Professional Documents

Culture Documents

Centrifugal Pump

Uploaded by

safald100%(2)100% found this document useful (2 votes)

397 views68 pagesCentrifugal Pump design

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCentrifugal Pump design

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

100%(2)100% found this document useful (2 votes)

397 views68 pagesCentrifugal Pump

Uploaded by

safaldCentrifugal Pump design

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 68

Spec.

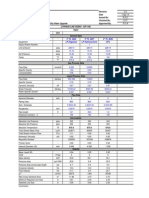

/Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Vendor: * Item no.: PU-1311

1 Equipment name : Potble Water Transfer Pump Number required (incl. spare) :

2 Liquid pumped : Water Capacity normal: 16 m/h ; rated : 19 m/h

3 Operation : continuous Discharge pressure at rated capacity : 3.813 bara

4 Solids : - %; max. size : mm Suction pressure min. : - bara

5 Corrosive/Erosive service : no Suction pressure max. : 0.918 bara

6 Pumping temperature (p.t.) : 25 C Differential pressure : 3 bar

7 Pumping temperature max. : 37.5 C Differential head : 30 m. liq.

8 Density at pumping temperature : 997 kg/m Shut-off head : * m. liq.

9 Viscosity at pumping temperature : 0.89 mPa.s NPSH available : 8.07 m. liq.

10 Vapour pressure at pumping temp. : 0.032 bara NPSH required : * m. liq.

11 Area classification : Shut-off head max. allowable : m. liq.

12 * to be stated by vendor Minimum continuous flow : m/h

13 Manufacturer (MFR) : * Nozzles Nom. diameter Rating Type/Fac. Pos.

14 Type : Centrifugal Suction * END

15 Model : * Discharge * TOP

16 Location : outdoor Vent * *

17 Arrangement : horizontal Drain * *

18 Rotation facing coupling : * cw/ccw Cooling * *

19 Suction : single Flushing * *

20 Number of stages : 1

21 Self priming : no Hydraulic power at rated capacity : 1.544 kW

22 Design pressure : * bara Hydraulic efficiency at normal capacity : * %

23 Design temperature : * C Power required : * kW

24 Max. allow. operating pressure : * barg Power installed : * kW

25 Casing split : radial Pump speed : * rpm

26 Impeller type : * Driver speed : * rpm

27 Impeller diameter supplied : * mm Pump drive : *

28 Impeller diameter min. : * mm ; max : * mm Driver type : *

29 Driver supply : *

30 Bearings : axial ; type: * Weight pump : * kg

31 Bearings : radial ; type: * Weight base plate : - kg

32 Bearings : intermittent ; type: * Weight driver : * kg

33 Bearing lubrication : oil Shipping weight : * kg

34 Common base plate Required : no

35 for pump and driver By MFR : no Test Required Witnessed

36 Coupling : yes ; type : * Performance yes no

37 Coupling guard : yes ; type : * Hydrostatic yes no

38 Foundation bolts : yes ; by MFR: yes NPSH yes no

39 Slide rails : yes/no Single

40 MFR : * ;type : Single

41 Smothering gland : yes Flushing liquid : *

42 Shipment of seal/packing : separate Flushing liquid flow rate : * m/h

43 Casing/bearing/seals/none/ Flushing liquid design pressure : * barg

44 Cooling/Heating Medium : - Flushing system acc. API-610 plan no. : -

45 Consumption : - kg/h Auxiliary piping by pump MFR : no

46 Design pressure : : - barg Seal/packing by pump MFR : yes

47 Stuffing box: number of rings :

48 Casing and cover : Cast Iron Packing : *

49 Casing wearring : Cast Iron Gland : *

50 Impeller : * (Note 3) Gaskets : *

51 Impeller wearring : * (Note 3) O-ring : *

52 Shaft : * Lantern ring : *

53 Shaft sleeve : * (Note 3) Throat bushing : *

54 Coupling guard : * (Note 3) Mechanical seal : *

55 Base plate : - Auxiliary piping : -

rev. Client: PT. UNILEVER INDONESIA TBK, Project: SILIWANGI 1 rev.

Client's Project No.: 13021 Plant Location: SILIWANGI 00

Description/Issued for Ckd Approved

RNA

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 1 of: 2

P

r

o

c

e

s

s

a

n

d

o

p

e

r

a

t

i

n

g

d

a

t

a

M

e

c

h

a

n

i

c

a

l

d

a

t

a

M

e

c

h

a

n

i

c

a

l

s

e

a

l

d

a

t

a

M

a

t

e

r

i

a

l

*

*

*

*

*

*

A 2/7/2014 IDC RK

Rev. Date By

LG

*

*

*

*

*

*

Spec./Data sheet for: (CONTINUATION)

Cost Acc. Code: Item no.:PU-1311

1

2

3 Motors / Turbine - : Motor

4 Power Supply V / Phase / Hz : 400 / 3 / 50

5 Transmission - : Direct Drive

6 Cooling Type - : *

7 Motive fluid - : *

8 Frame size - : *

9 Model - : *

10 Manufacture - : *

11 Rating - : *

12 NOL Power : *

13 Hazardous Area Classification - : Safe / Non Hazardus / Non Flammable

14 Surface finish & wetted Parts Micron : 0.8

15 Net weight - Pump. Base & Motor Kg : *

16 Max. Maintence Weight Kg : *

17 Noise Level dBA : <80

18

19

20

21 Notes:

22 * To be provided by vendor

23 Pump differential pressure should be reviewed and shall be confirmed after Plot Plan/ Equipment layout

24 MOC of all wetted part shall be suitable for water services.

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

rev. 43

Client: PT. UNILEVER INDONESIA TBK,

Client's Project No.: 13021

Project:SILIWANGI 1

Plant Location:SILIWANGI

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 2 of: 2

Description

D

r

i

v

e

r

s

&

T

r

a

n

s

m

i

s

s

i

o

n

R

e

m

a

r

k

s

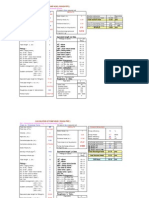

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Vendor: * Item no.: PU-1312

1 Equipment name : Potble Water Transfer Pump Number required (incl. spare) :

2 Liquid pumped : Water Capacity normal: 16 m/h ; rated : 19 m/h

3 Operation : continuous Discharge pressure at rated capacity : 3.813 bara

4 Solids : - %; max. size : mm Suction pressure min. : - bara

5 Corrosive/Erosive service : no Suction pressure max. : 0.918 bara

6 Pumping temperature (p.t.) : 25 C Differential pressure : 3 bar

7 Pumping temperature max. : 37.5 C Differential head : 30 m. liq.

8 Density at pumping temperature : 997 kg/m Shut-off head : * m. liq.

9 Viscosity at pumping temperature : 0.89 mPa.s NPSH available : 8.07 m. liq.

10 Vapour pressure at pumping temp. : 0.032 bara NPSH required : * m. liq.

11 Area classification : Shut-off head max. allowable : m. liq.

12 * to be stated by vendor Minimum continuous flow : m/h

13 Manufacturer (MFR) : * Nozzles Nom. diameter Rating Type/Fac. Pos.

14 Type : Centrifugal Suction * END

15 Model : * Discharge * TOP

16 Location : outdoor Vent * *

17 Arrangement : horizontal Drain * *

18 Rotation facing coupling : * cw/ccw Cooling * *

19 Suction : single Flushing * *

20 Number of stages : 1

21 Self priming : no Hydraulic power at rated capacity : 1.544 kW

22 Design pressure : * bara Hydraulic efficiency at normal capacity : * %

23 Design temperature : * C Power required : * kW

24 Max. allow. operating pressure : * barg Power installed : * kW

25 Casing split : radial Pump speed : * rpm

26 Impeller type : * Driver speed : * rpm

27 Impeller diameter supplied : * mm Pump drive : *

28 Impeller diameter min. : * mm ; max : * mm Driver type : *

29 Driver supply : *

30 Bearings : axial ; type: * Weight pump : * kg

31 Bearings : radial ; type: * Weight base plate : - kg

32 Bearings : intermittent ; type: * Weight driver : * kg

33 Bearing lubrication : oil Shipping weight : * kg

34 Common base plate Required : no

35 for pump and driver By MFR : no Test Required Witnessed

36 Coupling : yes ; type : * Performance yes no

37 Coupling guard : yes ; type : * Hydrostatic yes no

38 Foundation bolts : yes ; by MFR: yes NPSH yes no

39 Slide rails : yes/no Single

40 MFR : * ;type : Single

41 Smothering gland : yes Flushing liquid : *

42 Shipment of seal/packing : separate Flushing liquid flow rate : * m/h

43 Casing/bearing/seals/none/ Flushing liquid design pressure : * barg

44 Cooling/Heating Medium : - Flushing system acc. API-610 plan no. : -

45 Consumption : - kg/h Auxiliary piping by pump MFR : no

46 Design pressure : : - barg Seal/packing by pump MFR : yes

47 Stuffing box: number of rings :

48 Casing and cover : Cast Iron Packing : *

49 Casing wearring : Cast Iron Gland : *

50 Impeller : * (Note 3) Gaskets : *

51 Impeller wearring : * (Note 3) O-ring : *

52 Shaft : * Lantern ring : *

53 Shaft sleeve : * (Note 3) Throat bushing : *

54 Coupling guard : * (Note 3) Mechanical seal : *

55 Base plate : - Auxiliary piping : -

rev. Client: PT. UNILEVER INDONESIA TBK, Project: SILIWANGI 1 rev.

Client's Project No.: 13021 Plant Location: SILIWANGI 00

Description/Issued for Ckd Approved

RNA

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 1 of: 2

LG

M

e

c

h

a

n

i

c

a

l

s

e

a

l

d

a

t

a

M

a

t

e

r

i

a

l

Rev. Date By

A 2/7/2014 IDC RK

* *

* *

* *

P

r

o

c

e

s

s

a

n

d

o

p

e

r

a

t

i

n

g

d

a

t

a

M

e

c

h

a

n

i

c

a

l

d

a

t

a

* *

* *

* *

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Item no.: PU-1312

1

2

3 Motors / Turbine - : Motor

4 Power Supply V / Phase / Hz : 400 / 3 / 50

5 Transmission - : Direct Drive

6 Cooling Type - : *

7 Motive fluid - : *

8 Frame size - : *

9 Model - : *

10 Manufacture - : *

11 Rating - : *

12 NOL Power : *

13 Hazardous Area Classification - : Safe / Non Hazardus / Non Flammable

14 Surface finish & wetted Parts Micron : 0.8

15 Net weight - Pump. Base & Motor Kg : *

16 Max. Maintence Weight Kg : *

17 Noise Level dBA : <80

18

19

20

21 Notes:

22 * To be provided by vendor

23 Pump differential pressure should be reviewed and shall be confirmed after Plot Plan/ Equipment layout

24 MOC of all wetted part shall be suitable for water services.

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

rev. 43

Client: PT. UNILEVER INDONESIA TBK,

Client's Project No.: 13021

Project:SILIWANGI 1

Plant Location:SILIWANGI

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 2 of: 2

D

r

i

v

e

r

s

&

T

r

a

n

s

m

i

s

s

i

o

n

R

e

m

a

r

k

s

Description

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Vendor: * Item no.: PU-1411

1 Equipment name : Cooling tower pump Number required (incl. spare) :

2 Liquid pumped : Water Capacity normal: 360 m/h ; rated : 360 m/h

3 Operation : continuous Discharge pressure at rated capacity : 4.43 bara

4 Solids : - %; max. size : mm Suction pressure min. : - bara

5 Corrosive/Erosive service : no Suction pressure max. : 0.92 bara

6 Pumping temperature (p.t.) : 35 C Differential pressure : 2.013 bar

7 Pumping temperature max. : 52.5 C Differential head : 36 m. liq.

8 Density at pumping temperature : 969 kg/m Shut-off head : * m. liq.

9 Viscosity at pumping temperature : 0.719 mPa.s NPSH available : 7.87 m. liq.

10 Vapour pressure at pumping temp. : 0.056 bara NPSH required : * m. liq.

11 Area classification : Shut-off head max. allowable : * m. liq.

12 * to be stated by vendor Minimum continuous flow : * m/h

13 Manufacturer (MFR) : * Nozzles Nom. diameter Rating Type/Fac. Pos.

14 Type : Centrifugal Suction * END

15 Model : * Discharge * TOP

16 Location : outdoor Vent * *

17 Arrangement : horizontal Drain * *

18 Rotation facing coupling : * cw/ccw Cooling * *

19 Suction : single Flushing * *

20 Number of stages : 1

21 Self priming : no Hydraulic power at rated capacity : 35.08 kW

22 Design pressure : * bara Hydraulic efficiency at normal capacity : * %

23 Design temperature : * C Power required : * kW

24 Max. allow. operating pressure : * barg Power installed : * kW

25 Casing split : radial Pump speed : * rpm

26 Impeller type : * Driver speed : * rpm

27 Impeller diameter supplied : * mm Pump drive : *

28 Impeller diameter min. : * mm ; max : * mm Driver type : *

29 Driver supply : *

30 Bearings : axial ; type: * Weight pump : * kg

31 Bearings : radial ; type: * Weight base plate : - kg

32 Bearings : intermittent ; type: * Weight driver : * kg

33 Bearing lubrication : oil Shipping weight : * kg

34 Common base plate Required : no

35 for pump and driver By MFR : no Test Required Witnessed

36 Coupling : yes ; type : * Performance yes no

37 Coupling guard : yes ; type : * Hydrostatic yes no

38 Foundation bolts : yes ; by MFR: yes NPSH yes no

39 Slide rails : yes/no Single

40 MFR : * ;type : Single

41 Smothering gland : yes Flushing liquid : *

42 Shipment of seal/packing : separate Flushing liquid flow rate : * m/h

43 Casing/bearing/seals/none/ Flushing liquid design pressure : * barg

44 Cooling/Heating Medium : - Flushing system acc. API-610 plan no. : -

45 Consumption : - kg/h Auxiliary piping by pump MFR : no

46 Design pressure : : - barg Seal/packing by pump MFR : yes

47 Stuffing box: number of rings :

48 Casing and cover : Cast Iron Packing : *

49 Casing wearring : Cast Iron Gland : *

50 Impeller : * (Note 3) Gaskets : *

51 Impeller wearring : * (Note 3) O-ring : *

52 Shaft : * Lantern ring : *

53 Shaft sleeve : * (Note 3) Throat bushing : *

54 Coupling guard : * (Note 3) Mechanical seal : *

55 Base plate : - Auxiliary piping : -

rev. Client: PT. UNILEVER INDONESIA TBK, Project: SILIWANGI 1 rev.

Client's Project No.: 13021 Plant Location: SILIWANGI 00

Description/Issued for Ckd Approved

RNA

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 1 of: 2

LG

M

e

c

h

a

n

i

c

a

l

s

e

a

l

d

a

t

a

M

a

t

e

r

i

a

l

Rev. Date By

A 2/7/2014 IDC RK

* *

* *

* *

P

r

o

c

e

s

s

a

n

d

o

p

e

r

a

t

i

n

g

d

a

t

a

M

e

c

h

a

n

i

c

a

l

d

a

t

a

* *

* *

* *

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Item no.: PU-1411

1

2

3 Motors / Turbine - : Motor

4 Power Supply V / Phase / Hz : 400 / 3 / 50

5 Transmission - : Direct Drive

6 Cooling Type - : *

7 Motive fluid - : *

8 Frame size - : *

9 Model - : *

10 Manufacture - : *

11 Rating - : *

12 NOL Power : *

13 Hazardous Area Classification - : Safe / Non Hazardus / Non Flammable

14 Surface finish & wetted Parts Micron : 0.8

15 Net weight - Pump. Base & Motor Kg : *

16 Max. Maintence Weight Kg : *

17 Noise Level dBA : <80

18

19

20

21 Notes:

22 * To be provided by vendor

23 Pump differential pressure should be reviewed and shall be confirmed after Plot Plan/ Equipment layout

24 MOC of all wetted part shall be suitable for water services.

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

rev. 43

Client: PT. UNILEVER INDONESIA TBK,

Client's Project No.: 13021

Project:SILIWANGI 1

Plant Location:SILIWANGI

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 2 of: 2

D

r

i

v

e

r

s

&

T

r

a

n

s

m

i

s

s

i

o

n

R

e

m

a

r

k

s

Description

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Vendor: * Item no.: PU-1412

1 Equipment name : Cooling tower pump Number required (incl. spare) :

2 Liquid pumped : Water Capacity normal: 360 m/h ; rated : 360 m/h

3 Operation : continuous Discharge pressure at rated capacity : 4.43 bara

4 Solids : - %; max. size : mm Suction pressure min. : - bara

5 Corrosive/Erosive service : no Suction pressure max. : 0.92 bara

6 Pumping temperature (p.t.) : 35 C Differential pressure : 2.013 bar

7 Pumping temperature max. : 52.5 C Differential head : 36 m. liq.

8 Density at pumping temperature : 969 kg/m Shut-off head : * m. liq.

9 Viscosity at pumping temperature : 0.719 mPa.s NPSH available : 7.87 m. liq.

10 Vapour pressure at pumping temp. : 0.056 bara NPSH required : * m. liq.

11 Area classification : Shut-off head max. allowable : * m. liq.

12 * to be stated by vendor Minimum continuous flow : * m/h

13 Manufacturer (MFR) : * Nozzles Nom. diameter Rating Type/Fac. Pos.

14 Type : Centrifugal Suction * END

15 Model : * Discharge * TOP

16 Location : outdoor Vent * *

17 Arrangement : horizontal Drain * *

18 Rotation facing coupling : * cw/ccw Cooling * *

19 Suction : single Flushing * *

20 Number of stages : 1

21 Self priming : no Hydraulic power at rated capacity : 35.08 kW

22 Design pressure : * bara Hydraulic efficiency at normal capacity : * %

23 Design temperature : * C Power required : * kW

24 Max. allow. operating pressure : * barg Power installed : * kW

25 Casing split : radial Pump speed : * rpm

26 Impeller type : * Driver speed : * rpm

27 Impeller diameter supplied : * mm Pump drive : *

28 Impeller diameter min. : * mm ; max : * mm Driver type : *

29 Driver supply : *

30 Bearings : axial ; type: * Weight pump : * kg

31 Bearings : radial ; type: * Weight base plate : - kg

32 Bearings : intermittent ; type: * Weight driver : * kg

33 Bearing lubrication : oil Shipping weight : * kg

34 Common base plate Required : no

35 for pump and driver By MFR : no Test Required Witnessed

36 Coupling : yes ; type : * Performance yes no

37 Coupling guard : yes ; type : * Hydrostatic yes no

38 Foundation bolts : yes ; by MFR: yes NPSH yes no

39 Slide rails : yes/no Single

40 MFR : * ;type : Single

41 Smothering gland : yes Flushing liquid : *

42 Shipment of seal/packing : separate Flushing liquid flow rate : * m/h

43 Casing/bearing/seals/none/ Flushing liquid design pressure : * barg

44 Cooling/Heating Medium : - Flushing system acc. API-610 plan no. : -

45 Consumption : - kg/h Auxiliary piping by pump MFR : no

46 Design pressure : : - barg Seal/packing by pump MFR : yes

47 Stuffing box: number of rings :

48 Casing and cover : Cast Iron Packing : *

49 Casing wearring : Cast Iron Gland : *

50 Impeller : * (Note 3) Gaskets : *

51 Impeller wearring : * (Note 3) O-ring : *

52 Shaft : * Lantern ring : *

53 Shaft sleeve : * (Note 3) Throat bushing : *

54 Coupling guard : * (Note 3) Mechanical seal : *

55 Base plate : - Auxiliary piping : -

rev. Client: PT. UNILEVER INDONESIA TBK, Project: SILIWANGI 1 rev.

Client's Project No.: 13021 Plant Location: SILIWANGI 00

Description/Issued for Ckd Approved

RNA

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 1 of: 2

LG

M

e

c

h

a

n

i

c

a

l

s

e

a

l

d

a

t

a

M

a

t

e

r

i

a

l

Rev. Date By

A 2/7/2014 IDC RK

* *

* *

* *

P

r

o

c

e

s

s

a

n

d

o

p

e

r

a

t

i

n

g

d

a

t

a

M

e

c

h

a

n

i

c

a

l

d

a

t

a

* *

* *

* *

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Item no.: PU-1412

1

2

3 Motors / Turbine - : Motor

4 Power Supply V / Phase / Hz : 400 / 3 / 50

5 Transmission - : Direct Drive

6 Cooling Type - : *

7 Motive fluid - : *

8 Frame size - : *

9 Model - : *

10 Manufacture - : *

11 Rating - : *

12 NOL Power : *

13 Hazardous Area Classification - : Safe / Non Hazardus / Non Flammable

14 Surface finish & wetted Parts Micron : 0.8

15 Net weight - Pump. Base & Motor Kg : *

16 Max. Maintence Weight Kg : *

17 Noise Level dBA : <80

18

19

20

21 Notes:

22 * To be provided by vendor

23 Pump differential pressure should be reviewed and shall be confirmed after Plot Plan/ Equipment layout

24 MOC of all wetted part shall be suitable for water services.

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

rev. 43

Client: PT. UNILEVER INDONESIA TBK,

Client's Project No.: 13021

Project:SILIWANGI 1

Plant Location:SILIWANGI

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 2 of: 2

D

r

i

v

e

r

s

&

T

r

a

n

s

m

i

s

s

i

o

n

R

e

m

a

r

k

s

Description

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Vendor: * Item no.: PU-1413

1 Equipment name : Cooling tower pump Number required (incl. spare) :

2 Liquid pumped : Water Capacity normal: 360 m/h ; rated : 360 m/h

3 Operation : continuous Discharge pressure at rated capacity : 4.43 bara

4 Solids : - %; max. size : mm Suction pressure min. : - bara

5 Corrosive/Erosive service : no Suction pressure max. : 0.92 bara

6 Pumping temperature (p.t.) : 35 C Differential pressure : 2.013 bar

7 Pumping temperature max. : 52.5 C Differential head : 36 m. liq.

8 Density at pumping temperature : 969 kg/m Shut-off head : * m. liq.

9 Viscosity at pumping temperature : 0.719 mPa.s NPSH available : 7.87 m. liq.

10 Vapour pressure at pumping temp. : 0.056 bara NPSH required : * m. liq.

11 Area classification : Shut-off head max. allowable : * m. liq.

12 * to be stated by vendor Minimum continuous flow : * m/h

13 Manufacturer (MFR) : * Nozzles Nom. diameter Rating Type/Fac. Pos.

14 Type : Centrifugal Suction * END

15 Model : * Discharge * TOP

16 Location : outdoor Vent * *

17 Arrangement : horizontal Drain * *

18 Rotation facing coupling : * cw/ccw Cooling * *

19 Suction : single Flushing * *

20 Number of stages : 1

21 Self priming : no Hydraulic power at rated capacity : 35.08 kW

22 Design pressure : * bara Hydraulic efficiency at normal capacity : * %

23 Design temperature : * C Power required : * kW

24 Max. allow. operating pressure : * barg Power installed : * kW

25 Casing split : radial Pump speed : * rpm

26 Impeller type : * Driver speed : * rpm

27 Impeller diameter supplied : * mm Pump drive : *

28 Impeller diameter min. : * mm ; max : * mm Driver type : Direct

29 Driver supply : *

30 Bearings : axial ; type: * Weight pump : * kg

31 Bearings : radial ; type: * Weight base plate : - kg

32 Bearings : intermittent ; type: * Weight driver : * kg

33 Bearing lubrication : oil Shipping weight : * kg

34 Common base plate Required : no

35 for pump and driver By MFR : no Test Required Witnessed

36 Coupling : yes ; type : * Performance yes no

37 Coupling guard : yes ; type : * Hydrostatic yes no

38 Foundation bolts : yes ; by MFR: yes NPSH yes no

39 Slide rails : yes/no Single

40 MFR : * ;type : Single

41 Smothering gland : yes Flushing liquid : *

42 Shipment of seal/packing : separate Flushing liquid flow rate : * m/h

43 Casing/bearing/seals/none/ Flushing liquid design pressure : * barg

44 Cooling/Heating Medium : - Flushing system acc. API-610 plan no. : -

45 Consumption : - kg/h Auxiliary piping by pump MFR : no

46 Design pressure : : - barg Seal/packing by pump MFR : yes

47 Stuffing box: number of rings :

48 Casing and cover : Cast Iron Packing : *

49 Casing wearring : Cast Iron Gland : *

50 Impeller : * (Note 3) Gaskets : *

51 Impeller wearring : * (Note 3) O-ring : *

52 Shaft : * Lantern ring : *

53 Shaft sleeve : * (Note 3) Throat bushing : *

54 Coupling guard : * (Note 3) Mechanical seal : *

55 Base plate : - Auxiliary piping : -

rev. Client: PT. UNILEVER INDONESIA TBK, Project: SILIWANGI 1 rev.

Client's Project No.: 13021 Plant Location: SILIWANGI 00

Description/Issued for Ckd Approved

RNA

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 1 of: 2

LG

M

e

c

h

a

n

i

c

a

l

s

e

a

l

d

a

t

a

M

a

t

e

r

i

a

l

Rev. Date By

A 2/7/2014 IDC RK

* *

* *

* *

P

r

o

c

e

s

s

a

n

d

o

p

e

r

a

t

i

n

g

d

a

t

a

M

e

c

h

a

n

i

c

a

l

d

a

t

a

* *

* *

* *

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Item no.: PU-1413

1

2

3 Motors / Turbine - : Motor

4 Power Supply V / Phase / Hz : 400 / 3 / 50

5 Transmission - : Direct Drive

6 Cooling Type - : *

7 Motive fluid - : *

8 Frame size - : *

9 Model - : *

10 Manufacture - : *

11 Rating - : *

12 NOL Power : *

13 Hazardous Area Classification - : Safe / Non Hazardus / Non Flammable

14 Surface finish & wetted Parts Micron : 0.8

15 Net weight - Pump. Base & Motor Kg : *

16 Max. Maintence Weight Kg : *

17 Noise Level dBA : <80

18

19

20

21 Notes:

22 * To be provided by vendor

23 Pump differential pressure should be reviewed and shall be confirmed after Plot Plan/ Equipment layout

24 MOC of all wetted part shall be suitable for water services.

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

rev. 43

Client: PT. UNILEVER INDONESIA TBK,

Client's Project No.: 13021

Project: SILIWANGI 1

Plant Location: SILIWANGI

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 2 of:

R

e

m

a

r

k

s

Description

D

r

i

v

e

r

s

&

T

r

a

n

s

m

i

s

s

i

o

n

2

Description

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Vendor: * Item no.: PU-1511

1 Equipment name : Primary Chilled Water Pump Number required (incl. spare) :

2 Liquid pumped : Water Capacity normal: 252 m/h ; rated : 252 m/h

3 Operation : continuous Discharge pressure at rated capacity : 2.844 bara

4 Solids : - %; max. size : mm Suction pressure min. : - bara

5 Corrosive/Erosive service : no Suction pressure max. : 0.883 bara

6 Pumping temperature (p.t.) : 12 C Differential pressure : 1.013 bar

7 Pumping temperature max. : 18 C Differential head : 20 m. liq.

8 Density at pumping temperature : 1000 kg/m Shut-off head : * m. liq.

9 Viscosity at pumping temperature : 1.23 mPa.s NPSH available : 7.87 m. liq.

10 Vapour pressure at pumping temp. : 0.014 bara NPSH required : * m. liq.

11 Area classification : Shut-off head max. allowable : * m. liq.

12 * to be stated by vendor Minimum continuous flow : * m/h

13 Manufacturer (MFR) : * Nozzles Nom. diameter Rating Type/Fac. Pos.

14 Type : Centrifugal Suction * END

15 Model : * Discharge * TOP

16 Location : outdoor Vent * *

17 Arrangement : horizontal Drain * *

18 Rotation facing coupling : * cw/ccw Cooling * *

19 Suction : single Flushing * *

20 Number of stages : 1

21 Self priming : no Hydraulic power at rated capacity : 13.73 kW

22 Design pressure : * bara Hydraulic efficiency at normal capacity : * %

23 Design temperature : * C Power required : * kW

24 Max. allow. operating pressure : * barg Power installed : * kW

25 Casing split : radial Pump speed : * rpm

26 Impeller type : * Driver speed : * rpm

27 Impeller diameter supplied : * mm Pump drive : *

28 Impeller diameter min. : * mm ; max : * mm Driver type : Direct

29 Driver supply : *

30 Bearings : axial ; type: * Weight pump : * kg

31 Bearings : radial ; type: * Weight base plate : - kg

32 Bearings : intermittent ; type: * Weight driver : * kg

33 Bearing lubrication : oil Shipping weight : * kg

34 Common base plate Required : no

35 for pump and driver By MFR : no Test Required Witnessed

36 Coupling : yes ; type : * Performance yes no

37 Coupling guard : yes ; type : * Hydrostatic yes no

38 Foundation bolts : yes ; by MFR: yes NPSH yes no

39 Slide rails : yes/no Single

40 MFR : * ;type : Single

41 Smothering gland : yes Flushing liquid : *

42 Shipment of seal/packing : separate Flushing liquid flow rate : * m/h

43 Casing/bearing/seals/none/ Flushing liquid design pressure : * barg

44 Cooling/Heating Medium : - Flushing system acc. API-610 plan no. : -

45 Consumption : - kg/h Auxiliary piping by pump MFR : no

46 Design pressure : : - barg Seal/packing by pump MFR : yes

47 Stuffing box: number of rings :

48 Casing and cover : Cast Iron Packing : *

49 Casing wearring : Cast Iron Gland : *

50 Impeller : * (Note 3) Gaskets : *

51 Impeller wearring : * (Note 3) O-ring : *

52 Shaft : * Lantern ring : *

53 Shaft sleeve : * (Note 3) Throat bushing : *

54 Coupling guard : * (Note 3) Mechanical seal : *

55 Base plate : - Auxiliary piping : -

rev. Client: PT. UNILEVER INDONESIA TBK, Project: SILIWANGI 1 rev.

Client's Project No.: 13021 Plant Location: SILIWANGI 00

Description/Issued for Ckd Approved

RNA

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 1 of: 2

LG

M

e

c

h

a

n

i

c

a

l

s

e

a

l

d

a

t

a

M

a

t

e

r

i

a

l

Rev. Date By

A 2/7/2014 IDC RK

* *

* *

* *

P

r

o

c

e

s

s

a

n

d

o

p

e

r

a

t

i

n

g

d

a

t

a

M

e

c

h

a

n

i

c

a

l

d

a

t

a

* *

* *

* *

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Item no.: PU-1511

1

2

3 Motors / Turbine - : Motor

4 Power Supply V / Phase / Hz : 400 / 3 / 50

5 Transmission - : Direct Drive

6 Cooling Type - : *

7 Motive fluid - : *

8 Frame size - : *

9 Model - : *

10 Manufacture - : *

11 Rating - : *

12 NOL Power : *

13 Hazardous Area Classification - : Safe / Non Hazardus / Non Flammable

14 Surface finish & wetted Parts Micron : 0.8

15 Net weight - Pump. Base & Motor Kg : *

16 Max. Maintence Weight Kg : *

17 Noise Level dBA : <80

18

19

20

21 Notes:

22 * To be provided by vendor

23 Pump differential pressure should be reviewed and shall be confirmed after Plot Plan/ Equipment layout

24 MOC of all wetted part shall be suitable for water services.

25 Sizes & details to be furnished later by Instrument group.

26 Supplier to confirm insulation requirement , type & thickness

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

rev. 43

Client: PT. UNILEVER INDONESIA TBK,

Client's Project No.: 13021

Project: SILIWANGI 1

Plant Location: SILIWANGI

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 2 of:

R

e

m

a

r

k

s

Description

D

r

i

v

e

r

s

&

T

r

a

n

s

m

i

s

s

i

o

n

2

Description

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Vendor: * Item no.: PU-1512

1 Equipment name : Primary Chilled Water Pump Number required (incl. spare) :

2 Liquid pumped : Water Capacity normal: 252 m/h ; rated : 252 m/h

3 Operation : continuous Discharge pressure at rated capacity : 2.844 bara

4 Solids : - %; max. size : mm Suction pressure min. : - bara

5 Corrosive/Erosive service : no Suction pressure max. : 0.883 bara

6 Pumping temperature (p.t.) : 12 C Differential pressure : 1.013 bar

7 Pumping temperature max. : 18 C Differential head : 20 m. liq.

8 Density at pumping temperature : 1000 kg/m Shut-off head : * m. liq.

9 Viscosity at pumping temperature : 1.23 mPa.s NPSH available : 7.87 m. liq.

10 Vapour pressure at pumping temp. : 0.014 bara NPSH required : * m. liq.

11 Area classification : Shut-off head max. allowable : * m. liq.

12 * to be stated by vendor Minimum continuous flow : * m/h

13 Manufacturer (MFR) : * Nozzles Nom. diameter Rating Type/Fac. Pos.

14 Type : Centrifugal Suction * END

15 Model : * Discharge * TOP

16 Location : outdoor Vent * *

17 Arrangement : horizontal Drain * *

18 Rotation facing coupling : * cw/ccw Cooling * *

19 Suction : single Flushing * *

20 Number of stages : 1

21 Self priming : no Hydraulic power at rated capacity : 13.73 kW

22 Design pressure : * bara Hydraulic efficiency at normal capacity : * %

23 Design temperature : * C Power required : * kW

24 Max. allow. operating pressure : * barg Power installed : * kW

25 Casing split : radial Pump speed : * rpm

26 Impeller type : * Driver speed : * rpm

27 Impeller diameter supplied : * mm Pump drive : *

28 Impeller diameter min. : * mm ; max : * mm Driver type : Direct

29 Driver supply : *

30 Bearings : axial ; type: * Weight pump : * kg

31 Bearings : radial ; type: * Weight base plate : - kg

32 Bearings : intermittent ; type: * Weight driver : * kg

33 Bearing lubrication : oil Shipping weight : * kg

34 Common base plate Required : no

35 for pump and driver By MFR : no Test Required Witnessed

36 Coupling : yes ; type : * Performance yes no

37 Coupling guard : yes ; type : * Hydrostatic yes no

38 Foundation bolts : yes ; by MFR: yes NPSH yes no

39 Slide rails : yes/no Single

40 MFR : * ;type : Single

41 Smothering gland : yes Flushing liquid : *

42 Shipment of seal/packing : separate Flushing liquid flow rate : * m/h

43 Casing/bearing/seals/none/ Flushing liquid design pressure : * barg

44 Cooling/Heating Medium : - Flushing system acc. API-610 plan no. : -

45 Consumption : - kg/h Auxiliary piping by pump MFR : no

46 Design pressure : : - barg Seal/packing by pump MFR : yes

47 Stuffing box: number of rings :

48 Casing and cover : Cast Iron Packing : *

49 Casing wearring : Cast Iron Gland : *

50 Impeller : * (Note 3) Gaskets : *

51 Impeller wearring : * (Note 3) O-ring : *

52 Shaft : * Lantern ring : *

53 Shaft sleeve : * (Note 3) Throat bushing : *

54 Coupling guard : * (Note 3) Mechanical seal : *

55 Base plate : - Auxiliary piping : -

rev. Client: PT. UNILEVER INDONESIA TBK, Project: SILIWANGI 1 rev.

Client's Project No.: 13021 Plant Location: SILIWANGI 00

Description/Issued for Ckd Approved

RNA

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 1 of: 2

LG

M

e

c

h

a

n

i

c

a

l

s

e

a

l

d

a

t

a

M

a

t

e

r

i

a

l

Rev. Date By

A 2/7/2014 IDC RK

* *

* *

* *

P

r

o

c

e

s

s

a

n

d

o

p

e

r

a

t

i

n

g

d

a

t

a

M

e

c

h

a

n

i

c

a

l

d

a

t

a

* *

* *

* *

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Item no.: PU-1512

1

2

3 Motors / Turbine - : Motor

4 Power Supply V / Phase / Hz : 400 / 3 / 50

5 Transmission - : Direct Drive

6 Cooling Type - : *

7 Motive fluid - : *

8 Frame size - : *

9 Model - : *

10 Manufacture - : *

11 Rating - : *

12 NOL Power : *

13 Hazardous Area Classification - : Safe / Non Hazardus / Non Flammable

14 Surface finish & wetted Parts Micron : 0.8

15 Net weight - Pump. Base & Motor Kg : *

16 Max. Maintence Weight Kg : *

17 Noise Level dBA : <80

18

19

20

21 Notes:

22 * To be provided by vendor

23 Pump differential pressure should be reviewed and shall be confirmed after Plot Plan/ Equipment layout

24 MOC of all wetted part shall be suitable for water services.

25 Sizes & details to be furnished later by Instrument group.

26 Supplier to confirm insulation requirement , type & thickness

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

rev. 43

Client: PT. UNILEVER INDONESIA TBK,

Client's Project No.: 13021

Project: SILIWANGI 1

Plant Location: SILIWANGI

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 2 of:

R

e

m

a

r

k

s

Description

D

r

i

v

e

r

s

&

T

r

a

n

s

m

i

s

s

i

o

n

2

Description

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Vendor: * Item no.: PU-1513

1 Equipment name : Primary Chilled Water Pump Number required (incl. spare) :

2 Liquid pumped : Water Capacity normal: 252 m/h ; rated : 252 m/h

3 Operation : continuous Discharge pressure at rated capacity : 2.844 bara

4 Solids : - %; max. size : mm Suction pressure min. : - bara

5 Corrosive/Erosive service : no Suction pressure max. : 0.883 bara

6 Pumping temperature (p.t.) : 12 C Differential pressure : 1.013 bar

7 Pumping temperature max. : 18 C Differential head : 20 m. liq.

8 Density at pumping temperature : 1000 kg/m Shut-off head : * m. liq.

9 Viscosity at pumping temperature : 1.23 mPa.s NPSH available : 7.87 m. liq.

10 Vapour pressure at pumping temp. : 0.014 bara NPSH required : * m. liq.

11 Area classification : Shut-off head max. allowable : * m. liq.

12 * to be stated by vendor Minimum continuous flow : * m/h

13 Manufacturer (MFR) : * Nozzles Nom. diameter Rating Type/Fac. Pos.

14 Type : Centrifugal Suction * END

15 Model : * Discharge * TOP

16 Location : outdoor Vent * *

17 Arrangement : horizontal Drain * *

18 Rotation facing coupling : * cw/ccw Cooling * *

19 Suction : single Flushing * *

20 Number of stages : 1

21 Self priming : no Hydraulic power at rated capacity : 13.73 kW

22 Design pressure : * bara Hydraulic efficiency at normal capacity : * %

23 Design temperature : * C Power required : * kW

24 Max. allow. operating pressure : * barg Power installed : * kW

25 Casing split : radial Pump speed : * rpm

26 Impeller type : * Driver speed : * rpm

27 Impeller diameter supplied : * mm Pump drive : *

28 Impeller diameter min. : * mm ; max : * mm Driver type : Direct

29 Driver supply : *

30 Bearings : axial ; type: * Weight pump : * kg

31 Bearings : radial ; type: * Weight base plate : - kg

32 Bearings : intermittent ; type: * Weight driver : * kg

33 Bearing lubrication : oil Shipping weight : * kg

34 Common base plate Required : no

35 for pump and driver By MFR : no Test Required Witnessed

36 Coupling : yes ; type : * Performance yes no

37 Coupling guard : yes ; type : * Hydrostatic yes no

38 Foundation bolts : yes ; by MFR: yes NPSH yes no

39 Slide rails : yes/no Single

40 MFR : * ;type : Single

41 Smothering gland : yes Flushing liquid : *

42 Shipment of seal/packing : separate Flushing liquid flow rate : * m/h

43 Casing/bearing/seals/none/ Flushing liquid design pressure : * barg

44 Cooling/Heating Medium : - Flushing system acc. API-610 plan no. : -

45 Consumption : - kg/h Auxiliary piping by pump MFR : no

46 Design pressure : : - barg Seal/packing by pump MFR : yes

47 Stuffing box: number of rings :

48 Casing and cover : Cast Iron Packing : *

49 Casing wearring : Cast Iron Gland : *

50 Impeller : * (Note 3) Gaskets : *

51 Impeller wearring : * (Note 3) O-ring : *

52 Shaft : * Lantern ring : *

53 Shaft sleeve : * (Note 3) Throat bushing : *

54 Coupling guard : * (Note 3) Mechanical seal : *

55 Base plate : - Auxiliary piping : -

rev. Client: PT. UNILEVER INDONESIA TBK, Project: SILIWANGI 1 rev.

Client's Project No.: 13021 Plant Location: SILIWANGI 00

Description/Issued for Ckd Approved

RNA

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 1 of: 2

LG

M

e

c

h

a

n

i

c

a

l

s

e

a

l

d

a

t

a

M

a

t

e

r

i

a

l

Rev. Date By

A 2/7/2014 IDC RK

* *

* *

* *

P

r

o

c

e

s

s

a

n

d

o

p

e

r

a

t

i

n

g

d

a

t

a

M

e

c

h

a

n

i

c

a

l

d

a

t

a

* *

* *

* *

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Item no.: PU-1513

1

2

3 Motors / Turbine - : Motor

4 Power Supply V / Phase / Hz : 400 / 3 / 50

5 Transmission - : Direct Drive

6 Cooling Type - : *

7 Motive fluid - : *

8 Frame size - : *

9 Model - : *

10 Manufacture - : *

11 Rating - : *

12 NOL Power : *

13 Hazardous Area Classification - : Safe / Non Hazardus / Non Flammable

14 Surface finish & wetted Parts Micron : 0.8

15 Net weight - Pump. Base & Motor Kg : *

16 Max. Maintence Weight Kg : *

17 Noise Level dBA : <80

18

19

20

21 Notes:

22 * To be provided by vendor

23 Pump differential pressure should be reviewed and shall be confirmed after Plot Plan/ Equipment layout

24 MOC of all wetted part shall be suitable for water services.

25 Sizes & details to be furnished later by Instrument group.

26 Supplier to confirm insulation requirement , type & thickness

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

rev. 43

Client: PT. UNILEVER INDONESIA TBK,

Client's Project No.: 13021

Project: SILIWANGI 1

Plant Location: SILIWANGI

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 2 of:

R

e

m

a

r

k

s

Description

D

r

i

v

e

r

s

&

T

r

a

n

s

m

i

s

s

i

o

n

2

Description

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Vendor: * Item no.: PU-1521

1 Equipment name : Secondary Chilled Water Pump Number required (incl. spare) :

2 Liquid pumped : Water Capacity normal: 252 m/h ; rated : 252 m/h

3 Operation : continuous Discharge pressure at rated capacity : 6.077 bara

4 Solids : - %; max. size : mm Suction pressure min. : - bara

5 Corrosive/Erosive service : no Suction pressure max. : 0.881 bara

6 Pumping temperature (p.t.) : 6 C Differential pressure : 3.21 bar

7 Pumping temperature max. : 9 C Differential head : 53 m. liq.

8 Density at pumping temperature : 1000 kg/m Shut-off head : * m. liq.

9 Viscosity at pumping temperature : 1.475 mPa.s NPSH available : 7.89 m. liq.

10 Vapour pressure at pumping temp. : 0.009 bara NPSH required : * m. liq.

11 Area classification : Shut-off head max. allowable : * m. liq.

12 * to be stated by vendor Minimum continuous flow : * m/h

13 Manufacturer (MFR) : * Nozzles Nom. diameter Rating Type/Fac. Pos.

14 Type : Centrifugal Suction * END

15 Model : * Discharge * TOP

16 Location : outdoor Vent * *

17 Arrangement : horizontal Drain * *

18 Rotation facing coupling : * cw/ccw Cooling * *

19 Suction : single Flushing * *

20 Number of stages : 1

21 Self priming : no Hydraulic power at rated capacity : 36.37 kW

22 Design pressure : * bara Hydraulic efficiency at normal capacity : * %

23 Design temperature : * C Power required : * kW

24 Max. allow. operating pressure : * barg Power installed : * kW

25 Casing split : radial Pump speed : * rpm

26 Impeller type : * Driver speed : * rpm

27 Impeller diameter supplied : * mm Pump drive : *

28 Impeller diameter min. : * mm ; max : * mm Driver type : Direct

29 Driver supply : *

30 Bearings : axial ; type: * Weight pump : * kg

31 Bearings : radial ; type: * Weight base plate : - kg

32 Bearings : intermittent ; type: * Weight driver : * kg

33 Bearing lubrication : oil Shipping weight : * kg

34 Common base plate Required : no

35 for pump and driver By MFR : no Test Required Witnessed

36 Coupling : yes ; type : * Performance yes no

37 Coupling guard : yes ; type : * Hydrostatic yes no

38 Foundation bolts : yes ; by MFR: yes NPSH yes no

39 Slide rails : yes/no Single

40 MFR : * ;type : Single

41 Smothering gland : yes Flushing liquid : *

42 Shipment of seal/packing : separate Flushing liquid flow rate : * m/h

43 Casing/bearing/seals/none/ Flushing liquid design pressure : * barg

44 Cooling/Heating Medium : - Flushing system acc. API-610 plan no. : -

45 Consumption : - kg/h Auxiliary piping by pump MFR : no

46 Design pressure : : - barg Seal/packing by pump MFR : yes

47 Stuffing box: number of rings :

48 Casing and cover : Cast Iron Packing : *

49 Casing wearring : Cast Iron Gland : *

50 Impeller : * (Note 3) Gaskets : *

51 Impeller wearring : * (Note 3) O-ring : *

52 Shaft : * Lantern ring : *

53 Shaft sleeve : * (Note 3) Throat bushing : *

54 Coupling guard : * (Note 3) Mechanical seal : *

55 Base plate : - Auxiliary piping : -

rev. Client: PT. UNILEVER INDONESIA TBK, Project: SILIWANGI 1 rev.

Client's Project No.: 13021 Plant Location: SILIWANGI 00

Description/Issued for Ckd Approved

RNA

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 1 of: 2

LG

M

e

c

h

a

n

i

c

a

l

s

e

a

l

d

a

t

a

M

a

t

e

r

i

a

l

Rev. Date By

A 2/7/2014 IDC RK

* *

* *

* *

P

r

o

c

e

s

s

a

n

d

o

p

e

r

a

t

i

n

g

d

a

t

a

M

e

c

h

a

n

i

c

a

l

d

a

t

a

* *

* *

* *

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Item no.: PU-1521

1

2

3 Motors / Turbine - : Motor

4 Power Supply V / Phase / Hz : 400 / 3 / 50

5 Transmission - : Direct Drive

6 Cooling Type - : *

7 Motive fluid - : *

8 Frame size - : *

9 Model - : *

10 Manufacture - : *

11 Rating - : *

12 NOL Power : *

13 Hazardous Area Classification - : Safe / Non Hazardus / Non Flammable

14 Surface finish & wetted Parts Micron : 0.8

15 Net weight - Pump. Base & Motor Kg : *

16 Max. Maintence Weight Kg : *

17 Noise Level dBA : <80

18

19

20

21 Notes:

22 * To be provided by vendor

23 Pump differential pressure should be reviewed and shall be confirmed after Plot Plan/ Equipment layout

24 MOC of all wetted part shall be suitable for water services.

25 Sizes & details to be furnished later by Instrument group.

26 Supplier to confirm insulation requirement , type & thickness

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

rev. 43

Client: PT. UNILEVER INDONESIA TBK,

Client's Project No.: 13021

Project: SILIWANGI 1

Plant Location: SILIWANGI

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 2 of:

R

e

m

a

r

k

s

Description

D

r

i

v

e

r

s

&

T

r

a

n

s

m

i

s

s

i

o

n

2

Description

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Vendor: * Item no.: PU-1522

1 Equipment name : Secondary Chilled Water Pump Number required (incl. spare) :

2 Liquid pumped : Water Capacity normal: 252 m/h ; rated : 252 m/h

3 Operation : continuous Discharge pressure at rated capacity : 6.077 bara

4 Solids : - %; max. size : mm Suction pressure min. : - bara

5 Corrosive/Erosive service : no Suction pressure max. : 0.881 bara

6 Pumping temperature (p.t.) : 6 C Differential pressure : 3.21 bar

7 Pumping temperature max. : 9 C Differential head : 53 m. liq.

8 Density at pumping temperature : 1000 kg/m Shut-off head : * m. liq.

9 Viscosity at pumping temperature : 1.475 mPa.s NPSH available : 7.89 m. liq.

10 Vapour pressure at pumping temp. : 0.009 bara NPSH required : * m. liq.

11 Area classification : Shut-off head max. allowable : * m. liq.

12 * to be stated by vendor Minimum continuous flow : * m/h

13 Manufacturer (MFR) : * Nozzles Nom. diameter Rating Type/Fac. Pos.

14 Type : Centrifugal Suction * END

15 Model : * Discharge * TOP

16 Location : outdoor Vent * *

17 Arrangement : horizontal Drain * *

18 Rotation facing coupling : * cw/ccw Cooling * *

19 Suction : single Flushing * *

20 Number of stages : 1

21 Self priming : no Hydraulic power at rated capacity : 36.37 kW

22 Design pressure : * bara Hydraulic efficiency at normal capacity : * %

23 Design temperature : * C Power required : * kW

24 Max. allow. operating pressure : * barg Power installed : * kW

25 Casing split : radial Pump speed : * rpm

26 Impeller type : * Driver speed : * rpm

27 Impeller diameter supplied : * mm Pump drive : *

28 Impeller diameter min. : * mm ; max : * mm Driver type : Direct

29 Driver supply : *

30 Bearings : axial ; type: * Weight pump : * kg

31 Bearings : radial ; type: * Weight base plate : - kg

32 Bearings : intermittent ; type: * Weight driver : * kg

33 Bearing lubrication : oil Shipping weight : * kg

34 Common base plate Required : no

35 for pump and driver By MFR : no Test Required Witnessed

36 Coupling : yes ; type : * Performance yes no

37 Coupling guard : yes ; type : * Hydrostatic yes no

38 Foundation bolts : yes ; by MFR: yes NPSH yes no

39 Slide rails : yes/no Single

40 MFR : * ;type : Single

41 Smothering gland : yes Flushing liquid : *

42 Shipment of seal/packing : separate Flushing liquid flow rate : * m/h

43 Casing/bearing/seals/none/ Flushing liquid design pressure : * barg

44 Cooling/Heating Medium : - Flushing system acc. API-610 plan no. : -

45 Consumption : - kg/h Auxiliary piping by pump MFR : no

46 Design pressure : : - barg Seal/packing by pump MFR : yes

47 Stuffing box: number of rings :

48 Casing and cover : Cast Iron Packing : *

49 Casing wearring : Cast Iron Gland : *

50 Impeller : * (Note 3) Gaskets : *

51 Impeller wearring : * (Note 3) O-ring : *

52 Shaft : * Lantern ring : *

53 Shaft sleeve : * (Note 3) Throat bushing : *

54 Coupling guard : * (Note 3) Mechanical seal : *

55 Base plate : - Auxiliary piping : -

rev. Client: PT. UNILEVER INDONESIA TBK, Project: SILIWANGI 1 rev.

Client's Project No.: 13021 Plant Location: SILIWANGI 00

Description/Issued for Ckd Approved

RNA

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 1 of: 2

LG

M

e

c

h

a

n

i

c

a

l

s

e

a

l

d

a

t

a

M

a

t

e

r

i

a

l

Rev. Date By

A 2/7/2014 IDC RK

* *

* *

* *

P

r

o

c

e

s

s

a

n

d

o

p

e

r

a

t

i

n

g

d

a

t

a

M

e

c

h

a

n

i

c

a

l

d

a

t

a

* *

* *

* *

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Item no.: PU-1522

1

2

3 Motors / Turbine - : Motor

4 Power Supply V / Phase / Hz : 400 / 3 / 50

5 Transmission - : Direct Drive

6 Cooling Type - : *

7 Motive fluid - : *

8 Frame size - : *

9 Model - : *

10 Manufacture - : *

11 Rating - : *

12 NOL Power : *

13 Hazardous Area Classification - : Safe / Non Hazardus / Non Flammable

14 Surface finish & wetted Parts Micron : 0.8

15 Net weight - Pump. Base & Motor Kg : *

16 Max. Maintence Weight Kg : *

17 Noise Level dBA : <80

18

19

20

21 Notes:

22 * To be provided by vendor

23 Pump differential pressure should be reviewed and shall be confirmed after Plot Plan/ Equipment layout

24 MOC of all wetted part shall be suitable for water services.

25 Sizes & details to be furnished later by Instrument group.

26 Supplier to confirm insulation requirement , type & thickness

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

rev. 43

Client: PT. UNILEVER INDONESIA TBK,

Client's Project No.: 13021

Project: SILIWANGI 1

Plant Location: SILIWANGI

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 2 of:

R

e

m

a

r

k

s

Description

D

r

i

v

e

r

s

&

T

r

a

n

s

m

i

s

s

i

o

n

2

Description

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Vendor: * Item no.: PU-1523

1 Equipment name : Secondary Chilled Water Pump Number required (incl. spare) :

2 Liquid pumped : Water Capacity normal: 252 m/h ; rated : 252 m/h

3 Operation : continuous Discharge pressure at rated capacity : 6.077 bara

4 Solids : - %; max. size : mm Suction pressure min. : - bara

5 Corrosive/Erosive service : no Suction pressure max. : 0.881 bara

6 Pumping temperature (p.t.) : 6 C Differential pressure : 3.21 bar

7 Pumping temperature max. : 9 C Differential head : 53 m. liq.

8 Density at pumping temperature : 1000 kg/m Shut-off head : * m. liq.

9 Viscosity at pumping temperature : 1.475 mPa.s NPSH available : 7.89 m. liq.

10 Vapour pressure at pumping temp. : 0.009 bara NPSH required : * m. liq.

11 Area classification : Shut-off head max. allowable : * m. liq.

12 * to be stated by vendor Minimum continuous flow : * m/h

13 Manufacturer (MFR) : * Nozzles Nom. diameter Rating Type/Fac. Pos.

14 Type : Centrifugal Suction * END

15 Model : * Discharge * TOP

16 Location : outdoor Vent * *

17 Arrangement : horizontal Drain * *

18 Rotation facing coupling : * cw/ccw Cooling * *

19 Suction : single Flushing * *

20 Number of stages : 1

21 Self priming : no Hydraulic power at rated capacity : 36.37 kW

22 Design pressure : * bara Hydraulic efficiency at normal capacity : * %

23 Design temperature : * C Power required : * kW

24 Max. allow. operating pressure : * barg Power installed : * kW

25 Casing split : radial Pump speed : * rpm

26 Impeller type : * Driver speed : * rpm

27 Impeller diameter supplied : * mm Pump drive : *

28 Impeller diameter min. : * mm ; max : * mm Driver type : Direct

29 Driver supply : *

30 Bearings : axial ; type: * Weight pump : * kg

31 Bearings : radial ; type: * Weight base plate : - kg

32 Bearings : intermittent ; type: * Weight driver : * kg

33 Bearing lubrication : oil Shipping weight : * kg

34 Common base plate Required : no

35 for pump and driver By MFR : no Test Required Witnessed

36 Coupling : yes ; type : * Performance yes no

37 Coupling guard : yes ; type : * Hydrostatic yes no

38 Foundation bolts : yes ; by MFR: yes NPSH yes no

39 Slide rails : yes/no Single

40 MFR : * ;type : Single

41 Smothering gland : yes Flushing liquid : *

42 Shipment of seal/packing : separate Flushing liquid flow rate : * m/h

43 Casing/bearing/seals/none/ Flushing liquid design pressure : * barg

44 Cooling/Heating Medium : - Flushing system acc. API-610 plan no. : -

45 Consumption : - kg/h Auxiliary piping by pump MFR : no

46 Design pressure : : - barg Seal/packing by pump MFR : yes

47 Stuffing box: number of rings :

48 Casing and cover : Cast Iron Packing : *

49 Casing wearring : Cast Iron Gland : *

50 Impeller : * (Note 3) Gaskets : *

51 Impeller wearring : * (Note 3) O-ring : *

52 Shaft : * Lantern ring : *

53 Shaft sleeve : * (Note 3) Throat bushing : *

54 Coupling guard : * (Note 3) Mechanical seal : *

55 Base plate : - Auxiliary piping : -

rev. Client: PT. UNILEVER INDONESIA TBK, Project: SILIWANGI 1 rev.

Client's Project No.: 13021 Plant Location: SILIWANGI 00

Description/Issued for Ckd Approved

RNA

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 1 of: 2

LG

M

e

c

h

a

n

i

c

a

l

s

e

a

l

d

a

t

a

M

a

t

e

r

i

a

l

Rev. Date By

A 2/7/2014 IDC RK

* *

* *

* *

P

r

o

c

e

s

s

a

n

d

o

p

e

r

a

t

i

n

g

d

a

t

a

M

e

c

h

a

n

i

c

a

l

d

a

t

a

* *

* *

* *

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Item no.: PU-1523

1

2

3 Motors / Turbine - : Motor

4 Power Supply V / Phase / Hz : 400 / 3 / 50

5 Transmission - : Direct Drive

6 Cooling Type - : *

7 Motive fluid - : *

8 Frame size - : *

9 Model - : *

10 Manufacture - : *

11 Rating - : *

12 NOL Power : *

13 Hazardous Area Classification - : Safe / Non Hazardus / Non Flammable

14 Surface finish & wetted Parts Micron : 0.8

15 Net weight - Pump. Base & Motor Kg : *

16 Max. Maintence Weight Kg : *

17 Noise Level dBA : <80

18

19

20

21 Notes:

22 * To be provided by vendor

23 Pump differential pressure should be reviewed and shall be confirmed after Plot Plan/ Equipment layout

24 MOC of all wetted part shall be suitable for water services.

25 Sizes & details to be furnished later by Instrument group.

26 Supplier to confirm insulation requirement , type & thickness

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

rev. 43

Client: PT. UNILEVER INDONESIA TBK,

Client's Project No.: 13021

Project: SILIWANGI 1

Plant Location: SILIWANGI

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 2 of:

R

e

m

a

r

k

s

Description

D

r

i

v

e

r

s

&

T

r

a

n

s

m

i

s

s

i

o

n

2

Description

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Vendor: * Item no.: PU-1821

1 Equipment name : Hot Water Secondary Circulation Pump Number required (incl. spare) :

2 Liquid pumped : Hot Water Capacity normal: 72 m/h ; rated : 86 m/h

3 Operation : continuous Discharge pressure at rated capacity : 5.76 bara

4 Solids : - %; max. size : mm Suction pressure min. : - bara

5 Corrosive/Erosive service : no Suction pressure max. : 1.234 bara

6 Pumping temperature (p.t.) : 95 C Differential pressure : 2.955 bar

7 Pumping temperature max. : 142.5 C Differential head : 48 m. liq.

8 Density at pumping temperature : 962 kg/m Shut-off head : * m. liq.

9 Viscosity at pumping temperature : 0.297 mPa.s NPSH available : 3.62 m. liq.

10 Vapour pressure at pumping temp. : 0.85 bara NPSH required : * m. liq.

11 Area classification : Shut-off head max. allowable : * m. liq.

12 * to be stated by vendor Minimum continuous flow : * m/h

13 Manufacturer (MFR) : * Nozzles Nom. diameter Rating Type/Fac. Pos.

14 Type : Centrifugal Suction * END

15 Model : * Discharge * TOP

16 Location : Indoor Vent * *

17 Arrangement : horizontal Drain * *

18 Rotation facing coupling : * cw/ccw Cooling * *

19 Suction : single Flushing * *

20 Number of stages : 1

21 Self priming : no Hydraulic power at rated capacity : 10.86 kW

22 Design pressure : * bara Hydraulic efficiency at normal capacity : * %

23 Design temperature : * C Power required : * kW

24 Max. allow. operating pressure : * barg Power installed : * kW

25 Casing split : radial Pump speed : * rpm

26 Impeller type : * Driver speed : * rpm

27 Impeller diameter supplied : * mm Pump drive : *

28 Impeller diameter min. : * mm ; max : * mm Driver type : Direct

29 Driver supply : *

30 Bearings : axial ; type: * Weight pump : * kg

31 Bearings : radial ; type: * Weight base plate : - kg

32 Bearings : intermittent ; type: * Weight driver : * kg

33 Bearing lubrication : oil Shipping weight : * kg

34 Common base plate Required : no

35 for pump and driver By MFR : no Test Required Witnessed

36 Coupling : yes ; type : * Performance yes no

37 Coupling guard : yes ; type : * Hydrostatic yes no

38 Foundation bolts : yes ; by MFR: yes NPSH yes no

39 Slide rails : yes/no Single

40 MFR : * ;type : Single

41 Smothering gland : yes Flushing liquid : *

42 Shipment of seal/packing : separate Flushing liquid flow rate : * m/h

43 Casing/bearing/seals/none/ Flushing liquid design pressure : * barg

44 Cooling/Heating Medium : - Flushing system acc. API-610 plan no. : -

45 Consumption : - kg/h Auxiliary piping by pump MFR : no

46 Design pressure : : - barg Seal/packing by pump MFR : yes

47 Stuffing box: number of rings :

48 Casing and cover : Cast Iron Packing : *

49 Casing wearring : Cast Iron Gland : *

50 Impeller : * (Note 3) Gaskets : *

51 Impeller wearring : * (Note 3) O-ring : *

52 Shaft : * Lantern ring : *

53 Shaft sleeve : * (Note 3) Throat bushing : *

54 Coupling guard : * (Note 3) Mechanical seal : *

55 Base plate : - Auxiliary piping : -

rev. Client: PT. UNILEVER INDONESIA TBK, Project: SILIWANGI 1 rev.

Client's Project No.: 13021 Plant Location: SILIWANGI 00

Description/Issued for Ckd Approved

RNA

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 1 of: 2

LG

M

e

c

h

a

n

i

c

a

l

s

e

a

l

d

a

t

a

M

a

t

e

r

i

a

l

Rev. Date By

A 2/7/2014 IDC RK

* *

* *

* *

P

r

o

c

e

s

s

a

n

d

o

p

e

r

a

t

i

n

g

d

a

t

a

M

e

c

h

a

n

i

c

a

l

d

a

t

a

* *

* *

* *

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Item no.: PU-1821

1

2

3 Motors / Turbine - : Motor

4 Power Supply V / Phase / Hz : 400 / 3 / 50

5 Transmission - : Direct Drive

6 Cooling Type - : *

7 Motive fluid - : *

8 Frame size - : *

9 Model - : *

10 Manufacture - : *

11 Rating - : *

12 NOL Power : *

13 Hazardous Area Classification - : Safe / Non Hazardus / Non Flammable

14 Surface finish & wetted Parts Micron : 0.8

15 Net weight - Pump. Base & Motor Kg : *

16 Max. Maintence Weight Kg : *

17 Noise Level dBA : <80

18

19

20

21 Notes:

22 * To be provided by vendor

23 Pump differential pressure should be reviewed and shall be confirmed after Plot Plan/ Equipment layout

24 MOC of all wetted part shall be suitable for water services.

25 Sizes & details to be furnished later by Instrument group.

26 Supplier to confirm insulation requirement , type & thickness

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

rev. 43

Client: PT. UNILEVER INDONESIA TBK,

Client's Project No.: 13021

Project: SILIWANGI 1

Plant Location: SILIWANGI

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 2 of:

R

e

m

a

r

k

s

Description

D

r

i

v

e

r

s

&

T

r

a

n

s

m

i

s

s

i

o

n

2

Description

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Vendor: * Item no.: PU-1822

1 Equipment name : Hot Water Secondary Circulation Pump Number required (incl. spare) :

2 Liquid pumped : Hot Water Capacity normal: 72 m/h ; rated : 86 m/h

3 Operation : continuous Discharge pressure at rated capacity : 5.76 bara

4 Solids : - %; max. size : mm Suction pressure min. : - bara

5 Corrosive/Erosive service : no Suction pressure max. : 1.234 bara

6 Pumping temperature (p.t.) : 95 C Differential pressure : 2.955 bar

7 Pumping temperature max. : 142.5 C Differential head : 48 m. liq.

8 Density at pumping temperature : 962 kg/m Shut-off head : * m. liq.

9 Viscosity at pumping temperature : 0.297 mPa.s NPSH available : 3.62 m. liq.

10 Vapour pressure at pumping temp. : 0.85 bara NPSH required : * m. liq.

11 Area classification : Shut-off head max. allowable : * m. liq.

12 * to be stated by vendor Minimum continuous flow : * m/h

13 Manufacturer (MFR) : * Nozzles Nom. diameter Rating Type/Fac. Pos.

14 Type : Centrifugal Suction * END

15 Model : * Discharge * TOP

16 Location : Indoor Vent * *

17 Arrangement : horizontal Drain * *

18 Rotation facing coupling : * cw/ccw Cooling * *

19 Suction : single Flushing * *

20 Number of stages : 1

21 Self priming : no Hydraulic power at rated capacity : 10.86 kW

22 Design pressure : * bara Hydraulic efficiency at normal capacity : * %

23 Design temperature : * C Power required : * kW

24 Max. allow. operating pressure : * barg Power installed : * kW

25 Casing split : radial Pump speed : * rpm

26 Impeller type : * Driver speed : * rpm

27 Impeller diameter supplied : * mm Pump drive : *

28 Impeller diameter min. : * mm ; max : * mm Driver type : Direct

29 Driver supply : *

30 Bearings : axial ; type: * Weight pump : * kg

31 Bearings : radial ; type: * Weight base plate : - kg

32 Bearings : intermittent ; type: * Weight driver : * kg

33 Bearing lubrication : oil Shipping weight : * kg

34 Common base plate Required : no

35 for pump and driver By MFR : no Test Required Witnessed

36 Coupling : yes ; type : * Performance yes no

37 Coupling guard : yes ; type : * Hydrostatic yes no

38 Foundation bolts : yes ; by MFR: yes NPSH yes no

39 Slide rails : yes/no Single

40 MFR : * ;type : Single

41 Smothering gland : yes Flushing liquid : *

42 Shipment of seal/packing : separate Flushing liquid flow rate : * m/h

43 Casing/bearing/seals/none/ Flushing liquid design pressure : * barg

44 Cooling/Heating Medium : - Flushing system acc. API-610 plan no. : -

45 Consumption : - kg/h Auxiliary piping by pump MFR : no

46 Design pressure : : - barg Seal/packing by pump MFR : yes

47 Stuffing box: number of rings :

48 Casing and cover : Cast Iron Packing : *

49 Casing wearring : Cast Iron Gland : *

50 Impeller : * (Note 3) Gaskets : *

51 Impeller wearring : * (Note 3) O-ring : *

52 Shaft : * Lantern ring : *

53 Shaft sleeve : * (Note 3) Throat bushing : *

54 Coupling guard : * (Note 3) Mechanical seal : *

55 Base plate : - Auxiliary piping : -

rev. Client: PT. UNILEVER INDONESIA TBK, Project: SILIWANGI 1 rev.

Client's Project No.: 13021 Plant Location: SILIWANGI 00

Description/Issued for Ckd Approved

RNA

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 1 of: 2

LG

M

e

c

h

a

n

i

c

a

l

s

e

a

l

d

a

t

a

M

a

t

e

r

i

a

l

Rev. Date By

A 2/7/2014 IDC RK

* *

* *

* *

P

r

o

c

e

s

s

a

n

d

o

p

e

r

a

t

i

n

g

d

a

t

a

M

e

c

h

a

n

i

c

a

l

d

a

t

a

* *

* *

* *

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Item no.: PU-1822

1

2

3 Motors / Turbine - : Motor

4 Power Supply V / Phase / Hz : 400 / 3 / 50

5 Transmission - : Direct Drive

6 Cooling Type - : *

7 Motive fluid - : *

8 Frame size - : *

9 Model - : *

10 Manufacture - : *

11 Rating - : *

12 NOL Power : *

13 Hazardous Area Classification - : Safe / Non Hazardus / Non Flammable

14 Surface finish & wetted Parts Micron : 0.8

15 Net weight - Pump. Base & Motor Kg : *

16 Max. Maintence Weight Kg : *

17 Noise Level dBA : <80

18

19

20

21 Notes:

22 * To be provided by vendor

23 Pump differential pressure should be reviewed and shall be confirmed after Plot Plan/ Equipment layout

24 MOC of all wetted part shall be suitable for water services.

25 Sizes & details to be furnished later by Instrument group.

26 Supplier to confirm insulation requirement , type & thickness

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

rev. 43

Client: PT. UNILEVER INDONESIA TBK,

Client's Project No.: 13021

Project: SILIWANGI 1

Plant Location: SILIWANGI

Office: Indonesia Tebodin order: Document: Rev.: 00 Sheet: 2 of:

R

e

m

a

r

k

s

Description

D

r

i

v

e

r

s

&

T

r

a

n

s

m

i

s

s

i

o

n

2

Description

Spec./Data sheet for: CENTRIFUGAL PUMP

Cost Acc. Code: * Vendor: * Item no.: PU-1823

1 Equipment name : Hot Water Secondary Circulation Pump Number required (incl. spare) :

2 Liquid pumped : Hot Water Capacity normal: 22 m/h ; rated : 22 m/h

3 Operation : continuous Discharge pressure at rated capacity : 9.37 bara

4 Solids : - %; max. size : mm Suction pressure min. : - bara

5 Corrosive/Erosive service : no Suction pressure max. : 4.55 bara

6 Pumping temperature (p.t.) : 60 C Differential pressure : 3.17 bar

7 Pumping temperature max. : 90 C Differential head : 50 m. liq.

8 Density at pumping temperature : 983 kg/m Shut-off head : * m. liq.

9 Viscosity at pumping temperature : 0.47 mPa.s NPSH available : 44.14 m. liq.

10 Vapour pressure at pumping temp. : 0.2 bara NPSH required : * m. liq.

11 Area classification : Shut-off head max. allowable : * m. liq.

12 * to be stated by vendor Minimum continuous flow : * m/h

13 Manufacturer (MFR) : * Nozzles Nom. diameter Rating Type/Fac. Pos.

14 Type : Centrifugal Suction * END

15 Model : * Discharge * TOP

16 Location : Indoor Vent * *

17 Arrangement : horizontal Drain * *

18 Rotation facing coupling : * cw/ccw Cooling * *

19 Suction : single Flushing * *

20 Number of stages : 1

21 Self priming : no Hydraulic power at rated capacity : 2.943 kW

22 Design pressure : * bara Hydraulic efficiency at normal capacity : * %

23 Design temperature : * C Power required : * kW

24 Max. allow. operating pressure : * barg Power installed : * kW

25 Casing split : radial Pump speed : * rpm