CO

2

annually using coal-fired power plants, which represents about a fourth of global output.

Many countries have undertaken the challenge of reducing these emission levels using a

variety of incentives, regulations and penalties. Carbon taxes and credits are some of the

mechanisms under serious consideration. Examples: A European commission has gone

as far as to suggest a tax rate of about $40/ton of CO

2

produced. For a medium sized

power plant, that would be an annual levy of over $100M, which is on the order of the

entire annual operating cost for the plant. Furthermore, the Australian government has

pegged a value of $25/per ton for a yet to be established carbon credit market. So the

political pressure worldwide is firm and strengthening.

MSU-Dow-Phyco2 Full-Scale Test Plan Executive Summary DRAFT 2-July-12 2:37p PT

3

The Technology

Algae production (photosynthesis) requires more

than CO

2

, water, nutrients and sunlight. It

requires a photobioreactor that combines the

right CO

2

, water, nutrients and light. Current

processes depend upon large acreage surfaces

(e.g. ponds) to grow algae during daylight only.

This is economically impractical. PHYCO

2

has

developed an exclusive (patent pending) process

to grow any algae, any where and any time.

Our innovative algae photo bioreactor is a

vertical system powered by a constant high

intensity LED light source thus allowing 2-3

times the algae biomass production in less than

1/8

th

the space. It will produce more algae,

more quickly, utilizing less real estate.

The heart of the process is the closed loop

photobioreactor, a 10 foot tall vertical helix

coiled tube (designed in association with B-Side

Plastics and Parker Hannifin) wrapped around a

high intensity LED light source (developed in

jointly with IDT TOSHIBA and J&J Electronics).

Algae are grown inside the helix tube as it continuously circulates around the light source

24/7. Advantages include specifically tuned light sources to maximize growth, flow

dynamics to accelerate growth, indoor operation independent of geography or weather,

and the Photobioreactors are stackable for a minimal footprint resulting in efficient use of

available land.

Accomplished to Date

A scale prototype algae photobioreactor was constructed with the following design

objectives:

Reduced Footprint to grow more algae in less space than inefficient ponds or

other methods.

Eliminate Natural Sunlight Requirement by growing algae 24 hours a day indoors.

Increase Production Rate by growing more algae, more quickly, more selectively.

Vertical Expansion For further real estate savings by stacking bioreactors.

Cost Effective For CO

2

sequestration and algae production.

Internal testing resulted in successful outcomes of these objectives. The fundamental

technology of growing algae in a continuous flow helix coil photobioreactor with HILED

illumination was proven, and subsequently received confirmatory academic endorsement

in testing, at the Utah State University Energy Dynamics Laboratory in May 2010.

10 feet

MSU-Dow-Phyco2 Full-Scale Test Plan Executive Summary DRAFT 2-July-12 2:37p PT

4

Next Steps

With basic design, development and academic endorsement complete, the next step is to

prove the technology to be scalable. This will entail an 18-month project to ultimately

build, test, and validate performance of two (2) full-scale commercial HILED

photobioreactors at the T.B. Simon Power Plant located on campus at Michigan State

University, East Lansing, MI. The project will be conducted in two stages: Initial Assembly

and Full Scale Testing. The total project investment will be just under $1,500,000.

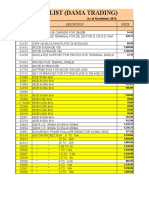

1 2 3 4 3 6 7 8 9 10 11 12 13 14 13 16 17 18

PHASE I - Initial Assemply (California/Texas)

ManufacLure ComponenLs (4 unlLs)

Assemble & lnlLlal 1esL 2 unlLs

1ransporL Lo MSu

PHASE II - Full Scale Testing (Michigan State University)

ueslgn 1esLlng roLocols

repare laclllLy aL Mlchlgan SLaLe

llue Cas ConnecLlons

Assemble 2 unlLs

SysLem 1esL / CpLlmlzaLlon

Complle & lormaL uaLa for 8eporL

uarter|y 1ota|

Cumu|at|ve Investment

MSU-Dow-Phyco2 Full Scale Photo-Bioreactor Testing - 18 Month Investment

MonLh

5380,000

5380,000

52S0,000 5184,000

51,318,000 51,482,000 5630,000

5290,000 5214,000

5920,000 51,134,000

5164,000

(See detail backup in appendix)

Phase I Initial Assembly (California/Texas)

The first 8 months will see the development, production, and testing of two full-scale

HILED photobioreactors. Working with B-Side Plastics, the helix coil injection molds will

be perfected. Parker-Hannifin will complete development of the special flanges to be used

during final coil assembly. Unique hardware and software components will be specified

and purchased. The high intensity LED light bars for the center of the helix coil designed

by IDT TOSHIBA and J&J Electronics, will be supplied by J&J Electronics. The completed

and tested HILED photobioreactor assemblies will be partially disassembled and

transported to the campus of Michigan State University, East Lansing, MI for reassembly

and installation at the power plant site.

PHASE II Full Scale Testing (Michigan)

In conjunction with the production of the two HILED photobioreactors by B-Side Plastics

and Parker Hannifin in Houston, a 300 sq. ft. site at the Michigan State University power

plant will be prepared to accept the units. This will include the build-out and temperature

control of the space. Also at this time flue gas connections will be plumed from the power

plan exhaust to the test site.

MSU-Dow-Phyco2 Full-Scale Test Plan Executive Summary DRAFT 2-July-12 2:37p PT

5

On month 8, the two units will be shipped from Texas to the staging area at the power

plant on campus. Final assembly, testing and test protocol optimization will be developed

by a collaboration of MSU, Dow, and PHYCO

2

. Once the HILED photobioreactors are

assembled and commissioned for use, full scale testing and begin on month 11.

The units will be monitored and controlled by a computer system, various algae strains

will be tested to determine optimal LED wavelength/duration cycles, and an efficient

harvesting process will be identified. This will complete performance testing and allow

final analysis and reporting of data to more specifically quantitate functional efficiency and

economic opportunity for this technology.

Expected Outcomes

Outcomes of this project include the optimization of connectivity to power plant emissions

exhaust system, selection of the most efficient algae strains, determining algae yields,

harvesting frequency, measuring CO

2

absorption rates, and improving current design

characteristics of the bioreactors and interconnections.

Scope of Project

Confirm optimal size/shape of HILED photobioreactor helix coil

Establish appropriate water flow rates

Engineer water circulation system

Optimize LED configuration & wavelengths

Optimize LED exposure frequency

Determine power usage requirements

Test two algae species for CO

2

absorption and algae production characteristics

Establish appropriate CO

2

input flow rates, pressures and temperatures

Determine extent of CO

2

input filtering required

Calculate CO

2

absorption rates

Optimize and measure algae product production yields

Determine harvesting cycle

Identify algae drying process for end product

Performance Hypotheses to be Validated

Per HILED photobioreactor

Algae Biomass Produced: 0.9 Tons / Year (extrapolated)

CO2 Absorbed: 5 Grams per each gram of dried Algae Biomass produced

Power Consumption: 34 Watts / Hour

Water Consumption: 5 Gallons / Day (15% daily loss of 110 liter capacity)

MSU-Dow-Phyco2 Full-Scale Test Plan Executive Summary DRAFT 2-July-12 2:37p PT

6

The Project Team

Don Hubbard Chief Executive Officer, PHYCO

2

Attorney. Alex Brown and Sons

Managing Director, Internet and Software Banking. UBS Warburg

Co-Head, Technology Investment Banking, Morgan Stanley

Co-Founder CFO, Chameleon Communications

Head of Merchant Banking for privately held Swiss Asset Management Company

Lieutenant Commander, U.S. Navy (Ret)

Claude Hutchison Chief Operating Officer, PHYCO

2

President, Security National Bank

Founder, Chairman & CEO CivicBank of Commerce

Managing Director, Smith & Crowley, Inc

Managing Director, LECG

Regent, University of California

Director, Office of Asset Enterprise Mgt. U.S. Dept of Veterans Affairs

Captain, U.S. Navy (Ret)

Eric Hagopian - Operations Director / Project Manager, PHYCO

2

BS Biological Science, San Jose State University

Founder of Insulated Shipping Containers, Inc. (ISC).

Invented and patented for ISC the VacIntact, a mechanical device to monitor the integrity

of a vacuum in an insulating wall

Operations Manager for MicroScan, Inc., a medical diagnostic manufacturer.

United States Army, Nuclear Weapons Specialist, Secret Clearance

Robert Morgan Chief Technology Officer, PHYCO

2

Over 25 years experience designing and working with technology systems

Designed and developed new technologies in the field of algal biomass production

Designed equipment for GHG emissions, capture/sequestration & alternative fuels feedstock

FBI training in hazardous materials investigation

Honored California Fire Service Member

United States Coast Guard

Wei Liao, Ph.D., P.E. Assistant Professor, Michigan State University

Department of Biosystems & Agricultural Engineering

Ph.D. Washington State University

BS & MS, Wuxi University of Light Industry, China

Over 10 years experience in fields of bioenergy & bioproducts

Mike Mazor, Ph.D., Fellow & Dow Scientist, Dow Chemical Company

Dow Scientist for Energy Efficiency & Sustainability

Ph.D. Physical Chemistry, University of Houston

BS Chemical Engineering, Penn State University

MSU-Dow-Phyco2 Full-Scale Test Plan Executive Summary DRAFT 2-July-12 2:37p PT

7

In Conclusion

Clearly there is ever-increasing global pressure to produce more energy with fewer

harmful emissions released into the atmosphere. A prime target is the operation of coal

and natural gas fired electric utility plants, where the sequestration of CO

2

would show

immediate environmental benefits. Several technologies to sequester CO

2

have been

under development for years; most are very expensive and none, with the exception of

PHYCO

2

s HILED Photobioreactor technology, have the capability to pay for themselves

with an economic byproduct. The conversion of CO

2

into usable algae biomass for food,

medicine or fuel is a scientific breakthrough with the promise of leveraging the value of

the sequestration process. Therefore, for the first time there is an identifiable path to

harvest a useful and marketable product while materially reducing noxious emissions.

The alignment of the scientific resource of Michigan State University, with the support and

guidance of Dow Chemical, and the patent pending technology of PHYCO

2

is an ideal

partnership. The technological and economic rewards for the successful completion of this

18-month testing process are enormous; particularly in light of the relatively nominal

investment required to take this next essential step.

Beyond completion of this 18 month full-scale test, PHYCO

2

will be positioned to move

forward with one of several scenarios. Possible pathways include:

Partnering with a large diversified company (e.g. Dow Chemical, DuPont, or similar

manufacturing/energy/agribusiness company) to integrate the technology into

ongoing algae production projects.

Commercialize the technology by linking with an emerging company in a strategic

alliance to accelerate the innovation to commercialization process.

Licensing the technology to manufacturing, natural resources or energy companies;

Sell the company outright.

MSU-Dow-Phyco2 Full-Scale Test Plan Executive Summary DRAFT 2-July-12 2:37p PT

8

Appendix Project Detail

MSU-Dow-Phyco2 Full Scale Photo-Bioreactor Testing - 18 Month Investment

updaLed: 4-!une-2012 4:23p 1

updaLe: 1-!une-12 11:30a 1 18-Month

Month 1 2 3 4 S 6 7 8 9 10 11 12 13 14 1S 16 17 18

1ota|

Mater|a|s

Pardware 2,000 2,000 2,000 $6,000

SofLware urchase/uevelopmenL 2,300 2,300 2,300 $7,300

1oollng/Machlnlng/Assembly 73,000 70,000 70,000 20,000 14,000 $249,000

MonlLorlng uevlces& Sensors 3,000 3,000 3,000 3,000 $20,000

Mlsc Assembly MaLerlal 1,000 1,000 1,000 1,000 1,000 1,000 1,000 1,000 1,000 1,000 1,000 1,000 1,000 1,000 1,000 1,000 1,000 $17,000

LxLernal Poldlng 1anks 1,300 1,300 1,300 $4,300

ParvesLlng /urylng LqulpmenL 63,000 10,000 $73,000

k&D ] Cperat|ons

ro[ecL Manager 6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

$108,000

ulrecLor of 1echnology 6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

6,000

1

$108,000

SclenLlsLs 0 0 0 0 0 10,000

1

10,000

1

10,000

1

10,000

1

10,000

1

10,000

1

10,000

1

10,000

1

10,000

1

10,000

1

10,000

1

10,000

1

0 $120,000

Lab 1echnlclans 0 0 0 0 0 2,000

1

2,000

1

4,000

2

4,000

2

4,000

2

4,000

2

4,000

2

4,000

2

4,000

2

4,000

2

2,000

1

2,000

1

0 $40,000

ConsulLanLs/Advlsors 3,000 8,000 3,000 10,300 7,300 7,300 7,300 10,300 10,300 10,300 7,300 7,300 7,300 10,300 8,000 3,000 $126,300

1ravel /Lodglng 7,300 7,300 7,300 7,300 7,300 9,300 9,300 9,300 9,300 9,300 9,300 9,300 7,300 7,300 7,300 7,300 7,300 7,300 $149,000

M|ch|gan State Iac|||ty

1esL Chamber 30,000 10,000 10,000 $30,000

PvAC & LlecLrlc lnsLallaLlon 2,300 2,300 2,300 $7,300

lumblng 2,300 2,300 $3,000

Adm|n|strat|ve

CLC/CCC 0 0 0 0 0 0 0 0 0 0 0 4,000

2

4,000

2

4,000

2

4,000

2

4,000

2

4,000

2

4,000

2

$28,000

aLenL roLecLlon /Legal 14,000 9,000 9,000 4,000 4,000 14,000 4,000 4,000 4,000 14,000 4,000 14,000 4,000 4,000 4,000 4,000 4,000 4,000 $122,000

AccounLlng 1,000

1

1,000

1

1,000

1

1,000

1

1,000

1

1,000

1

1,000

1

1,000

1

1,000

1

1,000

1

1,000

1

1,000

1

1,000

1

1,000

1

1,000

1

1,000

1

1,000

1

1,000

1

$18,000

lnsurance LlablllLy/ulrecLors 2,000 2,000 2,000 2,000 2,000 2,000 2,000 2,000 2,000 2,000 2,000 2,000 2,000 2,000 2,000 2,000 2,000 2,000 $36,000

1ravel /Lodglng 2,800 2,800 2,800 2,800 2,800 2,800 2,800 2,800 2,800 2,800 2,800 2,800 2,800 2,800 2,800 2,800 2,800 2,800 $30,400

Cont|ngency 11,330 11,780 11,230 6,030 8,380 8,130 13,330 6,880 6,130 6,680 3,680 7,080 3,380 3,380 3,380 3,680 3,430 3,830 $134,740

Month|y1ota|

126,830 129,S80 123,S30 66,330 94,380 89,430 146,630 7S,680 67,430 73,480 62,480 77,880 61,380 61,380 61,380 62,480 S9,730 42,130 51,482,140

PHASE I - Initial Assemply (California/Texas)

ManufacLure ComponenLs(4unlLs)

Assemble &lnlLlal 1esL2unlLs

1ransporLLoMSu

PHASE II - Full Scale Testing (Michigan State University)

ueslgn1esLlng roLocols

repare laclllLyaLMlchlganSLaLe

llue CasConnecLlons

Assemble 2unlLs

SysLem1esL/CpLlmlzaLlon

Complle &lormaLuaLa for8eporL

uarter|y1ota|

Cumu|at|veInvestment 920,000 1,134,000

380,000 2S0,000

380,000 630,000 1,318,000 1,482,000

290,000 214,000 184,000 164,000

MSU-Dow-Phyco2 Full-Scale Test Plan Executive Summary DRAFT 2-July-12 2:37p PT

9

Appendix PHYCO

2

Directors & Advisors

Board of Directors

Gregory Hagopian, Santa Maria, CA

Chairman BOD, PHYCO

2

CEO Fuel Technologies International

Don Hubbard, Maryland

CEO, PHYCO

2

BA, U.S naval Academy

JD, Maryland School of Law

Claude Hutchison, Jr., Glenbrook, NV

COO PHYCO

2

BS, University of California, Berkeley

MBA, Harvard University

Bruce Tatarian, San Juan Capistrano, CA

Principal, Tatarian & Associates

BA Chemistry,

Cal State University, Fresno

MBA, Cal State University, Long Beach

JD, Western State University

(Member California Bar)

William Clary, Tulsa, OK

Managing Director,

MIRATECH Holdings, LLC

BA Chemistry, Carleton College

MS Mechanical Engineering,

University of Minnesota

Keith Nahigian, Washington, DC

President, Nahigian Strategies

BA, College of Wooster

Karl Seitz, Huntington Beach, CA

Principal, Seitz & Associates, LLC

BS Economics,

University of California, Los Angeles

MBA Taxation, Golden West University

Certified Public Accountant

Advisory Board

Howard L. Chesneau President

Fuel Quality Services, Inc.

25 yrs experience in fuel stability

Chairman Atlanta Chapter SAE

Co-Chair ASTM Committee on Microbial

Contamination

Member ASTM D2 Committee on fuel

from middle distillates to heavy oil.

Co-Editor ASTM, STP 1005 Distillate

Fuel Contamination and Storage

Rafi Fass, Ph.D. Senior Scientist

Dept of Biotechnology,

Israel Inst. for Biological Research,

Ness-Ziona, Israel.

PhD Biotechnology,

Faculty of Agriculture, The Hebrew

University in Rehovot, Israel.

Fields of scientific activity include:

- Applied and environmental biotech,

- Microbiology of hydrocarbons fuel

distillates,

- Bioremediation of contaminated soils

and water,

- Biotechnology R&D and scaling up of

microbial fermentation processes

Edward English VP & Tech Director

Fuel Quality Services, Inc.

Experience in nuclear power industry

BS Chemistry, University of Florida

2 yrs Grad Studies, University of Miami

Norman Arikawa Asst Director of Trade

Port of Los Angeles

Formerly Chief Accountant, Port of LA

Advises LA Mayors Office of Econ Dev

Co-Chair LA Chamber of Commerce

Global Initiatives Committee

Member District Export Council of SoCal

MSU-Dow-Phyco2 Full-Scale Test Plan Executive Summary DRAFT 2-July-12 2:37p PT

10

Appendix Letter of Support Dow Chemical Company

MSU-Dow-Phyco2 Full-Scale Test Plan Executive Summary DRAFT 2-July-12 2:37p PT

11

Appendix Letter of Support Michigan State University

MSU-Dow-Phyco2 Full-Scale Test Plan Executive Summary DRAFT 2-July-12 2:37p PT

12

Appendix Letter of Support Wei Liao, Ph.D., Michigan State University

You might also like

- 017 PDFDocument11 pages017 PDFFrnndMHVilcNo ratings yet

- Algal Biofuels. The BackstoryDocument1 pageAlgal Biofuels. The BackstoryedgardokingNo ratings yet

- State of Technology Review - Algae BioenergyDocument158 pagesState of Technology Review - Algae BioenergyAbelardo Nardo Guzmán LavadoNo ratings yet

- 2016 Renewable Energy World Article - BR-1935Document18 pages2016 Renewable Energy World Article - BR-1935srajl94No ratings yet

- Applied SciencesDocument24 pagesApplied SciencesIonut NistorNo ratings yet

- Development of An Arduino-Based Photobioreactor To Investigate Algae Growth Rate and CO 2 Removal EfficiencyDocument20 pagesDevelopment of An Arduino-Based Photobioreactor To Investigate Algae Growth Rate and CO 2 Removal EfficiencyIAES International Journal of Robotics and AutomationNo ratings yet

- Rocky Farms Methane Recovery ProjectDocument33 pagesRocky Farms Methane Recovery ProjectNestor HubacNo ratings yet

- Isat Proposal Doc AdamDocument12 pagesIsat Proposal Doc Adamapi-323263725No ratings yet

- ChemEng 2007-Green EngineeringDocument4 pagesChemEng 2007-Green Engineeringsinnue92No ratings yet

- Algal Fuel SupplyDocument30 pagesAlgal Fuel Supplyyourpm0% (1)

- Indonesia Workshop Symposium Bioenergy BiomassDocument4 pagesIndonesia Workshop Symposium Bioenergy BiomassMmediong UdofiaNo ratings yet

- Biocatalysis RoadmapDocument41 pagesBiocatalysis RoadmapNavin RaviNo ratings yet

- Biochar, Climate and SoilDocument65 pagesBiochar, Climate and SoilDouglasAlanHuse100% (2)

- Submerged and Floating Photovoltaic Systems: Modelling, Design and Case StudiesFrom EverandSubmerged and Floating Photovoltaic Systems: Modelling, Design and Case StudiesNo ratings yet

- Envtally Benign Solar PowerDocument7 pagesEnvtally Benign Solar PowerHasnain RangwalaNo ratings yet

- Co2 Mitigation and Renewable Oil From Photosynthetic MicrobesDocument36 pagesCo2 Mitigation and Renewable Oil From Photosynthetic MicrobesCarey Pickard100% (7)

- Biophysical Chemistry: Diana Simionato, Stefania Basso, Giorgio M. Giacometti, Tomas MorosinottoDocument8 pagesBiophysical Chemistry: Diana Simionato, Stefania Basso, Giorgio M. Giacometti, Tomas MorosinottoAngel Quijano ArmengolNo ratings yet

- Biofuels in Emerging MarketsDocument23 pagesBiofuels in Emerging MarketsMehmet VarliogluNo ratings yet

- Journal 02 - Smart Aeroponics SystemDocument6 pagesJournal 02 - Smart Aeroponics SystemHYSBNXKNo ratings yet

- Verde Spring 2011Document28 pagesVerde Spring 2011david4084No ratings yet

- End of Design Life Recycling Challenges for PV Modules and BatteriesDocument1 pageEnd of Design Life Recycling Challenges for PV Modules and Batteriesyashas sNo ratings yet

- Unit - IDocument9 pagesUnit - ISasikala biotechNo ratings yet

- Cec 500 2013 157 PDFDocument178 pagesCec 500 2013 157 PDFJohn TauloNo ratings yet

- IOT Monitoring of Microalgae CultivationDocument13 pagesIOT Monitoring of Microalgae CultivationMunirul Ula PhDNo ratings yet

- Conceptual FrameworkDocument12 pagesConceptual Frameworkjohn adizas100% (2)

- Modelagem Fuzzy Aplicada Na Detec o Da Vulnerabildade Eros o CosteiraDocument172 pagesModelagem Fuzzy Aplicada Na Detec o Da Vulnerabildade Eros o CosteiraRuchita PoilkarNo ratings yet

- Análisis Del Ciclo de Vida de Un Sistema Fotovoltaico Integrado en Un Edificiooperando en BogotDocument10 pagesAnálisis Del Ciclo de Vida de Un Sistema Fotovoltaico Integrado en Un Edificiooperando en BogotCAMILO ANDRES VALDERRAMA BENITEZNo ratings yet

- Second Generation Biofuels: High-Efficiency Microalgae For Biodiesel ProductionDocument24 pagesSecond Generation Biofuels: High-Efficiency Microalgae For Biodiesel ProductionCharlesDayanNo ratings yet

- Waste Biorefineries: Advanced Design Concepts for Integrated Waste to Energy ProcessesFrom EverandWaste Biorefineries: Advanced Design Concepts for Integrated Waste to Energy ProcessesNo ratings yet

- Algae BiodiselDocument6 pagesAlgae BiodiselEttim Dwi YogaNo ratings yet

- Carbon Capture Storage Research PaperDocument5 pagesCarbon Capture Storage Research Papergpnovecnd100% (1)

- Environmental Impact Assessment and Emss: An IntroductionDocument17 pagesEnvironmental Impact Assessment and Emss: An IntroductionMunashe Josiah ChipatisoNo ratings yet

- Research Paper Algae BiofuelDocument7 pagesResearch Paper Algae Biofuelgvxphmm8100% (1)

- Lunar Di 2018Document20 pagesLunar Di 2018jorge morenoNo ratings yet

- IEA ExCo64 Algae The Future For Bioenergy Summary and ConclusionsDocument16 pagesIEA ExCo64 Algae The Future For Bioenergy Summary and ConclusionsjkhrashprashNo ratings yet

- Aj Both Ten Years of Hydroponic Lettuce Research 2003Document15 pagesAj Both Ten Years of Hydroponic Lettuce Research 2003Gutierrez MartinNo ratings yet

- Persea Americana Agro-Industrial Waste Biorefinery For Sustainable High-Value-Added ProductsDocument16 pagesPersea Americana Agro-Industrial Waste Biorefinery For Sustainable High-Value-Added ProductsKate Jewel CullamatNo ratings yet

- Substainable Production of Biofuels From BiomassDocument10 pagesSubstainable Production of Biofuels From BiomassBikesh ChaurasiyaNo ratings yet

- Synthetic BiologyDocument64 pagesSynthetic BiologyTaufik RizkiandiNo ratings yet

- UC San Diego: One of The Greenest UniversitiesDocument17 pagesUC San Diego: One of The Greenest UniversitiesjgogekNo ratings yet

- VIT Law School Report on Proposed Changes to India's EIA ProcessDocument7 pagesVIT Law School Report on Proposed Changes to India's EIA ProcessShanmathi TNo ratings yet

- Industrial BiotechnologyDocument6 pagesIndustrial BiotechnologyJorge Alberto CardosoNo ratings yet

- Seminar MaterialDocument76 pagesSeminar MaterialYashNo ratings yet

- Design of An Apparatus For Solar Drying of Farm Products: Chemical EngineeringDocument6 pagesDesign of An Apparatus For Solar Drying of Farm Products: Chemical EngineeringUmerNo ratings yet

- Biofuels From Microalgae PDFDocument6 pagesBiofuels From Microalgae PDFluis APNo ratings yet

- Unu-Gtp-Sc-02-08 Environmental and Social Issues in Geothermal Development in GuatemalaDocument8 pagesUnu-Gtp-Sc-02-08 Environmental and Social Issues in Geothermal Development in GuatemalaPrince MubaiwaNo ratings yet

- Mass Cultivation and Harvesting of Microalgal Biomass: Current Trends and Future PerspectivesDocument14 pagesMass Cultivation and Harvesting of Microalgal Biomass: Current Trends and Future PerspectivesggarzonjNo ratings yet

- NASA Algae Growth System - OMEGADocument3 pagesNASA Algae Growth System - OMEGALinh TranNo ratings yet

- Biomass Pyrolysis - A Guide To UK Capabilities May 2011v2Document26 pagesBiomass Pyrolysis - A Guide To UK Capabilities May 2011v2asimjoshiNo ratings yet

- Biomass From Microalgae: The Potential of Domestication Towards Sustainable BiofactoriesDocument18 pagesBiomass From Microalgae: The Potential of Domestication Towards Sustainable BiofactoriesggarzonjNo ratings yet

- Rooftop Greenhouse LCA and Energy SimulationDocument6 pagesRooftop Greenhouse LCA and Energy Simulationghoshsanjoy1986No ratings yet

- Microalgal Co-Cultivation For Biofuel Production and Bioremediation: Current Status and BenefitsDocument26 pagesMicroalgal Co-Cultivation For Biofuel Production and Bioremediation: Current Status and BenefitsJonathas FerreiraNo ratings yet

- Energy Use in Produciont of MicrochipsDocument7 pagesEnergy Use in Produciont of MicrochipsJai KrishnaNo ratings yet

- Biomass Energy in PhilippinesDocument58 pagesBiomass Energy in PhilippinesMichael Vince Arugay TulauanNo ratings yet

- Solutions to Environmental Problems Involving Nanotechnology and Enzyme TechnologyFrom EverandSolutions to Environmental Problems Involving Nanotechnology and Enzyme TechnologyNo ratings yet

- Research Paper On Algae BiodieselDocument7 pagesResearch Paper On Algae Biodieselefeq3hd0No ratings yet

- (L) Nagarajan2016. BiohydrogenDocument48 pages(L) Nagarajan2016. BiohydrogenSacra PsyntergiaNo ratings yet

- Ug Zs1 Iom Man Rev.h 2012 06Document110 pagesUg Zs1 Iom Man Rev.h 2012 06yulizard100% (1)

- Howell Bunger Valve 05. HBGR - Text New CoverDocument4 pagesHowell Bunger Valve 05. HBGR - Text New CovermuazeemKNo ratings yet

- GROUND Eng LowDocument16 pagesGROUND Eng LowJohanNo ratings yet

- TSID Standard PresentationDocument49 pagesTSID Standard Presentationapi-3695690No ratings yet

- Argus Crude (2022-08-04) PDFDocument37 pagesArgus Crude (2022-08-04) PDFJaffar MazinNo ratings yet

- Kumax: (1000 V / 1500 V) Cs3U-375 - 380 - 385 - 390 - 395MsDocument2 pagesKumax: (1000 V / 1500 V) Cs3U-375 - 380 - 385 - 390 - 395Mspatricio marin guerraNo ratings yet

- Batch Processing & Scheduling EDITED 19-3-2019Document47 pagesBatch Processing & Scheduling EDITED 19-3-2019Engr Muhammad IrfanNo ratings yet

- BP Master Ex Ship LNG Sale and Purchase Agreement 2019 EditionDocument67 pagesBP Master Ex Ship LNG Sale and Purchase Agreement 2019 EditionBlankformNo ratings yet

- Mycem CementDocument89 pagesMycem CementushadgsNo ratings yet

- RCC Cooling Tower Offer for ONGC Hazira PlantDocument11 pagesRCC Cooling Tower Offer for ONGC Hazira PlantPrasanna kumar subudhiNo ratings yet

- Larsen and Toubro Limited Mauritius Metro Express Project Engineering, Procurement and Construction WorkDocument32 pagesLarsen and Toubro Limited Mauritius Metro Express Project Engineering, Procurement and Construction WorkANILNo ratings yet

- A Fuel Saving Revolution?: The Rise of Electric TaxiingDocument92 pagesA Fuel Saving Revolution?: The Rise of Electric Taxiingrey1004100% (1)

- LNG 3.4.e Floating LNG Production19 19967Document12 pagesLNG 3.4.e Floating LNG Production19 19967Richard HollidayNo ratings yet

- UP5-11-37kW Fixed Speed Compressor BrochureDocument12 pagesUP5-11-37kW Fixed Speed Compressor BrochureMizan SarkarNo ratings yet

- Round II Ihub GuidelinesDocument12 pagesRound II Ihub GuidelinesMdau HalisiNo ratings yet

- Tax 1 - TereDocument57 pagesTax 1 - Terecmv mendoza100% (1)

- No 189 ENDocument11 pagesNo 189 ENgarozoNo ratings yet

- Cost Break Down Analysis From MoUDCDocument212 pagesCost Break Down Analysis From MoUDCABAMELANo ratings yet

- OHPC Balimela Volume 1Document108 pagesOHPC Balimela Volume 1gmdgfkNo ratings yet

- MC 2010-018Document7 pagesMC 2010-018caster troyNo ratings yet

- Lor 1Document14 pagesLor 1partha_gang4526No ratings yet

- Omer Farooq ResumeDocument3 pagesOmer Farooq ResumeomerfarooqscribdNo ratings yet

- Schnieder - 2017 Annual Report tcm50 370363 PDFDocument382 pagesSchnieder - 2017 Annual Report tcm50 370363 PDFRaghav BhatnagarNo ratings yet

- MNRE ManualDocument143 pagesMNRE ManualsamirdudhandeNo ratings yet

- Power and Machine Tools SectionDocument100 pagesPower and Machine Tools SectionSantiago UrgilesNo ratings yet

- Atlantic Coast Pipeline ReportDocument14 pagesAtlantic Coast Pipeline ReportDavid FritzNo ratings yet

- Rieter E36 Omegalap Brochure 2611 v6 88630 enDocument24 pagesRieter E36 Omegalap Brochure 2611 v6 88630 enPROLAY BASAKNo ratings yet

- Monarch Instrument: Nova-Strobe Dax and / Et / y Nova-Strobe DBXDocument42 pagesMonarch Instrument: Nova-Strobe Dax and / Et / y Nova-Strobe DBXmanuel008087No ratings yet

- Design of A Low Resistance Grounding System For A Hydro-Electric Plant Located On Highly Resistive SoilsDocument9 pagesDesign of A Low Resistance Grounding System For A Hydro-Electric Plant Located On Highly Resistive SoilsJose Jorge FontalvoNo ratings yet