Professional Documents

Culture Documents

Cooling Water Treatment Fundamentals

Uploaded by

Alfonso José García LagunaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cooling Water Treatment Fundamentals

Uploaded by

Alfonso José García LagunaCopyright:

Available Formats

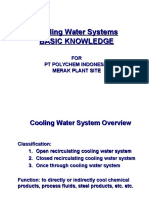

Cooling Water Treatment

Fundamentals

Cooling Water Systems

Once Through

e.g large utility plants

large quantity of water required.

Water taken from plant supply, passed through

cooling system and returned to receiving body

of water.

Closed Recirculating

e.g hot and chilled water loops used for heating,

WATER WATER

OUT OUT

PROCESS PROCESS

OUT OUT

WATER WATER

IN IN

PROCESS PROCESS

IN IN

e.g hot and chilled water loops used for heating,

refrigerating and air conditioning; also critical cooling

applications.

Negligible evaporation or exposure

to atmosphere

High chemical treatment levels but economical

Heat removed from closed loop by second cooling

water cycle e.g. evaporative

Open (Evaporative)

Recirculating

Hot process water cooled by evaporation of

water in contact with air. Cooling tower designed

to maximise water / air contact. Evaporation of water

leads to an increase in the concentration of solids.

PROCESS

IN

PROCESS

OUT

OUT IN

Make up

M

E

B

R R

Water Balance In An Open Evaporative

Cooling Water System

Recirculating Cooling Water (R)

Evaporative Loss (E)

Windage Loss (W)

Environment:

Health & Safety

BLOWDOWN

(B)

MAKEUP

(M)

Holding Water

Volume (H)

Heat Exchanger

Quality

Availability &

Cost

Environment:

Chemical

Discharge

Heat Exchanger

Efficiency

Terms & Symbols Related To Water Balance In

Open Evaporative Cooling Water Systems

Recirculating Water

Quantity

R, m

3

/hr total cooling water circulated by pumps per hour

Holding Water

Volume

V, m

3

total water volume held in cooling water system including piping

and cooling water tower basin

Evaporative Lossess E, m

3

/hr water lost by evaporation per hour

Windage Loss W, m

3

/hr water lost by windage + drift

Blowdown Water B, m

3

/hr water quantity discharged per hour in order to control

concentration

Make Up Water M, m

3

/hr water supplied to the cooling system to maintain system water Make Up Water M, m

3

/hr water supplied to the cooling system to maintain system water

volume

Temperature Drop

Through Cooling

Tower

T, C difference of cooling water temperature between the cooling

tower inlet and outlet

Concentration Factor

(Cycles of

Concentration)

C

F

concentration of dissolved solids in circulating water compared

to makeup water

Retention Time T

R

time required for water to make one trip around the circulating

loop

Holding Time Index,

or Half Life

HTI represents the time required to dilute an added chemical to

50% of its concentration

time required to concentrate makeup solids by a factor of 2

an important factor for establishing effective biofouling, scale

& corrosion control programme

Calculations

Makeup M = E + B + W

Concentration Factor C

F

= [X] Circulating Water

(or Concentration Factor) [X] Makeup Water

Evaporative Losses E = R x T

H

Blowdown B = E ,

(C

F

-1)

Holding Time Index = 0.693 x V ,

Or Half Life B+W

H

H = Latent heat of water evaporation,

Approx 578 kcal/kg at 40C

As a rule of thumb

E = 1.4% x R if T = 10C

E = 0.8% x R if T = 10F

Calculation continued/...

e.g. an open recirculating system has following operating and chemical parameters.

Calculate evaporative losses, concentration factor, blowdown and makeup.

R = 3,500 m

3

/hr [Cl] make up water = 250 ppm

T = 9C [Cl] recirculating water = 750 ppm

ANSWERS

1) Evaporative Losses (E) = R x T = 55 m

3

/hr

578

2) Concentration Factor (C

F

) = 3 (from chloride analysis)

3) Blowdown (B) = E = 55 = 27.5 m

3

/hr

(C

F

- 1) 2

4) Makeup (M) = E + B = (55 +27.5) = 82.5 m

3

/hr

Problems in Cooling Water Systems

Corrosion

(mild steel,

yellow metal)

Efficiency drop in

heat exchangers

Leakage from

heat exchangers

Reduction of

materials strength

Microbiological

(algae, fungi

& bacteria)

Plugging of

heat exchangers

Scale

(Calcium carbonate

calcium phosphate

Silicates and sulphates)

Increased pump

pressure and reduction

of flow rate

Acceleration of corrosion

Dirty Appearance

Sludge

(general deposits)

These problems occur most frequently in open evaporative cooling water systems since the

dissolved solids are concentrated in the cooling water by evaporation.

Adsorption and waste

of chemicals

Estimation of Calcium Carbonate Tendency and

Corrosivity of Cooling Water

Tendency for calcium carbonate formation increases as following water

characteristics increase:

skin temperature (water temperature at heat exchanger surface)

calcium hardness (calcium concentration in the water normally expressed as

calcium carbonate)

alkalinity (bicarbonate + carbonate + hydroxide normally expressed as alkalinity (bicarbonate + carbonate + hydroxide normally expressed as

calcium carbonate

total dissolved solids (tds)

pH

Tabular methods exist to calculate pHs = pH at which calcium carbonate is at

saturation

pH - pHs = Langelier Saturation Index (LSI):

2 pHs - pH = Ryznar Stability Index (RSI) :

Index Tendency of Water

LSI RSI

2.0

0.5

0

-0.5

-2.0

<5.0

5 to 6

6 to 6.5

6.5 to 7

7 to 8

heavily scale forming

slightly scale forming

balanced or at CaCO

3

saturation

non-scaling

undersaturated

sl

Example ..

Calculate LSI and RSI of a cooling water at 60 C, pH 8.5,

calcium hardness = 100 mg/l as calcium carbonate

total alkalinity = 80 mg/l as calcium carbonate

tds = 200 mg/l

pHs = (9.3 + A + B) - (C + D)

Answer:

pHs = (9.3 + A + B) - (C + D)

From tables

pHs = (9.3 + 0.1 + 1.35) - (1.65 + 1.95) = 7.15

LSI = 8.5 - 7.15 = +1.35

RSI = 14.3 - 8.5 = 5.8

Therefore this water is slightly scale forming and a programme

is required to primarily control calcium carbonate formation

Approaches to Efficient Operation of Open

Recirculating Cooling Systems

Operation at Alkaline pH range (8.0 - 9.2)

Higher pH substantially reduces natural corrosivity

,buffer capacity provided by water reduces impact

of system upsets

BUT

deposit control becomes more difficult

stabilisation of zinc and phosphate becomes more

difficult

Properties required from additives used for

effective treatment and maintenance of open

cooling water systems

Calcium carbonate inhibition and control LSI

multifunctional inorganic scale inhibition

effective dispersancy of silt/sludge/corrosion debris

stabilisation of zinc and phosphate in alkaline programmes

robust mild steel and yellow metal corrosion inhibition

under broad operating conditions

broad spectrum biocidal properties particularly at pH 8-9

economical

non-toxic to environment

BWA Water Additives:

Product for Industrial Cooling Water Treatment

Belclene 200 Maleic homopolymer providing outstanding calcium carbonate control under

severe service conditions (high LSI)

Belclene 283 Multifunctional maleic terpolymer providing stabilisation of zinc and

phosphonates: provides effective dispension and calcium carbonate control over

broad operating conditions

Belclene 400 Sulphonated copolymer providing stabilisation of extended phosphate

programmes, zinc, phosphonates: good dispersant for ironoxide & silt/sludge.

Polymeric

Scale

Inhibitor

&

Dispersants

Belclene 499 Provides both phosphonate and sulphonated copolymer functionality in one

molecule; building block for new formulations

Belcor 575 Cathodic corrosion inhibitor used as basis of all-organic, zinc and phosphate band Belcor 575 Cathodic corrosion inhibitor used as basis of all-organic, zinc and phosphate band

corrosion inhibitor programmes.

Belclene 500 Building block for zinc based corrosion programmes for soft water applications

Corrosion

Inhibitors

Belcor 593 Tricarboxylic acid used in combination with Belcor 575 in closed cooling systems

Bellacide 325 Terbuthylazine for control of algae in open recirculating cooling water systems,

ornamental pools and fountains. Exhibits synergistic effect with halogen.

Bellacide 350 Quaternary phosphonium chloride with broad spectrum fast kill performance;

hard surface cleaning properties

BromiCide Hydantoin bromine release product for controlled release of biocidal hypobromous

acid.

Oxidising

&

Non-Oxidising

BioCides

LiquiBrom Sodium Bromide providing safe efficient release of biocidal hypobromous acid

when activated by a chlorine source.

Belclene Phosphonates

Belclene 640: nitrilotris (methylene phosphonic) acid

(ATMP)

Belclene 650: phosphonobutane tricarboxylic acid

(PBTC) (PBTC)

Belclene 660: 1-hydroxyethylidene diphosphonic acid

(HEDP)

You might also like

- Cooling Water TreatmentDocument35 pagesCooling Water TreatmentZahid HussainNo ratings yet

- Cooling Water Treatment Liberty 01Document174 pagesCooling Water Treatment Liberty 01Masood Ahmed67% (3)

- Nalco Cooling Tower PresentationDocument115 pagesNalco Cooling Tower PresentationAnonymous ffje1rpa80% (10)

- GE Book Water TreatmentDocument280 pagesGE Book Water TreatmentRehab Adam100% (2)

- Cooling Water BasicsDocument163 pagesCooling Water BasicsTin Aung Kyi94% (16)

- Carryover in BoilerDocument2 pagesCarryover in Boilershan877No ratings yet

- Boiler Water ChemistryDocument60 pagesBoiler Water Chemistryنيرمين احمدNo ratings yet

- Phosphate Hideout: Questions and AnswersDocument4 pagesPhosphate Hideout: Questions and AnswersSivakumar Rajagopal100% (3)

- Water Treatment For Cooling TowersDocument8 pagesWater Treatment For Cooling TowersSrinivasan RaviNo ratings yet

- Water Treatment Methods for Cooling TowersDocument57 pagesWater Treatment Methods for Cooling TowersKiran Duggaraju100% (3)

- Basic Training WTCDocument244 pagesBasic Training WTCsushant100% (2)

- 7.0 Chemical Treatment: Association of Water Technologies - Technical ManualDocument38 pages7.0 Chemical Treatment: Association of Water Technologies - Technical ManualWaleed Emara100% (1)

- Boiler Water TrainingDocument113 pagesBoiler Water Trainingaramkhosrove92% (13)

- The Use of Polymers To Improve Control of Calcium Phosphonate and Calcium Carbonate in High StressedDocument23 pagesThe Use of Polymers To Improve Control of Calcium Phosphonate and Calcium Carbonate in High Stressedwilmar100% (1)

- Performance Management for Boiler SystemsDocument15 pagesPerformance Management for Boiler SystemsCHRISTIANCHIROQUENo ratings yet

- Cooling Water TreamentDocument112 pagesCooling Water TreamentAbdul BokhariNo ratings yet

- Inhibitor Choice & DosageDocument6 pagesInhibitor Choice & DosagemnasiroleslamiNo ratings yet

- Open Cooling System Guide ALP 25 July 2013 Final VerDocument42 pagesOpen Cooling System Guide ALP 25 July 2013 Final VerivanrhsNo ratings yet

- Boiler Water ChemistryDocument60 pagesBoiler Water ChemistryBhargav Chaudhari93% (14)

- McCoy, James W. - Chemical Analysis of Industrial Water-Chemical Publishing Company Inc. (1969) PDFDocument319 pagesMcCoy, James W. - Chemical Analysis of Industrial Water-Chemical Publishing Company Inc. (1969) PDFVALENTINA ZAPATA ROSERO100% (1)

- Cooling Water Seminar Agenda Nalco TVWD Stress ManagementDocument115 pagesCooling Water Seminar Agenda Nalco TVWD Stress ManagementAttyub100% (2)

- Adv 885 Ro Pac M QuickrefguideDocument8 pagesAdv 885 Ro Pac M QuickrefguideAlejandroOdioCastilloNo ratings yet

- Co-Ordinated and Congruent Phosphate Treatment of Boiler WaterDocument3 pagesCo-Ordinated and Congruent Phosphate Treatment of Boiler WaterRavi Shankar0% (1)

- Dummies Guide To CoagulantsDocument9 pagesDummies Guide To CoagulantsRobert BrescaNo ratings yet

- Chloride RemovalDocument12 pagesChloride Removaldilshad kapoor100% (1)

- BK 3 Sec 3.4-Closed Recirculating SystemsDocument16 pagesBK 3 Sec 3.4-Closed Recirculating SystemsAlwi MahbubiNo ratings yet

- Condensate PolisherDocument20 pagesCondensate Polisherdipankar65No ratings yet

- Cooling Tower Treatment TrainingDocument114 pagesCooling Tower Treatment TrainingMasood Ahmed100% (1)

- Cooling Water Treatment Advanced Training Course Cooling Water Treatment ... (Pdfdrive)Document266 pagesCooling Water Treatment Advanced Training Course Cooling Water Treatment ... (Pdfdrive)mohamed YaakoupNo ratings yet

- NALCO Corrosionmanual72Document126 pagesNALCO Corrosionmanual72Diego Alexander B100% (4)

- ECISGROUP - Cooling Tower Water Treatment - Rev1Document31 pagesECISGROUP - Cooling Tower Water Treatment - Rev1Ecisgroup100% (2)

- Phosphinosuccinic Oligomer (PSO)Document3 pagesPhosphinosuccinic Oligomer (PSO)mirceablaga86No ratings yet

- Cooling Water Chemistry: Specific Skills Training by Laeeq Ahmad RumiDocument31 pagesCooling Water Chemistry: Specific Skills Training by Laeeq Ahmad RumiIqbalAwais100% (1)

- Film Forming Amine in Water or Steam CycleDocument42 pagesFilm Forming Amine in Water or Steam Cycleabdoelandhakim100% (1)

- Cooling Water Treatment NoteDocument13 pagesCooling Water Treatment Notesuparnabhose100% (1)

- Chlorination of Cooling Water Systems PDFDocument4 pagesChlorination of Cooling Water Systems PDFhappale2002No ratings yet

- Nalco ACT: Boiler Water Operator Training NotesDocument4 pagesNalco ACT: Boiler Water Operator Training NotesSheikh Sahab100% (1)

- Silica Carryover in BoilerDocument3 pagesSilica Carryover in BoilermnasiroleslamiNo ratings yet

- ASME - Standard Consensus Water ChemistryDocument30 pagesASME - Standard Consensus Water Chemistryviveksingh061100% (1)

- HP Boiler Water Treatment TrainingDocument79 pagesHP Boiler Water Treatment TrainingJayanath Nuwan Sameera100% (1)

- Boiler Film Forming Amines Hydrocarbon Engineering Sept2015Document5 pagesBoiler Film Forming Amines Hydrocarbon Engineering Sept2015MarcTimNo ratings yet

- Evaluating Polymers and Phosphonates For Use As Inhibitors For Calcium, Phosphate and Iron in Steam BoilersDocument23 pagesEvaluating Polymers and Phosphonates For Use As Inhibitors For Calcium, Phosphate and Iron in Steam Boilersmnasiroleslami100% (3)

- NALCO - Cooling System DynamicsDocument24 pagesNALCO - Cooling System DynamicsRubensBoerngenNo ratings yet

- Uk PDFDocument1 pageUk PDFabuzar khan almaniNo ratings yet

- Orthopolyphosphate Corrosion Inhibitors PDFDocument2 pagesOrthopolyphosphate Corrosion Inhibitors PDFmudassarhussainNo ratings yet

- Boiler Water BBGS PDFDocument32 pagesBoiler Water BBGS PDFproloy12No ratings yet

- Boiler Phosphate TreatmentDocument4 pagesBoiler Phosphate TreatmentSilvina C. Gómez Correa0% (1)

- Nalco ACT® Advanced CondensateDocument2 pagesNalco ACT® Advanced Condensatemirceablaga86No ratings yet

- Dow Industrial Water Treatment Scale Inhibitor and DispersantDocument19 pagesDow Industrial Water Treatment Scale Inhibitor and Dispersantdalton2004100% (2)

- Recommended Abma & Asme Boiler Water LimitsDocument1 pageRecommended Abma & Asme Boiler Water Limitshamid vahedil larijani83% (6)

- Sizing An Ion Exchange SystemDocument14 pagesSizing An Ion Exchange Systemgnino2No ratings yet

- Aromatics UnitsDocument5 pagesAromatics UnitsAbraham Juarez LuisNo ratings yet

- Water Treatment EssentialsDocument24 pagesWater Treatment EssentialsNagaraju BasaNo ratings yet

- EPRI Phosphat & Caustic Treatment GuidelinesDocument404 pagesEPRI Phosphat & Caustic Treatment Guidelinesrizal100% (7)

- BK 305 (REVISION) 2-1-10-Pertanyaan2 Basic Yg Perlu DijawabDocument129 pagesBK 305 (REVISION) 2-1-10-Pertanyaan2 Basic Yg Perlu DijawabDony Abram SimanjuntakNo ratings yet

- HRSG Water ChemistryDocument83 pagesHRSG Water ChemistrynivasssvNo ratings yet

- Cooling Water Chemistry Problems and SolutionsDocument60 pagesCooling Water Chemistry Problems and Solutionspavanchem61No ratings yet

- Demineralization by Ion Exchange: In Water Treatment and Chemical Processing of Other LiquidsFrom EverandDemineralization by Ion Exchange: In Water Treatment and Chemical Processing of Other LiquidsRating: 4 out of 5 stars4/5 (2)

- Training Cooling Water Handout For OperatorDocument33 pagesTraining Cooling Water Handout For Operatordikha haryantoNo ratings yet

- Power Plant ChemistryDocument136 pagesPower Plant ChemistryGajender Singh RajputNo ratings yet

- General Layout W Coordinates & Loads For KELLER 160616Document1 pageGeneral Layout W Coordinates & Loads For KELLER 160616Alfonso José García LagunaNo ratings yet

- ArcelorMittal A3CSoftware Manual PDFDocument49 pagesArcelorMittal A3CSoftware Manual PDFAlfonso José García LagunaNo ratings yet

- V Sohar Support April 4 2016Document5 pagesV Sohar Support April 4 2016Alfonso José García LagunaNo ratings yet

- Pipeline RouteDocument1 pagePipeline RouteAlfonso José García LagunaNo ratings yet

- Pump Station Improvements 2011 - PDR - 201407231644149204Document206 pagesPump Station Improvements 2011 - PDR - 201407231644149204Alfonso José García LagunaNo ratings yet

- MBR-C1 Fundamentals of MBRDocument36 pagesMBR-C1 Fundamentals of MBRAlfonso José García Laguna100% (3)

- Basic Hoist ConfigurationsDocument1 pageBasic Hoist ConfigurationsAlfonso José García LagunaNo ratings yet

- 9.7.2Document3 pages9.7.2Shajit KumarNo ratings yet

- 1021Q - West Bay Pump EvaluationDocument47 pages1021Q - West Bay Pump EvaluationAlfonso José García LagunaNo ratings yet

- STF CatalogueDocument18 pagesSTF CatalogueAlfonso José García LagunaNo ratings yet

- Plastics Pipe Institute Handbook of Polyethylene Pipe: Handbook Errata Sheet - March 2009Document1 pagePlastics Pipe Institute Handbook of Polyethylene Pipe: Handbook Errata Sheet - March 2009Alfonso José García LagunaNo ratings yet

- MBR-C3 Fouling & CleaningDocument31 pagesMBR-C3 Fouling & CleaningAlfonso José García Laguna100% (1)

- 02.P4 Anexo KKS DescriptionDocument29 pages02.P4 Anexo KKS DescriptionAlfonso José García Laguna100% (1)

- MBBR Baru PDFDocument67 pagesMBBR Baru PDFirpansejatiNo ratings yet

- Psa 5 Product OverviewDocument26 pagesPsa 5 Product OverviewAlfonso José García LagunaNo ratings yet

- PVE5 BrochureDocument2 pagesPVE5 BrochureAlfonso José García LagunaNo ratings yet

- MBR C0 IntroductionDocument4 pagesMBR C0 IntroductionAlfonso José García LagunaNo ratings yet

- P Ve 5 Product OverviewDocument26 pagesP Ve 5 Product OverviewAlfonso José García LagunaNo ratings yet

- Psa 5 BrochureDocument2 pagesPsa 5 BrochureAlfonso José García LagunaNo ratings yet

- Whessoe Computing Systems - PVE5Document1 pageWhessoe Computing Systems - PVE5Alfonso José García LagunaNo ratings yet

- VH User Manual - 4.1Document161 pagesVH User Manual - 4.1Alfonso José García LagunaNo ratings yet

- Fig-40 - Simbología Central NuclearDocument2 pagesFig-40 - Simbología Central NuclearAlfonso José García LagunaNo ratings yet

- Learn MATLABDocument61 pagesLearn MATLABsayyanNo ratings yet

- Optimizing Pumping Systems (OPS 9 - Executive - SummaryDocument13 pagesOptimizing Pumping Systems (OPS 9 - Executive - SummaryAlfonso José García LagunaNo ratings yet

- Pumping System Prescreening Form Final 4-16Document2 pagesPumping System Prescreening Form Final 4-16Alfonso José García LagunaNo ratings yet

- Declaration Letter PDFDocument1 pageDeclaration Letter PDFAlfonso José García LagunaNo ratings yet

- EPDM Technical CatalogueDocument3 pagesEPDM Technical CatalogueAlfonso José García LagunaNo ratings yet

- VSP Executive SummaryDocument25 pagesVSP Executive SummaryAlfonso José García LagunaNo ratings yet

- Water and Wastewater International - September & October 2014Document53 pagesWater and Wastewater International - September & October 2014Alfonso José García Laguna100% (1)

- Siemens Forty X Disc Filters Tech. Specs.Document25 pagesSiemens Forty X Disc Filters Tech. Specs.Alfonso José García LagunaNo ratings yet

- AY - XP 081013 CE AE-X 081013 BE S Manual 2004-s2Document52 pagesAY - XP 081013 CE AE-X 081013 BE S Manual 2004-s2José MacedoNo ratings yet

- Vibration Reduction in A Variable Displacement Engine Using Pendulum AbsorbersDocument6 pagesVibration Reduction in A Variable Displacement Engine Using Pendulum Absorbersdeepak_gupta_pritiNo ratings yet

- Entreprenuership: Ej Faith Tabia ABM 12-CDocument11 pagesEntreprenuership: Ej Faith Tabia ABM 12-CErica Faye JometanoNo ratings yet

- Tax Invoice: Plot No.E1-E2, Riico Industr-Ial Ajmer Gstin/Uin: 08AACCT2953Q1ZQ State Name: Rajasthan, Code: 08Document1 pageTax Invoice: Plot No.E1-E2, Riico Industr-Ial Ajmer Gstin/Uin: 08AACCT2953Q1ZQ State Name: Rajasthan, Code: 08SHIV SHAKTI TRUCKSNo ratings yet

- Times Leader 09-17-2012Document34 pagesTimes Leader 09-17-2012The Times LeaderNo ratings yet

- Risk Assessment TemplateDocument3 pagesRisk Assessment TemplateskiersteveNo ratings yet

- Data Sheet - Nvidia Jetson Tx2 System-On-moduleDocument61 pagesData Sheet - Nvidia Jetson Tx2 System-On-moduleDeepak RajamohanNo ratings yet

- BENZi ZINC CHROMATE PRIMER TSDSDocument2 pagesBENZi ZINC CHROMATE PRIMER TSDSMatt CerosNo ratings yet

- DUYA SLORD DEVT. CORP Vs NOYADocument2 pagesDUYA SLORD DEVT. CORP Vs NOYALYN MAE ELICANNo ratings yet

- Quantitative Research by Dr. Myla M. Arcinas SDRC WebinarDocument56 pagesQuantitative Research by Dr. Myla M. Arcinas SDRC WebinarFerry FrondaNo ratings yet

- Solution Manual For Personal Finance 12th Edition by GarmanDocument7 pagesSolution Manual For Personal Finance 12th Edition by Garmana719435805No ratings yet

- Tax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Document1 pageTax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Most WantedNo ratings yet

- Cisco IOS Configuration Fundamentals and Network Management Configuration Guide, Release 12.3Document3 pagesCisco IOS Configuration Fundamentals and Network Management Configuration Guide, Release 12.3christopherfaustNo ratings yet

- Mortgage Dispute ResolvedDocument175 pagesMortgage Dispute ResolvedGabrielle Adine SantosNo ratings yet

- Cat Logan RecDocument1 pageCat Logan Reccatlogan11No ratings yet

- Open Source Tools: Boring Head Exploded ViewDocument7 pagesOpen Source Tools: Boring Head Exploded ViewTom RuxtonNo ratings yet

- Minutes - Inventory Case FoldersDocument2 pagesMinutes - Inventory Case FoldersCA CANo ratings yet

- Reviewer RESA LAWDocument34 pagesReviewer RESA LAWMadonna P. EsperaNo ratings yet

- In The Chancery Court For Washington County, Tennessee at JonesboroughDocument9 pagesIn The Chancery Court For Washington County, Tennessee at JonesboroughJessica FullerNo ratings yet

- Jax Pyro-Kote Series Oils: High-Flash, High-Temperature, Antiwear, Synthetic Polyol Ester Conveyor Chain LubricantsDocument2 pagesJax Pyro-Kote Series Oils: High-Flash, High-Temperature, Antiwear, Synthetic Polyol Ester Conveyor Chain Lubricantsthehoang12310No ratings yet

- EnglishDocument7 pagesEnglishjeffersonbaltodano1No ratings yet

- HCF4017B: Decade Counter With 10 Decoded OutputsDocument11 pagesHCF4017B: Decade Counter With 10 Decoded Outputs19thmnlfreemsNo ratings yet

- Gearless Drives For Medium-Power Belt Conveyors: MotionDocument6 pagesGearless Drives For Medium-Power Belt Conveyors: MotionchalogdNo ratings yet

- LCI Brushless Exciter VFD System OverviewDocument58 pagesLCI Brushless Exciter VFD System Overviewakm-ntpc100% (4)

- 2018 Book KnowledgeManagementInTheSharin PDFDocument290 pages2018 Book KnowledgeManagementInTheSharin PDF16803244No ratings yet

- Inspire Awards - EditedDocument2 pagesInspire Awards - EditedVamsee Krishna Reddy BheriNo ratings yet

- Questionnaire San Pedro Good SamDocument16 pagesQuestionnaire San Pedro Good SamRommel Urbano YabisNo ratings yet

- ECTE323/8323 Synchronous Machines GuideDocument28 pagesECTE323/8323 Synchronous Machines GuideFUCKYOUNo ratings yet

- D7sys Funktion BDocument530 pagesD7sys Funktion BpandhuNo ratings yet

- Linear Hall Sensor Technical SpecsDocument3 pagesLinear Hall Sensor Technical SpecsjelhosteNo ratings yet